- Home

- Industrial Flanges

- Blind Flange

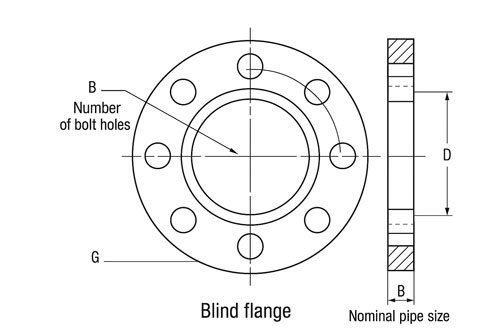

Blind Flange

Blind Flange: Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

ASME B16.5 Blind Flanges – Trusted Manufacturer & Global Exporter in Carbon, Stainless, Alloy & Nickel Alloys | ½”–24”, Class 150–2500 | Delivered to Germany, Canada, Saudi Arabia & Singapore

Best Export Prices: sales@midlandforgefittings.com

At Midland Forge and Fittings Pvt. Ltd., we specialize in manufacturing and exporting top-quality flanges and fittings that meet stringent international standards. With years of experience in forging, machining, and quality control, we have established ourselves as a trusted partner for industries requiring durable and reliable piping components. Our state-of-the-art manufacturing facilities and advanced testing equipment ensure precision, consistency, and compliance with global specifications.

We also focus on continuous innovation and sustainable practices, making our products not only high-performing but also environmentally responsible. Our commitment to excellence ensures that every product leaving our facility, including blind flanges, delivers superior performance and longevity in demanding applications.

Blind Flanges (ASME B16.5) are designed to seal the ends of pipelines, valves, or equipment safely and efficiently. Made from premium materials such as carbon steel, stainless steel, alloy steel, and high nickel alloys, these flanges provide leak-proof sealing while withstanding high pressure and temperature conditions. Unlike other flange types, blind flanges do not have a bore, making them ideal for isolating sections of a pipeline, performing system maintenance, or providing access points for inspection.

BLRF flanges from Midland Forge are widely used across chemical processing plants, refineries, water treatment facilities, power plants, and shipbuilding industries. They offer excellent corrosion resistance, strength, and durability, ensuring safe operation under challenging conditions. Our blind flanges are available in sizes ranging from ½” to 24” and pressure classes from 150# to 2500#, making them suitable for both small and large-scale piping systems. By choosing our products, clients benefit from precise engineering, consistent quality, and timely delivery tailored to global industrial needs.

Blind Pipe Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Blind Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

ANSI/ASME B16.5 Class 150 Blind Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (D) |

Thickness of Flange (B) |

Dia of Raised Face (G) |

No of Bolt Holes |

Dia of Bolt Holes (L) |

Dia of Bolt (inches) |

Dia of Bolt Circle (K) |

|---|---|---|---|---|---|---|---|

| 1/2 | 88.9 | 11.2 | 35.1 | 4 | 15.7 | 1/2 | 60.5 |

| 3/4 | 98.6 | 12.7 | 42.9 | 4 | 15.7 | 1/2 | 69.9 |

| 1 | 108 | 14.2 | 50.8 | 4 | 15.7 | 1/2 | 79.2 |

| 1-1/4 | 117.3 | 15.7 | 63.5 | 4 | 15.7 | 1/2 | 88.9 |

| 1-1/2 | 127 | 17.5 | 73.2 | 4 | 15.7 | 1/2 | 98.6 |

| 2 | 152.4 | 19.1 | 91.9 | 4 | 19.1 | 5/8 | 120.7 |

| 2-1/2 | 177.8 | 22.4 | 104.6 | 4 | 19.1 | 5/8 | 139.7 |

| 3 | 190.5 | 23.9 | 127 | 4 | 19.1 | 5/8 | 152.4 |

| 3-1/2 | 215.9 | 23.9 | 139.7 | 8 | 19.1 | 5/8 | 177.8 |

| 4 | 228.6 | 23.9 | 157.2 | 8 | 19.1 | 5/8 | 190.5 |

| 5 | 254 | 23.9 | 185.7 | 8 | 22.4 | 3/4 | 215.9 |

| 6 | 279.4 | 25.4 | 215.9 | 8 | 22.4 | 3/4 | 241.3 |

| 8 | 342.9 | 28.4 | 269.7 | 8 | 22.4 | 3/4 | 298.5 |

| 10 | 406.4 | 30.2 | 323.9 | 12 | 25.4 | 7/8 | 362 |

| 12 | 482.6 | 31.8 | 381 | 12 | 25.4 | 7/8 | 431.8 |

| 14 | 533.4 | 35.1 | 412.8 | 12 | 28.4 | 1 | 476.3 |

| 16 | 596.9 | 36.6 | 469.9 | 16 | 28.4 | 1 | 539.8 |

| 18 | 635 | 39.6 | 533.4 | 16 | 31.8 | 1-1/8 | 577.9 |

| 20 | 698.5 | 42.9 | 584.2 | 20 | 31.8 | 1-1/8 | 635 |

| 24 | 812.8 | 47.8 | 692.2 | 20 | 35.1 | 1-1/4 | 749.3 |

ANSI/ASME B16.5 Class 300 Blind Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (D) |

