- Home

- Industrial Flanges

- Lap Joint Flange

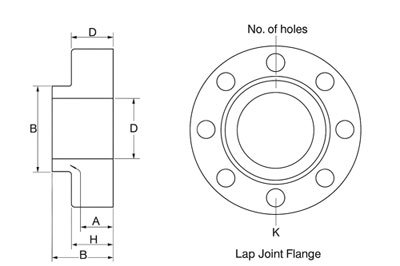

Lap Joint Flange

Lap Joint Flange: Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Lap Joint Flanges (ASME B16.5) – Trusted Manufacturer & Global Exporter in Carbon, Stainless, Alloy & Nickel Alloys | ½”–24”, Class 150–2500 | Delivered to USA, France, UAE & Qatar

Best Export Prices: sales@midlandforgefittings.com

At Midland Forge and Fittings Pvt. Ltd., we take pride in being a trusted manufacturer and exporter of premium-quality lap joint flanges that meet the highest standards of precision, durability, and reliability. With years of expertise in forging and machining, our company has built a strong reputation for delivering products that comply with strict international norms.

Our Lap Joint Flanges are designed to be used with a stub end and are ideal for pipelines that require frequent dismantling, inspection, or cleaning. Unlike other flange types, the lap joint flange does not come into direct contact with the process fluid, which makes it an economical choice where corrosion resistance is critical. This unique design also allows easy alignment during installation, saving both time and effort.

By combining quality raw materials with advanced manufacturing techniques, we produce lap joint flanges in carbon steel, stainless steel, alloy steel, and high nickel alloys, ensuring suitability across a wide range of industries. These flanges are extensively used in chemical processing plants, refineries, shipbuilding, water treatment facilities, pharmaceuticals, and food processing units. With the ability to handle demanding pressure and temperature conditions, our products offer both strength and long-term performance.

we are committed to supplying reliable piping solutions backed by strict quality checks, timely delivery, and a customer-first approach. Our lap joint flanges continue to be a preferred choice for clients across the globe who value both efficiency and cost-effectiveness in their piping systems.

Lap Joint Pipe Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Lap Joint Flange – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

ANSI/ASME B16.5 Class 150 Lap Joint Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

Outside diameter of flange (D) |

Thick of flange (B) |

Diameter of Hub at base (A) |

Length thru Hub (H) |

Dia of bore (ID) |

Fillet radius (r) |

No of holes |

Dia of holes (L) |

Dia of bolts |

Diam of bolt circle (K) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 88.9 | 11.2 | 30.2 | 15.7 | 22.9 | 3 | 4 | 15.7 | 1/2 | 60.5 |

