- Home

- Industrial Flanges

- Orifice Flange

Orifice Flange

Orifice Flange: Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

ASME B16.36 Orifice Flanges Manufacturer and Exporter – Available in Carbon Steel, Stainless Steel, Alloy Steel, and Nickel Alloys, Sizes ½”–24”, Classes 150#–2500#, Delivered Worldwide including Spain, Turkey, UAE, and Canada

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd has built its reputation by combining industrial expertise with rigorous quality controls. We invest in precision machining, metallurgical testing, and modern forging techniques to manufacture flanges that perform reliably under tough conditions.

Our team doesn’t just meet industry standards — we often exceed them by tailoring flange thicknesses, material grades, and finishing based on end-use requirements. Serving sectors such as energy, chemical processing, and water treatment, we ensure each order delivers consistent quality, supported by detailed inspection reports and material traceability.

Our operations are structured into distinct stages: design & engineering, raw material procurement, forging & machining, heat treatment, and final inspection. We maintain strict policies for material sourcing—only certified mills and tested alloy batches are used. After forging, each flange passes through dimensional checks (OD, bolt circle, bore), surface finish testing, and pressure/leakage testing where required. We also practice environmental stewardship in our manufacturing: our facilities aim to minimize waste material and comply with safety regulations for workers and emissions.

An ASME B16.36 orifice flange is engineered to host an orifice plate that forces fluid flow through a precisely machined opening, creating a pressure differential. The flange includes pressure tapping points (upstream and downstream) to measure this differential, enabling flow rate calculation.

Important technical details include: the tolerance of the orifice opening (which directly affects accuracy), the material’s resistance to erosion or corrosion from the flowing medium, and proper matching with the piping schedule to avoid flow disturbances. Orifice flanges are often manufactured per ASME B16.36, and must meet standards for bore finishing, alignment with flange face, and seating for pressure taps to ensure accurate readings.

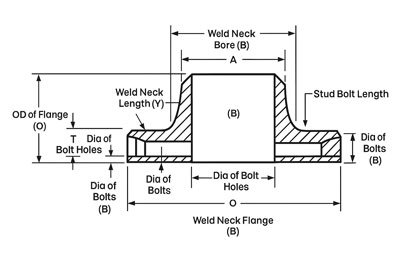

An Orifice Flange is not an entirely separate type of flange but rather a special modification of standard flanges. It is usually manufactured in the form of Weld Neck Flanges or Slip-On Flanges, depending on the pressure and application requirements. Among these, the Weld Neck Orifice Flange is the most common choice because of its ability to withstand high pressure and provide accurate flow measurements, while Slip-On Orifice Flanges are preferred for lower pressure conditions.

The design of an orifice flange includes radial pressure tapping holes drilled into both flanges (upstream and downstream) that allow the measurement of differential pressure across an orifice plate. This setup helps in calculating the flow rate of liquids and gases within a pipeline. All dimensions and technical requirements for these flanges are standardized under ASME B16.36, which ensures reliability, interchangeability, and safety across industries.

orifice Pipe Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Orifice Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

ANSI/ASME B16.36 Class 300 Orifice Flange – Dimensions & Sizes in mm

| NPS inch |

OD

of Flange (O) |

Dia

of Raised Face (R) |

Min

Thk of Flange (T) |

Weld

Neck Length (Y) |

Hub

Dia at Base (X) |

Hub

Dia at End (A) |

Weld

Neck Bore (B) |

Dia

of Tap (Tt) |

Bolt Circle |

No.

of Bolt Holes |

Dia

of Bolt Holes |

Dia

of Bolts |

Stud

Bolt Length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 125 | 50.8 | 36.6 | 81 | 54 | 33.4 | (1) | 6.4 | 88.9 | 4 | 11/16 | 5/8 | 125 |

| 1-1/2 | 155 | 73 | 36.6 | 84 | 70 | 48.3 | (1) | 6.4 | 114.3 | 4 | 13/16 | 3/4 | 135 |

| 2 | 165 | 92.1 | 36.6 | 84 | 84 | 60.3 | (1) | 6.4 | 127 | 8 | 11/16 | 5/8 | 125 |

| 2-1/2 | 190 | 104.8 | 36.6 | 87 | 100 | 73 | (1) | 6.4 | 149.2 | 8 | 13/16 | 3/4 | 135 |

| 3 | 210 | 127 | 36.6 | 87 | 117 | 88.9 | (1) | 9.5 | 168.3 | 8 | 13/16 | 3/4 | 135 |

