- Home

- Industrial Flanges

- Tongue and Groove Flanges

Tongue and Groove Flanges

T&G Flange : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Leading Manufacturer & Exporter of ASME B16.5 Tongue and Groove Flanges – Available in Carbon Steel, Stainless Steel, Alloy Steel, and Nickel Alloys. Sizes ½”–24”, Pressure Classes 150#–2500#. Serving Worldwide Clients in UAE, Australia, UK, Mexico, and India.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd is a trusted manufacturer and exporter of high-quality ASME B16.5 Tongue and Groove Flanges. Designed for superior performance in high-pressure piping systems, our flanges are available in Carbon, SS, Alloy Steel, and Nickel Alloys. We offer a wide range of sizes from ½” to 24” and pressure classes from 150# to 2500#, ensuring a precise fit for industrial applications in oil & gas, petrochemical, power, and chemical industries.

With a commitment to excellence, We delivers T and G Flanges worldwide, serving clients in countries including USA, UAE, Spain, Turkey, Canada, and more. Each flange is manufactured in compliance with ANSI/ASME standards, ensuring reliability, durability, and leak-proof sealing.

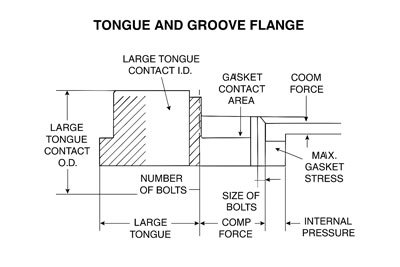

A Tongue and Groove Flange is a type of flange connection designed for precise alignment and secure sealing. One flange has a raised protruding ridge called the tongue, while the mating flange has a corresponding recessed area known as the groove. The tongue fits into the groove, creating a tight fit that prevents leakage and ensures proper gasket compression. This design allows for self-centering of the flanges during assembly, which is particularly useful in high-pressure or high-temperature piping systems.

T and G Flanges are available in Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ) configurations. The depth and width of the groove, as well as the height of the tongue, are engineered according to ANSI/ASME B16.5 standards to handle specific pressure classes. These flanges are typically used with metallic or spiral-wound gaskets, where the groove acts as a reservoir to improve sealing efficiency and prevent blowouts. The design also helps distribute bolt stress evenly across the flange, enhancing durability and reliability under cyclic loads.

Tongue and Groove Pipe Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Tongue and Groove Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

ANSI/ASME B16.5 Class 150 Tongue and Groove Flange – Dimensions & Sizes in mm

| Nominal | Large Tongue | Large Tongue | Gasket | Number | Size of | Bolt Torque | Comp Force | Max. Gasket | Internal | Min. Rec’d | Min. Rec’d | Max. Rec’d/Avail. | Preferred |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Contact I.D. | Contact O.D. | Contact Area | Of | Bolts | at 60ksi Stress | Per Bolt @ 60ksi | Stress Avail. | Pressure | Gasket Stress | Torque/Bolt | Gasket Stress | Torque/Bolt |

| (in) | (in) | (in) | (sq.in.) | Bolts | (in) | (ft.lbs.) | (psi) | (psi) | (psig) | (psi) | (ft.lbs.) | (psi) | (ft.lbs.) |

| 0.5 | 1.00 | 1.38 | 0.71 | 4 | 0.50 | 60 | 7560 | 42594 | <300 | 4800 | 7 | 10000 | 14 |

| 0.75 | 1.31 | 1.69 | 0.89 | 4 | 0.50 | 60 | 7560 | 33791 | <300 | 4800 | 9 | 10000 | 18 |

| 1 | 1.50 | 2.00 | 1.37 | 4 | 0.50 | 60 | 7560 | 22013 | <300 | 4800 | 13 | 10000 | 27 |

| 1.25 | 1.88 | 2.50 | 2.13 | 4 | 0.50 | 60 | 7560 | 14186 | <300 | 4800 | 20 | 10000 | 42 |

