- Home

- Industrial Flanges

- Ring Type Joint Flange

Ring Type Joint Flange

RTJ Flange: Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

High-quality ASME B16.5 Ring Type Joint Flanges manufactured and exported in carbon, stainless, alloy, and nickel alloys. Sizes range from ½” to 24” with pressure classes 150–2500. Shipped globally including Canada, Saudi Arabia, Singapore, and Italy.

Best Export Prices: sales@midlandforgefittings.com

At Midland Forge and Fittings Pvt. Ltd, we are committed to delivering world-class piping components that meet the most demanding industry requirements. With a focus on innovation, precision, and quality assurance, we have established ourselves as a reliable manufacturer and exporter of RTJ flanges for global markets. Our expertise extends across a wide range of materials, allowing us to serve diverse industries with customized solutions.

We pride ourselves on our to provide products that are engineered to international standards while maintaining competitive pricing and timely deliveries. Whether it is for oil & gas, petrochemical, or power generation projects, we are trusted by clients worldwide for supplying products that ensure durability, safety, and performance under critical operating conditions.

A RTJ Flange is a high-pressure flange designed with a machined groove that holds a metal ring gasket, creating a strong and leak-proof seal. These flanges are ideal for applications where high-pressure and high-temperature resistance is essential. RTJ flanges are commonly used in oil refineries, offshore drilling, chemical plants, and power generation systems, where safety and reliability cannot be compromised.

ASME B16.5 RTJ Flanges are manufactured to meet global standards, available in sizes ranging from ½” to 24” and pressure classes from 150# to 2500#. Each flange is crafted with precision, ensuring accurate dimensions, excellent surface finish, and long-lasting performance. By offering RTJ flanges in multiple materials and finishes, we provide clients with tailored solutions that match their project requirements.

Ring Type Joint Pipe Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Ring Type Joint Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

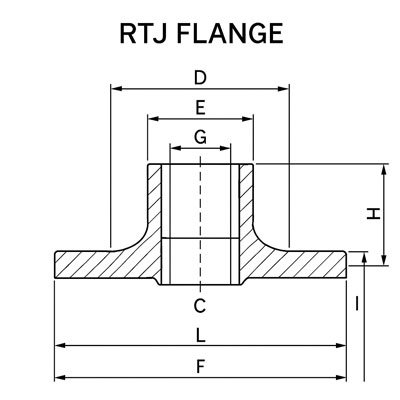

ANSI/ASME B16.5 Class 150 RTJ Flange – Dimensions & Sizes in mm

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

RTJ RF Dia | RTJ RF Height | PCD | RTJ Pitch dia |

RTJ Depth |

RTJ Width |

Bore |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | N/A | N/A | 60.3 | N/A | N/A | N/A | Welding Neck bore is derived from the pipe schedule |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | N/A | N/A | 69.9 | N/A | N/A | N/A | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 63.5 | 6.35 | 79.4 | 47.63 | 6.35 | 8.74 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 73 | 6.35 | 88.9 | 57.15 | 6.35 | 8.74 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 82.5 | 6.35 | 98.4 | 65.07 | 6.35 | 8.74 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 102 | 6.35 | 120.7 | 82.55 | 6.35 | 8.74 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 121 | 6.35 | 139.7 | 101.6 | 6.35 | 8.74 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 133 | 6.35 | 152.4 | 114.3 | 6.35 | 8.74 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 154 | 6.35 | 177.8 | 131.78 | 6.35 | 8.74 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 171 | 6.35 | 190.5 | 149.23 | 6.35 | 8.74 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 194 | 6.35 | 215.9 | 171.45 | 6.35 | 8.74 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 219 | 6.35 | 241.3 | 193.68 | 6.35 | 8.74 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 273 | 6.35 | 298.5 | 247.65 | 6.35 | 8.74 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 330 | 6.35 | 362 | 304.8 | 6.35 | 8.74 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 406 | 6.35 | 431.8 | 381 | 6.35 | 8.74 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 425 | 6.35 | 476.3 | 396.88 | 6.35 | 8.74 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 483 | 6.35 | 539.8 | 454.03 | 6.35 | 8.74 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 546 | 6.35 | 577.9 | 517.53 | 6.35 | 8.74 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 597 | 6.35 | 635 | 558.8 | 6.35 | 8.74 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 711 | 6.35 | 749.3 | 673.1 | 6.35 | 8.74 |

