- Home

- Industrial Flanges

- Male and Female Flange

Male and Female Flange

Male and Female Flange : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Top Manufacturer & Exporter of ASME B16.5 Male & Female Flanges – Carbon Steel, Stainless Steel, Alloy Steel, and Nickel Alloys. Available Sizes ½”–24”, Pressure Classes 150#–2500#. Supplying Clients in Japan, UAE, France, Mexico, and Australia.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd is a trusted manufacturer and supplier of male and female flanges, delivering high-quality products that meet the exacting requirements of industries worldwide. We specialize in producing flanges from carbon, stainless, alloy steel, and nickel alloys, combining superior materials with precision engineering to ensure strength, durability, and reliability in every component.

With a strong focus on quality and consistency, we operates modern manufacturing facilities equipped with advanced forging, machining, and testing technologies. Our products undergo strict quality control at every stage—from material sourcing and forging to finishing and inspection—ensuring that every flange we supply adheres to international standards such as ASME, ANSI, ASTM, and API.

Male and Female (M&F) flanges are a specialized type of flange connection designed with a matching raised area on the male flange and a corresponding recessed area on the female flange. This design provides accurate alignment, improved sealing, and better gasket retention compared to standard flat-face or raised-face flanges.

The male flange face extends slightly beyond the flange’s contact surface, while the female flange contains a matching depression of the same dimensions, ensuring a secure fit when bolted together. This configuration reduces the risk of gasket blowout, enhances pressure containment, and provides excellent performance in piping systems operating under high pressure and temperature conditions.

As a global supplier, we cater to clients across North America, Europe, Middle East, and Asia, offering customized solutions to meet diverse project requirements. Our commitment to timely delivery, technical support, and long-term reliability has made Midland Forge and Fittings Pvt. Ltd a preferred partner for industries including oil & gas, petrochemical, power, and shipbuilding. We take pride in providing flanges that combine precision, performance, and trust, supporting the success of our clients’ critical operations.

Male & Female Pipe Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Male and Female Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

