- Home

- Industrial Flanges

- Weld Neck Flange

Weld Neck Flange

Weld Neck Flange: Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Weld Neck Flange ASME B16.5 / B16.47 (Series A & Series B) – Leading Manufacturer & Stockist of Flanges in Carbon Steel, Stainless Steel, Alloy Steel, Duplex, Super Duplex & High Nickel Alloys. Available from ½”–24” (B16.5) and 26”–60” (B16.47) in pressure classes 150#–2500#. Widely supplied to oil, gas, petrochemical & power industries across USA, Europe, Middle East & South America.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a trusted name in the field of industrial piping solutions, delivering precision-engineered flanges and fittings to global markets. With a focus on quality, innovation, and reliability, we specialize in manufacturing products that meet international standards such as ASME, ANSI, DIN, and EN.

Our state-of-the-art facility is equipped with advanced forging and machining technology, enabling us to produce flanges that perform seamlessly in high-pressure, high-temperature, and corrosive environments. Over the years, we have built a reputation for supplying critical components to industries such as oil & gas, petrochemicals, and water treatment across USA, Europe, Middle East, and Asia.

Our Weld Neck Flanges are designed and manufactured in strict compliance with ASME B16.5 and ASME B16.47 standards. Known for their strength and leak-proof connection, these flanges are widely used in demanding applications where reliability and durability are essential. The long tapered hub ensures smooth stress distribution, making them ideal for high-pressure and high-temperature piping systems.

We offer WNRF Flange in a wide range of materials, including carbon steel, stainless steel, alloy steel, duplex, super duplex, and high nickel alloys. Sizes are available from ½” to 24” (ASME B16.5) and 26” to 60” (ASME B16.47), with pressure classes ranging from 150# to 2500#. Each flange undergoes rigorous quality checks, including dimensional inspection, material traceability, and pressure testing, to ensure maximum performance and safety.

Our Weld Neck Raised Flanges are extensively supplied to refineries, chemical plants, LNG terminals, offshore platforms, and power generation units. Whether you require standard sizes or custom-engineered solutions, Midland Forge and Fittings Pvt. Ltd. ensures timely delivery and consistent quality for critical pipeline projects.

Weld Neck Pipe Flange Specifications

Size Range

Pressure Rating - Class

Marking

Face Type / Flange Connection Type

Flange Form

Manufacturing Standards

Materials

Test Certificates

Dimensional Standards

Testing

Flange Coating/Surface Treatment

Production technique

Weld Neck Flanges – Materials, Grades & Standards

| Material Category | Standards / Grades (ASTM / ASME) | Pressure Class / Size Range | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | Class 150 – 2500, Size ½”–48” | General purpose, corrosion-resistant piping |

| ASTM A182 F316 / F316L / F316H | Class 150 – 2500, Size ½”–48” | Chemical, marine, food & pharma industries | |

| ASTM A182 F321 / F321H | Class 150 – 1500, Size ½”–24” | High temperature, stabilized service | |

| Carbon Steel | ASTM A105 (Forged CS) | Class 150 – 2500, Size ½”–48” | Pressure piping, oil & gas, general industries |

| ASTM A350 LF2 (Low Temp CS) | Class 150 – 1500, Size ½”–24” | Cryogenic & low temperature applications | |

| Alloy Steel | ASTM A182 F11 / F22 (Cr-Mo) | Class 150 – 2500, Size ½”–24” | Power plants, refineries, steam pipelines |

| ASTM A182 F91 | Class 150 – 2500, Size ½”–24” | High-temperature, power generation | |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 / F60 (UNS S31803 / S32205 / S32750 / S32760) | Class 150 – 2500, Size ½”–24” | Offshore, seawater, high corrosion service |

| Nickel Alloys | ASTM B564 Inconel 600 / 625 / 718 | Class 150 – 2500, Size ½”–24” | Heat exchangers, chemical, aerospace |

| ASTM B564 Monel 400 / K500 | Class 150 – 2500, Size ½”–24” | Marine, seawater handling, pumps | |

| Copper Nickel | ASTM B151 / B467 (Cu-Ni 90/10, 70/30) | Class 150 – 600, Size ½”–24” | Shipbuilding, desalination, seawater systems |

| Titanium | ASTM B381 Gr. 2 / Gr. 5 | Class 150 – 600, Size ½”–12” | Aerospace, seawater, lightweight piping |

| Aluminium | ASTM B247 6061 / 5083 | Class 150 – 300, Size ½”–12” | Lightweight, non-corrosive, low-pressure piping |

