- Home

- Buttweld Pipe Fittings

- 180° Return Bend

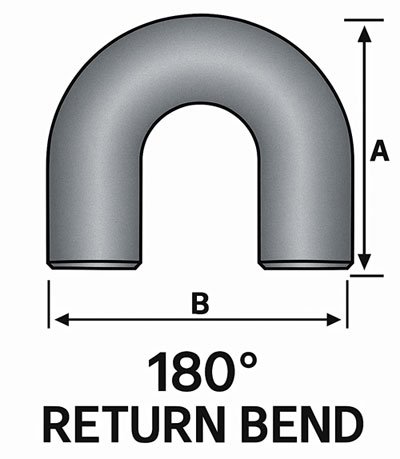

180° Return Bend

180° Return Bend : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Leading Manufacturers, Suppliers, and Exporters of ASME B16.9 Buttweld 180° Return Bends in Seamless and Welded types, available in Sch 40 / Sch 80. We offer 180° Pipe Bends in Stainless Steel, Carbon Steel, Alloy Steel, and High Nickel Alloys, catering to clients across the USA, UK, and Middle East markets.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a trusted name in the piping solutions industry, known for delivering high-quality buttweld fittings across global markets. With advanced manufacturing facilities and a skilled workforce, the company produces precision-engineered 180 Degree Return Bends that meet the stringent standards of ASME B16.9. Whether for industrial, commercial, or high-pressure applications, Midland ensures every fitting offers superior durability, accurate dimensions, and smooth flow characteristics.

The 180 Degree Return Bend is a specialized pipe fitting designed to completely reverse the direction of flow within a piping system. Commonly used in heat exchangers, condensers, and process pipelines, these bends are ideal for compact installations where space is limited. Manufactured in both seamless and welded forms, these fittings are available in various wall thicknesses such as Sch 40 and Sch 80, ensuring compatibility with diverse operating conditions and system requirements.

Midland Forge and Fittings Pvt. Ltd. offers 180° Return Bends in a range of materials, including Stainless Steel, Carbon Steel, Alloy Steel, and High Nickel Alloys, catering to demanding industries like oil & gas, petrochemicals, power generation, and marine. The company serves clients in the USA, UK, Middle East, and other global markets, offering timely deliveries and reliable service. Every product undergoes rigorous quality checks to meet international standards, making Midland a preferred partner for premium piping components.

Buttweld 180° Return Bend Specifications, Sizes & Standards

Size Range – Seamless

Wall Thickness

Marking

Fitting Types

Size Range – Welded

Ends Connection

Manufacturing Standards

Materials

Size Range – Fabricated

Dimensional Standards

Testing

Surface Finish

BW 180° Bend – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use/Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A403 WP304/304L/304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A403 WP316/316L/316H | Marine & chemical applications | |

| 317 / 317L | ASTM A403 WP317/317L | High corrosion resistance | |

| 321 / 321H | ASTM A403 WP321/321H | High temperature, stabilized | |

| 347 / 347H | ASTM A403 WP347/347H | High-temp pressure systems | |

| 904L | ASTM A403 WP904L / B625 | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A403 / B366 | High chloride environments | |

| Carbon Steel | A234 WPB / WPC | ASTM A234 | Pressure piping & general piping systems |

| A420 WPL6 | ASTM A420 | Low temperature services | |

| Alloy Steel | A234 WP1 / WP5 / WP9 | ASTM A234 | High-temp & pressure pipelines |

| A234 WP11 / WP22 | ASTM A234 | Steam lines & refineries | |

| A234 WP91 | ASTM A234 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A815 / A790 | Corrosion & high strength use |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A815 / A790 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B366 / B162 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B366 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B366 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B366 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B366 | Seawater, chemical industries | |

| Alloy 20 | ASTM B366 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B366 / B637 | High-temp applications | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B466 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B363 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B361 | Low-pressure, non-corrosive piping |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Dimensions of 180° Return Bend

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Center to Center (A) | Back to Face (B) | Wall Thickness (SCH 40) |

|---|---|---|---|---|

| 1/2″ | 21.3 mm | 38 mm | 25 mm | 2.77 mm |

| 1″ | 33.4 mm | 76 mm | 51 mm | 3.38 mm |

| 2″ | 60.3 mm | 152 mm | 102 mm | 3.91 mm |

| 3″ | 88.9 mm | 229 mm | 152 mm | 5.49 mm |

| 4″ | 114.3 mm | 305 mm | 203 mm | 6.02 mm |

| 6″ | 168.3 mm | 457 mm | 305 mm | 7.11 mm |

| 8″ | 219.1 mm | 610 mm | 406 mm | 8.18 mm |

| 10″ | 273 mm | 762 mm | 508 mm | 9.27 mm |

| 12″ | 323.9 mm | 914 mm | 610 mm | 9.53 mm |

Weight Chart: ASME B16.9 Buttweld 180 deg Return Bend(Carbon Steel, SCH 40 / STD)