| 1.5 | 2.12 | 2.88 | 2.98 | 4 | 0.50 | 60 | 7560 | 10137 | <300 | 4800 | 28 | 10000 | 59 |

| 2 | 2.88 | 3.62 | 3.78 | 4 | 0.63 | 120 | 12120 | 12839 | <300 | 4800 | 45 | 10000 | 93 |

| 2.5 | 3.38 | 4.12 | 4.36 | 4 | 0.63 | 120 | 12120 | 11128 | <300 | 4800 | 52 | 10000 | 108 |

| 3 | 4.25 | 5.00 | 5.45 | 4 | 0.63 | 120 | 12120 | 8902 | <300 | 4800 | 65 | 8902 | 120 |

| 3.5 | 4.75 | 5.50 | 6.03 | 8 | 0.63 | 120 | 12120 | 16067 | <300 | 4800 | 36 | 10000 | 75 |

| 4 | 5.19 | 6.19 | 8.93 | 8 | 0.63 | 120 | 12120 | 10854 | <300 | 4800 | 53 | 10854 | 120 |

| 5 | 6.31 | 7.31 | 10.69 | 8 | 0.75 | 200 | 18120 | 13558 | <300 | 4800 | 71 | 13558 | 200 |

| 6 | 7.50 | 8.50 | 12.56 | 8 | 0.75 | 200 | 18120 | 11541 | <300 | 4800 | 83 | 11541 | 200 |

| 8 | 9.38 | 10.62 | 19.47 | 8 | 0.75 | 200 | 18120 | 7446 | <300 | 4800 | 129 | 7446 | 200 |

| 10 | 11.25 | 12.75 | 28.26 | 12 | 0.88 | 320 | 25140 | 10675 | <300 | 4800 | 144 | 10675 | 320 |

| 12 | 13.50 | 15.00 | 33.56 | 12 | 0.88 | 320 | 25140 | 8990 | <300 | 4800 | 171 | 8990 | 320 |

| 14 | 14.75 | 16.25 | 36.50 | 12 | 1.00 | 490 | 33060 | 10868 | <300 | 4800 | 216 | 10868 | 490 |

| 16 | 16.75 | 18.50 | 48.42 | 16 | 1.00 | 490 | 33060 | 10923 | <300 | 4800 | 215 | 10923 | 490 |

| 18 | 19.25 | 21.00 | 55.29 | 16 | 1.13 | 710 | 43680 | 12639 | <300 | 4800 | 270 | 12639 | 710 |

| 20 | 21.00 | 23.00 | 69.08 | 20 | 1.13 | 710 | 43680 | 12646 | <300 | 4800 | 269 | 12646 | 710 |

| 24 | 25.25 | 27.25 | 82.43 | 20 | 1.25 | 1000 | 55740 | 13525 | <300 | 4800 | 355 | 13525 | 1000 |

ANSI/ASME B16.5 Class 300 Tongue and Groove Flange – Dimensions & Sizes in mm

| Nominal | Large Tongue | Large Tongue | Gasket | Number | Size of | Bolt Torque | Comp Force | Max. Gasket | Internal | Min. Rec’d | Min. Rec’d | Max. Rec’d/Avail. | Preferred |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Contact I.D. | Contact O.D. | Contact Area | Of | Bolts | at 60ksi Stress | Per Bolt @ 60ksi | Stress Avail. | Pressure | Gasket Stress | Torque/Bolt | Gasket Stress | Torque/Bolt |

| (in) | (in) | (in) | (sq.in.) | Bolts | (in) | (ft.lbs.) | (psi) | (psi) | (psig) | (psi) | (ft.lbs.) | (psi) | (ft.lbs.) |

| 0.5 | 1.00 | 1.38 | 0.71 | 4 | 0.50 | 60 | 7560 | 42594 | <800 | 6200 | 12 | 10000 | 14 |

