Titanium Gr 2 / Gr 5: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Manufacturer of Titanium Grade 2 and 5 Pipe Fittings & Flanges | Buttweld & Forged. Durable Elbows, Tees, Reducers, End Caps, and Industrial Flanges meeting ASTM B363/B338/B381 standards, supplied to customers in USA, Canada, Germany, UAE, India, and international markets.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd is a leading manufacturer and supplier of high-precision Titanium Grade 2 and Grade 5 pipe fittings and flanges, specializing in forged, buttweld, and custom-engineered solutions. Utilizing advanced forging techniques and stringent quality controls, we produce products that conform to ASTM B363, B338, B381, and international piping standards. Our Titanium solutions offer exceptional corrosion resistance, strength, and longevity, making them ideal for demanding industries.

Driven by innovation and client-focused solutions, we combine cutting-edge manufacturing infrastructure with specialized engineering expertise. By consistently exceeding industry benchmarks, we empower our clients to achieve superior operational efficiency, safety, and long-term performance in high-performance and corrosive piping systems.

Titanium Grade 2 and Grade 5 are high-performance materials widely used in demanding piping systems. Grade 2 is commercially pure titanium, known for its excellent corrosion resistance in oxidizing and mildly reducing environments, making it suitable for chemical, marine, and desalination applications. Grade 5, also known as Ti-6Al-4V, is an alloyed titanium grade that combines superior mechanical strength with corrosion resistance, making it ideal for high-pressure and high-temperature applications such as aerospace, power generation, and chemical processing.

Titanium Grade 2 and Grade 5 pipe fittings and flanges are available in forged and buttweld forms, manufactured to meet stringent ASTM standards (B363, B338, B381) and ASME specifications. These products ensure precise dimensional tolerances, high structural integrity, and long-term reliability, providing durable solutions for aggressive and critical industrial environments where both performance and safety are paramount.

Ti Grade 2 buttweld fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

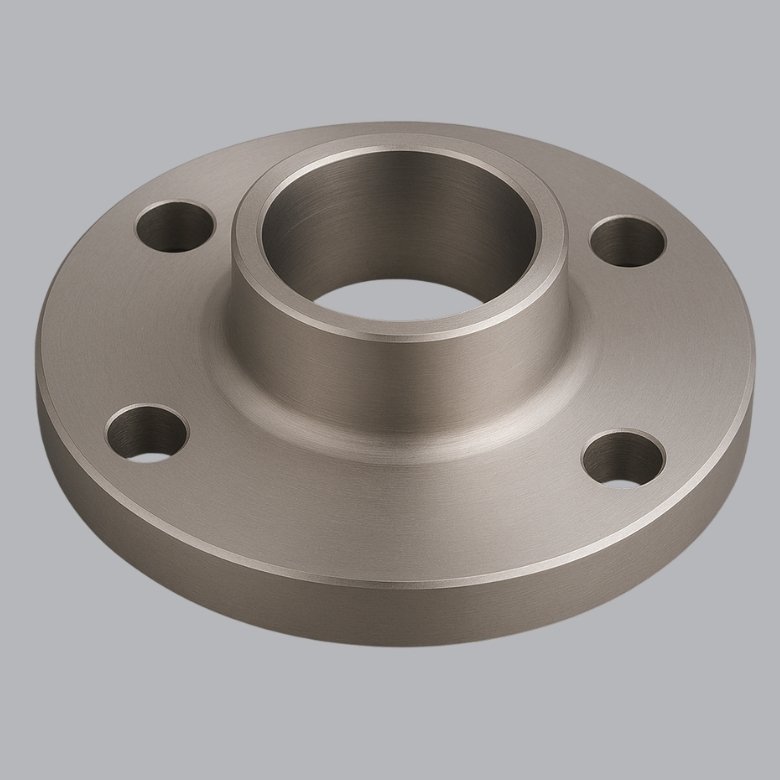

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

CP-Ti (Grade 1–4), Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI, Ti-3Al-2.5V, Ti-6Al-2Sn-4Zr-2Mo

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Additional Considerations

Titanium Gr 5 corrosion-resistant fittings– Grades & Standards

| Material / Alloy |

Grade / UNS |

ASTM /

ASME Standard |

Product Type | Typical Applications |

|---|---|---|---|---|

| Titanium (CP-Ti) | Grade 2 | ASTM B265 / B348 (Buttweld), ASTM B367 / B381 (Forged & Flanges) |

Buttweld, Forged, Flanges | Industrial piping, marine piping, chemical plants, power plants |

| Titanium Alloy | Ti-6Al-4V (Grade 5) | ASTM B348 / B381 (Buttweld, Forged & Flanges) |

Buttweld, Forged, Flanges | Aerospace, chemical, marine, high-temperature & high-pressure piping systems |

Explore Titanium Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Titanium Grade 2 / Grade 5 Products

