- Home

- Industrial Flanges

- Long Weld Neck Flange

Long Weld Neck Flange

Long Weld Neck Flange: Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Reliable ASME B16.5 Long Weld Neck Flanges from a trusted manufacturer and exporter of carbon, stainless, alloy, and nickel alloys. Available in sizes from ½” to 24” and pressure classes from 150 to 2500. Delivered worldwide including Spain, Turkey, South Korea, and Argentina.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd, is a globally recognized manufacturer and exporter of high-quality Long Weld Neck Flanges, catering to diverse industries including oil & gas, petrochemical, power, and shipbuilding. Our products are meticulously engineered to meet international standards such as ASME B16.5, ensuring precision, durability, and optimum performance in high-pressure and high-temperature applications.

We specialize in Long Weld Neck Flanges made from a wide range of materials including carbon steel, stainless steel, alloy steel, and high nickel alloys, offering versatility for various chemical, industrial, and mechanical applications. Each flange is crafted to provide a smooth transition between pipe and flange, reducing stress concentrations and enhancing the structural integrity of piping systems.

LWN Flanges are available in sizes ranging from ½” to 24” and pressure classes from 150# to 2500#, accommodating both standard and custom requirements. With strict adherence to quality control protocols, we ensure every flange undergoes dimensional inspection, material testing, and surface finishing to meet client specifications and industry standards.

Our commitment to excellence extends beyond manufacturing. As a reliable global exporter, We delivers Long Weld Neck Flanges worldwide, including regions like USA, Germany, UAE, Singapore, and Australia. Our efficient logistics, competitive pricing, and dedicated customer support make us a preferred choice for international clients seeking high-performance flanges.

Choose Midland Forge and Fittings Pvt. Ltd for long-lasting, precision-engineered Long Weld Neck Flanges that combine superior material strength, reliable performance, and seamless integration into critical piping systems.

Long Weld Neck Pipe Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Long Weld Neck Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

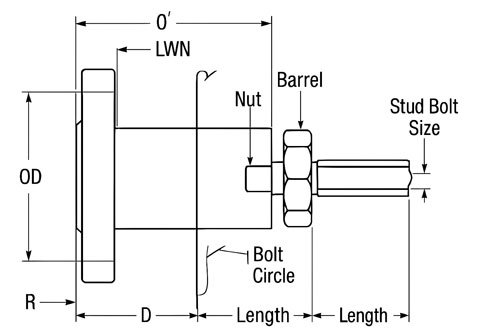

ANSI/ASME B16.5 Class 150 Long Weld Neck Flange – Dimensions & Sizes in mm

| Size | Flange | Barrel OD | Bolting | Nut | Stud Bolt | Weights | Length | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom | Bore LWN & E | Bore HB | OD | Thk. | RF of OD | LWN | HB | E | # of Holes | Hole Size | Bolt Circle | Stop Dia | Relief Dia | Relief Length | Size | RF Length | RTJ Length | LWN | HB | E | Base | |||

| B | B | O | T | R | D | D | D | C | NS | NR | NL | Base | Per 1″ | Base | Per 1″ | Base | Per 1″ | L | ||||||

| 1/2 | 0.5 | 0.55 | 3.5 | 0.44 | 1.38 | 1.25 | 1.5 | 3.5 | 4 | 0.62 | 2.38 | 1.5 | 1.25 | 0.75 | 1/2 | 2 1/4 | 2 3/4 | 3 | 0.3 | 5 | 0.4 | 21 | 2.7 | 9 |

| 3/4 | 0.75 | 0.74 | 3.88 | 0.5 | 1.69 | 1.62 | 1.88 | 3.88 | 4 | 0.62 | 2.75 | 1.88 | 1.62 | 0.75 | 1/2 | 2 1/2 | 3 | 5 | 0.5 | 7 | 0.7 | 27 | 3.2 | 9 |

| 1 | 1 | 0.96 | 4.25 | 0.56 | 2 | 2 | 2.25 | 4.25 | 4 | 0.62 | 3.12 | 2.25 | 2 | 0.75 | 1/2 | 2 1/2 | 3 | 7 | 0.7 | 10 | 0.9 | 30 | 3.8 | 9 |

| 1 1/4 | 1.25 | 1.28 | 4.62 | 0.62 | 2.5 | 2.38 | 2.62 | 4.62 | 4 | 0.62 | 3.5 | 2.62 | 2.38 | 0.75 | 1/2 | 2 3/4 | 3 1/4 | 10 | 0.9 | 12 | 1.2 | 36 | 4.4 | 9 |

| 1 1/2 | 1.5 | 1.5 | 5 | 0.69 | 2.88 | 2.62 | 3 | 5 | 4 | 0.62 | 3.88 | 3 | 2.62 | 0.75 | 1/2 | 2 3/4 | 3 1/4 | 12 | 1 | 16 | 1.5 | 41 | 5.1 | 9 |

| 2 | 2 | 1.94 | 6 | 0.75 | 3.62 | 3.06 | 3.69 | 6 | 4 | 0.75 | 4.75 | 3.69 | 3.06 | 0.88 | 5/8 | 3 1/4 | 3 3/4 | 15 | 1.2 | 23 | 2.2 | 57 | 7.1 | 9 |

| 2 1/2 | 2.5 | 2.32 | 7 | 0.88 | 4.12 | 3.75 | 4.44 | 7 | 4 | 0.75 | 5.5 | 4.44 | 3.75 | 0.88 | 5/8 | 3 1/2 | 4 | 22 | 1.7 | 34 | 3.2 | 79 | 10 | 9 |

| 3 | 3 | 2.9 | 7.5 | 0.94 | 5 | 4.25 | 4.94 | 7.5 | 4 | 0.75 | 6 | 4.94 | 4.25 | 0.88 | 5/8 | 3 1/2 | 4 1/4 | 25 | 2 | 38 | 3.6 | 86 | 11 | 9 |

| 3 1/2 | 3.5 | 3.36 | 8.5 | 0.94 | 5.5 | 4.88 | 5.94 | 8.5 | 8 | 0.75 | 7 | 5.94 | 4.88 | 0.88 | 5/8 | 3 1/2 | 4 1/4 | 32 | 2.6 | 55 | 5.3 | 110 | 13 | 9 |