ANSI/ASME B16.5 Class 300 RTJ Flange – Dimensions & Sizes in mm

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

RTJ RF Dia |

RTJ RF Height |

PCD | RTJ Pitch dia |

RTJ Depth |

RTJ Width |

Bore |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| 1/2 | 15 | 95 | 12.7 | 38 | 21.3 | 51 | 51 | 5.54 | 66.7 | 34.14 | 5.54 | 7.14 | Welding Neck bore is derived from the pipe schedule |

| 3/4 | 20 | 115 | 14.3 | 48 | 26.7 | 56 | 63.5 | 6.35 | 82.6 | 42.88 | 6.35 | 8.74 | |

| 1 | 25 | 125 | 15.9 | 54 | 33.4 | 60 | 70 | 6.35 | 88.9 | 50.8 | 6.35 | 8.74 | |

| 1 1/4 | 32 | 135 | 17.5 | 64 | 42.2 | 64 | 79.5 | 6.35 | 98.4 | 60.33 | 6.35 | 8.74 | |

| 1 1/2 | 40 | 155 | 19.1 | 70 | 48.3 | 67 | 90.5 | 6.35 | 114.3 | 68.27 | 6.35 | 8.74 | |

| 2 | 50 | 165 | 20.7 | 84 | 60.3 | 68 | 108 | 7.92 | 127 | 82.55 | 7.92 | 11.91 | |

| 2 1/2 | 65 | 190 | 23.9 | 100 | 73 | 75 | 127 | 7.92 | 149.2 | 101.6 | 7.92 | 11.91 | |

| 3 | 80 | 210 | 27 | 117 | 88.9 | 78 | 146 | 7.92 | 168.3 | 123.83 | 7.92 | 11.91 | |

| 3 1/2 | 90 | 230 | 28.6 | 133 | 101.6 | 79 | 159 | 7.92 | 184.2 | 131.78 | 7.92 | 11.91 | |

| 4 | 100 | 255 | 30.2 | 146 | 114.3 | 84 | 175 | 7.92 | 200 | 149.23 | 7.92 | 11.91 | |

| 5 | 125 | 280 | 33.4 | 178 | 141.3 | 97 | 210 | 7.92 | 235 | 180.98 | 7.92 | 11.91 | |

| 6 | 150 | 320 | 35 | 206 | 168.3 | 97 | 241 | 7.92 | 269.9 | 211.12 | 7.92 | 11.91 | |

| 8 | 200 | 380 | 39.7 | 260 | 219.1 | 110 | 302 | 7.92 | 330.2 | 269.88 | 7.92 | 11.91 | |

| 10 | 250 | 445 | 46.1 | 321 | 273 | 116 | 356 | 7.92 | 387.4 | 323.85 | 7.92 | 11.91 | |

| 12 | 300 | 520 | 49.3 | 375 | 323.8 | 129 | 413 | 7.92 | 450.8 | 381 | 7.92 | 11.91 | |

| 14 | 350 | 585 | 52.4 | 425 | 355.6 | 141 | 457 | 7.92 | 514.4 | 419.1 | 7.92 | 11.91 | |

| 16 | 400 | 650 | 55.6 | 483 | 406.4 | 144 | 508 | 7.92 | 571.5 | 469.9 | 7.92 | 11.91 | |

| 18 | 450 | 710 | 58.8 | 533 | 457 | 157 | 575 | 7.92 | 628.6 | 533.4 | 7.92 | 11.91 | |

| 20 | 500 | 775 | 62 | 587 | 508 | 160 | 635 | 9.53 | 685.8 | 584.2 | 9.53 | 13.49 | |

| 24 | 600 | 915 | 68.3 | 702 | 610 | 167 | 749 | 11.13 | 812.8 | 692.15 | 11.13 | 16.66 |