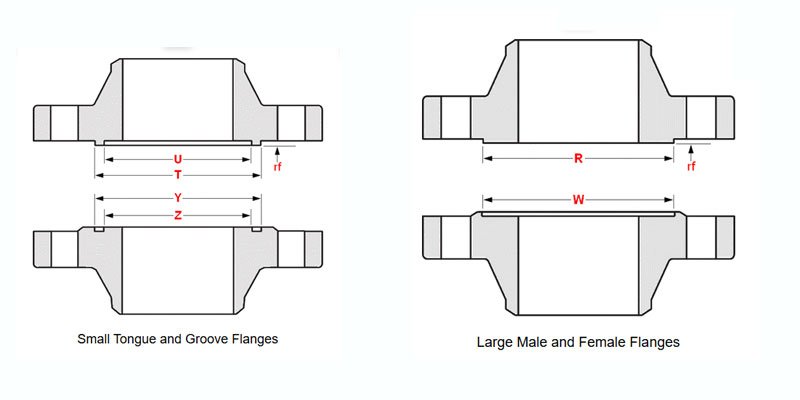

ANSI/ASME B16.5 Male and Female Flange – Dimensions & Sizes in mm

| NPS | R | S | T | U | W | X | Y | Z |

|---|---|---|---|---|---|---|---|---|

| 1/2 | 35.05 | 18.28 | 35.05 | 25.4 | 36.57 | 19.81 | 36.57 | 23.87 |

| 3/4 | 42.92 | 23.87 | 42.92 | 33.27 | 44.45 | 25.4 | 44.45 | 31.75 |

| 1 | 50.8 | 30.22 | 47.75 | 38.1 | 52.32 | 31.75 | 49.27 | 36.57 |

| 1¼ | 63.5 | 38.1 | 57.15 | 47.75 | 65.02 | 39.62 | 58.67 | 45.97 |

| 1½ | 73.15 | 44.45 | 63.5 | 53.84 | 74.67 | 45.97 | 65.02 | 52.32 |

| 2 | 91.94 | 57.15 | 82.55 | 73.15 | 93.72 | 58.67 | 84.07 | 71.37 |

| 2½ | 104.64 | 68.32 | 95.25 | 85.85 | 106.42 | 69.85 | 96.77 | 84.07 |

| 3 | 127 | 84.07 | 117.34 | 107.95 | 128.52 | 85.85 | 119.12 | 106.42 |

| 3½ | 139.7 | 96.77 | 130.04 | 120.65 | 141.22 | 98.55 | 131.82 | 119.12 |

| 4 | 157.22 | 109.47 | 144.52 | 131.82 | 158.75 | 111.25 | 146.05 | 130.04 |

| 5 | 185.67 | 136.65 | 172.97 | 160.27 | 187.45 | 138.17 | 174.75 | 158.75 |

| 6 | 215.9 | 162.05 | 203.2 | 190.5 | 217.42 | 163.57 | 204.72 | 188.97 |

| 8 | 269.74 | 212.85 | 254 | 238.25 | 271.52 | 214.37 | 255.52 | 236.47 |

| 10 | 323.85 | 266.7 | 304.8 | 285.75 | 325.37 | 268.22 | 306.32 | 284.22 |

| 12 | 381 | 317.5 | 361.95 | 342.9 | 382.52 | 319.02 | 363.47 | 341.37 |

| 14 | 412.75 | 349.25 | 393.7 | 374.65 | 414.27 | 350.77 | 395.22 | 373.12 |

| 16 | 469.9 | 400.05 | 447.54 | 425.45 | 471.42 | 401.57 | 449.32 | 423.92 |

| 18 | 533.4 | 450.85 | 511.04 | 488.95 | 534.92 | 452.37 | 512.82 | 487.42 |

| 20 | 584.2 | 501.65 | 558.8 | 533.4 | 585.72 | 503.17 | 560.32 | 531.87 |

| 24 | 692.15 | 603.25 | 666.75 | 641.35 | 693.67 | 604.77 | 668.27 | 639.82 |

Male & Female Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| NPS (in) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

|---|---|---|---|---|---|---|---|

| 1/2 | 3 | 4.5 | 5 | 6 | 9 | 14 | 23 |

| 3/4 | 3.5 | 5.5 | 6.5 | 8 | 12 | 20 | 32 |

| 1 | 4.5 | 7 | 8.5 | 11 | 16 | 27 | 45 |

| 1-1/2 | 7.5 | 12 | 14 | 18 | 28 | 48 | 80 |

| 2 | 11 | 17 | 21 | 27 | 42 | 72 | 120 |

| 3 | 16 | 27 | 33 | 43 | 67 | 115 | 190 |

| 4 | 24 | 40 | 50 | 65 | 100 | 170 | 280 |

| 6 | 45 | 75 | 92 | 120 | 185 | 315 | 520 |

| 8 | 70 | 115 | 140 | 180 | 280 | 470 | 780 |

| 10 | 100 | 165 | 200 | 260 | 400 | 670 | 1120 |

| 12 | 150 | 245 | 300 | 385 | 590 | 990 | 1650 |

| 14 | 190 | 310 | 380 | 490 | 750 | 1260 | 2100 |

| 16 | 250 | 400 | 490 | 630 | 950 | 1600 | 2700 |

| 18 | 310 | 500 | 610 | 785 | 1180 | 1980 | 3300 |

| 20 | 370 | 600 | 730 | 940 | 1410 | 2370 | 3960 |

| 24 | 540 | 880 | 1060 | 1370 | 2060 | 3470 | 5790 |

Male & Female Flange Tolerances as per ANSI / ASME B16.5, B16.47

| Parameter | Tolerance (B16.5: NPS ½″–24″) | Tolerance (B16.47: NPS 26″–60″) |

|---|---|---|

| Male Face Height (h1) | +0.00 / –0.25 mm | +0.00 / –0.40 mm |

| Female Recess Depth (h2) | +0.25 / –0.00 mm | +0.40 / –0.00 mm |

| Male Outside Diameter (Dm) | ±0.50 mm | ±0.80 mm |

| Female Recess Diameter (Df) | ±0.50 mm | ±0.80 mm |

| Alignment (Male to Female faces) | Max 0.50 mm | Max 0.80 mm |

| Gasket Contact Surface Finish (Ra) | 3.2 – 6.3 µm (125–250 AARH) | 3.2 – 6.3 µm (125–250 AARH) |

| Runout of Facing | 0.30 mm max | 0.50 mm max |

What is the main difference between Male & Female Flanges compared to Raised Face (RF) flanges?

- Contact Area:

- RF flanges have a single raised surface that compresses the gasket.

- M&F flanges have a recess (female) and a protrusion (male) that fit together, creating positive alignment.

- Leak Prevention: M&F design ensures the gasket remains confined within the recess, which reduces blow-out risk under high pressure & temperature.

- Applications: Preferred in critical services like steam lines, high-pressure chemical piping, and offshore environments where leakage tolerance is minimal.

Which gasket types are used with Male & Female flanges?

- Flat Ring Gaskets are typically used.

- Confined Seating: The gasket sits entirely within the female recess, preventing lateral movement.

- Material Selection:

- Soft gaskets (spiral wound with filler, PTFE, graphite) for low to medium pressure.

- Metallic gaskets (RTJ style, corrugated, or solid metal) for high-temperature / high-pressure duties.

- This confinement design reduces gasket creep & extrusion, extending service life.

What are the main limitations of Male & Female flanges?

- Not interchangeable with Raised Face or Tongue & Groove flanges.

- Higher machining precision required, hence costlier than RF flanges.

- Gasket availability may be limited compared to RF types.

- Field installation challenge: Requires exact male–female alignment, making it less forgiving than flat or raised face.