- Home

- Buttweld Pipe Fittings

Buttweld Pipe Fittings

Buttweld Fittings: Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

ASME B16.9 Buttweld Fittings Manufacturers, Suppliers and Exporters of Seamless & Welded Sch 10 to Sch XXS Pipe Fittings in Stainless, Alloy, Carbon Steel, and other High Nickel Grades to USA, UK, Middle East Countries

Best Export Prices: sales@midlandforgefittings.com

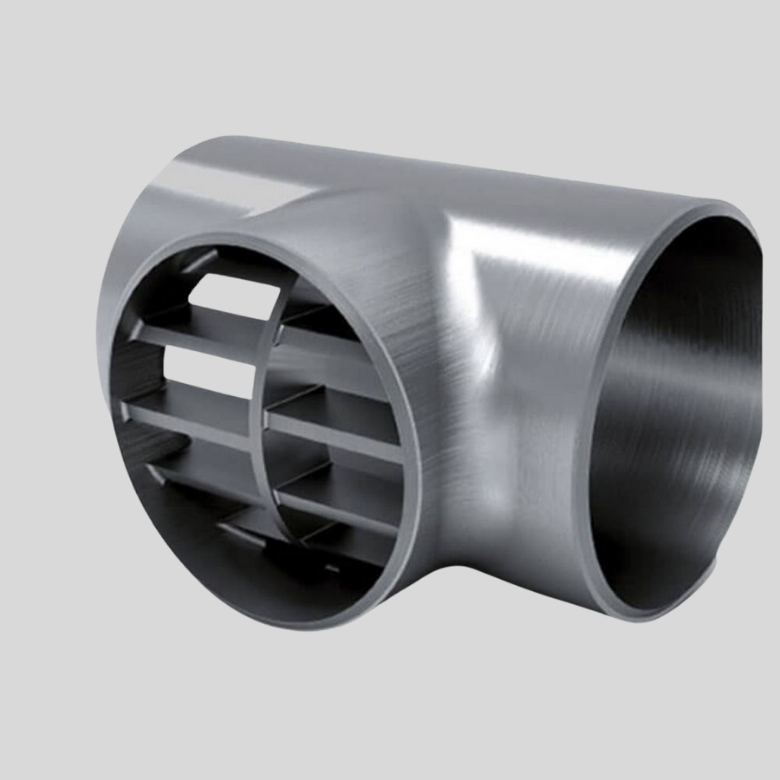

Midland Forge and Fittings Pvt. Ltd. is a trusted manufacturer and global supplier of high-quality buttweld pipe fittings in India, designed for critical piping applications across various industries. Our extensive inventory includes elbows, tees, reducers, stub ends, pipe caps, and cross fittings, available in seamless, welded, and fabricated types.

We manufacture buttweld fittings in compliance with ASME B16.9, MSS-SP-43, and ANSI/ASME standards, offering a comprehensive size range from ½” to 48” NB, and thicknesses ranging from SCH 10 to SCH XXS. Available in stainless steel, carbon steel, alloy steel, duplex & super duplex, and other high-performance materials, our fittings are built to handle high pressure, corrosive environments, and demanding applications.

Buttweld fittings are seamless or welded pipe components that are permanently joined to the pipeline by welding. They provide a strong, leak-proof, and smooth-flow connection between pipes of different sizes and diameters, ensuring minimal turbulence and pressure drop in the system. Common types include: 90° & 45° Elbows (long/short radius), Equal & Reducing Tees, Concentric & Eccentric Reducers, End Caps & Stub Ends (Type A/B/C), Pipe Crosses & Customized Fabricated Fittings.

These fittings are widely used in oil & gas, petrochemical, power generation, water treatment, shipbuilding, and chemical processing industries.

We offer both seamless buttweld fittings (for high-pressure and high-temperature applications) and welded buttweld fittings (preferred for large diameters or standard-pressure pipelines). Our seamless range is manufactured from hot-pierced billets, while the welded fittings are produced from quality pipes or plates with 100% radiographic and hydro testing.

Buttweld Fittings Specifications

Size Range – Seamless

Wall Thickness

Marking

Fitting Types

Size Range – Welded

Ends Connection

Manufacturing Standards

Materials

Size Range – Fabricated

Dimensional Standards

Testing

Surface Finish

Buttweld Fittings – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use/Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A403 WP304/304L/304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A403 WP316/316L/316H | Marine & chemical applications | |

| 317 / 317L | ASTM A403 WP317/317L | High corrosion resistance | |

| 321 / 321H | ASTM A403 WP321/321H | High temperature, stabilized | |

| 347 / 347H | ASTM A403 WP347/347H | High-temp pressure systems | |

| 904L | ASTM A403 WP904L / B625 | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A403 / B366 | High chloride environments | |

| Carbon Steel | A234 WPB / WPC | ASTM A234 | Pressure piping & general piping systems |

| A420 WPL6 | ASTM A420 | Low temperature services | |

| Alloy Steel | A234 WP1 / WP5 / WP9 | ASTM A234 | High-temp & pressure pipelines |

| A234 WP11 / WP22 | ASTM A234 | Steam lines & refineries | |

| A234 WP91 | ASTM A234 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A815 / A790 | Corrosion & high strength use |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A815 / A790 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B366 / B162 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B366 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B366 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B366 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B366 | Seawater, chemical industries | |

| Alloy 20 | ASTM B366 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B366 / B637 | High-temp applications | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B466 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B363 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B361 | Low-pressure, non-corrosive piping |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Types of ASME B16.9 Buttweld Fittings

