- Home

- Industrial Flanges

- Weldoflange

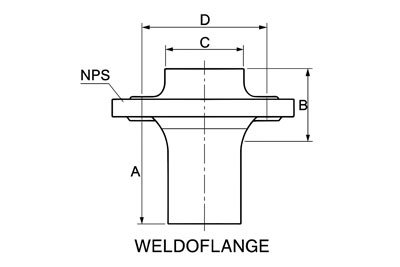

Weldoflange

Weldoflange : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

High-Quality ASME B16.5 Weldoflange Manufacturer – Offering Carbon Steel, Stainless Steel, Alloy Steel, and Nickel Alloy Weldoflanges. Available in sizes from ½” to 24” and pressure classes 150# to 2500#, suitable for oil & gas, petrochemical, and industrial piping applications.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd, is a trusted manufacturer and supplier of high-quality Weldoflanges designed for industrial piping systems. Specializing in ASME B16.5 compliant Weldoflanges, our products are precision-engineered to meet stringent standards for carbon steel, stainless steel, alloy steel, and nickel alloys. Each flange is manufactured with strict adherence to dimensional accuracy, hub reinforcement, and surface finish requirements, ensuring reliable performance in high-pressure, high-temperature, and corrosive environments.

With a commitment to delivering durable and technically superior products, We serves a diverse range of industries, including oil & gas, petrochemical, power generation, and chemical processing.

Our extensive range of Weldoflanges, available in sizes ½” to 24” and pressure classes 150# to 2500#, is designed for seamless integration into complex piping networks. By combining advanced manufacturing processes, rigorous quality checks, and responsive customer support, we ensure our clients receive flanges that guarantee safety, reliability, and long-term operational efficiency.

A Weldoflange is an integrally reinforced branch outlet flange designed to provide a flanged connection on a pressure pipeline without requiring a full pipe tee. Essentially, it combines a buttweld hub (similar to a weldolet) with a welding neck flange, allowing the branch line to be welded onto the main pipe while maintaining standard flange dimensions for easy bolting.

The Weldo flange works by transferring internal pressure loads from the branch line to the parent pipe, with the hub providing reinforcement at the junction to prevent stress concentration. This design ensures leak-proof connections and enables safe isolation, maintenance, or integration of instrumentation, valves, or auxiliary piping in high-pressure systems.

Weldo Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Weldoflange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

ANSI/ASME B16.5 Weldoflange – Dimensions NPS 1/2 to 24

| NPS | A | B | C | D |

|---|---|---|---|---|

| 1/2 | 3/4 19.05 |

1.3/8 34.93 |

15/16 23.81 |

5/8 15.88 |

| 3/4 | 7/8 22.23 |

1.5/8 41.28 |

1.3/16 30.16 |

13/16 20.64 |

| 1 | 1.1/16 26.99 |

2 50.80 |

1.7/16 36.51 |

1.1/32 26.19 |

| 1.1/4 | 1.1/4 31.75 |

2.3/8 60.3 |

1.3/4 44.45 |

1.3/8 34.93 |

| 1.1/2 | 1.5/16 33.34 |

2.7/8 73 |

2 50.80 |

1.5/8 41.28 |

| 2 | 1.1/2 38.10 |

3.1/2 88.90 |

2.9/16 65.09 |

2.1/16 52.39 |

| 2.1/2 | 1.5/8 41.28 |

4.1/16 103.19 |

3 76.20 |

2.7/16 61.91 |

| 3 | 1.3/4 44.45 |

4.13/16 122.24 |

3.11/16 93.66 |

3.1/16 77.79 |

| 3.1/2 | 2 50.80 |

5.3/8 136.53 |

3.7/8 98.43 |

3.9/16 90.49 |

| 4 | 2 50.80 |

6 152.40 |

4.3/4 120.65 |

4 101.60 |

| 5 | 2.1/4 57.15 |

7.1/8 180.98 |

5.9/16 141.29 |

5.1/16 128.59 |

| 6 | 2.3/8 60.3 |

8.1/2 215.90 |

6.11/16 169.86 |

6.1/16 153.99 |

| 8 | 2.3/4 69.85 |

10.3/8 263.53 |

8.11/16 220.66 |

7.15/16 201.61 |

| 10 | 3.1/16 77.79 |

12.9/16 319.09 |

10.13/16 274.64 |

10 254.00 |

| 12 | 3.3/8 85.73 |

14.7/8 377.83 |

12.13/16 325.44 |

12 304.80 |

| 14 | 3.1/2 88.90 |

16.1/8 409.58 |

14.1/16 357.19 |

13.1/4 336.55 |

| 16 | 3.11/16 93.66 |

18.1/4 463.55 |

16.1/16 407.99 |

15.1/4 387.35 |

| 18 | 4.1/16 103.19 |

20.3/4 527.05 |

18.5/8 473.08 |

17.1/4 438.15 |

| 20 | 4.5/8 117.48 |

23.1/16 585.79 |

20.1/16 509.59 |

19.1/4 488.95 |

| 24 | 5.3/8 136.53 |

27.7/8 708.03 |

25.1/8 638.18 |

23.1/4 590.55 |

ANSI/ASME B16.5 Weldo Flange – Dimensions Branch ½”