| 3/4 | 98.6 | 12.7 | 38.1 | 15.7 | 28.2 | 3 | 4 | 15.7 | 1/2 | 69.9 |

| 1 | 108 | 14.2 | 49.3 | 17.5 | 35.1 | 3 | 4 | 15.7 | 1/2 | 79.2 |

| 1-1/4 | 117.3 | 15.7 | 58.7 | 20.6 | 43.7 | 4.8 | 4 | 15.7 | 1/2 | 88.9 |

| 1-1/2 | 127 | 17.5 | 65 | 22.4 | 50 | 6.4 | 4 | 15.7 | 1/2 | 98.6 |

| 2 | 152.4 | 19.1 | 77.7 | 25.4 | 62.5 | 7.9 | 4 | 19.1 | 5/8 | 120.7 |

| 2-1/2 | 177.8 | 22.4 | 90.4 | 28.4 | 75.4 | 7.9 | 4 | 19.1 | 5/8 | 139.7 |

| 3 | 190.5 | 23.9 | 108 | 30.2 | 91.4 | 9.7 | 4 | 19.1 | 5/8 | 152.4 |

| 3-1/2 | 215.9 | 23.9 | 122.2 | 31.8 | 104.1 | 9.7 | 8 | 19.1 | 5/8 | 177.8 |

| 4 | 228.6 | 23.9 | 134.9 | 33.3 | 116.8 | 11.2 | 8 | 19.1 | 5/8 | 190.5 |

| 5 | 254 | 23.9 | 163.6 | 36.6 | 144.5 | 11.2 | 8 | 22.4 | 3/4 | 215.9 |

| 6 | 279.4 | 25.4 | 192 | 39.6 | 171.5 | 12.7 | 8 | 22.4 | 3/4 | 241.3 |

| 8 | 342.9 | 28.4 | 246.1 | 44.5 | 222.3 | 12.7 | 8 | 22.4 | 3/4 | 298.5 |

| 10 | 406.4 | 30.2 | 304.8 | 49.3 | 277.4 | 12.7 | 12 | 25.4 | 7/8 | 362 |

| 12 | 482.6 | 31.8 | 365.3 | 55.6 | 328.2 | 12.7 | 12 | 25.4 | 7/8 | 431.8 |

| 14 | 533.4 | 35.1 | 400.1 | 79.2 | 360.2 | 12.7 | 12 | 28.4 | 1 | 476.3 |

| 16 | 596.9 | 36.6 | 457.2 | 87.4 | 411.2 | 12.7 | 16 | 28.4 | 1 | 539.8 |

| 18 | 635 | 39.6 | 505 | 96.8 | 462.3 | 12.7 | 20 | 31.8 | 1-1/8 | 577.9 |

| 20 | 698.5 | 42.9 | 558.8 | 103.1 | 514.4 | 12.7 | 20 | 31.8 | 1-1/8 | 635 |

| 24 | 812.8 | 47.8 | 663.4 | 111.3 | 616 | 12.7 | 20 | 35.1 | 1-1/4 | 749.3 |

ANSI/ASME B16.5 Class 300 Lap Joint Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

Outside diameter of flange (D) |

Thick of flange (B) |

Diameter of Hub at base (A) |

Length thru Hub (H) |

Dia of bore (ID) |

Fillet radius (r) |

No of holes |

Dia of holes (L) |

Dia of bolts |

Diam of bolt circle (K) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 95.3 | 14.2 | 38.1 | 22.4 | 22.9 | 3 | 4 | 15.7 | 1/2 | 66.5 |

| 3/4 | 117.3 | 15.7 | 47.8 | 25.4 | 28.2 | 3 | 4 | 19.1 | 5/8 | 82.6 |

| 1 | 124 | 17.5 | 53.8 | 26.9 | 35.1 | 3 | 4 | 19.1 | 5/8 | 88.9 |

| 1-1/4 | 133.4 | 19.1 | 63.5 | 26.9 | 43.7 | 4.8 | 4 | 19.1 | 5/8 | 98.6 |

| 1-1/2 | 155.4 | 20.6 | 69.9 | 30.2 | 50 | 6.4 | 4 | 22.4 | 3/4 | 114.3 |

| 2 | 165.1 | 22.4 | 84.1 | 33.3 | 62.5 | 7.9 | 8 | 19.1 | 5/8 | 127 |

| 2-1/2 | 190.5 | 25.4 | 100.1 | 38.1 | 75.4 | 7.9 | 8 | 22.4 | 3/4 | 149.4 |

| 3 | 209.6 | 28.4 | 117.3 | 42.9 | 91.4 | 9.7 | 8 | 22.4 | 3/4 | 168.1 |

| 3-1/2 | 228.6 | 30.2 | 133.4 | 44.5 | 104.1 | 9.7 | 8 | 22.4 | 3/4 | 184.2 |

| 4 | 254 | 31.8 | 146.1 | 47.8 | 116.8 | 11.2 | 8 | 22.4 | 3/4 | 200.2 |

| 5 | 279.4 | 35.1 | 177.8 | 50.8 | 144.5 | 11.2 | 8 | 22.4 | 3/4 | 235 |

| 6 | 317.5 | 36.6 | 206.2 | 52.3 | 171.5 | 12.7 | 12 | 22.4 | 3/4 | 269.7 |

| 8 | 381 | 41.1 | 260.4 | 62 | 222.3 | 12.7 | 12 | 25.4 | 7/8 | 330.2 |

| 10 | 444.5 | 47.8 | 320.5 | 95.3 | 277.4 | 12.7 | 16 | 28.4 | 1 | 387.4 |

| 12 | 520.7 | 50.8 | 374.7 | 101.6 | 328.2 | 12.7 | 16 | 31.8 | 1-1/8 | 450.9 |

| 14 | 584.2 | 53.8 | 425.5 | 111.3 | 360.2 | 12.7 | 20 | 31.8 | 1-1/8 | 514.4 |

| 16 | 647.7 | 57.2 | 482.6 | 120.7 | 411.2 | 12.7 | 20 | 35.1 | 1-1/4 | 571.5 |

| 18 | 711.2 | 60.5 | 533.4 | 130 | 462.3 | 12.7 | 24 | 35.1 | 1-1/4 | 628.7 |

| 20 | 774.7 | 63.5 | 587.2 | 139.7 | 514.4 | 12.7 | 24 | 35.1 | 1-1/4 | 685.8 |

| 24 | 914.4 | 69.9 | 701.5 | 152.4 | 616 | 12.7 | 24 | 41.1 | 1-1/4 | 812.8 |

ANSI/ASME B16.5 Class 600 Lap Joint Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