Thickness of Flange (B) |

Dia of Raised Face (G) |

No of Bolt Holes |

Dia of Bolt Holes (L) |

Dia of Bolt (inches) |

Dia of Bolt Circle (K) |

|---|---|---|---|---|---|---|---|

| 1/2 | 95.3 | 14.2 | 35.1 | 4 | 15.7 | 1/2 | 66.5 |

| 3/4 | 117.3 | 15.7 | 42.9 | 4 | 19.1 | 1/2 | 82.6 |

| 1 | 124 | 17.5 | 50.8 | 4 | 19.1 | 1/2 | 88.9 |

| 1-1/4 | 133.4 | 19.1 | 63.5 | 4 | 19.1 | 1/2 | 98.6 |

| 1-1/2 | 155.4 | 20.6 | 73.2 | 4 | 22.4 | 1/2 | 114.3 |

| 2 | 165.1 | 22.4 | 91.9 | 8 | 19.1 | 5/8 | 127 |

| 2-1/2 | 190.5 | 25.4 | 104.6 | 8 | 22.4 | 5/8 | 149.4 |

| 3 | 209.6 | 28.4 | 127 | 8 | 22.4 | 5/8 | 168.1 |

| 3-1/2 | 228.6 | 30.2 | 139.7 | 8 | 22.4 | 5/8 | 184.2 |

| 4 | 254 | 31.8 | 157.2 | 8 | 22.4 | 5/8 | 200.2 |

| 5 | 279.4 | 35.1 | 185.7 | 8 | 22.4 | 5/8 | 235 |

| 6 | 317.5 | 36.6 | 215.9 | 12 | 22.4 | 3/4 | 269.7 |

| 8 | 381 | 41.1 | 269.7 | 12 | 25.4 | 3/4 | 330.2 |

| 10 | 444.5 | 47.8 | 323.9 | 16 | 28.4 | 1 | 387.4 |

| 12 | 520.7 | 50.8 | 381 | 16 | 31.8 | 1-1/8 | 450.9 |

| 14 | 584.2 | 53.8 | 412.8 | 20 | 31.8 | 1-1/8 | 514.4 |

| 16 | 647.7 | 57.2 | 469.9 | 20 | 35.1 | 1-1/4 | 571.5 |

| 18 | 711.2 | 60.5 | 533.4 | 24 | 35.1 | 1-1/4 | 628.7 |

| 20 | 774.7 | 63.5 | 584.2 | 24 | 35.1 | 1-1/4 | 685.8 |

| 24 | 914.4 | 69.9 | 692.2 | 24 | 41.1 | 1-1/2 | 812.8 |

ANSI/ASME B16.5 Class 600 Blind Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (D) |