| 4 | 255 | 157.2 | 36.6 | 90 | 146 | 114.3 | (1) | 12.7 | 200 | 8 | 13/16 | 3/4 | 135 |

| 6 | 320 | 215.9 | 36.6 | 98 | 206 | 168.3 | (1) | 12.7 | 269.9 | 12 | 7/8 | 3/4 | 135 |

| 8 | 380 | 269.9 | 39.7 | 110 | 260 | 219.1 | (1) | 12.7 | 330.2 | 12 | 1 | 7/8 | 145 |

| 10 | 445 | 323.8 | 46.1 | 116 | 321 | 273 | (1) | 12.7 | 387.4 | 16 | 1-1/8 | 1 | 165 |

| 12 | 520 | 381 | 49.3 | 129 | 375 | 323.8 | (1) | 12.7 | 450.8 | 16 | 1-1/4 | 1-1/8 | 180 |

| 14 | 585 | 412.8 | 52.4 | 141 | 425 | 355.6 | (1) | 12.7 | 514.4 | 20 | 1-1/4 | 1-1/8 | 185 |

| 16 | 650 | 469.9 | 55.6 | 144 | 483 | 406.4 | (1) | 12.7 | 571.5 | 20 | 1-3/8 | 1-1/4 | 195 |

| 18 | 710 | 533.4 | 58.8 | 157 | 533 | 457 | (1) | 12.7 | 628.6 | 24 | 1-3/8 | 1-1/4 | 205 |

| 20 | 775 | 584.2 | 62 | 160 | 587 | 508 | (1) | 12.7 | 685.8 | 24 | 1-3/8 | 1-1/4 | 215 |

| 24 | 915 | 692.2 | 68.3 | 167 | 702 | 610 | (1) | 12.7 | 812.8 | 24 | 1-5/8 | 1-1/2 | 240 |

ANSI/ASME B16.36 Class 600 Orifice Flange – Dimensions & Sizes in mm

| NPS inch |

OD of Flange (O) |

Dia of Raised Face (R) |

Min Thk of Flange (T) |

Weld Neck Length (Y) |

Hub Dia at Base (X) |

Hub Dia at End (A) |

Weld Neck Bore (B) |

Dia of Tap (Tt) |

Bolt |

No. of Bolt Holes |

Dia of Bolt Holes |

Dia of Bolts |

Stud Bolt Length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 125 | 50.8 | 36.6 | 81 | 54 | 33.5 | (1) | 6.4 | 88.9 | 4 | 11/16 | 5/8 | 125 |

| 1-1/2 | 155 | 73 | 36.6 | 84 | 70 | 48.3 | (1) | 6.4 | 114.3 | 4 | 13/16 | 3/4 | 135 |

| 2 | 165 | 92.1 | 36.6 | 84 | 84 | 60.3 | (1) | 6.4 | 127 | 8 | 11/16 | 5/8 | 125 |

| 2-1/2 | 190 | 104.8 | 36.6 | 87 | 100 | 73 | (1) | 6.4 | 149.2 | 8 | 13/16 | 3/4 | 135 |

| 3 | 210 | 127 | 36.6 | 87 | 117 | 88.9 | (1) | 9.5 | 168.3 | 8 | 13/16 | 3/4 | 135 |

| 4 | 275 | 157.2 | 38.1 | 102 | 152 | 114.3 | (1) | 12.7 | 215.9 | 8 | 1 | 7/8 | 150 |

| 6 | 355 | 215.9 | 47.7 | 117 | 222 | 168.3 | (1) | 12.7 | 292.1 | 12 | 1-1/8 | 1 | 180 |

| 8 | 420 | 269.9 | 55.6 | 133 | 273 | 219.1 | (1) | 12.7 | 349.2 | 12 | 1-1/4 | 1-1/8 | 195 |

| 10 | 510 | 323.8 | 63.5 | 152 | 343 | 273 | (1) | 12.7 | 431.8 | 16 | 1-3/8 | 1-1/4 | 220 |

| 12 | 560 | 381 | 66.7 | 156 | 400 | 323.8 | (1) | 12.7 | 489 | 20 | 1-3/8 | 1-1/4 | 230 |

| 14 | 605 | 412.8 | 69.9 | 165 | 432 | 355.6 | (1) | 12.7 | 527 | 20 | 1-1/2 | 1-3/8 | 240 |

| 16 | 685 | 469.9 | 76.2 | 178 | 495 | 406.4 | (1) | 12.7 | 603.2 | 20 | 1-5/8 | 1-1/2 | 260 |

| 18 | 745 | 533.4 | 82.6 | 184 | 546 | 457.2 | (1) | 12.7 | 654 | 20 | 1-3/4 | 1-5/8 | 280 |

| 20 | 815 | 584.2 | 88.9 | 190 | 610 | 508 | (1) | 12.7 | 723.9 | 24 | 1-3/4 | 1-5/8 | 300 |

| 24 | 940 | 692.2 | 101.6 | 203 | 718 | 609.6 | (1) | 12.7 | 838.2 | 24 | 2 | 1-7/8 | 335 |