| 4 | 4 | 3.83 | 9 | 0.94 | 6.19 | 5.5 | 6.44 | 9 | 8 | 0.75 | 7.5 | 6.44 | 5.5 | 0.88 | 5/8 | 3 1/2 | 4 1/4 | 47 | 3.2 | 78 | 6 | 164 | 14 | 12 |

| 5 | 5 | 4.81 | 10 | 0.94 | 7.31 | 6.50 | 7.25 | 10 | 8 | 0.88 | 8.5 | 7.25 | 6.50 | 1 | 3/4 | 3 3/4 | 4 1/2 | 57 | 3.8 | 87 | 6.50 | 189 | 17 | 12 |

| 6 | 6 | 5.76 | 11 | 1 | 8.5 | 7.75 | 8.25 | 11 | 8 | 0.88 | 9.5 | 8.25 | 7.75 | 1 | 3/4 | 4 | 4 1/2 | 75 | 5.4 | 103 | 7.8 | 216 | 19 | 12 |

| 8 | 8 | 7.62 | 13.5 | 1.12 | 10.62 | 9.75 | 10.5 | 13.5 | 8 | 0.88 | 11.75 | 10.5 | 9.75 | 1 | 3/4 | 4 1/4 | 4 3/4 | 102 | 6.9 | 157 | 11 | 292 | 26 | 12 |

| 10 | 10 | 9.56 | 16 | 1.19 | 12.75 | 12 | 12.81 | 16 | 12 | 1 | 14.25 | 12.81 | 12 | 1.12 | 7/8 | 4 3/4 | 5 1/4 | 143 | 9.8 | 214 | 16 | 382 | 35 | 12 |

| 12 | 12 | 11.38 | 19 | 1.25 | 15 | 14.38 | 15.56 | 19 | 12 | 1 | 17 | 15.56 | 14.38 | 1.12 | 7/8 | 4 3/4 | 5 1/2 | 205 | 14 | 329 | 25 | 535 | 48 | 12 |

| 14 | 14 | 14 | 21 | 1.38 | 16.25 | 16 | 17.12 | 21 | 12 | 1.12 | 18.75 | 17.12 | 16 | 1.25 | 1 | 5 1/4 | 6 | 211 | 13 | 296 | 22 | 585 | 55 | 12 |

| 16 | 16 | 16 | 23.5 | 1.44 | 18.5 | 18 | 19.62 | 23.5 | 16 | 1.12 | 21.25 | 19.62 | 18 | 1.25 | 1 | 5 1/2 | 6 | 246 | 15 | 388 | 29 | 714 | 66 | 12 |

| 18 | 18 | 18 | 25 | 1.56 | 21 | 20 | 20.94 | 25 | 16 | 1.25 | 22.75 | 20.94 | 20 | 1.38 | 1 1/8 | 6 | 6 1/2 | 270 | 17 | 362 | 25 | 711 | 67 | 12 |

| 20 | 20 | 20 | 27.5 | 1.69 | 23 | 22 | 23.19 | 27.5 | 20 | 1.25 | 25 | 23.19 | 22 | 1.38 | 1 1/8 | 6 1/4 | 7 | 311 | 19 | 434 | 31 | 840 | 79 | 12 |

| 24 | 24 | 24 | 32 | 1.88 | 27.25 | 26.25 | 27.5 | 32 | 20 | 1.38 | 29.5 | 27.5 | 26.25 | 1.5 | 1 1/4 | 7 | 7 3/4 | 423 | 25 | 574 | 40 | 1046 | 100 | 12 |

ANSI/ASME B16.5 Class 300 LWN Flange – Dimensions & Sizes in mm

| Size | Flange | Barrel OD | Bolting | Nut | Stud Bolt | Weights | Length | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom | Bore LWN & E | Bore HB | OD | Thk | RF of OD | LWN | HB | E | # ofHoles | Hole Size | Bolt Circle | Stop Dia | Relief Dia | Relief Length | Size | RF Length | RTJ Length | LWN | HB | E | Base | |||

| B | B | O | T | R | D | D | D | C | NS | NR | NL | Base | Per 1″ | Base | Per 1″ | Base | Per 1″ | L | ||||||

| 1/2 | 0.5 | 0.55 | 3.75 | 0.56 | 1.38 | 1.5 | 1.75 | 3.75 | 4 | 0.62 | 2.62 | 1.75 | 1.5 | 0.75 | 1/2 | 2 1/2 | 3 | 5 | 0.4 | 7 | 0.6 | 24 | 3.1 | 9 |

| 3/4 | 0.75 | 0.74 | 4.62 | 0.62 | 1.69 | 1.88 | 2.19 | 4.62 | 4 | 0.75 | 3.25 | 2.19 | 1.88 | 0.88 | 5/8 | 3 | 3 1/2 | 9 | 0.7 | 11 | 0.9 | 37 | 4.6 | 9 |

| 1 | 1 | 0.96 | 4.88 | 0.69 | 2 | 2.12 | 2.44 | 4.88 | 4 | 0.75 | 3.5 | 2.44 | 2.12 | 0.88 | 5/8 | 3 1/4 | 3 1/2 | 9 | 0.8 | 12 | 1.1 | 40 | 5.1 | 9 |

| 1 1/4 | 1.25 | 1.28 | 5.25 | 0.75 | 2.5 | 2.5 | 2.81 | 5.25 | 4 | 0.75 | 3.88 | 2.81 | 2.5 | 0.88 | 5/8 | 3 1/4 | 3 3/4 | 13 | 1 | 15 | 1.4 | 45 | 5.8 | 9 |

| 1 1/2 | 1.5 | 1.5 | 6.12 | 0.81 | 2.88 | 2.75 | 3.25 | 6.12 | 4 | 0.88 | 4.5 | 3.25 | 2.75 | 1 | 3/4 | 3 1/2 | 4 | 15 | 1.2 | 21 | 1.9 | 61 | 7.8 | 9 |