Thickness of Flange (B) |

Dia of Raised Face (G) |

No of Bolt Holes |

Dia of Bolt Holes (L) |

Dia of Bolt (inches) |

Dia of Bolt Circle (K) |

|---|---|---|---|---|---|---|---|

| 1/2 | 95.3 | 14.2 | 35.1 | 4 | 15.7 | 1/2 | 66.5 |

| 3/4 | 117.3 | 15.7 | 42.9 | 4 | 19.1 | 5/8 | 82.6 |

| 1 | 124 | 17.5 | 50.8 | 4 | 19.1 | 5/8 | 88.9 |

| 1-1/4 | 133.4 | 20.6 | 63.5 | 4 | 19.1 | 5/8 | 98.6 |

| 1-1/2 | 155.4 | 22.4 | 73.2 | 4 | 22.4 | 3/4 | 114.3 |

| 2 | 165.1 | 25.4 | 91.9 | 8 | 19.1 | 5/8 | 127 |

| 2-1/2 | 190.5 | 28.4 | 104.6 | 8 | 22.4 | 3/4 | 149.4 |

| 3 | 209.6 | 31.8 | 127 | 8 | 22.4 | 3/4 | 168.1 |

| 3-1/2 | 228.6 | 35.1 | 139.7 | 8 | 25.4 | 7/8 | 184.2 |

| 4 | 273.1 | 38.1 | 157.2 | 8 | 25.4 | 7/8 | 215.9 |

| 5 | 330.2 | 44.5 | 185.7 | 8 | 28.4 | 1 | 266.7 |

| 6 | 355.6 | 47.8 | 215.9 | 12 | 28.4 | 1 | 292.1 |

| 8 | 419.1 | 55.6 | 269.7 | 12 | 31.8 | 1-1/8 | 349.3 |

| 10 | 508 | 63.5 | 323.9 | 16 | 35.1 | 1-1/4 | 431.8 |

| 12 | 558.8 | 66.5 | 381 | 20 | 35.1 | 1-1/4 | 489 |

| 14 | 603.3 | 69.9 | 412.8 | 20 | 38.1 | 1-3/8 | 527.1 |

| 16 | 685.8 | 76.2 | 469.9 | 20 | 41.1 | 1-1/2 | 603.3 |

| 18 | 743 | 82.6 | 533.4 | 20 | 44.5 | 1-5/8 | 654.1 |

| 20 | 812.8 | 88.9 | 584.2 | 24 | 44.5 | 1-5/8 | 723.9 |

| 24 | 939.8 | 101.6 | 692.2 | 24 | 50.8 | 1-7/8 | 838.2 |

ANSI/ASME B16.5 Class 900 Blind Flange – Dimensions & Sizes in mm

| Nominal Pipe Size | OD of Flange (D) | Thickness of Flange (B) | Dia of Raised Face (G) | No of Bolt Holes | Dia of Bolt Holes (L) | Dia of Bolt (inches) | Dia of Bolt Circle (K) |

|---|---|---|---|---|---|---|---|

| 1/2 | 120.7 | 22.4 | 35.1 | 4 | 22.4 | 3/4 | 82.6 |

| 3/4 | 130 | 25.4 | 42.9 | 4 | 22.4 | 3/4 | 88.9 |

| 1 | 149.4 | 28.4 | 50.8 | 4 | 25.4 | 7/8 | 101.6 |

| 1-1/4 | 158.8 | 28.4 | 63.5 | 4 | 25.4 | 1 | 111.3 |

| 1-1/2 | 177.8 | 31.8 | 73.2 | 4 | 28.4 | 1-1/8 | 124 |

| 2 | 215.9 | 38.1 | 91.9 | 8 | 25.4 | 1 | 165.1 |

| 2-1/2 | 244.3 | 41.1 | 104.6 | 8 | 28.4 | 1-1/8 | 190.5 |

| 3 | 241.3 | 38.1 | 127 | 8 | 25.4 | 7/8 | 190.5 |

| 4 | 292.1 | 44.5 | 157.2 | 8 | 31.8 | 1-1/8 | 235 |

| 5 | 349.3 | 50.8 | 185.7 | 8 | 35.1 | 1-1/4 | 279.4 |

| 6 | 381 | 55.6 | 215.9 | 12 | 31.8 | 1-1/8 | 317.5 |

| 8 | 469.9 | 63.5 | 269.7 | 12 | 38.1 | 1-3/8 | 393.7 |

| 10 | 546.1 | 69.9 | 323.9 | 16 | 38.1 | 1-3/8 | 469.9 |

| 12 | 609.6 | 79.2 | 381 | 20 | 38.1 | 1-3/8 | 533.4 |

| 14 | 641.4 | 85.9 | 412.8 | 20 | 41.1 | 1-1/2 | 558.8 |

| 16 | 704.9 | 88.9 | 469.9 | 20 | 44.5 | 1-5/8 | 616 |

| 18 | 787.4 | 101.6 | 533.4 | 20 | 50.8 | 1-7/8 | 685.8 |

| 20 | 857.3 | 108 | 584.2 | 20 | 53.8 | 2 | 749.3 |

| 24 | 1041.4 | 139.7 | 692.2 | 20 | 66.5 | 2-1/2 | 901.7 |

ANSI/ASME B16.5 Class 1500 Blind Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (D) |

