- Home

- Industrial Flanges

- Sweldolet Flange

Sweldolet Flange

SweD-Olet flange : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Trusted Source for SweD-Olet Flanges in Carbon, Stainless, Alloy & High-Nickel Steel — ½″–24″, 150#–2500# Pressure Classes, Ideal for High-Pressure Pipelines in Oil, Gas, and Petrochemical Industries.

Best Export Prices: sales@midlandforgefittings.com

At Midland Forge and Fittings Pvt. Ltd., we manufacture high-quality SweD-Olet flanges designed for secure and leak-free branch connections in industrial piping systems. Available in carbon steel, stainless steel, alloy steel, and high-nickel steel.

our SweD-Olets are engineered to meet ASME B16.9 standards, ensuring precise dimensions, proper stress distribution, and exceptional durability under high-pressure and high-temperature conditions. These fittings are ideal for oil & gas, petrochemical, power generation, and chemical process industries.

Our SweD-Olet flanges are available in sizes ranging from ½″ to 24″ and pressure classes from 150# to 2500#, making them versatile for a wide range of industrial applications. Each product undergoes strict quality control, dimensional verification, and NDT inspections to guarantee leak-proof, long-lasting performance. With us you get reliable, ASME-compliant SweD-Olet flanges ready for domestic and international projects, delivering both precision and peace of mind to your piping systems.

A Sweldolet flange is a butt-weld branch outlet fitting that connects a smaller branch pipe to a main run line. It features a hub for welding and a flanged end for secure connections, ensuring leak-proof and stress-free piping junctions. SweD-Olets are available in carbon steel, stainless steel, alloy steel, and high-nickel alloys. They are manufactured according to ASME B16.9 / B16.11 standards for precise dimensions and pressure ratings.

SweD-Olet flanges are used to reduce stress concentration, prevent leaks, and ensure structural integrity at branch connections. Their compact hub design distributes stress evenly, making them suitable for high-pressure and high-temperature applications.

Sweldolet Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Sweldolet Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Carbon Steel | ASTM A105 (Forged CS), ASTM A350 LF2 (Low Temp CS) | Class 150 – 2500, Size ½”–24” | Oil & gas, general industrial piping, pressure lines |

| Stainless Steel | ASTM A182 F304 / F304L / F316 / F316L | Class 150 – 2500, Size ½”–24” | Corrosive and high-temperature applications, chemical, marine, and pharmaceutical industries |

| Alloy Steel | ASTM A182 F11 / F22 / F91 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines, high-temperature applications |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high-corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718, Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Chemical, heat exchangers, marine, aerospace, seawater handling |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, seawater systems, desalination plants |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

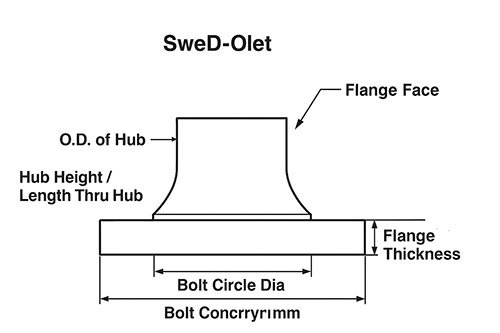

ANSI/ASME B16.9 SweD-Olet Flange– Dimensions

| Branch NPS | O.D. of Hub (mm) | Hub Height / Length Thru Hub (mm) | Flange Thickness (mm) | Bolt Circle Dia (mm) | Bolt Hole Dia (mm) |

|---|---|---|---|---|---|

| ½″ | 21.3 | 25 | 12 | 85 | 18 |

| ¾″ | 26.7 | 30 | 14 | 95 | 18 |

| 1″ | 33.4 | 35 | 16 | 105 | 18 |

| 1¼″ | 42.2 | 40 | 18 | 115 | 18 |

| 1½″ | 48.3 | 45 | 20 | 125 | 18 |

| 2″ | 60.3 | 50 | 22 | 140 | 18 |

| 2½″ | 73 | 55 | 24 | 155 | 18 |

| 3″ | 88.9 | 60 | 26 | 170 | 18 |

| 4″ | 114.3 | 70 | 30 | 200 | 22 |

| 6″ | 168.3 | 85 | 34 | 240 | 22 |

| 8″ | 219.1 | 100 | 38 | 295 | 26 |

| 10″ | 273 | 120 | 42 | 350 | 26 |

| 12″ | 323.9 | 140 | 46 | 400 | 30 |

| 14″ | 355.6 | 160 | 50 | 450 | 30 |

| 16″ | 406.4 | 180 | 54 | 500 | 33 |

| 18″ | 457.2 | 200 | 58 | 550 | 36 |

| 20″ | 508 | 220 | 62 | 600 | 36 |

| 24″ | 609.6 | 250 | 70 | 700 | 39 |

Sweldolet Flange Weight Chart

| Schedule | 1/2″ | 3/4″ | 1″ | 1 1/4″ | 1 1/2″ | 2″ | 2 1/2″ | 3″ | 3 1/2″ | 4″ | 5″ | 6″ | 8″ | 10″ | 12″ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STD | 0.09 | 0.14 | 0.21 | 0.41 | 0.50 | 0.79 | 1.81 | 1.86 | 2.54 | 2.90 | 10.43 | 16.78 | 20.87 | 27.67 | 31.75 |