Outside diameter of flange (D) |

Thick of flange (B) |

Diameter of Hub at base (A) |

Length thru Hub (H) |

Dia of bore (ID) |

Fillet radius (r) |

No of holes |

Dia of holes (L) |

Dia of bolts |

Diam of bolt circle (K) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 95.3 | 14.2 | 38.1 | 22.4 | 22.9 | 3 | 4 | 15.7 | 1/2 | 66.5 |

| 3/4 | 117.3 | 15.7 | 47.8 | 25.4 | 28.2 | 3 | 4 | 19.1 | 5/8 | 82.6 |

| 1 | 124 | 17.5 | 53.8 | 26.9 | 35.1 | 3 | 4 | 19.1 | 5/8 | 88.9 |

| 1-1/4 | 133.4 | 20.6 | 63.5 | 28.4 | 43.7 | 4.8 | 4 | 19.1 | 5/8 | 98.6 |

| 1-1/2 | 155.4 | 22.4 | 69.9 | 31.8 | 50 | 6.4 | 4 | 22.4 | 3/4 | 114.3 |

| 2 | 165.1 | 25.4 | 84.1 | 36.6 | 62.5 | 7.9 | 8 | 19.1 | 5/8 | 127 |

| 2-1/2 | 190.5 | 28.4 | 100.1 | 41.1 | 75.4 | 7.9 | 8 | 22.4 | 3/4 | 149.4 |

| 3 | 209.6 | 31.8 | 117.3 | 46 | 91.4 | 9.7 | 8 | 22.4 | 3/4 | 168.1 |

| 3-1/2 | 228.6 | 35.1 | 133.4 | 49.3 | 104.1 | 9.7 | 8 | 25.4 | 7/8 | 184.2 |

| 4 | 273.1 | 38.1 | 152.4 | 53.8 | 116.8 | 11.2 | 8 | 25.4 | 7/8 | 215.9 |

| 5 | 330.2 | 44.5 | 189 | 60.5 | 144.5 | 11.2 | 8 | 28.4 | 1 | 266.7 |

| 6 | 355.6 | 47.8 | 222.3 | 66.5 | 171.5 | 12.7 | 12 | 28.4 | 1 | 292.1 |

| 8 | 419.1 | 55.6 | 273.1 | 76.2 | 222.3 | 12.7 | 12 | 31.8 | 1-1/8 | 349.3 |

| 10 | 508 | 63.5 | 342.9 | 111.3 | 277.4 | 12.7 | 16 | 35.1 | 1-1/4 | 431.8 |

| 12 | 558.8 | 66.5 | 400.1 | 117.3 | 328.2 | 12.7 | 20 | 35.1 | 1-1/4 | 489 |

| 14 | 603.3 | 69.9 | 431.8 | 127 | 360.2 | 12.7 | 20 | 38.1 | 1-3/8 | 527.1 |

| 16 | 685.8 | 76.2 | 495.3 | 139.7 | 411.2 | 12.7 | 20 | 41.1 | 1-1/2 | 603.3 |

| 18 | 743 | 82.6 | 546.1 | 152.4 | 462.3 | 12.7 | 20 | 44.5 | 1-5/8 | 654.1 |

| 20 | 812.8 | 88.9 | 609.6 | 165.1 | 514.4 | 12.7 | 24 | 44.5 | 1-5/8 | 723.9 |

| 24 | 939.8 | 101.6 | 717.6 | 184.2 | 616 | 12.7 | 24 | 50.8 | 1-7/8 | 838.2 |

ANSI/ASME B16.5 Class 900 Lap Joint Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