| 2 | 2 | 1.94 | 6.5 | 0.88 | 3.62 | 3.31 | 3.94 | 6.5 | 8 | 0.75 | 5 | 3.94 | 3.31 | 0.88 | 5/8 | 3 1/2 | 4 1/4 | 20 | 1.5 | 28 | 2.6 | 68 | 8.5 | 9 |

| 2 1/2 | 2.5 | 2.32 | 7.5 | 1 | 4.12 | 3.94 | 4.62 | 7.5 | 8 | 0.88 | 5.88 | 4.62 | 3.94 | 1 | 3/4 | 4 | 4 1/2 | 25 | 2.1 | 38 | 3.6 | 89 | 11 | 9 |

| 3 | 3 | 2.9 | 8.25 | 1.12 | 5 | 4.62 | 5.38 | 8.25 | 8 | 0.88 | 6.62 | 5.38 | 4.62 | 1 | 3/4 | 4 1/4 | 5 | 35 | 2.7 | 49 | 4.6 | 106 | 13 | 9 |

| 3 1/2 | 3.5 | 3.36 | 9 | 1.19 | 5.5 | 5.25 | 6 | 9 | 8 | 0.88 | 7.25 | 6 | 5.25 | 1 | 3/4 | 4 1/4 | 5 | 42 | 3.4 | 59 | 5.5 | 122 | 15 | 9 |

| 4 | 4 | 3.83 | 10 | 1.25 | 6.19 | 5.75 | 6.62 | 10 | 8 | 0.88 | 7.88 | 6.62 | 5.75 | 1 | 3/4 | 4 1/2 | 5 1/4 | 62 | 3.8 | 91 | 6.5 | 207 | 19 | 12 |

| 5 | 5 | 4.81 | 11 | 1.38 | 7.31 | 7 | 8 | 11 | 8 | 0.88 | 9.25 | 8 | 7 | 1 | 3/4 | 4 3/4 | 5 1/4 | 84 | 5.3 | 124 | 9.1 | 241 | 21 | 12 |

| 6 | 6 | 5.76 | 12.5 | 1.44 | 8.5 | 8.12 | 9.38 | 12.5 | 12 | 0.88 | 10.62 | 9.38 | 8.12 | 1 | 3/4 | 4 3/4 | 5 3/4 | 105 | 6.7 | 165 | 12 | 303 | 27 | 12 |

| 8 | 8 | 7.62 | 15 | 1.62 | 10.62 | 10.25 | 11.56 | 15 | 12 | 1 | 13 | 11.56 | 10.25 | 1.12 | 7/8 | 5 1/2 | 6 1/4 | 148 | 9.1 | 228 | 17 | 405 | 36 | 12 |

| 10 | 10 | 9.56 | 17.5 | 1.88 | 12.75 | 12.62 | 13.62 | 17.5 | 16 | 1.12 | 15.25 | 13.62 | 12.62 | 1.25 | 1 | 6 1/4 | 7 1/4 | 210 | 13 | 291 | 21 | 499 | 46 | 12 |

| 12 | 12 | 11.38 | 20.5 | 2 | 15 | 14.75 | 15.94 | 20.5 | 16 | 1.25 | 17.75 | 15.94 | 14.75 | 1.38 | 1 1/8 | 6 3/4 | 7 1/2 | 275 | 16 | 392 | 28 | 651 | 61 | 12 |

| 14 | 14 | 14 | 23 | 2.12 | 16.25 | 16.75 | 18.44 | 23 | 20 | 1.25 | 20.25 | 18.44 | 16.75 | 1.38 | 1 1/8 | 7 | 7 3/4 | 324 | 19 | 456 | 32 | 785 | 74 | 12 |

| 16 | 16 | 16 | 25.5 | 2.25 | 18.5 | 19 | 20.5 | 25.5 | 20 | 1.38 | 22.5 | 20.5 | 19 | 1.5 | 1 1/4 | 7 1/2 | 8 1/2 | 404 | 23 | 529 | 37 | 914 | 88 | 12 |

| 18 | 18 | 18 | 28 | 2.38 | 21 | 21 | 22.75 | 28 | 24 | 1.38 | 24.75 | 22.75 | 21 | 1.5 | 1 1/4 | 7 3/4 | 8 1/4 | 465 | 26 | 630 | 43 | 1066 | 102 | 12 |

| 20 | 20 | 20 | 30.5 | 2.5 | 23 | 23.12 | 25 | 30.5 | 24 | 1.38 | 27 | 25 | 23.12 | 1.5 | 1 1/4 | 8 1/4 | 9 1/4 | 549 | 30 | 741 | 50 | 1228 | 118 | 12 |

| 24 | 24 | 24 | 36 | 2.75 | 27.25 | 27.62 | 29.62 | 36 | 24 | 1.62 | 32 | 29.62 | 27.62 | 1.75 | 1 1/2 | 9 1/4 | 10 1/4 | 778 | 42 | 1016 | 67 | 1627 | 160 | 12 |

ANSI/ASME B16.5 Class 600 Long Weld Neck Flange – Dimensions & Sizes in mm

| Size | Flange | Barrel OD | Bolting | Nut | Stud Bolt | Weights | Length | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom | Bore LWN & E | Bore HB | OD | Thk | RF of OD | LWN | HB | E | # ofHoles | Hole Size | Bolt Circle | Stop Dia | Relief Dia | Relief Length | Size | RF Length | RTJ Length | LWN | HB | E | Base | |||

| B | B | O | T | R | D | D | D | C | NS | NR | NL | Base | Per 1″ | Base | Per 1″ | Base | Per 1″ | L | ||||||

| 1/2 | 0.5 | 0.55 | 3.75 | 0.56 | 1.38 | 1.5 | 1.75 | 3.75 | 4 | 0.62 | 2.62 | 1.75 | 1.5 | 0.75 | 1/2 | 3 | 3 | 5 | 0.4 | 7 | 0.6 | 24 | 3.1 | 9 |