ANSI/ASME B16.36 Class 900 Orifice Flange – Dimensions & Sizes in mm

| NPS inch |

OD of Flange (O) |

Dia of Raised Face (R) |

Min Thk of Flange (T) |

Weld Neck Length (Y) |

Hub Dia at Base (X) |

Hub Dia at End (A) |

Weld Neck Bore (B) |

Dia of Tap (Tt) |

Bolt |

No. of Bolt Holes |

Dia of Bolt Holes |

Dia of Bolts |

Stud Bolt Length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 150 | 50.8 | 38.1 | 83 | 52 | 33.5 | (1) | 6.4 | 101.6 | 4 | 1 | 7/8 | 150 |

| 1-1/2 | 180 | 73 | 38.1 | 89 | 70 | 48.3 | (1) | 6.4 | 123.8 | 4 | 1-1/8 | 1 | 160 |

| 2 | 215 | 92.1 | 38.1 | 102 | 105 | 60.3 | (1) | 6.4 | 165.1 | 8 | 1 | 7/8 | 150 |

| 2-1/2 | 245 | 104.8 | 41.3 | 105 | 124 | 73 | (1) | 6.4 | 190.5 | 8 | 1-1/8 | 1 | 165 |

| 3 | 240 | 127 | 38.1 | 102 | 127 | 88.9 | (1) | 9.5 | 190.5 | 8 | 1 | 7/8 | 150 |

| 4 | 290 | 157.2 | 44.5 | 114 | 159 | 114.3 | (1) | 12.7 | 235 | 8 | 1-1/4 | 1-1/8 | 180 |

| 6 | 380 | 215.9 | 55.6 | 140 | 235 | 168.3 | (1) | 12.7 | 317.5 | 12 | 1-1/4 | 1-1/8 | 195 |

| 8 | 470 | 269.9 | 63.5 | 162 | 298 | 219.1 | (1) | 12.7 | 393.7 | 12 | 1-1/2 | 1-3/8 | 230 |

| 10 | 545 | 323.8 | 69.9 | 184 | 368 | 273 | (1) | 12.7 | 469.9 | 16 | 1-1/2 | 1-3/8 | 240 |

| 12 | 610 | 381 | 79.4 | 200 | 419 | 323.8 | (1) | 12.7 | 533.4 | 20 | 1-1/2 | 1-3/8 | 260 |

| 14 | 640 | 412.8 | 85.8 | 213 | 451 | 355.6 | (1) | 12.7 | 558.8 | 20 | 1-5/8 | 1-1/2 | 280 |

| 16 | 705 | 469.9 | 88.9 | 216 | 508 | 406.4 | (1) | 12.7 | 616 | 20 | 1-3/4 | 1-5/8 | 290 |

| 18 | 785 | 533.4 | 101.6 | 229 | 565 | 457.2 | (1) | 12.7 | 685.8 | 20 | 2 | 1-7/8 | 330 |

| 20 | 855 | 584.2 | 108 | 248 | 622 | 508 | (1) | 12.7 | 749.3 | 20 | 2-1/8 | 2 | 355 |

| 24 | 1040 | 692.2 | 139.7 | 292 | 749 | 609.6 | (1) | 12.7 | 901.7 | 20 | 2-5/8 | 2-1/2 | 445 |

ANSI/ASME B16.36 Class 1500 Orifice Flange – Dimensions & Sizes in mm

| NPS inch |

OD of Flange (O) |

Dia of Raised Face (R) |

Min Thk of Flange (T) |

Weld Neck Length (Y) |

Hub Dia at Base (X) |

Hub Dia at End (A) |

Weld Neck Bore (B) |

Dia of Tap (Tt) |

Bolt |

No. of Bolt Holes |

Dia of Bolt Holes |

Dia of Bolts |

Stud Bolt Length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 150 | 50.8 | 38.1 | 83 | 52 | 33.5 | (1) | 6.4 | 101.6 | 4 | 1 | 7/8 | 150 |

