- Home

- Industrial Flanges

- Spectacle Blind Flange

Spectacle Blind Flange

Figure 8 Blank Flange : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Manufacturer & Exporter of ASME B16.48 Spectacle Blind Flanges (Figure 8 Blanks) in Carbon Steel, Stainless Steel, Alloy Steel & Nickel Alloys – Sizes ½” to 24”, Pressure Classes 150# to 2500#.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a forward-looking manufacturer and exporter specializing in high-performance ASME B16.5 Spectacle Blind Flanges. With decades of engineering experience, we have built our reputation on precision, consistency, and the ability to meet the toughest project requirements across global markets.

Every Spectacle Blind Flange we produce is backed by a deep understanding of international standards such as ASME, ANSI, DIN, and EN, as well as project-specific requirements from our clients. From standard sizes to complex, custom-engineered flanges, our team ensures absolute dimensional accuracy, metallurgical integrity, and long service reliability.

Spectacle Blind Flange (Figure 8 Blank Flange) is a specialized piping component used to isolate a section of a pipeline or equipment for maintenance, inspection, or testing purposes without disrupting the flow in the rest of the system. It is called a “Figure 8” flange because of its unique shape—one side is solid (the blind) and the other is an open ring, connected by a narrow section, resembling the number 8. When installed, the solid side blocks the flow completely, while the open side allows the fluid or gas to pass. Spectacle Blind Flanges are widely used in high-pressure, high-temperature, and critical service pipelines where safe and controlled isolation is required.

We operate with a diverse materials portfolio, including Carbon Steel, Stainless Steel, Alloy Steel, Duplex & Super Duplex, and High Nickel Alloys. Each raw material undergoes rigorous testing before entering our production lines, and every finished Spectacle Blind Flange is subjected to advanced non-destructive and destructive testing methods to guarantee compliance with international quality benchmarks.

We are proudly supplied Figure 8 Flanges and other critical piping components to industries such as oil & gas, petrochemicals, power generation, offshore drilling, and marine engineering. Our customer base spans across North America, Europe, the Middle East, and Asia, where reliability, timely delivery, and technical expertise make us a trusted partner for high-pressure and high-temperature applications.

Spectacle Blind Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Figure 8 Blank Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