ANSI/ASME B16.5 Class 400 RTJ Flange – Dimensions & Sizes in mm

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

RTJ RF Dia |

RTJ RF Height |

PCD | RTJ Pitch dia |

RTJ Depth |

RTJ Width |

Bore |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| 1/2 | 15 | 95 | 14.3 | 38 | 21.3 | 52 | 51 | 5.54 | 66.7 | 34.14 | 5.54 | 7.14 | Welding Neck bore is derived from the pipe schedule |

| 3/4 | 20 | 115 | 15.9 | 48 | 26.7 | 57 | 63.5 | 6.35 | 82.6 | 42.88 | 6.35 | 8.74 | |

| 1 | 25 | 125 | 17.5 | 54 | 33.4 | 62 | 70 | 6.35 | 88.9 | 50.8 | 6.35 | 8.74 | |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 42.2 | 67 | 79.5 | 6.35 | 98.4 | 60.33 | 6.35 | 8.74 | |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 48.3 | 70 | 90.5 | 6.35 | 114.3 | 68.27 | 6.35 | 8.74 | |

| 2 | 50 | 165 | 25.4 | 84 | 60.3 | 73 | 108 | 7.92 | 127 | 82.55 | 7.92 | 11.9 | |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 73 | 79 | 127 | 7.92 | 149.2 | 101.6 | 7.92 | 11.9 | |

| 3 | 80 | 210 | 31.8 | 117 | 88.9 | 83 | 146 | 7.92 | 168.3 | 123.83 | 7.92 | 11.9 | |

| 3 1/2 | 90 | 230 | 35 | 133 | 101.6 | 86 | 159 | 7.92 | 184.2 | 131.78 | 7.92 | 11.9 | |

| 4 | 100 | 255 | 35 | 146 | 114.3 | 89 | 175 | 7.92 | 200 | 149.23 | 7.92 | 11.91 | |

| 5 | 125 | 280 | 38.1 | 178 | 141.3 | 102 | 210 | 7.92 | 235 | 180.98 | 7.92 | 11.91 | |

| 6 | 150 | 320 | 41.3 | 206 | 168.3 | 103 | 241 | 7.92 | 269.9 | 211.12 | 7.92 | 11.91 | |

| 8 | 200 | 380 | 47.7 | 260 | 219.1 | 117 | 302 | 7.92 | 330 | 269.88 | 7.92 | 11.91 | |

| 10 | 250 | 445 | 54 | 321 | 273 | 124 | 356 | 7.92 | 387.4 | 323.85 | 7.92 | 11.91 | |

| 12 | 300 | 520 | 57.2 | 375 | 323.8 | 137 | 413 | 7.92 | 450.8 | 381 | 7.92 | 11.91 | |

| 14 | 350 | 585 | 60.4 | 425 | 355.6 | 149 | 457 | 7.92 | 514.4 | 419.1 | 7.92 | 11.91 | |

| 16 | 400 | 650 | 63.5 | 483 | 406.4 | 152 | 508 | 7.92 | 571.5 | 469.9 | 7.92 | 11.91 | |

| 18 | 450 | 710 | 66.7 | 533 | 457 | 165 | 575 | 7.92 | 628.6 | 533.4 | 7.92 | 11.91 | |

| 20 | 500 | 775 | 69.9 | 587 | 508 | 168 | 635 | 9.53 | 685.8 | 584.2 | 9.53 | 13.49 | |

| 24 | 600 | 915 | 76.2 | 702 | 610 | 175 | 749 | 11.13 | 812.8 | 692.15 | 11.13 | 16.66 |