| 3/4 | 0.75 | 0.74 | 4.62 | 0.62 | 1.69 | 1.88 | 2.19 | 4.62 | 4 | 0.75 | 3.25 | 2.19 | 1.88 | 0.88 | 5/8 | 3 1/2 | 3 1/2 | 8 | 0.7 | 11 | 0.9 | 36 | 4.6 | 9 |

| 1 | 1 | 0.96 | 4.88 | 0.69 | 2 | 2.12 | 2.44 | 4.88 | 4 | 0.75 | 3.5 | 2.44 | 2.12 | 0.88 | 5/8 | 3 1/2 | 3 1/2 | 9 | 0.8 | 12 | 1.1 | 39 | 5.1 | 9 |

| 1 1/4 | 1.25 | 1.28 | 5.25 | 0.81 | 2.5 | 2.5 | 2.81 | 5.25 | 4 | 0.75 | 3.88 | 2.81 | 2.5 | 0.88 | 5/8 | 3 3/4 | 3 3/4 | 13 | 1 | 15 | 1.4 | 44 | 5.8 | 9 |

| 1 1/2 | 1.5 | 1.5 | 6.12 | 0.88 | 2.88 | 2.75 | 3.25 | 6.12 | 4 | 0.88 | 4.5 | 3.25 | 2.75 | 1 | 3/4 | 4 1/4 | 4 1/4 | 16 | 1.2 | 21 | 1.9 | 59 | 7.8 | 9 |

| 2 | 2 | 1.94 | 6.5 | 1 | 3.62 | 3.31 | 3.94 | 6.5 | 8 | 0.75 | 5 | 3.94 | 3.31 | 0.88 | 5/8 | 4 1/4 | 4 1/4 | 20 | 1.5 | 29 | 2.6 | 67 | 8.5 | 9 |

| 2 1/2 | 2.5 | 2.32 | 7.5 | 1.12 | 4.12 | 3.94 | 4.62 | 7.5 | 8 | 0.88 | 5.88 | 4.62 | 3.94 | 1 | 3/4 | 5 | 4 3/4 | 27 | 2.1 | 39 | 3.6 | 85 | 11 | 9 |

| 3 | 3 | 2.9 | 8.25 | 1.25 | 5 | 4.62 | 5.38 | 8.25 | 8 | 0.88 | 6.62 | 5.38 | 4.62 | 1 | 3/4 | 5 | 5 1/4 | 36 | 2.7 | 50 | 4.6 | 104 | 13 | 9 |

| 3 1/2 | 3.5 | 3.36 | 9 | 1.38 | 5.5 | 5.25 | 5.81 | 9 | 8 | 1 | 7.25 | 5.81 | 5.25 | 1.12 | 7/8 | 5 1/2 | 5 1/2 | 45 | 3.4 | 57 | 5 | 116 | 15 | 9 |

| 4 | 4 | 3.83 | 10.75 | 1.5 | 6.19 | 6 | 7.06 | 10.75 | 8 | 1 | 8.5 | 7.06 | 6 | 1.12 | 7/8 | 5 3/4 | 6 | 77 | 4.5 | 113 | 7.8 | 238 | 22 | 12 |

| 5 | 5 | 4.81 | 13 | 1.75 | 7.31 | 7.5 | 8.88 | 13 | 8 | 1.12 | 10.5 | 8.88 | 7.5 | 1.25 | 1 | 6 1/2 | 6 1/2 | 123 | 7 | 180 | 12 | 336 | 32 | 12 |

| 6 | 6 | 5.76 | 14 | 1.88 | 8.5 | 8.75 | 9.88 | 14 | 12 | 1.12 | 11.5 | 9.88 | 8.75 | 1.25 | 1 | 6 3/4 | 7 | 152 | 9 | 207 | 14 | 373 | 36 | 12 |

| 8 | 8 | 7.62 | 16.5 | 2.19 | 10.62 | 10.75 | 11.94 | 16.5 | 12 | 1.25 | 13.75 | 11.94 | 10.75 | 1.38 | 1 1/8 | 7 3/4 | 8 | 207 | 11 | 277 | 19 | 478 | 46 | 12 |

| 10 | 10 | 9.56 | 20 | 2.5 | 12.75 | 13.5 | 15 | 20 | 16 | 1.38 | 17 | 15 | 13.5 | 1.5 | 1 1/4 | 8 1/2 | 8 3/4 | 324 | 18 | 433 | 30 | 683 | 67 | 12 |

| 12 | 12 | 11.38 | 22 | 2.62 | 15 | 15.75 | 17.25 | 22 | 20 | 1.38 | 19.25 | 17.25 | 15.75 | 1.5 | 1 1/4 | 8 3/4 | 9 | 393 | 23 | 533 | 37 | 779 | 76 | 12 |

| 14 | 14 | 14 | 23.75 | 2.75 | 16.25 | 17 | 18.56 | 23.75 | 20 | 1.5 | 20.75 | 18.56 | 17 | 1.62 | 1 3/8 | 9 1/4 | 9 1/2 | 471 | 21 | 631 | 33 | 1149 | 82 | 16 |

| 16 | 16 | 16 | 27 | 3 | 18.5 | 19.5 | 21.38 | 27 | 20 | 1.62 | 23.75 | 21.38 | 19.5 | 1.75 | 1 1/2 | 10 | 10 1/4 | 638 | 28 | 856 | 45 | 1471 | 105 | 16 |

| 18 | 18 | 18 | 29.25 | 3.25 | 21 | 21.5 | 23.19 | 29.25 | 20 | 1.75 | 25.75 | 23.19 | 21.5 | 1.88 | 1 5/8 | 10 3/4 | 11 | 731 | 31 | 941 | 48 | 1628 | 118 | 16 |

| 20 | 20 | 20 | 32 | 3.5 | 23 | 24 | 25.94 | 32 | 24 | 1.75 | 28.5 | 25.94 | 24 | 1.88 | 1 5/8 | 11 1/2 | 11 3/4 | 916 | 39 | 1180 | 61 | 1920 | 139 | 16 |

| 24 | 24 | 24 | 37 | 4 | 27.25 | 28.25 | 30.06 | 37 | 24 | 2 | 33 | 30.06 | 28.25 | 2.12 | 1 7/8 | 13 | 13 1/2 | 1210 | 49 | 1486 | 73 | 2376 | 176 | 16 |