Explore Industrial Flanges

- Flanges

- Slip On Flange

- Weld Neck Flange

- Socket Weld Flange

- Threaded Flange

- Lap Joint Flange

- Blind Flange

- Long Weld Neck Flange

- Reducing Flange

- Ring Type Joint (RTJ) Flange

- Plate Flange

- ASME B16.36 Orifice Flange

- Tongue and Groove Flange

- Male and Female Flange

- ASME B16.48 Spectacle Blind / Figure 8 Blank Flange

- Weldoflange

- Nipoflange

- Sweldolet Flange

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

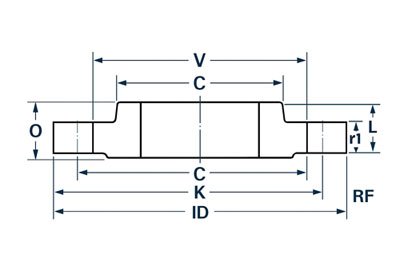

ANSI/ASME B16.47 Class 150 Weld Neck Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (O) |

Thickness of Flange (C) |

Length thru Hub (V) |

Dia of Hub at base (X) |

Dia of Hub at end (A) |

Dia of Raised Face (R) |

Dia of Bolt Circle |

No of Bolt Holes |

Dia of Bolt Holes |

Dia of Bolt |

Fillet Radius (r1) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 26 | 870 | 68.3 | 120.7 | 676.1 | 660.4 | 749.3 | 806.5 | 24 | 35.1 | 31.8 | 9.7 |

| 28 | 927.1 | 71.4 | 125.5 | 726.9 | 711.2 | 800.1 | 863.6 | 28 | 35.1 | 31.8 | 11.2 |

| 30 | 984.30 | 74.70 | 136.7 | 781.1 | 762 | 857.3 | 914.4 | 28 | 35.1 | 31.8 | 11.2 |

| 32 | 1060.5 | 81 | 144.5 | 831.9 | 812.8 | 914.4 | 977.9 | 28 | 41.1 | 38.1 | 11.2 |

| 34 | 1111.3 | 82.6 | 149.4 | 882.7 | 863.6 | 965.2 | 1028.7 | 32 | 41.1 | 38.1 | 12.7 |

| 36 | 1168.4 | 90.4 | 157.2 | 933.5 | 914.4 | 1022.4 | 1085.9 | 32 | 41.1 | 38.1 | 12.7 |

| 38 | 1238.3 | 87.4 | 157.2 | 990.6 | 965.2 | 1073.2 | 1149.4 | 32 | 41.1 | 38.1 | 12.7 |

| 40 | 1289 | 90.4 | 163.6 | 1041.4 | 1016 | 1124 | 1200.2 | 36 | 41.1 | 38.1 | 12.7 |

| 42 | 1346.2 | 96.8 | 171.5 | 1092.2 | 1066.8 | 1193.8 | 1257.3 | 36 | 41.1 | 38.1 | 12.7 |

| 44 | 1403.4 | 101.6 | 177.8 | 114.3 | 1117.6 | 1244.6 | 1314.5 | 40 | 41.1 | 38.1 | 12.7 |

| 46 | 1454.2 | 103.1 | 185.7 | 1196.8 | 1168.4 | 1295.4 | 1365.3 | 40 | 41.1 | 38.1 | 12.7 |

| 48 | 1511.3 | 108 | 192 | 1247.6 | 1219.2 | 1358.9 | 1422.4 | 44 | 41.1 | 38.1 | 12.7 |