ANSI/ASME B16.5 Class 600 RTJ Flange – Dimensions & Sizes in mm

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

RTJ RF Dia |

RTJ RF Height |

PCD | RTJ Pitch dia |

RTJ Depth |

RTJ Width |

Bore |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| 1/2 | 15 | 95 | 14.3 | 38 | 21.3 | 52 | 51 | 5.54 | 66.7 | 34.14 | 5.54 | 7.14 | Welding Neck bore is derived from the pipe schedule |

| 3/4 | 20 | 115 | 15.9 | 48 | 26.7 | 57 | 63.5 | 6.35 | 82.6 | 42.88 | 6.35 | 8.74 | |

| 1 | 25 | 125 | 17.5 | 54 | 33.4 | 62 | 70 | 6.35 | 88.9 | 50.8 | 6.35 | 8.74 | |

| 1 1/4 | 32 | 135 | 20.7 | 64 | 42.2 | 67 | 79.5 | 6.35 | 98.4 | 60.33 | 6.35 | 8.74 | |

| 1 1/2 | 40 | 155 | 22.3 | 70 | 48.3 | 70 | 90.5 | 6.35 | 114.3 | 68.27 | 6.35 | 8.74 | |

| 2 | 50 | 165 | 25.4 | 84 | 60.3 | 73 | 108 | 7.92 | 127 | 82.55 | 7.92 | 11.91 | |

| 2 1/2 | 65 | 190 | 28.6 | 100 | 73 | 79 | 127 | 7.92 | 149.2 | 101.6 | 7.92 | 11.91 | |

| 3 | 80 | 210 | 31.8 | 117 | 88.9 | 83 | 146 | 7.92 | 168.3 | 123.83 | 7.92 | 11.91 | |

| 3 1/2 | 90 | 230 | 35 | 133 | 101.6 | 86 | 159 | 7.92 | 184.2 | 131.78 | 7.92 | 11.91 | |

| 4 | 100 | 275 | 38.1 | 152 | 114.3 | 102 | 175 | 7.92 | 215.9 | 149.23 | 7.92 | 11.91 | |

| 5 | 125 | 330 | 44.5 | 189 | 141.3 | 114 | 210 | 7.92 | 266.7 | 180.98 | 7.92 | 11.91 | |

| 6 | 150 | 355 | 47.7 | 222 | 168.3 | 117 | 241 | 7.92 | 292.1 | 211.12 | 7.92 | 11.91 | |

| 8 | 200 | 420 | 55.6 | 273 | 219.1 | 133 | 302 | 7.92 | 349.2 | 269.88 | 7.92 | 11.91 | |

| 10 | 250 | 510 | 63.5 | 343 | 273 | 152 | 356 | 7.92 | 431.8 | 323.85 | 7.92 | 11.91 | |

| 12 | 300 | 560 | 66.7 | 400 | 323.8 | 156 | 413 | 7.92 | 489 | 381 | 7.92 | 11.91 | |

| 14 | 350 | 605 | 69.9 | 432 | 355.6 | 165 | 457 | 7.92 | 527 | 419.1 | 7.92 | 11.91 | |

| 16 | 400 | 685 | 76.2 | 495 | 406.4 | 178 | 508 | 7.92 | 603.2 | 469.9 | 7.92 | 11.91 | |

| 18 | 450 | 745 | 82.6 | 546 | 457 | 184 | 575 | 7.92 | 654 | 533.4 | 7.92 | 11.91 | |

| 20 | 500 | 815 | 88.9 | 610 | 508 | 190 | 635 | 9.53 | 723.9 | 584.2 | 9.53 | 13.49 | |

| 24 | 600 | 940 | 101.6 | 718 | 610 | 203 | 749 | 11.13 | 838.2 | 692.15 | 11.13 | 16.66 |