| RATING | NOMINAL PIPE SIZE FROM 3/4″ TO 36″ | |||||

|---|---|---|---|---|---|---|

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 0,9 | |||

| 150# | XS | 13,8 | 17,6 | 88,9 | 11,2 | 0,9 |

| 160 | 11,7 | 11,7 | 0,9 | |||

| XXS | 6,4 | 6,4 | 0,9 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 1,2 | |||

| 300# | XS | 13,8 | 17,6 | 95,3 | 14,3 | 1,2 |

| 160 | 11,7 | 11,7 | 1,2 | |||

| XXS | 6,4 | 6,4 | 1,2 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 1,3 | |||

| 600# | XS | 13,8 | 17,6 | 95,3 | 14,3 | 1,3 |

| 160 | 11,7 | 11,7 | 1,3 | |||

| XXS | 6,4 | 6,4 | 1,3 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 2,4 | |||

| 900# | XS | 13,8 | 17,6 | 120,6 | 22,4 | 2,4 |

| 160 | 11,7 | 11,7 | 2,4 | |||

| XXS | 6,4 | 6,4 | 2,4 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 2,4 | |||

| 1500# | XS | 13,8 | 17,6 | 120,6 | 22,4 | 2,4 |

| 160 | 11,7 | 11,7 | 2,4 | |||

| XXS | 6,4 | 6,4 | 2,4 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 15,8 | 18,5 | 3,6 | |||

| 2500# | XS | 13,8 | 17,6 | 133,4 | 30,2 | 3,6 |

| 160 | 11,7 | 11,7 | 3,6 | |||

| XXS | 6,4 | 6,4 | 3,6 | |||

ANSI/ASME B16.5 Weldo Flange – Dimensions Branch ¾”

| RATING | NOMINAL PIPE SIZE FROM 1″ TO 36″ | ||||||

|---|---|---|---|---|---|---|---|

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 21 | 23,8 | 1,2 | ||||

| 150# | XS | 18,9 | 22,8 | 98,6 | 12,7 | 1,2 | |

| 160 | 15,6 | 15,6 | 1,4 | ||||

| XXS | 11,1 | 11,1 | 1,5 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 21 | 23,8 | 1,7 | ||||

| 300# | XS | 18,9 | 22,8 | 117,4 | 15,8 | 1,9 | |

| 160 | 15,6 | 15,6 | 2 | ||||

| XXS | 11,1 | 11,1 | 2,1 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 21 | 23,8 | 2 | ||||

| 600# | XS | 18,9 | 22,8 | 117,4 | 15,8 | 2,1 | |

| 160 | 15,6 | 15,6 | 2,2 | ||||

| XXS | 11,1 | 11,1 | 2,2 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 21 | 23,8 | 3,1 | ||||

| 900# | XS | 18,9 | 22,8 | 130 | 25,4 | 3,2 | |

| 160 | 15,6 | 15,6 | 3,2 | ||||

| XXS | 11,1 | 11,1 | 3,3 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 21 | 23,8 | 3,1 | ||||

| 1500# | XS | 18,9 | 22,8 | 130 | 25,4 | 3,2 | |

| 160 | 15,6 | 15,6 | 3,2 | ||||

| XXS | 11,1 | 11,1 | 3,3 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 21 | 23,8 | 4,4 | ||||

| 2500# | XS | 18,9 | 22,8 | 139,7 | 31,8 | 4,5 | |

| 160 | 15,6 | 15,6 | 4,5 | ||||

| XXS | 11,1 | 11,1 | 4,6 | ||||

ANSI/ASME B16.5 Weldo Flange – Dimensions Branch 1”

| RATING | NOMINAL PIPE SIZE FROM 1.1/2″ TO 36″ | |||||

|---|---|---|---|---|---|---|

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 26,6 | 30 | 1,7 | |||

| 150# | XS | 24,3 | 28,8 | 108 | 14,3 | 1,7 |

| 160 | 20,7 | 20,7 | 2 | |||

| XXS | 15,2 | 15,2 | 2,2 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 26,6 | 30 | 2,3 | |||