| 1-1/2 | 180 | 73 | 38.1 | 89 | 70 | 48.3 | (1) | 6.4 | 123.8 | 4 | 1-1/8 | 1 | 160 |

| 2 | 215 | 92.1 | 38.1 | 102 | 105 | 60.3 | (1) | 6.4 | 165.1 | 8 | 1 | 7/8 | 150 |

| 2-1/2 | 245 | 104.8 | 41.3 | 105 | 124 | 73 | (1) | 6.4 | 190.5 | 8 | 1-1/8 | 1 | 165 |

| 3 | 265 | 127 | 47.7 | 117 | 133 | 88.9 | (1) | 9.5 | 203.2 | 8 | 1-1/4 | 1-1/8 | 185 |

| 4 | 310 | 157.2 | 54 | 124 | 162 | 114.3 | (1) | 12.7 | 241.3 | 8 | 1-3/8 | 1-1/4 | 205 |

| 6 | 395 | 215.9 | 82.6 | 171 | 229 | 168.3 | (1) | 12.7 | 317.5 | 12 | 1-1/2 | 1-3/8 | 265 |

| 8 | 485 | 269.9 | 92.1 | 213 | 292 | 219.1 | (1) | 12.7 | 393.7 | 12 | 1-3/4 | 1-5/8 | 300 |

| 10 | 585 | 323.8 | 108 | 254 | 368 | 273 | (1) | 12.7 | 482.6 | 12 | 2 | 1-7/8 | 345 |

| 12 | 675 | 381 | 123.9 | 283 | 451 | 323.8 | (1) | 12.7 | 571.6 | 16 | 2-1/8 | 2 | 380 |

| 14 | 750 | 412.8 | 133.4 | 298 | 495 | 355.6 | (1) | 12.7 | 635 | 16 | 2-3/8 | 2-1/4 | 415 |

| 16 | 825 | 469.9 | 146.1 | 311 | 552 | 406.4 | (1) | 12.7 | 704.8 | 16 | 2-5/8 | 2-1/2 | 450 |

| 18 | 915 | 533.4 | 162 | 327 | 597 | 457.2 | (1) | 12.7 | 774.7 | 16 | 2-7/8 | 2-3/4 | 500 |

| 20 | 985 | 584.2 | 177.8 | 356 | 641 | 508 | (1) | 12.7 | 831.8 | 16 | 3-1/8 | 3 | 545 |

| 24 | 1170 | 692.2 | 203.2 | 406 | 762 | 609.6 | (1) | 12.7 | 990.6 | 16 | 3-5/8 | 3-1/2 | 620 |

ANSI/ASME B16.36 Class 2500 Orifice Flange – Dimensions & Sizes in mm

| NPS inch |

OD of Flange (O) |

Dia of Raised Face (R) |

Min Thk of Flange (T) |

Weld Neck Length (Y) |

Hub Dia at Base (X) |

Hub Dia at End (A) |

Weld Neck Bore (B) |

Dia of Tap (Tt) |

Bolt |

No. of Bolt Holes |

Dia of Bolt Holes |

Dia of Bolts |

Stud Bolt Length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 160 | 50.8 | 38.1 | 92 | 57 | 33.5 | (1) | 6.4 | 108 | 4 | 1 | 7/8 | 150 |

| 1-1/2 | 205 | 73 | 44.5 | 111 | 79 | 48.3 | (1) | 6.4 | 146 | 4 | 1-1/4 | 1-1/8 | 180 |

| 2 | 235 | 92.1 | 50.8 | 127 | 95 | 60.3 | (1) | 6.4 | 171.4 | 8 | 1-1/8 | 1 | 185 |

| 2-1/2 | 265 | 104.8 | 57.2 | 143 | 114 | 73 | (1) | 6.4 | 196.8 | 8 | 1-1/4 | 1-1/8 | 205 |

| 3 | 305 | 127 | 66.7 | 168 | 133 | 88.9 | (1) | 9.5 | 228.6 | 8 | 1-3/8 | 1-1/4 | 230 |

| 4 | 355 | 157.2 | 76.2 | 190 | 165 | 114.3 | (1) | 12.7 | 273 | 8 | 1-5/8 | 1-1/2 | 260 |

| 6 | 485 | 215.9 | 108 | 273 | 235 | 168.3 | (1) | 12.7 | 368.3 | 8 | 2-1/8 | 2 | 350 |

| 8 | 550 | 269.9 | 127 | 318 | 305 | 219.1 | (1) | 12.7 | 438.2 | 12 | 2-1/8 | 2 | 385 |

| 10 | 675 | 323.8 | 165.1 | 419 | 375 | 273 | (1) | 12.7 | 539.8 | 12 | 2-5/8 | 2-1/2 | 490 |

| 12 | 760 | 381 | 184.2 | 464 | 441 | 323.8 | (1) | 12.7 | 619.1 | 12 | 2-7/8 | 2-3/4 | 540 |