ANSI/ASME B16.5 Class 900 RTJ Flange – Dimensions & Sizes in mm

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

RTJ RF Dia |

RTJ RF Height |

PCD | RTJ Pitch dia |

RTJ Depth |

RTJ Width |

Bore |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| 1/2 | 15 | 120 | 22.3 | 38 | 21.3 | 60 | 60.5 | 6.35 | 82.6 | 39.67 | 6.35 | 8.74 | Welding Neck bore is derived from the pipe schedule |

| 3/4 | 20 | 130 | 25.4 | 44 | 26.7 | 70 | 66.5 | 6.35 | 88.9 | 44.45 | 6.35 | 8.74 | |

| 1 | 25 | 150 | 28.6 | 52 | 33.4 | 73 | 71.5 | 6.35 | 101.6 | 50.8 | 6.35 | 8.74 | |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 42.2 | 73 | 81 | 6.35 | 111.1 | 60.33 | 6.35 | 8.74 | |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 48.3 | 83 | 92 | 6.35 | 123.8 | 68.27 | 6.35 | 8.74 | |

| 2 | 50 | 215 | 38.1 | 105 | 60.3 | 102 | 124 | 7.92 | 165.1 | 95.25 | 7.92 | 11.91 | |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 73 | 105 | 137 | 7.92 | 190.5 | 107.95 | 7.92 | 11.91 | |

| 3 | 80 | 240 | 38.1 | 127 | 88.9 | 102 | 156 | 7.92 | 190.5 | 123.83 | 7.92 | 11.91 | |

| 4 | 100 | 290 | 44.5 | 159 | 114.3 | 114 | 181 | 7.92 | 235 | 149.23 | 7.92 | 11.91 | |

| 5 | 125 | 350 | 50.8 | 190 | 141.3 | 127 | 216 | 7.92 | 279.4 | 180.98 | 7.92 | 11.91 | |

| 6 | 150 | 380 | 55.6 | 235 | 168.3 | 140 | 241 | 7.92 | 317.5 | 211.12 | 7.92 | 11.91 | |

| 8 | 200 | 470 | 63.5 | 298 | 219.1 | 162 | 308 | 7.92 | 393.7 | 269.88 | 7.92 | 11.91 | |

| 10 | 250 | 545 | 69.9 | 368 | 273 | 184 | 362 | 7.92 | 469.9 | 323.85 | 7.92 | 11.91 | |

| 12 | 300 | 610 | 79.4 | 419 | 323.8 | 200 | 419 | 7.92 | 533.4 | 381 | 7.92 | 11.91 | |

| 14 | 350 | 640 | 85.8 | 451 | 355.6 | 213 | 467 | 11.13 | 558.8 | 419.1 | 11.13 | 16.66 | |

| 16 | 400 | 705 | 88.9 | 508 | 406.4 | 216 | 524 | 11.13 | 616 | 469.9 | 11.13 | 16.66 | |

| 18 | 450 | 785 | 101.6 | 565 | 457 | 229 | 594 | 12.7 | 685.8 | 533.4 | 12.7 | 19.84 | |

| 20 | 500 | 855 | 108 | 622 | 508 | 248 | 648 | 12.7 | 749.3 | 584.2 | 12.7 | 19.84 | |

| 24 | 600 | 1040 | 139.7 | 749 | 610 | 292 | 772 | 15.88 | 901.7 | 692.15 | 15.88 | 26.97 |