| 300# | XS | 24,3 | 28,8 | 124 | 17,6 | 2,5 |

| 160 | 20,7 | 20,7 | 2,6 | |||

| XXS | 15,2 | 15,2 | 2,8 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 26,6 | 30 | 2,6 | |||

| 600# | XS | 24,3 | 28,8 | 124 | 17,6 | 2,7 |

| 160 | 20,7 | 20,7 | 2,8 | |||

| XXS | 15,2 | 15,2 | 3 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 26,6 | 30 | 4,5 | |||

| 900# | XS | 24,3 | 28,8 | 149,4 | 28,5 | 4,6 |

| 160 | 20,7 | 20,7 | 4,7 | |||

| XXS | 15,2 | 15,2 | 4,8 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 26,6 | 30 | 4,5 | |||

| 1500# | XS | 24,3 | 28,8 | 149,4 | 28,5 | 4,6 |

| 160 | 20,7 | 20,7 | 4,7 | |||

| XXS | 15,2 | 15,2 | 4,8 | |||

| Bore schedule | B | C | D | E | Weight [kg] | |

| STD | 26,6 | 30 | 6,1 | |||

| 2500# | XS | 24,3 | 28,8 | 158,8 | 35,1 | 6,2 |

| 160 | 20,7 | 20,7 | 6,2 | |||

| XXS | 15,2 | 15,2 | 6,3 | |||

ANSI/ASME B16.5 Weldoflange – Dimensions Branch 1½”

| RATING | NOMINAL PIPE SIZE FROM 2″ TO 36″ | ||||||

|---|---|---|---|---|---|---|---|

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 40,9 | 44,6 | 3,1 | ||||

| 150# | XS | 38,1 | 43,2 | 127 | 17,5 | 3,3 | |

| 160 | 34 | 34 | 3,5 | ||||

| XXS | 28 | 28 | 3,8 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 40,9 | 44,6 | 4,1 | ||||

| 300# | XS | 38,1 | 43,2 | 155,5 | 20,6 | 4,5 | |

| 160 | 34 | 34 | 4,7 | ||||

| XXS | 28 | 28 | 5 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 40,9 | 44,6 | 4,9 | ||||

| 600# | XS | 38,1 | 43,2 | 155,5 | 22,4 | 5 | |

| 160 | 34 | 34 | 5,2 | ||||

| XXS | 28 | 28 | 5,5 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 40,9 | 44,6 | 7,2 | ||||

| 900# | XS | 38,1 | 43,2 | 177,8 | 31,8 | 7,4 | |

| 160 | 34 | 34 | 7,6 | ||||

| XXS | 28 | 28 | 7,9 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 40,9 | 44,6 | 7,2 | ||||

| 1500# | XS | 38,1 | 43,2 | 177,8 | 31,8 | 7,4 | |

| 160 | 34 | 34 | 7,6 | ||||

| XXS | 28 | 28 | 7,9 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 40,9 | 44,6 | 12 | ||||

| 2500# | XS | 38,1 | 43,2 | 203,2 | 44,5 | 12 | |

| 160 | 34 | 34 | 12,2 | ||||

| XXS | 28 | 28 | 12,5 | ||||

ANSI/ASME B16.5 Weldo Flange – Dimensions Branch 2″

| RATING | NOMINAL PIPE SIZE FROM 3″ TO 36″ | ||||||

|---|---|---|---|---|---|---|---|

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 52,5 | 56,4 | 4,1 | ||||

| 150# | XS | 49,2 | 54,8 | 152,4 | 19,1 | 4,8 | |

| 160 | 42,8 | 42,8 | 5,1 | ||||

| XXS | 38,2 | 38,2 | 5,5 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 52,5 | 56,4 | 5,5 | ||||

| 300# | XS | 49,2 | 54,8 | 165,1 | 22,4 | 5,8 | |

| 160 | 42,8 | 42,8 | 6,1 | ||||

| XXS | 38,2 | 38,2 | 6,5 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 52,5 | 56,4 | 6,2 | ||||

| 600# | XS | 49,2 | 54,8 | 165,1 | 25,4 | 6,5 | |

| 160 | 42,8 | 42,8 | 7 | ||||

| XXS | 38,2 | 38,2 | 7,2 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 52,5 | 56,4 | 13 | ||||

| 900# | XS | 49,2 | 54,8 | 215,9 | 38,1 | 13,3 | |

| 160 | 42,8 | 42,8 | 13,6 | ||||

| XXS | 38,2 | 38,2 | 13,9 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 52,5 | 56,4 | 13 | ||||