Orifice Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| Nominal Pipe Size (NPS) | Class 300 | Class 600 | Class 900 | Class 1500 | Class 2500 |

|---|---|---|---|---|---|

| 1/2 | 6.5 | 9.5 | 14.0 | 21.0 | 30.0 |

| 3/4 | 7.5 | 11.0 | 16.0 | 25.0 | 36.0 |

| 1 | 10.0 | 16.0 | 23.0 | 35.0 | 52.0 |

| 2 | 21.0 | 34.0 | 52.0 | 78.0 | 116.0 |

| 3 | 33.0 | 55.0 | 84.0 | 126.0 | 188.0 |

| 4 | 45.0 | 76.0 | 116.0 | 174.0 | 260.0 |

| 6 | 72.0 | 123.0 | 188.0 | 280.0 | 420.0 |

| 8 | 108.0 | 182.0 | 278.0 | 414.0 | 624.0 |

| 10 | 152.0 | 258.0 | 392.0 | 586.0 | 884.0 |

| 12 | 198.0 | 336.0 | 510.0 | 764.0 | 1150.0 |

| 14 | 236.0 | 404.0 | 614.0 | 922.0 | 1390.0 |

| 16 | 278.0 | 478.0 | 724.0 | 1086.0 | 1640.0 |

| 18 | 328.0 | 566.0 | 858.0 | 1284.0 | 1940.0 |

| 20 | 382.0 | 656.0 | 994.0 | 1488.0 | 2240.0 |

| 24 | 500.0 | 860.0 | 1300.0 | 1940.0 | 2900.0 |

Orifice Flange Tolerances as per ANSI / ASME B16.36

| Parameter | Tolerance |

|---|---|

| Outside Diameter (OD) of Flange | ±1.5 mm (up to 24”) |

| Bolt Circle Diameter | ±1.5 mm |

| Diameter of Bolt Holes | +1.5 mm / –0 mm |

| Bolt Hole Center-to-Center | ±1.0 mm |

| Flange Thickness (C) | ±1.5 mm |

| Raised Face Height (h) | ±0.5 mm |

| Bore Diameter | +1.0 mm / –0.0 mm |

| Hub Diameter at Base | ±1.5 mm |

| Concentricity of Bore to OD | ≤ 1.5 mm |

| Facing Finish (Ra) | 125–500 AARH (per ASME B16.36) |

| Squareness of Flange Face to Bore | ≤ 1.5 mm across diameter |

What is an orifice flange and how does it work?

An orifice flange is a specialized type of flange assembly designed for flow measurement in pipelines. It is used with an orifice plate and differential pressure transmitters to measure the flow rate of liquids, gases, or steam.

-

Working Principle:

- The orifice plate with a hole is placed between a pair of orifice flanges.

- As the fluid passes through the restriction, a pressure drop occurs.

- This pressure difference is measured through pressure taps provided in the flange assembly.

- The differential pressure is then converted into flow rate using fluid dynamics equations.

- Applications: Flow monitoring in refineries, chemical plants, power plants, and water treatment facilities.

How are orifice flanges installed and maintained?

Proper installation and maintenance are crucial for ensuring accurate flow measurement.

-

Installation:

- Ensure the flange pair is aligned properly.

- Insert the orifice plate in the central position with the bore facing the flow direction.

- Connect pressure tapping lines to differential pressure transmitters.

- Tighten bolts uniformly to avoid leakage.

-

Maintenance:

- Regularly check orifice plate condition (erosion, corrosion, or deposits).

- Clean or replace clogged pressure tappings.

- Recalibrate measuring instruments periodically.

- Verify gasket integrity to prevent leakage.

What are the different types of orifice flanges?

Orifice flanges are available in several configurations depending on the pressure class, flange type, and measurement requirement:

- Weld Neck Orifice Flange – Provides high strength and is used in high-pressure applications.

- Slip-On Orifice Flange – Easier to install and ideal for low to medium pressure systems.

- Threaded Orifice Flange – Used in smaller pipe sizes where welding is not practical.

- Blind Orifice Flange – Comes with taps for testing or calibration purposes.

- RTJ (Ring Type Joint) Orifice Flange – Suitable for high pressure and temperature services.