ANSI/ASME B16.5 Class 1500 RTJ Flange – Dimensions & Sizes in mm

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

RTJ RF Dia |

RTJ RF Height |

PCD | RTJ Pitch dia |

RTJ Depth |

RTJ Width |

Bore |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| 1/2 | 15 | 120 | 22.3 | 38 | 21.3 | 60 | 60.5 | 6.35 | 82.6 | 39.67 | 6.35 | 8.74 | Welding Neck bore is derived from the pipe schedule |

| 3/4 | 20 | 130 | 25.4 | 44 | 26.7 | 70 | 66.5 | 6.35 | 88.9 | 44.45 | 6.35 | 8.74 | |

| 1 | 25 | 150 | 28.6 | 52 | 33.4 | 73 | 71.5 | 6.35 | 101.6 | 50.8 | 6.35 | 8.74 | |

| 1 1/4 | 32 | 160 | 28.6 | 64 | 42.2 | 73 | 81 | 6.35 | 111.1 | 60.33 | 6.35 | 8.74 | |

| 1 1/2 | 40 | 180 | 31.8 | 70 | 48.3 | 83 | 92 | 6.35 | 123.8 | 68.27 | 6.35 | 8.74 | |

| 2 | 50 | 215 | 38.1 | 105 | 60.3 | 102 | 124 | 7.92 | 165.1 | 95.25 | 7.92 | 11.91 | |

| 2 1/2 | 65 | 245 | 41.3 | 124 | 73 | 105 | 137 | 7.92 | 190.5 | 107.95 | 7.92 | 11.91 | |

| 3 | 80 | 265 | 47.7 | 133 | 88.9 | 117 | 168 | 7.92 | 203.2 | 136.53 | 7.92 | 11.91 | |

| 4 | 100 | 310 | 54 | 162 | 114.3 | 124 | 194 | 7.92 | 241.3 | 161.93 | 7.92 | 11.91 | |

| 5 | 125 | 375 | 73.1 | 197 | 141.3 | 156 | 229 | 7.92 | 292.1 | 193.68 | 7.92 | 11.91 | |

| 6 | 150 | 395 | 82.6 | 229 | 168.3 | 171 | 248 | 9.53 | 317.5 | 211.14 | 9.53 | 13.49 | |

| 8 | 200 | 485 | 92.1 | 292 | 219.1 | 213 | 318 | 11.13 | 393.7 | 269.88 | 11.13 | 16.66 | |

| 10 | 250 | 585 | 108 | 368 | 273 | 254 | 371 | 11.13 | 482.6 | 323.85 | 11.13 | 16.66 | |

| 12 | 300 | 675 | 123.9 | 451 | 323.8 | 283 | 438 | 14.27 | 571.5 | 381 | 14.27 | 23.01 | |

| 14 | 350 | 750 | 133.4 | 495 | 355.6 | 298 | 489 | 15.88 | 635 | 419.1 | 15.88 | 26.97 | |

| 16 | 400 | 825 | 146.1 | 552 | 406.4 | 311 | 546 | 17.48 | 704.8 | 469.9 | 17.48 | 30.18 | |

| 18 | 450 | 915 | 162 | 597 | 457 | 327 | 613 | 17.48 | 774.7 | 533.4 | 17.48 | 30.18 | |

| 20 | 500 | 985 | 177.8 | 641 | 508 | 356 | 673 | 17.48 | 831.8 | 584.2 | 17.48 | 33.32 | |

| 24 | 600 | 1170 | 203.2 | 762 | 610 | 406 | 794 | 20.62 | 990.6 | 692.15 | 20.62 | 36.53 |

ANSI/ASME B16.5 Class 2500 RTJ Flange – Dimensions & Sizes in mm

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thickness |

Hub OD |

Weld Neck OD |

Welding Neck Length |

RTJ RF Dia |

RTJ RF Height |

PCD | RTJ Pitch dia |

RTJ Depth |

RTJ Width |

Bore |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | ||

| 1/2 | 15 | 135 | 30.2 | 43 | 21.3 | 73 | 65 | 6.35 | 88.9 | 42.88 | 6.35 | 8.74 | Welding Neck bore is derived from the pipe schedule |

| 3/4 | 20 | 140 | 31.8 | 51 | 26.7 | 79 | 73 | 6.35 | 95.2 | 50.8 | 6.35 | 8.74 | |

