- Home

- Buttweld Pipe Fittings

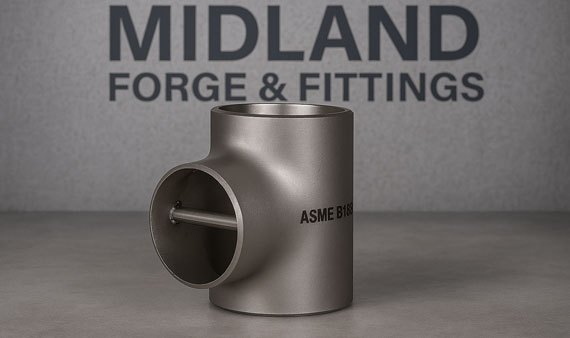

- Buttweld Barred Tee

Buttweld Barred Tee

Barred Tee : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Leading ASME B16.9 Buttweld Barred Tee Manufacturer & Exporter – Supplying premium Stainless Steel, Carbon Steel, Alloy Steel, and High Nickel Alloy Barred Tees (Seamless & Welded, SCH 40 / SCH 80) to Germany, Australia, UAE, South Africa, and Malaysia.

Best Export Prices: sales@midlandforgefittings.com

We are a trusted manufacturer and global supplier of high-quality pipe fittings, catering to industries such as oil & gas, petrochemicals, and marine engineering. With state-of-the-art facilities and a skilled workforce, we deliver precision-engineered products that meet international standards. Our commitment to quality, timely delivery, and customer satisfaction has earned us a strong presence in markets across the USA, UK, UAE, Saudi Arabia, Australia, and more.

We specialize in standard and custom-made solutions and offer a wide range of buttweld fittings and specialty items for demanding applications. We understand that every project has unique requirements, and our team ensures that every product is manufactured to exact specifications for maximum performance and durability.

Our barred tees are designed to control the passage of cleaning or inspection pigs in pipelines, ensuring safe and efficient operation. These fittings feature an internal bar structure that prevents pigging equipment from entering branch connections, thus avoiding damage or operational issues. Manufactured from premium-grade materials such as carbon steel, stainless steel, and alloy steel, our barred tees comply with ASME, ANSI, and other global standards. Available in various sizes, pressure classes, and finishes, they are widely used in oil & gas transmission lines, petrochemical plants, and offshore pipelines.

With a strong export network and inventory management system, we ensure fast dispatch and competitive pricing for clients worldwide. Our products are rigorously tested to guarantee reliability under extreme conditions, making us the preferred choice for pipeline fittings globally.

Barred Tee Specifications, Sizes & Standards

Size Range – Seamless

Wall Thickness

Marking

Fitting Types

Size Range – Welded

Ends Connection

Manufacturing Standards

Materials

Size Range – Fabricated

Dimensional Standards

Testing

Surface Finish

Buttweld Barred Tee – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use/Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A403 WP304/304L/304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A403 WP316/316L/316H | Marine & chemical applications | |

| 317 / 317L | ASTM A403 WP317/317L | High corrosion resistance | |

| 321 / 321H | ASTM A403 WP321/321H | High temperature, stabilized | |

| 347 / 347H | ASTM A403 WP347/347H | High-temp pressure systems | |

| 904L | ASTM A403 WP904L / B625 | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A403 / B366 | High chloride environments | |

| Carbon Steel | A234 WPB / WPC | ASTM A234 | Pressure piping & general piping systems |

| A420 WPL6 | ASTM A420 | Low temperature services | |

| Alloy Steel | A234 WP1 / WP5 / WP9 | ASTM A234 | High-temp & pressure pipelines |

| A234 WP11 / WP22 | ASTM A234 | Steam lines & refineries | |

| A234 WP91 | ASTM A234 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A815 / A790 | Corrosion & high strength use |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A815 / A790 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B366 / B162 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B366 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B366 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B366 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B366 | Seawater, chemical industries | |

| Alloy 20 | ASTM B366 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B366 / B637 | High-temp applications | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B466 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B363 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B361 | Low-pressure, non-corrosive piping |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Dimensions of Barred Tee

| Nominal Pipe Size (Run × Branch) | OD (Run x Branch) (mm) | Center-to-End Run (C) mm | Center-to-End Branch (M) mm |