| 50 | 1568.5 | 111.3 | 203.2 | 1301.8 | 1270 | 1409.7 | 1479.6 | 44 | 47.8 | 44.5 | 12.7 |

| 52 | 1625.6 | 115.8 | 209.6 | 1352.6 | 1320.8 | 1460.5 | 1530.4 | 44 | 47.8 | 44.5 | 12.7 |

| 54 | 1682.8 | 120.7 | 215.9 | 1403.4 | 1371.6 | 1511.3 | 1593.9 | 44 | 47.8 | 44.5 | 12.7 |

| 56 | 1746.3 | 124 | 228.6 | 1457.5 | 1422.4 | 1574.8 | 1651 | 48 | 47.8 | 44.5 | 12.7 |

| 58 | 1803.4 | 128.5 | 235 | 1508.3 | 1473.2 | 1625.6 | 1708.2 | 48 | 47.8 | 44.5 | 12.7 |

| 60 | 1854.2 | 131.8 | 239.8 | 1559.1 | 1524 | 1676.4 | 1759 | 52 | 47.8 | 44.5 | 12.7 |

ANSI/ASME B16.47 Class 300 Weld Neck Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (O) |

Thickness of Flange (C) |

Length thru Hub (V) |

Dia of Hub at base (X) |

Dia of Hub at end (A) |

Dia of Raised Face (R) |

Dia of Bolt Circle |

No of Bolt Holes |

Dia of Bolt Holes |

Dia of Bolt |

Fillet Radius (r1) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 26 | 971.6 | 79.2 | 184.2 | 720.9 | 660.4 | 749.3 | 876.3 | 28 | 44.5 | 41.4 | 9.7 |

| 28 | 1035.1 | 85.9 | 196.9 | 774.7 | 711.2 | 800.1 | 939.8 | 28 | 44.5 | 41.4 | 11.2 |

| 30 | 1092.2 | 91.9 | 209.6 | 827 | 762 | 857.3 | 997 | 28 | 47.8 | 44.5 | 11.2 |

| 32 | 1149.4 | 98.6 | 222.3 | 881.1 | 812.8 | 914.4 | 1054.1 | 28 | 50.8 | 47.8 | 11.2 |

| 34 | 1206.5 | 101.6 | 231.6 | 936.8 | 863.6 | 965.2 | 1104.9 | 28 | 50.8 | 47.8 | 12.7 |

| 36 | 1270 | 104.6 | 241.3 | 990.6 | 914.4 | 1022.4 | 1168.4 | 32 | 53.8 | 50.8 | 12.7 |

| 38 | 1168.4 | 108 | 180.8 | 993.6 | 965.2 | 1028.7 | 1092.2 | 32 | 41.1 | 38.1 | 12.7 |

| 40 | 1238.3 | 114.3 | 193.5 | 1054.6 | 1016 | 1085.9 | 1155.7 | 32 | 44.5 | 41.4 | 12.7 |

| 42 | 1289.1 | 119.1 | 200.2 | 1098.6 | 1066.8 | 1136.7 | 1206.5 | 32 | 44.5 | 41.4 | 12.7 |

| 44 | 1352.6 | 124 | 206.2 | 1149.4 | 1117.6 | 1193.8 | 1263.7 | 32 | 47.8 | 44.5 | 12.7 |

| 46 | 1416.1 | 128.5 | 215.9 | 1203.5 | 1168.4 | 1244.6 | 1320.8 | 28 | 50.8 | 47.8 | 12.7 |

| 48 | 1466.9 | 108 | 192 | 1247.6 | 1219.2 | 1358.9 | 1422.4 | 32 | 41.1 | 38.1 | 12.7 |

| 50 | 1530.4 | 139.7 | 231.6 | 1305.1 | 1270 | 1358.9 | 1428.8 | 32 | 53.8 | 50.8 | 12.7 |