| 1 | 25 | 160 | 35 | 57 | 33.4 | 89 | 82.5 | 6.35 | 108 | 60.33 | 6.35 | 8.74 | |

| 1 1/4 | 32 | 185 | 38.1 | 73 | 42.2 | 95 | 102 | 7.92 | 130.2 | 72.23 | 7.92 | 11.91 | |

| 1 1/2 | 40 | 205 | 44.5 | 79 | 48.3 | 111 | 114 | 7.92 | 146 | 82.55 | 7.92 | 11.91 | |

| 2 | 50 | 235 | 50.9 | 95 | 60.3 | 127 | 133 | 7.92 | 171.4 | 101.6 | 7.92 | 11.91 | |

| 2 1/2 | 65 | 265 | 57.2 | 114 | 73 | 143 | 149 | 9.53 | 196.8 | 111.13 | 9.52 | 13.49 | |

| 3 | 80 | 305 | 66.7 | 133 | 88.9 | 168 | 168 | 9.53 | 228.6 | 127 | 9.52 | 13.49 | |

| 4 | 100 | 355 | 76.2 | 165 | 114.3 | 190 | 203 | 11.13 | 273 | 157.18 | 11.13 | 16.66 | |

| 5 | 125 | 420 | 92.1 | 203 | 141.3 | 229 | 241 | 12.7 | 323.8 | 190.5 | 12.7 | 19.84 | |

| 6 | 150 | 485 | 108 | 235 | 168.3 | 273 | 279 | 12.7 | 368.3 | 228.6 | 12.7 | 19.84 | |

| 8 | 200 | 550 | 127 | 305 | 219.1 | 318 | 340 | 14.27 | 438.2 | 279.4 | 14.27 | 23.01 | |

| 10 | 250 | 675 | 165.1 | 375 | 273 | 419 | 425 | 17.48 | 539.8 | 342.9 | 17.48 | 30.18 | |

| 12 | 300 | 760 | 184.2 | 441 | 323.8 | 464 | 495 | 17.48 | 619.1 | 406.4 | 17.48 | 33.32 |

RTJ Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| Nominal Pipe Size (NPS) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