| 0.75 | 1.31 | 1.69 | 0.89 | 4 | 0.63 | 120 | 12120 | 54174 | <800 | 6200 | 21 | 10000 | 22 |

| 1 | 1.50 | 2.00 | 1.37 | 4 | 0.63 | 120 | 12120 | 35290 | <800 | 6400 | 28 | 10000 | 34 |

| 1.25 | 1.88 | 2.50 | 2.13 | 4 | 0.63 | 120 | 12120 | 22742 | <800 | 6400 | 43 | 10000 | 53 |

| 1.5 | 2.12 | 2.88 | 2.98 | 4 | 0.75 | 200 | 18120 | 24298 | <800 | 6400 | 64 | 10000 | 82 |

| 2 | 2.88 | 3.62 | 3.78 | 8 | 0.63 | 120 | 12120 | 25679 | <800 | 6400 | 46 | 10000 | 47 |

| 2.5 | 3.38 | 4.12 | 4.36 | 8 | 0.75 | 200 | 18120 | 33273 | <800 | 6400 | 60 | 10000 | 60 |

| 3 | 4.25 | 5.00 | 5.45 | 8 | 0.75 | 200 | 18120 | 26618 | <800 | 6400 | 88 | 10000 | 75 |

| 3.5 | 4.75 | 5.50 | 6.03 | 8 | 0.75 | 200 | 18120 | 24021 | <800 | 6400 | 99 | 10000 | 83 |

| 4 | 5.19 | 6.19 | 8.93 | 8 | 0.75 | 200 | 18120 | 16227 | <800 | 6400 | 125 | 10000 | 123 |

| 5 | 6.31 | 7.31 | 10.69 | 8 | 0.75 | 200 | 18120 | 13558 | <800 | 6400 | 156 | 10000 | 148 |

| 6 | 7.50 | 8.50 | 12.56 | 12 | 0.75 | 200 | 18120 | 17312 | <800 | 6400 | 131 | 10000 | 116 |

| 8 | 9.38 | 10.62 | 19.47 | 12 | 0.88 | 320 | 25140 | 15496 | <800 | 6400 | 205 | 10000 | 207 |

| 10 | 11.25 | 12.75 | 28.26 | 16 | 1.00 | 490 | 33060 | 18718 | <800 | 6400 | 219 | 10000 | 262 |

| 12 | 13.50 | 15.00 | 33.56 | 16 | 1.13 | 710 | 43680 | 20826 | <800 | 6400 | 319 | 15000 | 511 |

| 14 | 14.75 | 16.25 | 36.50 | 20 | 1.13 | 710 | 43680 | 23933 | <800 | 6600 | 287 | 15000 | 445 |

| 16 | 16.75 | 18.50 | 48.42 | 20 | 1.25 | 1000 | 55740 | 23021 | <800 | 6600 | 401 | 15000 | 652 |

| 18 | 19.25 | 21.00 | 55.29 | 24 | 1.25 | 1000 | 55740 | 24194 | <800 | 6400 | 439 | 15000 | 620 |

| 20 | 21.00 | 23.00 | 69.08 | 24 | 1.25 | 1000 | 55740 | 19365 | <800 | 6400 | 484 | 15000 | 775 |

| 24 | 25.25 | 27.25 | 82.43 | 24 | 1.50 | 1600 | 84300 | 24546 | <800 | 6400 | 662 | 15000 | 978 |