| 52 | 1581.2 | 144.5 | 238.3 | 1355.9 | 1320.8 | 1409.7 | 1479.6 | 32 | 53.8 | 50.8 | 12.7 |

| 54 | 1657.4 | 152.4 | 252.5 | 1409.7 | 1371.6 | 1466.9 | 1549.4 | 28 | 60.5 | 57.2 | 12.7 |

| 56 | 1708.2 | 153.9 | 260.4 | 1463.5 | 1422.4 | 1517.7 | 1600.2 | 28 | 60.5 | 57.2 | 12.7 |

| 58 | 1759 | 158.8 | 266.7 | 1514.3 | 1473.2 | 1574.8 | 1651 | 32 | 60.5 | 57.2 | 12.7 |

| 60 | 1809.8 | 163.6 | 273.1 | 1565.1 | 1524 | 1625.6 | 1701.8 | 32 | 60.5 | 57.2 | 12.7 |

ANSI/ASME B16.47 Class 600 Weld Neck Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (O) |

Thickness of Flange (C) |

Length thru Hub (V) |

Dia of Hub at base (X) |

Dia of Hub at end (A) |

Dia of Raised Face (R) |

Dia of Bolt Circle |

No of Bolt Holes |

Dia of Bolt Holes |

Dia of Bolt |

Fillet Radius (r1) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 26 | 1016 | 108 | 222.3 | 747.8 | 660.4 | 749.3 | 914.4 | 28 | 50.8 | 47.6 | 12.7 |

| 28 | 1073.2 | 111.3 | 235 | 803.1 | 711.2 | 800.1 | 965.2 | 28 | 53.8 | 50.8 | 12.7 |

| 30 | 1130.3 | 114.3 | 247.7 | 862.1 | 762 | 857.3 | 1022.4 | 28 | 53.8 | 50.8 | 12.7 |

| 32 | 1193.8 | 117.3 | 260.4 | 917.4 | 812.8 | 914.4 | 1079.5 | 28 | 60.5 | 57.2 | 12.7 |

| 34 | 1244.6 | 120.7 | 269.7 | 973.1 | 863.6 | 965.2 | 1130.3 | 28 | 60.5 | 57.2 | 14.2 |

| 36 | 1314.5 | 124 | 282.4 | 1031.7 | 914.4 | 1022.4 | 1193.8 | 28 | 60.5 | 57.2 | 14.2 |

| 38 | 1270 | 152.4 | 254 | 1022.4 | 965.2 | 1054.1 | 1162.1 | 28 | 60.5 | 57.2 | 14.2 |

| 40 | 1320.8 | 158.8 | 263.7 | 1073.2 | 1016 | 1111.3 | 1212.9 | 32 | 60.5 | 57.2 | 14.2 |

| 42 | 1403.4 | 168.1 | 279.4 | 1127.3 | 1066.8 | 1168.4 | 1282.7 | 28 | 66.5 | 63.5 | 14.2 |

| 44 | 1454 | 173 | 289.1 | 1181.1 | 1117.6 | 1225.6 | 1333.5 | 32 | 66.5 | 63.5 | 14.2 |

| 46 | 1511.2 | 179.3 | 300 | 1234.9 | 1168.4 | 1276.4 | 1390.7 | 32 | 66.5 | 63.5 | 14.2 |

| 48 | 1593.9 | 189 | 316 | 1289.1 | 1219.2 | 1333.5 | 1460.5 | 32 | 73.12 | 69.9 | 14.2 |

| 50 | 1670.1 | 196.9 | 328.7 | 1343.2 | 1270 | 1384.3 | 1524 | 28 | 79.2 | 76.2 | 14.2 |

| 52 | 1720.9 | 203.2 | 336.6 | 1394 | 1320.8 | 1435.1 | 1574.8 | 32 | 79.2 | 76.2 | 14.2 |

| 54 | 1778 | 209.6 | 349.3 | 1447.8 | 1371.6 | 1492.3 | 1632 | 32 | 79.2 | 76.2 | 14.2 |

| 56 | 1854.2 | 217.4 | 362 | 1501.6 | 1422.4 | 1543.1 | 1695.5 | 32 | 85.9 | 82.6 | 15.7 |

| 58 | 1905 | 222.3 | 369.8 | 1552.4 | 1473.2 | 1600.2 | 1746.3 | 32 | 85.9 | 82.6 | 15.7 |

| 60 | 1993.9 | 233.4 | 388.9 | 1609.9 | 1524 | 1657.4 | 1822.5 | 28 | 91.9 | 88.9 | 17.5 |