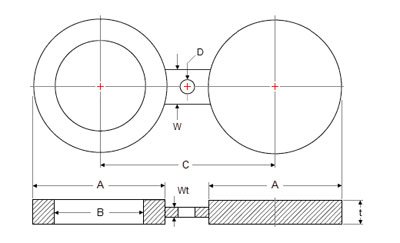

ANSI/ASME B16.48 Class 150 Spectacle Blind Flange – Dimensions

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 45 | 16 | 60 | 3 | 38 |

| 3/4 | 54 | 21 | 70 | 3 | 38 |

| 1 | 64 | 27 | 80 | 3 | 38 |

| 1.1/4 | 73 | 42 | 90 | 6.4 | 38 |

| 1.1/2 | 83 | 48 | 100 | 6.4 | 38 |

| 2 | 102 | 61 | 120 | 6.4 | 51 |

| 2.1/2 | 107 | 73 | 140 | 6.4 | 51 |

| 3 | 133 | 89 | 150 | 6.4 | 64 |

| 3.1/2 | 159 | 102 | 175 | 9.7 | 64 |

| 4 | 172 | 114 | 190 | 9.7 | 64 |

| 5 | 194 | 141 | 215 | 9.7 | 76 |

| 6 | 219 | 168 | 240 | 12.7 | 76 |

| 8 | 276 | 219 | 300 | 12.7 | 76 |

| 10 | 337 | 273 | 360 | 15.7 | 102 |

| 12 | 406 | 324 | 430 | 19.1 | 102 |

| 14 | 448 | 356 | 475 | 19.1 | 108 |

| 16 | 511 | 406 | 460 | 22.4 | 108 |

| 18 | 546 | 457 | 580 | 25.4 | 114 |

| 20 | 603 | 508 | 635 | 28.4 | 121 |

| 24 | 714 | 610 | 750 | 31.8 | 140 |

ANSI/ASME B16.48 Class 300 Spectacle Blind Flange – Dimensions

| NPS | Outside Ø A | Inside Ø B | Center Line C | THK t | Web Width W |

|---|---|---|---|---|---|

| 1/2 | 51 | 16 | 65 | 6.4 | 38 |

| 3/4 | 64 | 21 | 80 | 6.4 | 38 |

| 1 | 70 | 27 | 90 | 6.4 | 38 |

| 1.1/4 | 79 | 42 | 100 | 6.4 | 38 |

| 1.1/2 | 92 | 48 | 115 | 6.4 | 38 |

| 2 | 108 | 61 | 125 | 9.7 | 51 |

| 2.1/2 | 127 | 73 | 150 | 9.7 | 51 |

| 3 | 146 | 89 | 170 | 9.7 | 64 |

| 3.1/2 | 162 | 102 | 185 | 12.7 | 64 |

| 4 | 178 | 114 | 200 | 12.7 | 64 |

| 5 | 213 | 141 | 235 | 15.7 | 76 |

| 6 | 248 | 168 | 270 | 15.7 | 76 |

| 8 | 305 | 219 | 330 | 22.4 | 76 |

| 10 | 359 | 273 | 385 | 25.4 | 102 |

| 12 | 419 | 324 | 450 | 28.4 | 102 |

| 14 | 483 | 356 | 515 | 31.8 | 108 |

| 16 | 536 | 406 | 570 | 38.1 | 108 |

| 18 | 594 | 457 | 630 | 41.1 | 114 |

| 20 | 651 | 508 | 685 | 44.5 | 121 |

| 24 | 772 | 610 | 810 | 50.8 | 140 |

ANSI/ASME B16.48 Class 600 Spectacle Blind Flange – Dimensions

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 51 | 16 | 65 | 6.4 | 38 |

| 3/4 | 64 | 21 | 80 | 6.4 | 38 |

| 1 | 70 | 27 | 90 | 6.4 | 57 |

| 1.1/4 | 79 | 37 | 100 | 9.7 | 57 |

| 1.1/2 | 92 | 43 | 115 | 9.7 | 67 |

| 2 | 108 | 55 | 125 | 9.7 | 57 |

| 2.1/2 | 127 | 67 | 150 | 12.7 | 67 |

| 3 | 146 | 83 | 170 | 12.7 | 67 |

| 3.1/2 | 159 | 96 | 185 | 15.7 | 76 |

| 4 | 191 | 108 | 215 | 15.7 | 76 |

| 5 | 238 | 135 | 265 | 19.1 | 86 |

| 6 | 264 | 162 | 290 | 22.4 | 86 |

| 8 | 318 | 212 | 350 | 28.4 | 95 |

| 10 | 397 | 265 | 430 | 35.1 | 105 |

| 12 | 454 | 315 | 490 | 41.1 | 105 |

| 14 | 489 | 346 | 525 | 44.5 | 114 |

| 16 | 562 | 397 | 605 | 50.8 | 124 |

| 18 | 610 | 448 | 655 | 53.8 | 133 |

| 20 | 679 | 497 | 725 | 63.5 | 133 |

| 24 | 787 | 597 | 840 | 73.2 | 152 |

ANSI/ASME B16.48 Class 900 Spectacle Blind Flange – Dimensions

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 60 | 16 | 80 | 6.4 | 38 |

| 3/4 | 67 | 21 | 90 | 6.4 | 41 |

| 1 | 76 | 27 | 100 | 6.4 | 57 |

| 1.1/4 | 86 | 37 | 110 | 9.7 | 57 |

| 1.1/2 | 95 | 43 | 125 | 9.7 | 67 |

| 2 | 140 | 55 | 165 | 12.7 | 57 |

| 2.1/2 | 162 | 67 | 190 | 12.7 | 67 |

| 3 | 165 | 83 | 190 | 15.7 | 67 |

| 4 | 203 | 108 | 235 | 19.1 | 76 |

| 5 | 244 | 135 | 280 | 22.4 | 86 |

| 6 | 286 | 162 | 320 | 25.4 | 86 |

| 8 | 356 | 212 | 395 | 35.1 | 95 |

| 10 | 432 | 265 | 470 | 41.1 | 105 |

| 12 | 495 | 315 | 535 | 47.8 | 105 |

| 14 | 518 | 346 | 560 | 53.8 | 114 |

| 16 | 572 | 397 | 615 | 60.5 | 124 |

| 18 | 635 | 448 | 685 | 66.5 | 133 |

| 20 | 696 | 497 | 750 | 73.2 | 133 |

| 24 | 835 | 597 | 900 | 88.9 | 152 |

ANSI/ASME B16.48 Class 1500 Spectacle Blind Flange – Dimensions

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 61 | 16 | 80 | 6.4 | 38 |

| 3/4 | 67 | 21 | 90 | 9.7 | 41 |

| 1 | 76 | 27 | 100 | 9.7 | 64 |

| 1.1/4 | 86 | 35 | 110 | 9.7 | 64 |

| 1.1/2 | 95 | 41 | 125 | 12.7 | 70 |

| 2 | 140 | 53 | 165 | 12.7 | 70 |

| 2.1/2 | 162 | 63 | 190 | 15.7 | 76 |

| 3 | 172 | 78 | 205 | 19.1 | 76 |

| 4 | 206 | 102 | 240 | 22.4 | 89 |

| 5 | 251 | 128 | 290 | 28.4 | 89 |

| 6 | 279 | 154 | 320 | 35.1 | 89 |