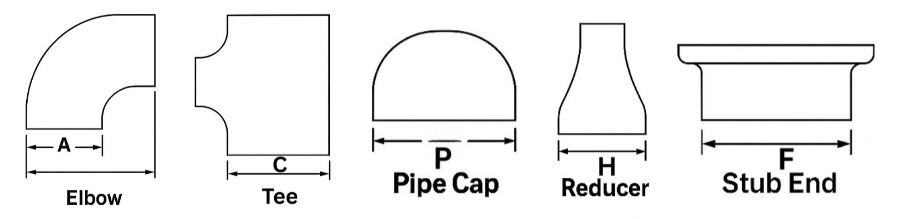

Dimensions of ASME B16.9 Fittings

| NPS (in) | Elbow (90°) A (mm) | Tee C (mm) | Reducer H (mm) | End Cap P (mm) | Stub End F (mm) |

|---|---|---|---|---|---|

| 1/2 | 38 | 25 | 76 | 25 | 16 |

| 3/4 | 38 | 29 | 76 | 29 | 19 |

| 1 | 38 | 38 | 89 | 38 | 22 |

| 1 1/4 | 48 | 48 | 102 | 48 | 25 |

| 1 1/2 | 57 | 57 | 114 | 57 | 29 |

| 2 | 76 | 64 | 127 | 64 | 32 |

| 2 1/2 | 95 | 76 | 140 | 76 | 35 |

| 3 | 114 | 86 | 152 | 86 | 38 |

| 3 1/2 | 133 | 95 | 165 | 95 | 41 |

| 4 | 152 | 105 | 178 | 105 | 44 |

| 5 | 190 | 127 | 203 | 127 | 48 |

| 6 | 229 | 152 | 229 | 152 | 51 |

| 8 | 305 | 203 | 254 | 203 | 57 |

| 10 | 381 | 254 | 305 | 254 | 64 |

| 12 | 457 | 305 | 356 | 305 | 70 |

| 14 | 533 | 337 | 381 | 337 | 76 |

| 16 | 610 | 386 | 406 | 386 | 83 |

| 18 | 686 | 419 | 457 | 419 | 89 |

| 20 | 762 | 457 | 508 | 457 | 95 |

| 22 | 838 | 495 | 559 | 495 | 102 |

| 24 | 914 | 521 | 610 | 521 | 108 |

| 26 | 991 | 559 | 660 | 559 | 114 |

| 28 | 1067 | 597 | 711 | 597 | 121 |

| 30 | 1143 | 635 | 762 | 635 | 127 |

| 32 | 1219 | 673 | 813 | 673 | 133 |

| 34 | 1295 | 711 | 864 | 711 | 140 |

| 36 | 1372 | 749 | 914 | 749 | 146 |

| 38 | 1448 | 787 | 965 | 787 | 152 |

| 40 | 1524 | 825 | 1016 | 825 | 159 |

| 42 | 1600 | 864 | 1067 | 864 | 165 |

| 44 | 1676 | 902 | 1118 | 902 | 172 |

| 46 | 1753 | 940 | 1168 | 940 | 178 |

| 48 | 1829 | 978 | 1219 | 978 | 184 |

Weight Chart: ASME B16.9 Buttweld Fittings (Carbon Steel, SCH 40 / STD)

| Size (Inches) | 90° Elbow (kg) | 45° Elbow (kg) | 180° Return (kg) | Equal Tee (kg) | Concentric Reducer (kg) | Cap (kg) |