|---|---|---|---|---|---|---|---|

| ½” | 3.5 | 4.5 | 5.5 | 6.5 | 8.0 | 10.0 | 15.5 |

| ¾” | 4.5 | 6.0 | 7.5 | 9.0 | 12.0 | 16.0 | 22.5 |

| 1” | 6.0 | 7.5 | 9.5 | 12.0 | 16.0 | 21.5 | 31.5 |

| 1¼” | 7.5 | 10.0 | 12.5 | 16.0 | 22.0 | 29.0 | 44.0 |

| 1½” | 9.0 | 12.5 | 15.5 | 20.5 | 28.0 | 38.5 | 58.0 |

| 2” | 12.0 | 17.5 | 21.5 | 28.0 | 40.0 | 55.0 | 85.0 |

| 2½” | 16.0 | 24.0 | 29.0 | 38.0 | 55.0 | 75.0 | 115.0 |

| 3” | 20.5 | 31.5 | 38.0 | 50.0 | 72.0 | 98.0 | 150.0 |

| 4” | 28.0 | 44.0 | 53.0 | 70.0 | 100.0 | 135.0 | 210.0 |

| 5” | 38.0 | 58.0 | 70.0 | 92.0 | 135.0 | 185.0 | 290.0 |

| 6” | 50.0 | 78.0 | 95.0 | 125.0 | 185.0 | 250.0 | 400.0 |

| 8” | 85.0 | 135.0 | 165.0 | 215.0 | 310.0 | 420.0 | 670.0 |

| 10” | 125.0 | 200.0 | 240.0 | 310.0 | 450.0 | 610.0 | 975.0 |

| 12” | 185.0 | 290.0 | 350.0 | 450.0 | 670.0 | 900.0 | 1450.0 |

| 14” | 215.0 | 340.0 | 415.0 | 535.0 | 800.0 | 1080.0 | 1750.0 |

| 16” | 310.0 | 480.0 | 580.0 | 750.0 | 1100.0 | 1500.0 | 2450.0 |

| 18” | 350.0 | 550.0 | 665.0 | 860.0 | 1275.0 | 1730.0 | 2850.0 |

| 20” | 420.0 | 670.0 | 810.0 | 1045.0 | 1550.0 | 2100.0 | 3450.0 |

| 24” | 610.0 | 975.0 | 1175.0 | 1525.0 | 2275.0 | 3075.0 | 5050.0 |

RTJ Flange Tolerances as per ANSI / ASME B16.5, 16.47

| Parameter | Tolerance |

|---|---|

| Groove Depth | ±0.2 mm (±0.008 in) |

| Groove Width | +0.18 mm / -0.0 mm (+0.007 / -0.000 in) |

| Groove Radius | ±0.4 mm (±0.016 in) |

| Groove Finish (Roughness Ra) | 63–125 µin (1.6–3.2 µm) |

| Flange Thickness ≤ 10 in (250 mm) | ±1.5 mm (±0.06 in) |

| Flange Thickness 10–24 in | ±3.0 mm (±0.12 in) |

| Flange Thickness > 24 in | ±4.0 mm (±0.16 in) |

| Bolt Circle Diameter | ±1.5 mm (±0.06 in) |

| Bolt Hole Diameter | +1.0 mm / 0.0 mm (+0.04 in / -0.00 in) |

| Bolt Hole Alignment | Max offset 1.5 mm (0.06 in); holes must straddle flange centerline |

| Outside Diameter (OD) ≤ 24 in | ±1.5 mm (±0.06 in) |

| Outside Diameter (OD) > 24 in | ±3.0 mm (±0.12 in) |

| Groove Concentricity to Bore | ±0.8 mm (±0.03 in) |

| Groove Flatness / Alignment | Max 0.2 mm (0.008 in) |

| Raised Face (if applicable) | Flat within 0.4 mm (0.016 in) across diameter |

| Bevel Angle (Weld Neck RTJ) | 37.5° ± 2.5° |

| Root Face (Weld Neck RTJ) | 1.6 mm ± 0.8 mm |

What are the different gasket types used in RTJ Flanges?

RTJ flanges require special precision-machined gaskets, categorized as:

-

R-Type Ring Gasket

- Available in oval or octagonal cross-section.

- Used in pressures up to 5000 psi.

- Most common type for standard RTJ connections.

-

RX-Type Ring Gasket

- Pressure-energized design.

- Provides tighter sealing under higher pressure than R-type.

- Can handle up to 15,000 psi.

-

BX-Type Ring Gasket

- Specially designed for very high pressures (up to 20,000 psi).

- Provides metal-to-metal sealing without leakage.

- Common in subsea and high-pressure drilling equipment.

How do RTJ Flanges differ from Raised Face (RF) or Flat Face (FF) flanges?

- Sealing Method:

- RTJ uses a metal gasket in a groove.

- RF uses soft/semi-metallic gaskets like spiral wound.

- FF uses full face gaskets for low-pressure service.

- Applications:

- RTJ = High pressure & temperature.

- RF = Medium pressure & temperature.

- FF = Low pressure, water systems, and cast iron equipment.

- Reliability:

- RTJ is the most secure for critical leak-proof operations.

Why are RTJ flanges preferred in critical operations?

RTJ flanges are preferred because they:

- Minimize the risk of hazardous leaks in pipelines.

- Provide reliable performance under cyclic loading (pressure and temperature fluctuations).

- Ensure safety compliance with oil & gas industry standards.

- Reduce downtime with reusable flange bodies.

- Improve system integrity, making them the best choice for offshore and subsea projects.