ANSI/ASME B16.5 Class 900 LWN Flange – Dimensions & Sizes in mm

| Size | Flange | Barrel OD | Bolting | Nut | Stud Bolt | Weights | Length | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom | Bore LWN & E | Bore HB | OD | Thk | RF of OD | LWN | HB | E | # ofHoles | Hole Size | Bolt Circle | Stop Dia | Relief Dia | Relief Length | Size | RF Length | RTJ Length | LWN | HB | E | Base | |||

| B | B | O | T | R | D | D | D | C | NS | NR | NL | Base | Per 1″ | Base | Per 1″ | Base | Per 1″ | L | ||||||

| 1/2 | 0.5 | 0.55 | 4.75 | 0.88 | 1.38 | 1.56 | 2 | 4.75 | 4 | 0.88 | 3.25 | 2 | 1.56 | 1 | 3/4 | 4 1/4 | 4 1/4 | 8 | 0.5 | 10 | 0.8 | 37 | 5 | 9 |

| 3/4 | 0.75 | 0.74 | 5.12 | 1 | 1.69 | 1.81 | 2.25 | 5.12 | 4 | 0.88 | 3.5 | 2.25 | 1.81 | 1 | 3/4 | 4 1/2 | 4 1/2 | 10 | 0.6 | 13 | 1 | 42 | 5.7 | 9 |

| 1 | 1 | 0.96 | 5.88 | 1.12 | 2 | 2.12 | 2.56 | 5.88 | 4 | 1 | 4 | 2.56 | 2.12 | 1.12 | 7/8 | 5 | 5 | 13 | 0.8 | 17 | 1.3 | 54 | 7.5 | 9 |

| 1 1/4 | 1.25 | 1.28 | 6.25 | 1.12 | 2.5 | 2.5 | 2.94 | 6.25 | 4 | 1 | 4.38 | 2.94 | 2.5 | 1.12 | 7/8 | 5 | 5 | 17 | 1 | 20 | 1.6 | 61 | 8.3 | 9 |

| 1 1/2 | 1.5 | 1.5 | 7 | 1.25 | 2.88 | 2.75 | 3.25 | 7 | 4 | 1.12 | 4.88 | 3.25 | 2.75 | 1.25 | 1 | 5 1/2 | 5 1/2 | 21 | 1.2 | 26 | 1.9 | 77 | 10 | 9 |

| 2 | 2 | 1.94 | 8.5 | 1.5 | 3.62 | 4.12 | 5.06 | 8.5 | 8 | 1 | 6.5 | 5.06 | 4.12 | 1.12 | 7/8 | 5 3/4 | 5 3/4 | 42 | 2.9 | 56 | 4.9 | 115 | 15 | 9 |

| 2 1/2 | 2.5 | 2.32 | 9.62 | 1.62 | 4.12 | 4.88 | 5.88 | 9.62 | 8 | 1.12 | 7.5 | 5.88 | 4.88 | 1.25 | 1 | 6 1/4 | 6 1/4 | 56 | 3.9 | 75 | 6.5 | 144 | 19 | 9 |

| 3 | 3 | 2.9 | 9.5 | 1.5 | 5 | 5 | 6.06 | 9.5 | 8 | 1 | 7.5 | 6.06 | 5 | 1.12 | 7/8 | 5 3/4 | 5 3/4 | 51 | 3.6 | 71 | 6.3 | 139 | 18 | 9 |

| 4 | 4 | 3.83 | 11.5 | 1.75 | 6.19 | 6.25 | 7.44 | 11.5 | 8 | 1.25 | 9.25 | 7.44 | 6.25 | 1.38 | 1 1/8 | 6 3/4 | 6 3/4 | 93 | 5.1 | 133 | 9.1 | 270 | 26 | 12 |

| 5 | 5 | 4.81 | 13.75 | 2 | 7.31 | 7.5 | 9 | 13.75 | 8 | 1.38 | 11 | 9 | 7.5 | 1.5 | 1 1/4 | 7 1/2 | 7 1/2 | 135 | 7 | 194 | 13 | 376 | 37 | 12 |

| 6 | 6 | 5.76 | 15 | 2.19 | 8.5 | 9.25 | 10.69 | 15 | 12 | 1.25 | 12.5 | 10.69 | 9.25 | 1.38 | 1 1/8 | 7 1/2 | 7 3/4 | 191 | 11 | 259 | 18 | 436 | 42 | 12 |

| 8 | 8 | 7.62 | 18.5 | 2.5 | 10.62 | 11.75 | 13.31 | 18.5 | 12 | 1.5 | 15.5 | 13.31 | 11.75 | 1.62 | 1 3/8 | 8 3/4 | 8 3/4 | 297 | 16 | 389 | 27 | 626 | 62 | 12 |

| 10 | 10 | 9.56 | 21.5 | 2.75 | 12.75 | 14.5 | 16.31 | 21.5 | 16 | 1.5 | 18.5 | 16.31 | 14.5 | 1.62 | 1 3/8 | 9 1/4 | 9 1/4 | 422 | 25 | 558 | 39 | 824 | 81 | 12 |

| 12 | 12 | 11.38 | 24 | 3.12 | 15 | 16.5 | 18.81 | 24 | 20 | 1.5 | 21 | 18.81 | 16.5 | 1.62 | 1 3/8 | 10 | 10 | 518 | 29 | 715 | 50 | 984 | 96 | 12 |

| 14 | 14 | 14 | 25.25 | 3.38 | 16.25 | 17.75 | 19.62 | 25.25 | 20 | 1.62 | 22 | 19.62 | 17.75 | 1.75 | 1 1/2 | 10 3/4 | 11 | 624 | 26 | 817 | 42 | 1368 | 98 | 16 |

| 16 | 16 | 16 | 27.75 | 3.5 | 18.5 | 20 | 21.69 | 27.75 | 20 | 1.75 | 24.25 | 21.69 | 20 | 1.88 | 1 5/8 | 11 1/4 | 11 1/2 | 750 | 32 | 942 | 48 | 1573 | 114 | 16 |