| 8 | 349 | 203 | 395 | 41.1 | 102 |

| 10 | 432 | 255 | 480 | 50.8 | 114 |

| 12 | 518 | 303 | 570 | 60.5 | 114 |

| 14 | 575 | 333 | 635 | 66.5 | 127 |

| 16 | 638 | 381 | 705 | 76.2 | 133 |

| 18 | 702 | 429 | 775 | 85.9 | 146 |

| 20 | 752 | 478 | 830 | 95.3 | 152 |

| 24 | 899 | 575 | 990 | 111.3 | 178 |

ANSI/ASME B16.48 Class 2500 Spectacle Blind Flange – Dimensions

| NPS | Outside Ø A |

Inside Ø B |

Center Line C |

THK t |

Web Width W |

|---|---|---|---|---|---|

| 1/2 | 67 | 16 | 90 | 9.7 | 38 |

| 3/4 | 73 | 21 | 95 | 9.7 | 41 |

| 1 | 83 | 27 | 110 | 9.7 | 64 |

| 1.1/4 | 102 | 35 | 130 | 12.7 | 64 |

| 1.1/2 | 114 | 41 | 145 | 15.7 | 70 |

| 2 | 143 | 53 | 170 | 15.7 | 70 |

| 2.1/2 | 165 | 63 | 195 | 19.1 | 76 |

| 3 | 194 | 78 | 230 | 22.4 | 76 |

| 4 | 232 | 102 | 275 | 28.4 | 89 |

| 5 | 276 | 128 | 325 | 35.1 | 89 |

| 6 | 314 | 154 | 370 | 41.1 | 89 |

| 8 | 384 | 198 | 440 | 53.8 | 102 |

| 10 | 473 | 248 | 540 | 66.5 | 114 |

| 12 | 546 | 289 | 620 | 79.2 | 114 |

Figure 8 Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| Nominal Pipe Size (in) | Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 | Class 2500 |

|---|---|---|---|---|---|---|

| ½ | 3 | 5 | 9 | 12 | 20 | 35 |

| 1 | 7 | 12 | 22 | 30 | 50 | 90 |

| 2 | 15 | 25 | 50 | 70 | 115 | 210 |

| 4 | 45 | 70 | 130 | 180 | 290 | 540 |

| 6 | 85 | 140 | 260 | 350 | 560 | 1040 |

| 8 | 145 | 230 | 420 | 560 | 900 | 1700 |

| 10 | 210 | 340 | 620 | 820 | 1320 | 2500 |

| 12 | 300 | 480 | 880 | 1160 | 1880 | 3600 |

| 16 | 600 | 950 | 1800 | 2350 | 3800 | 7300 |

| 24 | 1200 | 1900 | 3600 | 4700 | 7600 | 14600 |

Figure 8 Blank Flange Tolerances as per ANSI / ASME B16.48

| Parameter | Tolerance (Small NPS ½″–24″) | Tolerance (Large NPS 26″–60″) |

|---|---|---|

| Overall Flange Thickness (T) | ±0.50 mm | ±0.80 mm |

| Male Face Height (h1) | +0.00 / –0.25 mm | +0.00 / –0.40 mm |

| Female Recess Depth (h2) | +0.25 / –0.00 mm | +0.40 / –0.00 mm |

| Flange Outside Diameter (OD) | ±0.50 mm | ±0.80 mm |

| Bolt Circle Diameter (BCD / K) | ±0.50 mm | ±0.80 mm |

| Bolt Hole Diameter (d) | ±0.25 mm | ±0.50 mm |

| Alignment / Runout | 0.30 mm max | 0.50 mm max |

| Gasket Contact Surface Finish (Ra) | 3.2–6.3 µm (125–250 AARH) | 3.2–6.3 µm (125–250 AARH) |

How does the thickness of the blind and ring portion affect flange performance under high pressure?

- Stress Distribution: The blind portion thickness must be sufficient to withstand internal pipeline pressure without yielding. Thicker blind portions reduce localized stress at the hub-to-body junction.

- Bolt Loading: Uneven thickness can create non-uniform gasket compression, leading to leakage at high pressures.

- Ring Portion: Must maintain adequate rigidity; too thin can deform under bolt torque or thermal expansion.

- Engineering Guidance: ASME B16.48 specifies thickness proportional to nominal pipe size (NPS) and pressure class to balance strength, weight, and cost.

What is the impact of cyclic pressure or thermal fluctuation on spectacle blind flanges?

- Cyclic loading: Repeated pressure cycles can induce fatigue at the hub-blind junction.

- Thermal cycling: Differential expansion between flange material and gasket can reduce sealing efficiency.

- Engineering Control: Use of alloy or duplex materials and controlled hub radius mitigates fatigue and thermal stress effects.

- Routine inspection recommended in power, chemical, and offshore systems for high-cycle operations.

How to calculate the weight and torque requirements for large spectacle blind flanges?

- Weight Calculation: Depends on NPS, pressure class, material density, blind thickness, and ring thickness.

- Torque Estimation: Based on bolt size, gasket type, and pressure class; ensures uniform seating without over-stressing flange.

- Engineering Note: For flanges ≥24″ NPS or Class 1500–2500, mechanical lifting devices and torque wrenches are mandatory to avoid flange damage or improper sealing.