|---|---|---|---|

| ½″ × ¼″ | 21.3 × 13.7 | 25 | 25 |

| ¾″ × ⅜″ | 26.7 × 17.3 | 29 | 29 |

| 1″ × ½″ | 33.4 × 21.3 | 38 | 38 |

| 1¼″ × 1″ | 42.2 × 33.4 | 48 | 48 |

| 1½″ × 1¼″ | 48.3 × 42.2 | 57 | 57 |

| 2″ × 1½″ | 60.3 × 48.3 | 64 | 60 |

| 2½″ × 2″ | 73.0 × 60.3 | 76 | 70 |

| 3″ × 2½″ | 88.9 × 73.0 | 86 | 83 |

| 3½″ × 3″ | 101.6 × 88.9 | 95 | 92 |

| 4″ × 3½″ | 114.3 × 101.6 | 105 | 102 |

| 5″ × 4″ | 141.3 × 114.3 | 124 | 117 |

| 6″ × 5″ | 168.3 × 141.3 | 143 | 137 |

| 8″ × 6″ | 219.1 × 168.3 | 178 | 168 |

| 10″ × 8″ | 273.0 × 219.1 | 216 | 203 |

| 12″ × 10″ | 323.8 × 273.0 | 254 | 241 |

| 14″ × 12″ | 355.6 × 323.8 | 279 | 270 |

| 16″ × 14″ | 406.4 × 355.6 | 305 | 295 |

| 18″ × 16″ | 457.0 × 406.4 | 343 | 330 |

| 20″ × 18″ | 508.0 × 457.0 | 381 | 368 |

| 22″ × 20″ | 559.0 × 508.0 | 419 | 406 |

| 24″ × 22″ | 610.0 × 559.0 | 432 | 432 |

Weight Chart: ASME B16.9 Barred Tee (SCH 40 / STD)

| Nominal Pipe Size (NPS) | Outside Diameter (mm) | Wall Thickness (mm) | Length (mm) | Approx. Weight (Kg) |

|---|---|---|---|---|

| 2″ | 60.3 | 5.54 | 150 | 4.8 |

| 3″ | 88.9 | 5.49 | 200 | 8.5 |

| 4″ | 114.3 | 6.02 | 250 | 13.7 |

| 6″ | 168.3 | 7.11 | 300 | 28.5 |

| 8″ | 219.1 | 8.18 | 350 | 48.6 |

| 10″ | 273.0 | 9.27 | 400 | 76.2 |

| 12″ | 323.9 | 9.53 | 450 | 104.5 |

| 14″ | 355.6 | 9.53 | 500 | 122.3 |

| 16″ | 406.4 | 12.7 | 550 | 165.7 |

| 18″ | 457.2 | 12.7 | 600 | 201.8 |

| 20″ | 508.0 | 12.7 | 650 | 240.3 |

| 24″ | 609.6 | 12.7 | 700 | 325.6 |

Buttweld Barred Tee Tolerances as per ASME B16.9

| Fitting Type | Parameter | Tolerance | |

|---|---|---|---|

| Up to 4” NPS | Above 4” NPS | ||

| Barred Tee | Outside Diameter at Bevel | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) |

| Center-to-End (A, B) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Ovality | Shall not exceed 1% of specified OD | ||

Where is a Barred Tee used?

Piggable Pipeline Systems: Ensures smooth pig passage while allowing branch connections without obstruction.

Oil & Gas Transmission Lines: Prevents pigs from entering side branches during cleaning or inspection.

Petrochemical & Process Industries: Maintains continuous flow and system integrity during pigging operations.

Offshore & Subsea Pipelines: Used where regular pigging is critical for preventing blockages and corrosion.

Maintenance-Intensive Pipelines: Ideal for systems requiring frequent cleaning or internal inspection.

What is the function of the bar in a Barred Tee?

-

The bar in a barred tee is a structural element (usually flat bars, round bars, or plates) welded across the branch opening inside the fitting.

-

Its primary function is to act as a mechanical barrier to pipeline pigs (cleaning tools, inspection tools, or gauging devices) moving through the main pipeline during pigging operations.

-

It permits normal fluid flow into the branch connection without causing significant pressure drop or turbulence.

-

During pigging, the bar prevents the pig from entering the branch outlet, ensuring it continues along the main line. This protects both the pig and branch equipment from potential damage or jamming.

-

Bars are designed and spaced according to the size of the pig and pipeline standards (such as ASME B31.4 or company-specific pigging requirements).

-

The structure is fully welded and reinforced to withstand operating pressures, flow velocities, and pig impact forces in oil, gas, and process pipelines.

-

This design is widely used in piggable pipeline systems, offshore platforms, oil & gas transmission lines, and refineries where regular cleaning, inspection, and maintenance are carried out without shutting down the pipeline.

How is a Barred Tee designed as per ASME B16.9?

-

Base Design Standard

- The main body of the Barred Tee is manufactured according to ASME B16.9 (for buttweld fittings) or MSS SP-75 (for high-strength pipeline fittings).

- These standards ensure accurate dimensions for overall length, branch size, wall thickness, and bevel end preparation.

-

Bar Configuration

- Bars are welded across the branch opening to block pipeline pigs from entering.

- The number, size, and spacing of bars are determined based on pipeline diameter, pig type, and flow velocity to maintain smooth pigging operations.

-

Welding & Fabrication

- Bars are usually full penetration welded to the inside of the branch for maximum mechanical strength.

- Weld quality follows ASME Section IX and project-specific welding procedures (WPS/PQR).

-

Tolerances

- The main tee body follows ASME B16.9 dimensional tolerances, covering parameters like out-of-roundness, center-to-end dimensions, and wall thickness.

- Bar placement tolerances are maintained as per client specifications to prevent pig snagging.

-

Material Matching

- Bars are fabricated from the same material grade as the tee body (e.g., carbon steel, stainless steel, alloy steel) to ensure uniform corrosion resistance and matching mechanical properties.

-

Inspection & Testing

- Welds undergo non-destructive testing (NDT) such as radiography (RT), ultrasonic testing (UT), or magnetic particle testing (MT).

- Hydrostatic or pneumatic pressure testing is carried out as per ASME B31.3, B31.4, or B31.8 pipeline codes.