ANSI/ASME B16.47 Class 900 Weld Neck Flange – Dimensions & Sizes in mm

| Nominal Pipe Size |

OD of Flange (O) |

Thickness of Flange (C) |

Length thru Hub (V) |

Dia of Hub at base (X) |

Dia of Hub at end (A) |

Dia of Raised Face (R) |

Dia of Bolt Circle |

No of Bolt Holes |

Dia of Bolt Holes |

Dia of Bolt |

Fillet Radius (r1) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 26 | 1085.9 | 139.7 | 258.8 | 774.7 | 660.4 | 749.3 | 952.5 | 20 | 73.2 | 69.9 | 11.2 |

| 28 | 1168.4 | 142.7 | 298.5 | 831.9 | 711.2 | 800.1 | 1022.4 | 20 | 79.2 | 76.2 | 12.7 |

| 30 | 1231.9 | 149.4 | 311.2 | 889 | 762 | 857.3 | 1085.9 | 20 | 79.2 | 76.2 | 12.7 |

| 32 | 1314.5 | 158.8 | 330.2 | 946.2 | 812.8 | 914.4 | 1155.7 | 20 | 85.9 | 82.6 | 12.7 |

| 34 | 1397 | 165.1 | 349.3 | 1006.3 | 863.6 | 965.2 | 1225.6 | 20 | 91.9 | 88.9 | 14.2 |

| 36 | 1460.5 | 171.5 | 362 | 1063.8 | 914.4 | 1022.4 | 1289.1 | 20 | 91.9 | 88.9 | 14.2 |

| 38 | 1460.5 | 190.5 | 352.6 | 1073.2 | 965.2 | 1098.6 | 1289.1 | 20 | 91.9 | 88.9 | 19.1 |

| 40 | 1511.3 | 196.9 | 363.5 | 1127.3 | 1016 | 1162.1 | 1339.9 | 24 | 91.9 | 88.9 | 20.6 |

| 42 | 1562.1 | 206.2 | 371.3 | 1176.3 | 1066.8 | 1212.9 | 1390.7 | 24 | 91.9 | 88.9 | 20.6 |

| 44 | 1648 | 214.4 | 390.7 | 1234.9 | 1117.6 | 1270 | 1463.5 | 24 | 98.6 | 95.3 | 22.4 |

| 46 | 1733.6 | 225.6 | 411 | 1292.4 | 1168.4 | 1333.5 | 1536.7 | 24 | 104.6 | 101.6 | 22.4 |

| 48 | 1784.4 | 233.4 | 419.1 | 1343.2 | 1219.2 | 1384.3 | 1587.5 | 24 | 104.6 | 101.6 | 23.9 |