Outside diameter of flange (D) |

Thick of flange (B) |

Diameter of Hub at base (A) |

Length thru Hub (H) |

Dia of bore (ID) |

Fillet radius (r) |

No of holes |

Dia of holes (L) |

Dia of bolts |

Diam of bolt circle (K) |

Approx weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 120.7 | 22.4 | 38.1 | 31.8 | 22.9 | 3 | 4 | 22.4 | 3/4 | 82.6 | 2 |

| 3/4 | 130 | 25.4 | 44.5 | 35.1 | 28.2 | 3 | 4 | 22.4 | 3/4 | 88.9 | 2 |

| 1 | 149.4 | 28.4 | 52.3 | 41.1 | 35.1 | 3 | 4 | 25.4 | 7/8 | 101.6 | 4 |

| 1-1/4 | 158.8 | 28.4 | 63.5 | 41.1 | 43.7 | 4.8 | 4 | 25.4 | 7/8 | 111.3 | 4 |

| 1-1/2 | 177.8 | 31.8 | 69.9 | 44.5 | 50 | 6.4 | 4 | 28.4 | 1 | 124 | 5 |

| 2 | 215.9 | 38.1 | 104.6 | 57.2 | 62.5 | 7.9 | 8 | 25.4 | 7/8 | 165.1 | 11 |

| 2-1/2 | 244.3 | 41.1 | 124 | 63.5 | 75.4 | 7.9 | 8 | 28.4 | 1 | 190.5 | 16 |

| 3 | 241.3 | 38.1 | 127 | 53.8 | 91.4 | 9.7 | 8 | 25.4 | 7/8 | 190.5 | 11 |

| 4 | 292.1 | 44.5 | 158.8 | 69.9 | 116.8 | 11.2 | 8 | 31.8 | 1-1/8 | 235 | 23 |

| 5 | 349.3 | 50.8 | 190.5 | 79.2 | 144.5 | 11.2 | 8 | 35.1 | 1-1/4 | 279.4 | 37 |

| 6 | 381 | 55.6 | 235 | 85.9 | 171.5 | 12.7 | 12 | 31.8 | 1-1/8 | 317.5 | 48 |

| 8 | 469.9 | 63.5 | 298.5 | 114.3 | 222.3 | 12.7 | 12 | 38.1 | 1-3/8 | 393.7 | 86 |

| 10 | 546.1 | 69.9 | 368.3 | 127 | 277.4 | 12.7 | 16 | 38.1 | 1-3/8 | 469.9 | 125 |

| 12 | 609.6 | 79.2 | 419.1 | 142.7 | 328.2 | 12.7 | 20 | 38.1 | 1-3/8 | 533.4 | 168 |

| 14 | 641.4 | 85.9 | 450.9 | 155.4 | 360.2 | 12.7 | 20 | 41.1 | 1-1/2 | 558.8 | 188 |

| 16 | 704.9 | 88.9 | 508 | 165.1 | 411.2 | 12.7 | 20 | 44.5 | 1-5/8 | 616 | 211 |

| 18 | 787.4 | 101.6 | 565.2 | 190.5 | 462.3 | 12.7 | 20 | 50.8 | 1-7/8 | 685.8 | 295 |

| 20 | 857.3 | 108 | 622.3 | 209.6 | 514.4 | 12.7 | 20 | 53.8 | 2 | 749.3 | 367 |

| 24 | 1041.4 | 139.7 | 749.3 | 266.7 | 616 | 12.7 | 20 | 66.5 | 2-1/2 | 901.7 | 703 |

ANSI/ASME B16.5 Class 1500 Lap Joint Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

Outside diameter of flange (D) |

Thick of flange (B) |

Diameter of Hub at base (A) |

Length thru Hub (H) |

Dia of bore (ID) |

Fillet radius (r) |

No of holes |

Dia of holes (L) |

Dia of bolts |

Diam of bolt circle (K) |

Approx weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 120.7 | 22.4 | 38.1 | 31.8 | 22.9 | 3 | 4 | 22.4 | 3/4 | 82.6 | 2 |

| 3/4 | 130 | 25.4 | 44.5 | 35.1 | 28.2 | 3 | 4 | 22.4 | 3/4 | 88.9 | 2 |

| 1 | 149.4 | 28.4 | 52.3 | 41.1 | 35.1 | 3 | 4 | 25.4 | 7/8 | 101.6 | 4 |

| 1-1/4 | 158.8 | 28.4 | 63.5 | 41.1 | 43.7 | 4.8 | 4 | 25.4 | 7/8 | 111.3 | 4 |

| 1-1/2 | 177.8 | 31.8 | 69.9 | 44.5 | 50 | 6.4 | 4 | 28.4 | 1 | 124 | 5 |

| 2 | 215.9 | 38.1 | 104.6 | 57.2 | 62.5 | 7.9 | 8 | 25.4 | 7/8 | 165.1 | 11 |

| 2-1/2 | 244.3 | 41.1 | 124 | 63.5 | 75.4 | 7.9 | 8 | 28.4 | 1 | 190.5 | 16 |

| 3 | 266.7 | 47.8 | 133.4 | 73.2 | 91.4 | 9.7 | 8 | 31.8 | 1-1/8 | 203.2 | 21 |

| 4 | 311.2 | 53.8 | 162.1 | 90.4 | 116.8 | 11.2 | 8 | 35.1 | 1-1/4 | 241.3 | 34 |