| 18 | 18 | 18 | 31 | 4 | 21 | 22.25 | 24.06 | 31 | 20 | 2 | 27 | 24.06 | 22.25 | 2.12 | 1 7/8 | 12 3/4 | 13 1/4 | 950 | 38 | 1169 | 57 | 1898 | 142 | 16 |

| 20 | 20 | 20 | 33.75 | 4.25 | 23 | 24.5 | 26.38 | 33.75 | 20 | 2.12 | 29.5 | 26.38 | 24.5 | 2.25 | 2 | 13 3/4 | 14 1/4 | 1121 | 43 | 1378 | 66 | 2182 | 164 | 16 |

| 24 | 24 | 24 | 41 | 5.5 | 27.25 | 29.5 | 31.62 | 41 | 20 | 2.62 | 35.5 | 31.62 | 29.5 | 2.75 | 2 1/2 | 17 1/4 | 18 | 1865 | 65 | 2160 | 94 | 3084 | 246 | 16 |

ANSI/ASME B16.5 Class 1500 Long Weld Neck Flange – Dimensions & Sizes in mm

| Size | Flange | Barrel OD | Bolting | Nut | Stud Bolt | Weights | Length | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom | Bore LWN & E | Bore HB | OD | Thk | RF of OD | LWN | HB | E | # ofHoles | Hole Size | Bolt Circle | Stop Dia | Relief Dia | Relief Length | Size | RF Length | RTJ Length | LWN | HB | E | Base | |||

| B | B | O | T | R | D | D | D | C | NS | NR | NL | Base | Per 1″ | Base | Per 1″ | Base | Per 1″ | L | ||||||

| 1/2 | 0.5 | 0.55 | 4.75 | 0.88 | 1.38 | 1.56 | 2 | 4.75 | 4 | 0.88 | 3.25 | 2 | 1.56 | 1 | 3/4 | 4 1/4 | 4 1/4 | 8 | 0.5 | 10 | 0.8 | 37 | 5 | 9 |

| 3/4 | 0.75 | 0.74 | 5.12 | 1 | 1.69 | 1.81 | 2.25 | 5.12 | 4 | 0.88 | 3.5 | 2.25 | 1.81 | 1 | 3/4 | 4 1/2 | 4 1/2 | 10 | 0.6 | 13 | 1 | 42 | 5.7 | 9 |

| 1 | 1 | 0.96 | 5.88 | 1.12 | 2 | 2.12 | 2.56 | 5.88 | 4 | 1 | 4 | 2.56 | 2.12 | 1.12 | 7/8 | 5 | 5 | 13 | 0.8 | 17 | 1.3 | 54 | 7.5 | 9 |

| 1 1/4 | 1.25 | 1.28 | 6.25 | 1.12 | 2.5 | 2.5 | 2.94 | 6.25 | 4 | 1 | 4.38 | 2.94 | 2.5 | 1.12 | 7/8 | 5 | 5 | 17 | 1 | 20 | 1.6 | 61 | 8.3 | 9 |

| 1 1/2 | 1.5 | 1.5 | 7 | 1.25 | 2.88 | 2.75 | 3.25 | 7 | 4 | 1.12 | 4.88 | 3.25 | 2.75 | 1.25 | 1 | 5 1/2 | 5 1/2 | 21 | 1.2 | 26 | 1.9 | 77 | 10 | 9 |

| 2 | 2 | 1.94 | 8.5 | 1.5 | 3.62 | 4.12 | 5.06 | 8.5 | 8 | 1 | 6.5 | 5.06 | 4.12 | 1.12 | 7/8 | 5 3/4 | 5 3/4 | 42 | 2.9 | 56 | 4.9 | 115 | 15 | 9 |

| 2 1/2 | 2.5 | 2.32 | 9.62 | 1.62 | 4.12 | 4.88 | 5.88 | 9.62 | 8 | 1.12 | 7.5 | 5.88 | 4.88 | 1.25 | 1 | 6 1/4 | 6 1/4 | 56 | 3.9 | 75 | 6.5 | 144 | 19 | 9 |

| 3 | 3 | 2.9 | 10.5 | 1.88 | 5 | 5.25 | 6.19 | 10.5 | 8 | 1.25 | 8 | 6.19 | 5.25 | 1.38 | 1 1/8 | 7 | 7 | 67 | 4.1 | 84 | 6.7 | 161 | 23 | 9 |

| 4 | 4 | 3.83 | 12.25 | 2.12 | 6.19 | 6.38 | 7.5 | 12.25 | 8 | 1.38 | 9.5 | 7.5 | 6.38 | 1.5 | 1 1/4 | 7 3/4 | 7 3/4 | 110 | 5.5 | 147 | 9.3 | 302 | 30 | 12 |

| 5 | 5 | 4.81 | 14.75 | 2.88 | 7.31 | 7.75 | 9.12 | 14.75 | 8 | 1.62 | 11.5 | 9.12 | 7.75 | 1.75 | 1 1/2 | 9 3/4 | 9 3/4 | 181 | 7.8 | 233 | 13 | 414 | 43 | 12 |

| 6 | 6 | 5.76 | 15.5 | 3.25 | 8.5 | 9 | 10.31 | 15.5 | 12 | 1.5 | 12.5 | 10.31 | 9 | 1.62 | 1 3/8 | 10 1/4 | 10 1/2 | 215 | 10 | 272 | 16 | 445 | 46 | 12 |

| 8 | 8 | 7.62 | 19 | 3.62 | 10.62 | 11.5 | 12.94 | 19 | 12 | 1.75 | 15.5 | 12.94 | 11.5 | 1.88 | 1 5/8 | 11 1/2 | 12 3/4 | 337 | 15 | 417 | 24 | 629 | 67 | 12 |

| 10 | 10 | 9.56 | 23 | 4.25 | 12.75 | 14.5 | 16.06 | 23 | 12 | 2 | 19 | 16.06 | 14.5 | 2.12 | 1 7/8 | 13 1/4 | 13 1/2 | 546 | 25 | 651 | 37 | 888 | 97 | 12 |