| 1500# | XS | 49,2 | 54,8 | 215,9 | 38,1 | 13,3 | |

| 160 | 42,8 | 42,8 | 13,6 | ||||

| XXS | 38,2 | 38,2 | 13,9 | ||||

| Bore schedule | B | C | D | E | Weight [kg] | ||

| STD | 52,5 | 56,4 | 18,4 | ||||

| 2500# | XS | 49,2 | 54,8 | 235 | 50,8 | 18,6 | |

| 160 | 42,8 | 42,8 | 19 | ||||

| XXS | 38,2 | 38,2 | 19,3 | ||||

ANSI/ASME B16.5 Weldo Flange – Dimensions Branch 3”

| RATING | NOMINAL PIPE SIZE FROM 4″ TO 36″ | ||||

|---|---|---|---|---|---|

| Bore schedule | Length | D | E | Weight [kg] | |

| 150# | 10-STD | 115 | 7,5 | ||

| XS-80 | 115 | 191 | 23,9 | 7,5 | |

| 160-XXS | 145 | 8 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 300# | 10-STD | 125 | 10 | ||

| XS-80 | 125 | 210 | 28,5 | 10 | |

| 160-XXS | 150 | 11 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 600# | 10-STD | 135 | 13,5 | ||

| XS-80 | 135 | 210 | 38,2 | 13,5 | |

| 160-XXS | 165 | 14,5 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 900# | 10-STD | 155 | 17 | ||

| XS-80 | 155 | 241 | 44,5 | 17 | |

| 160-XXS | 180 | 18 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 1500# | 10-STD | 170 | 25 | ||

| XS-80 | 170 | 267 | 54,1 | 25 | |

| 160-XXS | 200 | 26 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 2500# | 10-STD | 220 | 45,5 | ||

| XS-80 | 220 | 305 | 72,9 | 45,5 | |

| 160-XXS | 250 | 51 | |||

ANSI/ASME B16.5 Weldo Flange – Dimensions Branch 4”

| RATING | NOMINAL PIPE SIZE FROM 5″ TO 36″ | ||||

|---|---|---|---|---|---|

| Bore schedule | Length | D | E | Weight [kg] | |

| 150# | 10-STD | 130 | 11,5 | ||

| XS-80 | 130 | 229 | 23,9 | 11,5 | |

| 160-XXS | 160 | 13 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 300# | 10-STD | 140 | 16 | ||

| XS-80 | 140 | 254 | 31,8 | 16 | |

| 160-XXS | 170 | 17 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 600# | 10-STD | 160 | 24 | ||

| XS-80 | 160 | 273 | 44,5 | 24 | |

| 160-XXS | 195 | 26 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 900# | 10-STD | 170 | 28 | ||

| XS-80 | 170 | 292 | 50,8 | 28 | |

| 160-XXS | 205 | 29,5 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 1500# | 10-STD | 180 | 38 | ||

| XS-80 | 180 | 311 | 60,2 | 38 | |

| 160-XXS | 215 | 40 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 2500# | 10-STD | 250 | 70,5 | ||

| XS-80 | 250 | 356 | 82,4 | 70,5 | |

| 160-XXS | 281 | 72 | |||

ANSI/ASME B16.5 Weldo Flange – Dimensions Branch 6”

| RATING | NOMINAL PIPE SIZE FROM 8″ TO 36″ | ||||

|---|---|---|---|---|---|

| Bore schedule | Length | D | E | Weight [kg] | |

| 150# | 10-STD | 150 | 23,5 | ||

| XS-80 | 170 | 279 | 25,4 | 25 | |

| 160-XXS | 195 | 27 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 300# | 10-STD | 160 | 36,6 | ||

| XS-80 | 175 | 318 | 36,6 | 37,5 | |

| 160-XXS | 205 | 39 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 600# | 10-STD | 185 | 49,5 | ||

| XS-80 | 200 | 356 | 54,1 | 51 | |

| 160-XXS | 230 | 53,2 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 900# | 10-STD | 210 | 62,5 | ||

| XS-80 | 225 | 381 | 62 | 64,3 | |

| 160-XXS | 250 | 66 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 1500# | 10-STD | 240 | 87,5 | ||

| XS-80 | 255 | 394 | 88,9 | 89 | |

| 160-XXS | 285 | 91,2 | |||

| Bore schedule | Length | D | E | Weight [kg] | |

| 2500# | 10-STD | 340 | 186 | ||

| XS-80 | 360 | 483 | 114,3 | 189 | |

| 160-XXS | 385 | 192,5 | |||

Weldoflange Weight Chart (lbs) – Pressure Class 150 to 2500

| NPS (inch) | 150# (lbs) | 300# (lbs) | 400# (lbs) | 600# (lbs) | 900# (lbs) | 1500# (lbs) | 2500# (lbs) |