Tongue and Groove Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| Nominal Pipe Size (in) | Class 150# | Class 300# | Class 600# | Class 900# | Class 1500# | Class 2500# |

|---|---|---|---|---|---|---|

| ½ | 2.5 lbs | 3.2 lbs | 5.1 lbs | 6.2 lbs | 10 lbs | 15 lbs |

| ¾ | 3.0 lbs | 4.0 lbs | 6.5 lbs | 7.8 lbs | 12 lbs | 18 lbs |

| 1 | 4.5 lbs | 5.8 lbs | 9.0 lbs | 11 lbs | 16 lbs | 25 lbs |

| 1¼ | 6.2 lbs | 8.0 lbs | 12 lbs | 15 lbs | 21 lbs | 32 lbs |

| 1½ | 8.0 lbs | 10 lbs | 15 lbs | 18 lbs | 26 lbs | 38 lbs |

| 2 | 12 lbs | 15 lbs | 23 lbs | 28 lbs | 40 lbs | 60 lbs |

| 2½ | 16 lbs | 20 lbs | 30 lbs | 37 lbs | 52 lbs | 78 lbs |

| 3 | 20 lbs | 26 lbs | 40 lbs | 50 lbs | 68 lbs | 100 lbs |

| 4 | 35 lbs | 45 lbs | 70 lbs | 90 lbs | 120 lbs | 180 lbs |

| 6 | 60 lbs | 80 lbs | 125 lbs | 160 lbs | 210 lbs | 300 lbs |

| 8 | 95 lbs | 125 lbs | 200 lbs | 260 lbs | 320 lbs | 450 lbs |

| 10 | 150 lbs | 200 lbs | 320 lbs | 420 lbs | 520 lbs | 750 lbs |

| 12 | 200 lbs | 280 lbs | 450 lbs | 580 lbs | 720 lbs | 1050 lbs |

| 14 | 250 lbs | 350 lbs | 560 lbs | 720 lbs | 900 lbs | 1300 lbs |

| 16 | 320 lbs | 450 lbs | 720 lbs | 920 lbs | 1150 lbs | 1650 lbs |

| 18 | 400 lbs | 580 lbs | 900 lbs | 1150 lbs | 1400 lbs | 2000 lbs |

| 20 | 480 lbs | 680 lbs | 1050 lbs | 1350 lbs | 1650 lbs | 2400 lbs |

| 24 | 650 lbs | 900 lbs | 1400 lbs | 1800 lbs | 2200 lbs | 3200 lbs |

Tongue and Groove Flange Tolerances as per ANSI / ASME B16.5, B16.47

| Feature | Tolerance | Reference |

|---|---|---|

| Outside Diameter (OD) | ±1/16” (1.6 mm) | B16.5 / B16.47 |

| Thickness of Flange (T) | ±1/16” (1.6 mm) | B16.5 / B16.47 |

| Bolt Circle Diameter (PCD) | ±1/32” (0.8 mm) | B16.5 / B16.47 |

| Bolt Hole Diameter | +1/64” / -0 | B16.5 / B16.47 |

| Raised Face (RF) Height | ±1/32” (0.8 mm) | B16.5 / B16.47 |

| Ring-Type Joint (RTJ) Groove | As per API / B16.5 | Depth ±0.003–0.005” depending on size |

How does the tongue and groove design improve flange sealing?

- The tongue protrudes from one flange and fits into the corresponding groove of the mating flange.

- This design ensures self-alignment, preventing misalignment during assembly.

- The groove acts as a reservoir for gaskets, enhancing the sealing surface area.

- It helps maintain uniform bolt load distribution, reducing the risk of leaks under high-pressure or high-temperature conditions.

What gasket types are compatible with T&G flanges?

- Spiral Wound Gaskets: Suitable for high-pressure and temperature applications.

- Ring-Type Joint (RTJ) Gaskets: Ideal for Class 900# and above.

- Metallic or Composite Gaskets: Used in chemical or oil & gas pipelines.

- The gasket thickness must match the groove depth, and material must withstand the operating environment.

Can Tongue and Groove Flanges be used with RTJ and raised face systems?

-

Yes, T&G flanges are compatible with:

- Raised Face (RF): Common in general industrial and chemical piping.

- Flat Face (FF): For cast iron or low-pressure lines.

- Ring-Type Joint (RTJ): High-pressure, critical-service pipelines where metal-to-metal sealing is required.

- Selection depends on pressure, temperature, and gasket type.