| 12 | 12 | 11.38 | 26.5 | 4.88 | 15 | 17.75 | 19.38 | 26.5 | 16 | 2.12 | 22.5 | 19.38 | 17.75 | 2.25 | 2 | 14 3/4 | 15 1/4 | 946 | 38 | 1148 | 55 | 1683 | 127 | 16 |

| 14 | 14 | 14 | 29.5 | 5.25 | 16.25 | 19.5 | 21.5 | 29.5 | 16 | 2.38 | 25 | 21.5 | 19.5 | 2.5 | 2 1/4 | 16 | 16 3/4 | 1116 | 41 | 1308 | 59 | 1929 | 150 | 16 |

| 16 | 16 | 16 | 32.5 | 5.75 | 18.5 | 21.75 | 23.88 | 32.5 | 16 | 2.62 | 27.75 | 23.88 | 21.75 | 2.75 | 2 1/2 | 17 1/2 | 18 1/2 | 1371 | 48 | 1588 | 70 | 2238 | 178 | 16 |

| 18 | 18 | 18 | 36 | 6.38 | 21 | 23.5 | 26.25 | 36 | 16 | 2.88 | 30.5 | 26.25 | 23.5 | 3 | 2 3/4 | 19 1/2 | 20 3/4 | 1674 | 51 | 1959 | 81 | 2629 | 216 | 16 |

| 20 | 20 | 20 | 38.75 | 7 | 23 | 25.25 | 28.12 | 38.75 | 16 | 3.12 | 32.75 | 28.12 | 25.25 | 3.25 | 3 | 21 1/4 | 22 1/4 | 1943 | 53 | 2241 | 87 | 2868 | 245 | 16 |

| 24 | 24 | 24 | 46 | 8 | 27.25 | 30 | 33.62 | 46 | 16 | 3.62 | 39 | 33.62 | 30 | 3.75 | 3 1/2 | 24 1/4 | 25 1/2 | 2936 | 72 | 3334 | 123 | 3819 | 343 | 16 |

ANSI/ASME B16.5 Class 2500 LWN Flange – Dimensions & Sizes in mm

| Size | Flange | Barrel OD | Bolting | Nut | Stud Bolt | Weights | Length | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nom | Bore LWN & E | Bore HB | OD | Thk | RF of OD | LWN | HB | E | # ofHoles | Hole Size | Bolt Circle | Stop Dia | Relief Dia | Relief Length | Size | RF Length | RTJ Length | LWN | HB | E | Base | |||

| B | B | O | T | R | D | D | D | C | NS | NR | NL | Base | Per 1″ | Base | Per 1″ | Base | Per 1″ | L | ||||||

| 1/2 | 0.5 | 0.55 | 5.25 | 1.19 | 1.38 | 1.81 | 2.25 | 5.25 | 4 | 0.88 | 3.5 | 2.25 | 1.81 | 1 | 3/4 | 4 3/4 | 4 3/4 | 11 | 0.7 | 14 | 1.1 | 45 | 6.1 | 9 |

| 3/4 | 0.75 | 0.74 | 5.5 | 1.25 | 1.69 | 2.06 | 2.5 | 5.5 | 4 | 0.88 | 3.75 | 2.5 | 2.06 | 1 | 3/4 | 5 | 5 | 13 | 0.8 | 17 | 1.3 | 49 | 6.6 | 9 |

| 1 | 1 | 0.96 | 6.25 | 1.38 | 2 | 2.25 | 2.81 | 6.25 | 4 | 1 | 4.25 | 2.81 | 2.25 | 1.12 | 7/8 | 5 1/2 | 5 1/2 | 18 | 0.9 | 22 | 1.6 | 62 | 8.5 | 9 |

| 1 1/4 | 1.25 | 1.28 | 7.25 | 1.5 | 2.5 | 2.88 | 3.5 | 7.25 | 4 | 1.12 | 5.12 | 3.5 | 2.88 | 1.25 | 1 | 6 | 6 | 27 | 1.5 | 32 | 2.4 | 84 | 11 | 9 |

| 1 1/2 | 1.5 | 1.5 | 8 | 1.75 | 2.88 | 3.12 | 3.94 | 8 | 4 | 1.25 | 5.75 | 3.94 | 3.12 | 1.38 | 1 1/8 | 6 3/4 | 6 3/4 | 33 | 1.7 | 42 | 3 | 94 | 14 | 9 |

| 2 | 2 | 1.94 | 9.25 | 2 | 3.62 | 3.75 | 5.12 | 9.25 | 8 | 1.12 | 6.75 | 5.12 | 3.75 | 1.25 | 1 | 7 | 7 | 48 | 2.2 | 66 | 5 | 131 | 18 | 9 |

| 2 1/2 | 2.5 | 2.32 | 10.5 | 2.25 | 4.12 | 4.5 | 5.94 | 10.5 | 8 | 1.25 | 7.75 | 5.94 | 4.5 | 1.38 | 1 1/8 | 7 3/4 | 8 | 66 | 3.1 | 90 | 6.7 | 165 | 23 | 9 |

| 3 | 3 | 2.9 | 12 | 2.62 | 5 | 5.25 | 7 | 12 | 8 | 1.38 | 9 | 7 | 5.25 | 1.5 | 1 1/4 | 8 3/4 | 9 | 97 | 4.1 | 127 | 9 | 210 | 30 | 9 |

| 4 | 4 | 3.83 | 14 | 3 | 6.19 | 6.5 | 8.38 | 14 | 8 | 1.62 | 10.75 | 8.38 | 6.5 | 1.75 | 1 1/2 | 10 | 10 1/4 | 159 | 5.8 | 218 | 12 | 391 | 40 | 12 |

| 5 | 5 | 4.81 | 16.5 | 3.62 | 7.31 | 8 | 10 | 16.5 | 8 | 1.88 | 12.75 | 10 | 8 | 2 | 1 3/4 | 11 3/4 | 12 1/4 | 248 | 8.7 | 319 | 17 | 518 | 55 | 12 |