| 5 | 374.7 | 73.2 | 196.9 | 104.6 | 144.5 | 11.2 | 8 | 41.1 | 1-1/2 | 292.1 | 64 |

| 6 | 393.7 | 82.6 | 228.6 | 119.1 | 171.5 | 12.7 | 12 | 38.1 | 1-3/8 | 317.5 | 77 |

| 8 | 482.6 | 91.9 | 292.1 | 142.7 | 222.3 | 12.7 | 12 | 44.5 | 1-5/8 | 393.7 | 129 |

| 10 | 584.2 | 108 | 368.3 | 177.8 | 277.4 | 12.7 | 12 | 50.8 | 1-7/8 | 482.6 | 220 |

| 12 | 673.1 | 124 | 450.9 | 218.9 | 328.2 | 12.7 | 16 | 53.8 | 2 | 571.5 | 286 |

| 14 | 749.3 | 133.4 | 495.3 | 241.3 | 360.2 | 12.7 | 16 | 60.5 | 2-1/4 | 635 | 404 |

| 16 | 825.5 | 146.1 | 552.5 | 260.4 | 411.2 | 12.7 | 16 | 66.5 | 2-1/2 | 704.9 | 476 |

| 18 | 914.4 | 162.1 | 596.9 | 276.4 | 462.3 | 12.7 | 16 | 73.2 | 2-3/4 | 774.7 | 669 |

| 20 | 984.3 | 177.8 | 641.4 | 292.1 | 514.4 | 12.7 | 16 | 79.2 | 3 | 831.9 | 805 |

| 24 | 1168.4 | 203.2 | 762 | 330.2 | 616 | 12.7 | 16 | 91.9 | 3-1/2 | 990.6 | 1281 |

ANSI/ASME B16.5 Class 2500 Lap Joint Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

Outside diameter of flange (D) |

Thick of flange (B) |

Diameter of Hub at base (A) |

Length thru Hub (H) |

Dia of bore (ID) |

Fillet radius (r) |

No of holes |

Dia of holes (L) |

Dia of bolts |

Diam of bolt circle (K) |

Approx weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 133.4 | 30.2 | 42.9 | 39.6 | 22.9 | 3 | 4 | 22.4 | 3/4 | 88.9 | 3 |

| 3/4 | 139.7 | 31.8 | 50.8 | 42.9 | 28.2 | 3 | 4 | 22.4 | 3/4 | 95.3 | 4 |

| 1 | 158.8 | 35.1 | 57.2 | 47.8 | 35.1 | 3 | 4 | 25.4 | 7/8 | 108 | 5 |

| 1-1/4 | 184.2 | 38.1 | 73.2 | 52.3 | 43.7 | 4.8 | 4 | 28.4 | 1 | 130 | 7 |

| 1-1/2 | 203.2 | 44.5 | 79.2 | 60.5 | 50 | 6.4 | 4 | 31.8 | 1-1/8 | 146.1 | 10 |

| 2 | 235 | 50.8 | 95.3 | 69.9 | 62.5 | 7.9 | 8 | 28.4 | 1 | 171.5 | 17 |

| 2-1/2 | 266.7 | 57.2 | 114.3 | 79.2 | 75.4 | 7.9 | 8 | 31.8 | 1-1/8 | 196.9 | 24 |

| 3 | 304.8 | 66.5 | 133.4 | 91.9 | 91.4 | 9.7 | 8 | 35.1 | 1-1/4 | 228.6 | 36 |

| 4 | 355.6 | 76.2 | 165.1 | 108 | 116.8 | 11.2 | 8 | 41.1 | 1-1/2 | 273.1 | 54 |

| 5 | 419.1 | 91.9 | 203.2 | 130 | 144.5 | 11.2 | 8 | 47.8 | 1-3/4 | 323.9 | 93 |

| 6 | 482.6 | 108 | 235 | 152.4 | 171.5 | 12.7 | 8 | 53.8 | 2 | 368.3 | 143 |

| 8 | 552.5 | 127 | 304.8 | 177.8 | 222.3 | 12.7 | 12 | 53.8 | 2 | 438.2 | 213 |

| 10 | 673.1 | 165.1 | 374.7 | 228.6 | 277.4 | 12.7 | 12 | 66.5 | 2-1/2 | 539.8 | 408 |

| 12 | 762 | 184.2 | 441.5 | 254 | 328.2 | 12.7 | 12 | 73.2 | 2-3/4 | 619.3 | 499 |