Weld Neck Piping Flange Weight Chart (lbs) – Pressure Class 150 to 2500

| NPS (in) | 150# | 300# | 600# | 900# | 1500# | 2500# |

|---|---|---|---|---|---|---|

| 1/2 | 3 | 4 | 5 | 6 | 8 | 15 |

| 3/4 | 3 | 5 | 6 | 8 | 10 | 19 |

| 1 | 4 | 6 | 8 | 10 | 14 | 27 |

| 1-1/4 | 5 | 8 | 11 | 14 | 20 | 39 |

| 1-1/2 | 6 | 10 | 14 | 18 | 27 | 51 |

| 2 | 9 | 16 | 22 | 28 | 41 | 77 |

| 2-1/2 | 11 | 21 | 32 | 41 | 61 | 115 |

| 3 | 14 | 28 | 43 | 55 | 82 | 155 |

| 3-1/2 | 18 | 36 | 55 | 72 | 108 | 204 |

| 4 | 21 | 43 | 67 | 88 | 132 | 249 |

| 5 | 31 | 62 | 97 | 126 | 190 | 359 |

| 6 | 39 | 82 | 129 | 167 | 251 | 476 |

| 8 | 63 | 131 | 206 | 267 | 401 | 760 |

| 10 | 92 | 196 | 307 | 397 | 596 | 1129 |

| 12 | 134 | 281 | 442 | 570 | 853 | 1621 |

| 14 | 164 | 340 | 540 | 695 | 1042 | 1978 |

| 16 | 220 | 456 | 725 | 932 | 1406 | 2672 |

| 18 | 262 | 543 | 862 | 1107 | 1670 | 3175 |

| 20 | 326 | 677 | 1075 | 1380 | 2086 | 3971 |

| 22 | 380 | 787 | 1245 | 1599 | 2414 | 4596 |

| 24 | 444 | 919 | 1455 | 1868 | 2820 | 5371 |

WNRF Flange Tolerances as per ANSI / ASME B16.5, 16.47

| Parameter | Tolerance (ASME B16.5 & B16.47) | Notes |

|---|---|---|

| Outside Diameter of Flange (O.D.) | ± 1.5 mm (up to 24”)± 3.0 mm (above 24”) | Tighter control ensures bolt circle alignment. |

| Bolt Circle Diameter (BCD) | ± 1.5 mm | Critical for matching companion flanges. |

| Bolt Hole Diameter | +1.5 mm / -0.0 mm | Ensures clearance for bolts. |

| Bolt Hole Center-to-Center | ± 1.0 mm | Maintains correct alignment. |

| Flange Thickness (C/D) | ± 1.5 mm (up to 24”)± 3.0 mm (above 24”) | Ensures proper pressure containment. |

| Raised Face Diameter (RF) | ± 1.0 mm | Controls gasket seating area. |

| Raised Face Height | +0.0 / -0.3 mm | Must meet gasket compression requirements. |

| Hub Bore (to match pipe I.D.) | +1.0 mm / -0.0 mm | Must suit pipe wall thickness & schedule. |

| Hub Length (from flange face to bevel end) | ± 1.5 mm | Ensures proper welding length. |

| Bevel Angle | ± 2° | Standard 37.5° for welding end. |

| Flatness of Flange Face | ≤ 0.5 mm (up to 10” dia)≤ 1.0 mm (above 10”) | To ensure gasket tightness. |

| Concentricity of Bore to O.D. | ≤ 1.5 mm | Maintains balance & flow alignment. |

| Runout (Facing to Bore) | ≤ 0.8 mm (B16.5)≤ 1.5 mm (B16.47) | Important for gasket sealing integrity. |

How to identify a Weld Neck Flange?

-

Long tapered hub extending from the flange base.

-

Beveled end prepared for butt-welding.

-

Markings on outer rim include:

Nominal Pipe Size (NPS)

Pressure Rating (Class 150–2500)

Material Grade (ASTM / ASME)

Standard (ASME B16.5 / B16.47)

Heat Number & Manufacturer’s Logo

What are the welding requirements for Weld Neck Flanges?

-

Flange end is beveled to match the pipe.

-

Requires butt-weld joint, providing full penetration welding.

-

Welding must follow ASME Section IX (Welding Qualification).

-

Post-weld heat treatment (PWHT) may be required for alloy steels.

-

Proper alignment ensures flow efficiency and mechanical strength.

What are the differences between ASME B16.5 and ASME B16.47 Weld Neck Flanges?

-

ASME B16.5: Covers flanges from ½” to 24”, for pressure class 150#–2500#.

-

ASME B16.47 Series A: Heavy-duty, thicker flanges for 26” to 60”, used in oil & gas and critical services.

-

ASME B16.47 Series B: Lighter, economical option for 26” to 60”, suitable for low to medium pressure pipelines.