| Size (Inches) | 180° Return (kg) |

|---|---|

| ½” | 0.20 |

| ¾” | 0.35 |

| 1″ | 0.55 |

| 1½” | 1.20 |

| 2″ | 1.85 |

| 3″ | 4.50 |

| 4″ | 8.20 |

| 6″ | 16.50 |

| 8″ | 27.50 |

| 10″ | 42.00 |

| 12″ | 61.00 |

| 14″ | 82.00 |

| 16″ | 107.00 |

| 18″ | 137.00 |

| 20″ | 171.00 |

| 24″ | 246.00 |

| 26″ | 285.00 |

| 28″ | 325.00 |

| 30″ | 372.00 |

| 32″ | 420.00 |

| 36″ | 515.00 |

| 40″ | 620.00 |

| 42″ | 675.00 |

| 44″ | 730.00 |

| 48″ | 840.00 |

180° Pipe Bend Fitting Tolerances as per ASME B16.9

| Fitting Type | Parameter | Tolerance | |

|---|---|---|---|

| Up to 4” NPS | Above 4” NPS | ||

| 180° Bends | Outside Diameter at Bevel | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) |

| Center-to-End (A, B) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Ovality | Shall not exceed 1% of specified OD | ||

How are 180° Return Bends different from 90° and 45° elbows?

- 90° Elbow – Quarter Turn Direction Change

- Changes the flow direction by 90 degrees (a quarter turn).

- Commonly used in right-angle pipe connections for water, gas, and industrial piping systems.

- Available in long radius (LR) and short radius (SR) types to suit space and flow requirements.

- Ideal for branching pipelines or routing around obstacles.

- 45° Elbow – Eighth Turn Direction Change

- Redirects flow by 45 degrees (an eighth turn).

- Used where smooth directional change is required to minimize pressure loss.

- Helps in reducing turbulence and maintaining better flow efficiency.

- Common in HVAC ducts, chemical pipelines, and irrigation systems.

- 180° Return Bend – Complete Flow Reversal

- Changes the flow direction by a full 180 degrees, sending the fluid back in the opposite direction.

- Perfect for tight piping layouts or U-shaped pipe designs in heat exchangers, condensers, and process equipment.

- Maintains compact system design while ensuring proper flow circulation.

- Available in seamless and welded types, conforming to ASME B16.9 and other global standards.

Can we get custom-made 180° Return Bends?

Yes, custom-made 180° Return Bends are available to suit specific industrial and engineering requirements. Many leading manufacturers, such as Midland Forge and Fittings Pvt. Ltd., provide tailor-made solutions to meet unique project specifications. Custom fabrication options typically include:

- Material Selection – You can request bends in a variety of materials such as stainless steel, carbon steel, alloy steel, duplex, super duplex, copper nickel, and high nickel alloys depending on your application’s temperature, pressure, and corrosion resistance needs.

- Wall Thickness & Schedules – Options range from light schedules (SCH 10) to heavy-duty thick walls (SCH 160 / XXS) to handle different pressure ratings.

- Bend Radius – Custom radii can be designed, including short-radius (SR) or long-radius (LR) return bends, as well as extra-long sweeping bends for smooth flow.

- Size Range – Manufacturers can produce bends from small-diameter tubes (½”) to large-bore pipes (48″ or more) as per your piping layout.

- End Connection Type – Ends can be prepared as bevelled, plain, or flanged to match your system design.

- Surface Finish & Coatings – Depending on the operating environment, bends can be supplied with pickled and passivated surfaces, epoxy coatings, galvanizing, or other protective finishes.

- Compliance with Standards – Custom 180° return bends can be made to meet ASME B16.9, MSS-SP-75, DIN, JIS, EN, or other international standards.

How to select the correct size and radius for a 180° return bend?

-

Match Pipe Diameter with System Design

- The nominal diameter of the return bend should exactly match the connected pipe to ensure proper fit and flow continuity.

- Mismatched sizes can cause turbulence, pressure drop, and leakage risks.

-

Consider Wall Thickness (Schedule)

- Choose the bend’s wall thickness based on the pipe schedule (e.g., SCH 40, SCH 80, SCH 160) for strength and durability.

- Higher schedules are recommended for high-pressure or abrasive media.

-

Evaluate Flow Characteristics

- For smooth flow and minimal pressure loss, a Long Radius (LR) bend (radius = 1.5 × pipe diameter) is generally preferred.

- If the piping system has limited space, a Short Radius (SR) bend (radius = 1 × pipe diameter) is more practical, though it may cause slightly higher turbulence.

-

Check System Layout and Space Availability

- In compact or congested installations, SR bends save space but may require stronger pumping systems.

- LR bends are better for systems prioritizing flow efficiency and reduced erosion.

-

Comply with Standards and Codes

- Ensure the 180° return bend meets ASME B16.9, MSS SP-75, or DIN standards for dimensions, tolerances, and material grades.

- This ensures interchangeability and long-term reliability.

-

Account for Application Requirements

- In high-temperature or corrosive environments, select suitable materials such as stainless steel, duplex steel, or nickel alloys.

- For low-cost, non-critical uses, carbon steel or mild steel may suffice.