Thickness of Flange (B) |

Dia of Raised Face (G) |

No of Bolt Holes |

Dia of Bolt Holes (L) |

Dia of Bolt (inches) |

Dia of Bolt Circle (K) |

|---|---|---|---|---|---|---|---|

| 1/2 | 120.7 | 22.4 | 35.1 | 4 | 22.4 | 3/4 | 82.6 |

| 3/4 | 130 | 25.4 | 42.9 | 4 | 22.4 | 3/4 | 88.9 |

| 1 | 149.4 | 28.4 | 50.8 | 4 | 25.4 | 7/8 | 101.6 |

| 1-1/4 | 158.8 | 28.4 | 63.5 | 4 | 25.4 | 1 | 111.3 |

| 1-1/2 | 177.8 | 31.8 | 73.2 | 4 | 28.4 | 1-1/8 | 124 |

| 2 | 215.9 | 38.1 | 91.9 | 8 | 25.4 | 1 | 165.1 |

| 2-1/2 | 244.3 | 41.1 | 104.6 | 8 | 28.4 | 1-1/8 | 190.5 |

| 3 | 266.7 | 47.8 | 127 | 8 | 31.8 | 1-1/4 | 203.2 |

| 4 | 311.2 | 53.8 | 157.2 | 8 | 35.1 | 1-1/2 | 241.3 |

| 5 | 374.7 | 73.2 | 185.7 | 8 | 41.1 | 1-3/4 | 292.1 |

| 6 | 393.7 | 82.6 | 215.9 | 12 | 38.1 | 2 | 317.5 |

| 8 | 482.6 | 91.9 | 269.7 | 12 | 44.5 | 2 | 393.7 |

| 10 | 584.2 | 108 | 323.9 | 12 | 50.8 | 2-1/2 | 482.6 |

| 12 | 673.1 | 124 | 381 | 16 | 53.8 | 2-3/4 | 571.5 |

| 14 | 749.3 | 133.4 | 412.8 | 16 | 60.5 | 2-1/4 | 635 |

| 16 | 825.5 | 146.1 | 469.9 | 16 | 66.5 | 2-1/2 | 704.9 |

| 18 | 914.4 | 162.1 | 533.4 | 16 | 73.2 | 2-3/4 | 774.7 |

| 20 | 984.3 | 177.8 | 584.2 | 16 | 79.2 | 3 | 831.9 |

| 24 | 1168.4 | 203.2 | 692.2 | 16 | 91.9 | 3-1/2 | 990.6 |

ANSI/ASME B16.5 Class 2500 Blind Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (D) |

Thickness of Flange (B) |

Dia of Raised Face (G) |

No of Bolt Holes |

Dia of Bolt Holes (L) |

Dia of Bolt (inches) |

Dia of Bolt Circle (K) |

|---|---|---|---|---|---|---|---|

| 1/2 | 133.4 | 30.2 | 35.1 | 4 | 22.4 | 3/4 | 88.9 |

| 3/4 | 139.7 | 31.8 | 42.9 | 4 | 22.4 | 3/4 | 95.3 |

| 1 | 158.8 | 35.1 | 50.8 | 4 | 25.4 | 7/8 | 108 |

| 1-1/4 | 184.2 | 38.1 | 63.5 | 4 | 28.4 | 1 | 130 |

| 1-1/2 | 203.2 | 44.5 | 73.2 | 4 | 31.8 | 1-1/8 | 146.1 |

| 2 | 235 | 50.8 | 91.9 | 8 | 28.4 | 1 | 171.5 |

| 2-1/2 | 266.7 | 57.2 | 104.6 | 8 | 31.8 | 1-1/8 | 196.9 |

| 3 | 304.8 | 66.5 | 127 | 8 | 35.1 | 1-1/4 | 228.6 |

| 4 | 355.6 | 76.2 | 157.2 | 8 | 41.1 | 1-1/2 | 273.1 |

| 5 | 419.1 | 91.9 | 185.7 | 8 | 47.8 | 1-3/4 | 323.9 |

| 6 | 482.6 | 108 | 215.9 | 8 | 53.8 | 2 | 368.3 |

| 8 | 552.5 | 127 | 269.7 | 12 | 53.8 | 2 | 438.2 |

| 10 | 673.1 | 165.1 | 323.9 | 12 | 66.5 | 2-1/2 | 539.8 |

| 12 | 762 | 184.2 | 381 | 12 | 73.2 | 2-3/4 | 619.3 |

Blind Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| Nominal Pipe Size (NPS) | 150# | 300# | 600# | 900# | 1500# | 2500# |