Lap Joint Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| Nominal Pipe Size (NPS) | 150# | 300# | 600# | 900# | 1500# | 2500# |

|---|---|---|---|---|---|---|

| ½” | 1.2 | 2.0 | 2.8 | 3.4 | 4.0 | 5.2 |

| ¾” | 1.5 | 2.4 | 3.2 | 3.9 | 4.8 | 6.5 |

| 1″ | 1.9 | 3.0 | 3.9 | 4.8 | 6.0 | 8.0 |

| 1 ½” | 3.2 | 5.0 | 6.8 | 8.5 | 10.5 | 14.0 |

| 2″ | 4.0 | 6.5 | 8.8 | 11.0 | 13.5 | 18.0 |

| 3″ | 6.8 | 10.5 | 14.0 | 17.5 | 22.0 | 29.5 |

| 4″ | 9.5 | 15.0 | 20.5 | 25.5 | 32.0 | 43.5 |

| 6″ | 15.5 | 24.5 | 34.0 | 43.0 | 54.0 | 74.0 |

| 8″ | 24.0 | 38.5 | 52.0 | 67.0 | 85.0 | 116.0 |

| 10″ | 35. |

Lap Joint Flange Tolerances as per ANSI / ASME B16.5, 16.47

| Parameter | Tolerance | Reference Standard |

|---|---|---|

| Outside Diameter (OD) of Flange | ± 1.5 mm (up to 24”) / ± 3.0 mm (above 24”) | ASME B16.5 / B16.47 |

| Bolt Circle Diameter (K) | ± 1.5 mm | ASME B16.5 / B16.47 |

| Bolt Hole Diameter | +1.5 mm / 0 | ASME B16.5 / B16.47 |

| Bolt Hole Center-to-Center | ± 1.0 mm | ASME B16.5 / B16.47 |

| Raised Face Diameter (G) | ± 1.0 mm | ASME B16.5 |

| Hub Bore Diameter (ID) | +1.0 mm / 0 | ASME B16.5 |

| Flange Thickness (B) | ± 1.5 mm (up to 24”) / ± 3.0 mm (above 24”) | ASME B16.5 / B16.47 |

| Flatness of Flange Facing | ≤ 0.5 mm (for NPS ≤ 24”) / ≤ 1.0 mm (for NPS > 24”) | ASME B16.5 / B16.47 |

| Concentricity of Bore to OD | ≤ 1.5 mm | ASME B16.5 |

| Runout of Raised Face | ≤ 0.5 mm (for NPS ≤ 24”) / ≤ 1.0 mm (for NPS > 24”) | ASME B16.5 / B16.47 |

Why is a stub end essential in Lap Joint Flange assemblies?

-

Stub End Requirement – A Lap Joint Flange always works with a stub end, which provides the sealing surface against the gasket.

-

Backing Flange Role – The backing flange only supplies clamping force and does not come in contact with the process fluid.

-

Material Optimization – The separation of stub end and backing flange allows the use of corrosion-resistant alloys for the stub end, while the backing flange can be manufactured from cost-effective materials like carbon steel.

-

Cost Efficiency – This design can reduce material expenses by up to 40% in corrosive service when compared to full alloy flanges.

How does the rotating design of Lap Joint Flanges reduce installation time?

-

Unlike weld neck or slip-on flanges, a Lap Joint Flange can rotate freely around the stub end.

-

During installation, bolt holes can be aligned without rotating the entire pipe spool.

-

This feature reduces fit-up time in confined spaces such as ship engine rooms, offshore platforms, and chemical plants.

-

Studies in piping fabrication show that Lap Joint Flanges can cut bolt alignment time by 30–40% compared to fixed flanges.

Can Lap Joint Flanges be used in high-vibration or cyclic conditions?

-

No, Lap Joint Flanges are not ideal for vibration or cyclic loading environments.

-

Because the backing flange is not welded, the load transfer is weaker compared to Weld Neck or Socket Weld flanges.

-

In systems with thermal cycling, pressure pulsation, or rotating machinery, Lap Joint Flanges may lead to gasket fatigue and leakage.

-

For such cases, Weld Neck Flanges (ASME B16.5/B16.47) are recommended.