| XS | 0.11 | 0.32 | 0.38 | 0.57 | 0.79 | 0.97 | 1.53 | 2.87 | 4.76 | 6.46 | 12.70 | 20.41 | 38.56 | 27.67 | 31.75 |

| 160 | 0.11 | 0.32 | 0.38 | 0.57 | 0.79 | 0.97 | 1.53 | 2.87 | 4.76 | 6.46 | 12.70 | 20.41 | 38.56 | 27.67 | 31.75 |

| XXS | 0.11 | 0.32 | 0.38 | 0.57 | 0.79 | 0.97 | 1.53 | 2.87 | 4.76 | 6.46 | 12.70 | 20.41 | 38.56 | – | – |

Sweldo Olet flange Tolerances as per ANSI / ASME B16.9,16.11

| Nominal Pipe Size (NPS) | Outside Diameter Tolerance (D) | Inside Diameter Tolerance | Center-to-End / Wall Thickness (t) | Alignment (U) | Applicable Standard |

|---|---|---|---|---|---|

| 1/2″ – 2 1/2″ | +1.6 mm / -0.8 mm | 0.8 mm | ≥ 87.5% of nominal | ±1 mm per 200 mm | ASME B16.9 / B16.11 |

| 3″ – 3 1/2″ | ±1.6 mm | 1.6 mm | ≥ 87.5% of nominal | ±1 mm per 200 mm | ASME B16.9 / B16.11 |

| 4″ | ±1.6 mm | 1.6 mm | ≥ 87.5% of nominal | ±1 mm per 200 mm | ASME B16.9 / B16.11 |

| 5″ – 8″ | +2.4 mm / -1.6 mm | 1.6 mm | ≥ 87.5% of nominal | ±1 mm per 200 mm | ASME B16.9 / B16.11 |

| 10″ – 18″ | +4.0 mm / -3.2 mm | 3.2 mm | ≥ 87.5% of nominal | ±2 mm per 200 mm | ASME B16.9 / B16.11 |

| 20″ – 24″ | +6.4 mm / -4.8 mm | 4.8 mm | ≥ 87.5% of nominal | ±2 mm per 200 mm | ASME B16.9 / B16.11 |

| 26″ – 30″ | +6.4 mm / -4.8 mm | 4.8 mm | ≥ 87.5% of nominal | ±2 mm per 200 mm | ASME B16.9 / B16.11 |

| 32″ – 48″ | +6.4 mm / -4.8 mm | 4.8 mm | ≥ 87.5% of nominal | ±2 mm per 200 mm | ASME B16.9 / B16.11 |

What are the critical design considerations when selecting a Sweldolet for a high-pressure system?

-

Pipe Schedule and Wall Thickness:

- Sweldolet fittings must match the run pipe’s schedule to maintain structural integrity.

- The wall thickness of the Sweldolet is generally equal to or slightly greater than that of the branch pipe to prevent stress concentration at the junction.

-

Branch-to-Run Pipe Diameter Ratio:

- ASME B16.9 specifies limits for branch pipe sizes relative to run pipe diameter.

- Exceeding these ratios can increase stress on the run pipe and compromise the weld.

-

Pressure Rating Alignment:

- The Sweldolet pressure rating must be equal to or greater than the system pressure.

- Class ratings (3000, 6000, 9000) determine allowable stress for high-pressure applications.

-

Material Compatibility:

- The Sweldolet material must match or exceed the mechanical and corrosion resistance of the main pipe and branch pipe.

- Common materials: ASTM A105 (carbon steel), A182 F316/F304 (stainless steel), and alloy steels (F11/F22).

-

Stress Analysis:

- FEA (Finite Element Analysis) is recommended for large-diameter branches to predict stress distribution and deformation.

What are the technical differences between Sweldolets, Sockolets, and Threadolets?

| Feature | Sweldolet | Sockolet | Threadolet |

|---|---|---|---|

| Connection Type | Butt-weld | Socket-weld | Threaded |

| Pressure Rating | High (up to Class 9000) | Medium | Low to Medium |

| Installation Space | Compact | Compact | Very compact |

| Stress Handling | Excellent | Moderate | Limited |

| Use Case | High-pressure, high-temperature pipelines | Medium pressure lines | Low-pressure or temporary connections |

How does branch size affect Sweldolet selection and stress concentration?

-

Branch-to-Run Ratio:

- The maximum branch diameter is generally 50% of the main run pipe diameter.

- Exceeding this increases local stresses and may require reinforcement or use of a reducing Sweldolet.

-

Stress Distribution:

- Sweldolet hub design ensures gradual transfer of stresses from branch to run pipe.

- Proper fillet weld size and wall thickness minimize stress concentration factors (SCF).

-

Flow Considerations:

- For large branches, consider flow turbulence at the junction.

- Smooth transitions reduce erosion and pressure drop in high-velocity systems.