|---|---|---|---|---|---|---|

| ½” | 1.5 | 2.5 | 3.5 | 4.5 | 5.5 | 7.0 |

| ¾” | 2.0 | 3.2 | 4.5 | 5.5 | 6.8 | 8.5 |

| 1″ | 2.5 | 4.0 | 5.5 | 7.0 | 8.5 | 11.0 |

| 1 ½” | 4.5 | 7.0 | 9.5 | 12.0 | 15.0 | 19.5 |

| 2″ | 6.0 | 9.5 | 13.0 | 16.0 | 20.0 | 26.0 |

| 3″ | 10.5 | 17.0 | 23.5 | 30.0 | 37.5 | 48.0 |

| 4″ | 15.0 | 24.0 | 33.0 | 42.0 | 52.0 | 68.0 |

| 6″ | 25.0 | 42.0 | 58.0 | 75.0 | 93.0 | 122.0 |

| 8″ | 40.0 | 67.0 | 92.0 | 118.0 | 150.0 | 195.0 |

| 10″ | 60.0 | 102.0 | 140.0 | 180.0 | 230.0 | 300.0 |

| 12″ | 85.0 | 145.0 | 200.0 | 260.0 | 330.0 | 435.0 |

| 14″ | 110.0 | 188.0 | 260.0 | 340.0 | 430.0 | 565.0 |

| 16″ | 140.0 | 240.0 | 330.0 | 430.0 | 540.0 | 710.0 |

| 18″ | 175.0 | 300.0 | 420.0 | 545.0 | 680.0 | 890.0 |

| 20″ | 210.0 | 360.0 | 500.0 | 650.0 | 810.0 | 1060.0 |

| 24″ | 300.0 | 520.0 | 730.0 | 950.0 | 1180.0 | 1550.0 |

Blind Flange Tolerances as per ANSI / ASME B16.5, 16.47

| Parameter | Tolerance | Reference Standard |

|---|---|---|

| Outside Diameter (OD) of Flange | ± 1.5 mm (up to 24”) / ± 3.0 mm (above 24”) | ASME B16.5 / B16.47 |

| Bolt Circle Diameter (K) | ± 1.5 mm | ASME B16.5 / B16.47 |

| Bolt Hole Diameter | +1.5 mm / 0 | ASME B16.5 / B16.47 |

| Bolt Hole Center-to-Center | ± 1.0 mm | ASME B16.5 / B16.47 |

| Raised Face Diameter (G) | ± 1.0 mm | ASME B16.5 |

| Flange Thickness (B) | ± 1.5 mm (up to 24”) / ± 3.0 mm (above 24”) | ASME B16.5 / B16.47 |

| Flatness of Flange Facing | ≤ 0.5 mm (NPS ≤ 24”) / ≤ 1.0 mm (NPS > 24”) | ASME B16.5 / B16.47 |

| Concentricity of Bore to OD | ≤ 1.5 mm | ASME B16.5 |

| Runout of Raised Face | ≤ 0.5 mm (NPS ≤ 24”) / ≤ 1.0 mm (NPS > 24”) | ASME B16.5 / B16.47 |

How are Blind Flanges installed and aligned?

Step 1 – Pipe/Nozzle Preparation:

Ensure the end of the pipe or nozzle is square cut, cleaned, and free from burrs.

Check the mating flange or pad for flatness.

Step 2 – Gasket Placement:

Select a gasket compatible with pressure, temperature, and fluid type (metallic or non-metallic).

Place the gasket between the flange faces.

Step 3 – Flange Alignment:

Position the blind flange to align bolt holes precisely with the mating flange or nozzle pad.

Large-diameter flanges may require lifting equipment for precise placement.

Step 4 – Bolting:

Tighten bolts in a cross or star pattern to ensure uniform load distribution.

Use torque wrenches to meet pressure-class specifications.

Step 5 – Inspection:

Check flange flatness, bolt load, and gasket compression to prevent leakage under operational conditions.

What are the advantages of using Blind Flanges?

Pressure Resistance: Designed to withstand high-pressure systems up to 2500# as per ASME B16.5 / B16.47 standards.

Versatility: Can be used with all flange types – Weld Neck, Slip-On, Socket Weld, Threaded, Lap Joint.

Material Savings: In corrosive systems, the flange can be made from cost-effective materials, while the sealing face can be made from corrosion-resistant alloys.

Ease of Maintenance: Provides a removable closure for pipeline ends, allowing inspections or modifications without dismantling other parts of the system.

Leak Prevention: When installed correctly with a suitable gasket, it provides a 100% tight seal against high-pressure fluid leakage.

What are the limitations of Blind Flanges?

-

No Flow Passage: Cannot carry fluid; purely for end closure.

-

High Weight: Large-diameter or high-pressure blind flanges can be extremely heavy, requiring lifting equipment and careful handling.

-

Not Suitable for Dynamic Loads: Systems with vibration, cyclic pressure, or thermal expansion may require Weld Neck or Socket Weld flanges instead.

-

Bolt Sensitivity: Uneven bolting can lead to flange distortion, gasket failure, or leakage, especially in Class 1500# and 2500# flanges.