| 6 | 6 | 5.76 | 19 | 4.25 | 8.5 | 9.25 | 11.38 | 19 | 8 | 2.12 | 14.5 | 11.38 | 9.25 | 2.25 | 2 | 13 1/2 | 14 | 358 | 11 | 441 | 21 | 641 | 73 | 12 |

| 8 | 8 | 7.62 | 21.75 | 5 | 10.62 | 12 | 14.12 | 21.75 | 12 | 2.12 | 17.25 | 14.12 | 12 | 2.25 | 2 | 15 | 15 1/2 | 589 | 18 | 743 | 31 | 1167 | 92 | 16 |

| 10 | 10 | 9.56 | 26.5 | 6.5 | 12.75 | 14.75 | 17.38 | 26.50 | 12 | 2.62 | 21.25 | 17.38 | 14.75 | 2.75 | 2 1/2 | 19 1/4 | 20 | 997 | 26 | 1202 | 47 | 1625 | 134 | 16 |

| 12 | 12 | 11.38 | 30 | 7.25 | 15 | 17.38 | 20.12 | 30 | 12 | 2.88 | 24.38 | 20.12 | 17.38 | 3 | 2 3/4 | 21 1/4 | 22 | 1363 | 35 | 1609 | 61 | 1995 | 168 | 16 |

LWN Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| Nominal Pipe Size | Class 150 (lbs) | Class 300 (lbs) | Class 400 (lbs) | Class 600 (lbs) | Class 900 (lbs) | Class 1500 (lbs) | Class 2500 (lbs) |

|---|---|---|---|---|---|---|---|

| ½” | 5 | 6 | 6 | 7 | 8 | 10 | 12 |

| ¾” | 6 | 7 | 8 | 9 | 10 | 12 | 14 |

| 1″ | 7 | 9 | 10 | 12 | 13 | 15 | 18 |

| 1½” | 10 | 13 | 14 | 16 | 18 | 22 | 25 |

| 2″ | 12 | 16 | 18 | 20 | 22 | 26 | 30 |

| 3″ | 20 | 26 | 28 | 32 | 35 | 40 | 48 |

| 4″ | 28 | 36 | 38 | 44 | 48 | 55 | 65 |

| 6″ | 45 | 58 | 62 | 72 | 78 | 90 | 110 |

| 8″ | 72 | 92 | 98 | 112 | 120 | 140 | 170 |

| 10″ | 110 | 140 | 150 | 172 | 185 | 210 | 250 |

| 12″ | 145 | 185 | 200 | 230 | 250 | 280 | 330 |

| 14″ | 200 | 250 | 270 | 310 | 335 | 370 | 440 |

| 16″ | 260 | 320 | 350 | 400 | 430 | 480 | 560 |

| 18″ | 330 | 400 | 440 | 500 | 540 | 600 | 700 |

| 20″ | 400 | 500 | 550 | 620 | 670 | 740 | 850 |

| 24″ | 600 | 750 | 820 | 920 | 1000 | 1100 | 1300 |

Long Weld Neck Flange Tolerances as per ANSI / ASME B16.5, 16.47

| Parameter | Tolerance (Class 150–600) | Tolerance (Class 900–2500) | Standard Reference |

|---|---|---|---|

| Outside Diameter (OD)> | ±1/8″ (3.2 mm) | ±1/8″ to ±1/4″ (3.2–6.4 mm) depending on size | ASME B16.5, B16.47 |

| Thickness of Flange (B)> | ±1/16″ (1.6 mm) | ±1/16″ to ±1/8″ (1.6–3.2 mm) | ASME B16.5, B16.47 |

| Bolt Circle Diameter (K)> | ±1/32″ (0.8 mm) | ±1/16″ (1.6 mm) | ASME B16.5, B16.47 |

| Bolt Hole Diameter (L)> | +1/64″ / -0 | +1/64″ / -0 | ASME B16.5, B16.47 |

| Raised Face Diameter (G)> | ±1/32″ (0.8 mm) | ±1/32″ to ±1/16″ (0.8–1.6 mm) | ASME B16.5, B16.47 |

| Hub Diameter at Base (A)> | ±1/32″ (0.8 mm) | ±1/32″ to ±1/16″ (0.8–1.6 mm) | ASME B16.5, B16.47 |

| Hub Length / Neck Length (H)> | ±1/16″ (1.6 mm) | ±1/16″ to ±1/8″ (1.6–3.2 mm) | ASME B16.5, B16.47 |

| Concentricity / Runout> | 1/16″ max | 1/16″ to 1/8″ max | ASME B16.5, B16.47 |

| Face Flatness> | 0.005″ per inch of diameter | 0.005″ per inch of diameter | ASME B16.5, B16.47 |

What is a Long Weld Neck Flange?

A Long Weld Neck (LWN) Flange is a type of flange designed to be welded to the pipe at its neck, providing a smooth transition from flange thickness to pipe wall thickness. This design helps in reducing stress concentration at the base of the flange, making it suitable for high-pressure, high-temperature, and critical service applications.

Key Features:

- Extended hub length compared to standard weld neck flanges.

- Smooth stress distribution along the hub.

- Compatible with butt-welded piping systems.

- Available in carbon steel, stainless steel, alloy steel, and nickel alloys.

How are Long Weld Neck Flanges manufactured?

The manufacturing of LWN Flanges involves several precise processes to ensure performance and compliance with standards:

- Forging: The flange is forged from a solid piece of metal for superior strength.

- Machining: Critical dimensions such as flange thickness, OD, hub length, and bolt holes are machined to exact tolerances.

- Heat Treatment: Improves material strength, toughness, and stress relief.

- Inspection & Testing: Includes dimensional checks, pressure testing, and sometimes NDT (Non-Destructive Testing) for critical applications.

How to maintain and inspect Long Weld Neck Flanges?

Proper maintenance ensures long-term reliability:

- Regular Inspection: Check for signs of corrosion, cracks, or leaks.

- Torque Checks: Ensure bolts are tightened to recommended specifications.

- Cleaning: Remove deposits, scale, or rust to prevent corrosion.

- NDT (Non-Destructive Testing): Ultrasonic or dye-penetrant testing for critical applications.