|---|---|---|---|---|---|---|---|

| 1/2 | 5 | 6 | 7 | 8 | 10 | 12 | 15 |

| 3/4 | 6 | 7 | 9 | 10 | 12 | 15 | 18 |

| 1 | 8 | 10 | 12 | 14 | 18 | 22 | 28 |

| 1 1/4 | 12 | 15 | 18 | 22 | 28 | 34 | 42 |

| 1 1/2 | 14 | 18 | 22 | 26 | 34 | 42 | 52 |

| 2 | 20 | 25 | 30 | 36 | 46 | 56 | 70 |

| 2 1/2 | 28 | 34 | 42 | 50 | 64 | 78 | 98 |

| 3 | 36 | 44 | 52 | 64 | 82 | 100 | 126 |

| 4 | 55 | 66 | 78 | 96 | 124 | 152 | 190 |

| 6 | 95 | 114 | 136 | 168 | 218 | 266 | 334 |

| 8 | 150 | 180 | 216 | 268 | 348 | 428 | 534 |

| 10 | 220 | 264 | 316 | 396 | 514 | 632 | 794 |

| 12 | 320 | 384 | 460 | 576 | 748 | 920 | 1156 |

| 14 | 420 | 504 | 600 | 752 | 980 | 1200 | 1510 |

| 16 | 540 | 648 | 780 | 976 | 1270 | 1550 | 1960 |

| 18 | 700 | 840 | 1010 | 1260 | 1640 | 2000 | 2520 |

| 20 | 880 | 1056 | 1270 | 1580 | 2060 | 2520 | 3180 |

| 24 | 1300 | 1560 | 1880 | 2340 | 3040 | 3720 | 4680 |

Weldoflange Tolerances as per ANSI / ASME B16.5,16.47

| Feature / Dimension | NPS / Range | Tolerance / Allowable Variation |

|---|---|---|

| Outside Diameter (OD) | ½”–24″ | ±1/16″ (±1.6 mm) |

| 26″–60″ | ±1/8″ (±3.2 mm) | |

| Bolt Circle Diameter (PCD) | 150#–300# | ±1/32″ (±0.8 mm) |

| 400#–2500# | ±1/16″ (±1.6 mm) | |

| Bolt Hole Diameter | Up to 1″ | +1/64″ / -0″ (+0.4 mm / 0 mm) |

| 1″–2″ | +1/32″ / -0″ (+0.8 mm / 0 mm) | |

| Above 2″ | +1/16″ / -0″ (+1.6 mm / 0 mm) | |

| Raised Face Diameter (RF) | All sizes | ±1/32″ (±0.8 mm) |

| Raised Face Height (RF) | All sizes | ±1/64″ (±0.4 mm) |

| Flange Thickness (B) | 150#–600# | ±1/16″ (±1.6 mm) |

| 900#–2500# | ±1/8″ (±3.2 mm) | |

| Hub / Weld Neck Bore (Bore) | Up to 12″ | ±1/32″ (±0.8 mm) |

| Above 12″ | ±1/16″ (±1.6 mm) | |

| Face Flatness / Runout | RF | Max 0.002″ per inch of diameter |

| RTJ | Max 0.001″ per inch of diameter |

What are the installation and maintenance considerations?

-

Installation:

- Ensure pipe end bevel matches flange bore for proper butt-welding.

- Torque bolts uniformly to prevent flange distortion.

- Use correct gasket type (RF/RTJ) as per pressure and temperature.

-

Maintenance:

- Periodically check for bolt torque and flange alignment.

- Inspect for corrosion or erosion, especially in high-temperature or chemical service.

- Replace gaskets during maintenance to prevent leakage.

How are Weldoflanges tested before installation?

- Hydrostatic Test: Confirms flange strength at working pressure.

- Radiographic (RT) or Ultrasonic (UT) Testing: Checks weld quality and internal defects.

- Magnetic Particle (MT) or Dye Penetrant (PT) Testing: Detects surface cracks.

- Dimensional Inspection: Confirms OD, bolt hole alignment, raised face height, and hub bore tolerances.

What are the advantages of Weldoflanges over Slip-On or Socket Weld Flanges?

- Stress Distribution: WN flange hub transfers stress gradually.

- High-Pressure Applications: Can withstand higher pressures than SO or SW flanges.

- Low Turbulence: Smooth bore reduces flow disruption inside piping.

- Long-Term Reliability: Reduced chance of flange lifting under cyclic load.