|---|---|---|---|---|---|---|

| ½” | 0.15 | 0.08 | 0.20 | 0.20 | 0.10 | 0.08 |

| ¾” | 0.25 | 0.13 | 0.35 | 0.30 | 0.15 | 0.12 |

| 1″ | 0.40 | 0.20 | 0.55 | 0.45 | 0.25 | 0.20 |

| 1½” | 0.90 | 0.45 | 1.20 | 1.10 | 0.70 | 0.60 |

| 2″ | 1.40 | 0.70 | 1.85 | 1.75 | 1.10 | 0.90 |

| 3″ | 3.40 | 1.70 | 4.50 | 4.30 | 2.60 | 2.30 |

| 4″ | 6.00 | 3.00 | 8.20 | 7.80 | 4.60 | 4.00 |

| 6″ | 12.00 | 6.00 | 16.50 | 15.00 | 9.60 | 8.50 |

| 8″ | 20.00 | 10.00 | 27.50 | 26.00 | 16.00 | 14.00 |

| 10″ | 31.00 | 15.50 | 42.00 | 40.00 | 24.00 | 22.00 |

| 12″ | 45.00 | 22.50 | 61.00 | 58.00 | 35.00 | 32.00 |

| 14″ | 60.00 | 30.00 | 82.00 | 78.00 | 48.00 | 43.00 |

| 16″ | 78.00 | 39.00 | 107.00 | 102.00 | 64.00 | 58.00 |

| 18″ | 100.00 | 50.00 | 137.00 | 130.00 | 82.00 | 74.00 |

| 20″ | 125.00 | 62.50 | 171.00 | 162.00 | 105.00 | 95.00 |

| 24″ | 180.00 | 90.00 | 246.00 | 230.00 | 145.00 | 130.00 |

| 26″ | 210.00 | 105.00 | 285.00 | 265.00 | 170.00 | 150.00 |

| 28″ | 240.00 | 120.00 | 325.00 | 300.00 | 195.00 | 170.00 |

| 30″ | 275.00 | 137.50 | 372.00 | 340.00 | 225.00 | 200.00 |

| 32″ | 310.00 | 155.00 | 420.00 | 380.00 | 250.00 | 225.00 |

| 36″ | 380.00 | 190.00 | 515.00 | 460.00 | 310.00 | 280.00 |

| 40″ | 460.00 | 230.00 | 620.00 | 550.00 | 380.00 | 340.00 |

| 42″ | 500.00 | 250.00 | 675.00 | 600.00 | 410.00 | 370.00 |

| 44″ | 540.00 | 270.00 | 730.00 | 645.00 | 440.00 | 400.00 |

| 48″ | 620.00 | 310.00 | 840.00 | 730.00 | 500.00 | 455.00 |

Buttweld Fitting Tolerances as per ASME B16.9

| Fitting Type | Parameter | Tolerance | |

|---|---|---|---|

| Up to 4” NPS | Above 4” NPS | ||

| Elbows | Outside Diameter at Bevel | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) |

| Center-to-End (A, B) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Ovality | Shall not exceed 1% of specified OD | ||

| Tees | Center-to-End (Run & Branch) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) |

| Outside Diameter | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Reducers | Large End OD | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) |

| Small End OD | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) | |

| End-to-End Length | ±3.2 mm (1/8″) | ±6.4 mm (1/4″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Caps | Outside Diameter at Bevel | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) |

| Length (H) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Stub Ends | Lap Diameter | ±0.8 mm (1/32″) | ±1.6 mm (1/16″) |

| Length | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Cross | Center-to-End (Run & Branch) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) |

| Wall Thickness | -12.5% (no positive tolerance) | ||

What are the benefits of using buttweld fittings compared to socket weld or threaded fittings?

Buttweld fittings offer several advantages over socket weld and threaded fittings:

- Stronger and leak-proof joints due to full penetration welds.

- Smooth internal surface reduces pressure drop and minimizes corrosion or erosion.

- Ideal for high-pressure and high-temperature applications, especially in oil & gas and power plants.

- Better for larger pipe sizes (above 2 inches), where threading becomes difficult or weak.

- Aesthetic and hygienic design — especially important in food, pharma, and chemical industries.

- Permanent installation ensures long-term reliability, unlike detachable threaded joints.

What factors should be considered when selecting the right type of buttweld fitting for a piping system?

Selecting the correct buttweld fitting depends on multiple technical and application-based factors:

- Material Compatibility: Ensure the fitting material matches or complements the piping material to prevent galvanic corrosion.

- Pressure & Temperature Rating: Check the service conditions and select fittings that conform to the appropriate ASME B16.9 pressure-temperature ratings.

- Size & Wall Thickness: Match the fitting size and schedule (e.g., SCH 40, SCH 80) with the pipe for proper fit and strength.

- Type of Connection Required: Choose between elbows (for direction change), tees (for branching), reducers (for size transition), etc., depending on the piping layout.

- Corrosive or Abrasive Fluids: For aggressive media, materials like Stainless Steel 316, Hastelloy, or Alloy 20 may be required.

- Weldability and Fabrication Requirements: Some projects require fittings with high weldability or specific end-preparation (e.g., bevel ends).

What are the common manufacturing methods used for buttweld pipe fittings?

Buttweld fittings are manufactured using several industrial processes, each tailored for different sizes, pressure classes, and materials. Here’s an overview of the most common methods:

Hot Forming (Induction/Press Forging):

This is the most widely used method for elbows, reducers, and tees. The pipe is heated and shaped using dies and hydraulic presses or induction bending machines, ensuring dimensional accuracy and grain structure integrity.

Cold Forming (Extrusion / Pushing):

Used for smaller diameter fittings and thin-wall components. It involves shaping at room temperature, which improves strength but may require stress relieving afterward.

Machining from Forged Bar Stock:

Typically used for small fittings or special alloy grades. Machining ensures tight tolerances but results in higher material waste.

Welded Construction (Fabricated):

For large-diameter fittings or non-standard designs, plates or pipes are cut, rolled, and welded together. Though not seamless, they can meet pressure ratings if properly tested and certified.

Each method complies with ASME B16.9 standards and is selected based on factors like cost, material, pressure class, and custom requirements.