Titanium Grade 5 pipe flanges ASTM B381 - Equivalent Grades

| Property | Titanium Grade 2 | Titanium Grade 5 (Ti-6Al-4V) |

|---|---|---|

| UNS Number | R50400 | R56400 |

| ASTM / ASME | B363, B381, B338, B862 | B363, B381, B348, B863 |

| ISO / EN | ISO 5832-2 / EN 3.7035 | ISO 5832-3 / EN 3.7165 |

| JIS | JIS H4600 / SUS R50400 | JIS H4600 / SUS R56400 |

Titanium Grade 2 pipe fittings ASTM B363 - Chemical Composition

| Element | Titanium Grade 2 (R50400) | Titanium Grade 5 (Ti-6Al-4V, R56400) |

|---|---|---|

| Titanium (Ti) | Balance | Balance |

| Carbon (C) | 0.08 max | 0.08 max |

| Iron (Fe) | 0.30 max | 0.25 max |

| Oxygen (O) | 0.25 max | 0.20 max |

| Nitrogen (N) | 0.03 max | 0.05 max |

| Hydrogen (H) | 0.015 max | 0.012 max |

| Aluminum (Al) | — | 6.0 ± 0.5 |

| Vanadium (V) | — | 4.0 ± 0.5 |

| Other Elements | 0.10 max (each) | 0.50 max (each) |

Titanium Gr 5 threaded & socketweld fittings - Mechanical Properties

| Property | Titanium Grade 2 (R50400) | Titanium Grade 5 (Ti-6Al-4V, R56400) |

|---|---|---|

| Tensile Strength (MPa / ksi) | 345 MPa / 50 ksi | 895 MPa / 130 ksi |

| Yield Strength (0.2% Offset, MPa / ksi) | 275 MPa / 40 ksi | 828 MPa / 120 ksi |

| Elongation (%) | 20% min | 10–15% |

| Hardness (HB / HRC) | 150 HB | 334 HB / 36 HRC |

| Modulus of Elasticity (GPa / Msi) | 105 GPa / 15.2 Msi | 113.8 GPa / 16.5 Msi |

| Density (g/cm³ / lb/in³) | 4.51 g/cm³ / 0.163 lb/in³ | 4.43 g/cm³ / 0.160 lb/in³ |

| Operating Temperature Range | Up to 400°C / 752°F | Up to 480°C / 896°F |

ASTM B363 Titanium Grade 2 / 5 Buttweld Fittings

ASTM B381 Titanium Grade 2 / 5 Flanges

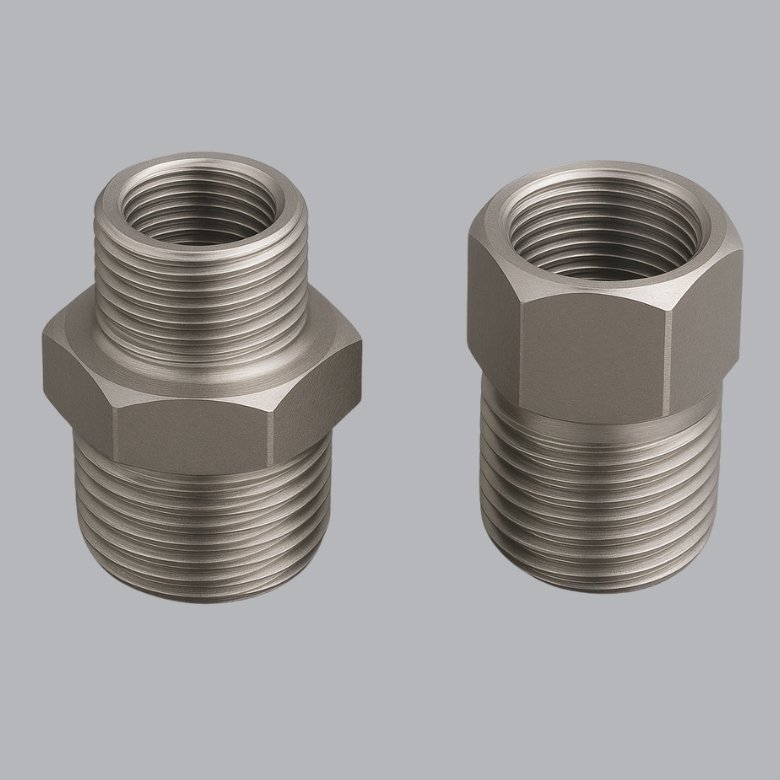

Precision Titanium Grade 2 / 5 Forged Fittings

How do Titanium Grade 2 and Grade 5 fittings behave under different welding processes?

Grade 2:

Easily weldable using TIG, MIG, and electron beam methods.

Minimal post-weld heat treatment required.

Maintains excellent corrosion resistance even in weld zones.

Grade 5:

More sensitive to heat; requires controlled welding conditions.

Preheating is generally not required, but post-weld stress relief can improve performance under cyclic loading.

Retains high strength, but the microstructure may vary if cooled too quickly, affecting ductility.

Practical advice: Use argon shielding gas to prevent contamination; avoid interpass temperatures >300°C to maintain properties.

What are the inspection and testing requirements for Titanium fittings and flanges?

Mechanical tests: Tensile, yield, elongation, and hardness per ASTM/ASME.

Non-destructive testing (NDT):

Radiography (RT) for welds

Ultrasonic testing (UT) for thickness and defect detection

Dye penetrant (PT) for surface crack detection

Material verification:

Positive Material Identification (PMI) to confirm Ti Grade 2 / Grade 5

Spectrochemical analysis for alloy composition

Hydrostatic testing: Required for pressure-rated flanges and fittings to validate sealing and integrity.

How do machining and threading differ between Grade 2 and Grade 5 fittings?

Grade 2:

Easier to machine; standard tooling can achieve smooth threads.

Less tool wear; better surface finish.

Grade 5:

Harder alloy; requires coated carbide tools or high-speed machining.

Thread tolerances must be closely monitored to prevent galling.

Implication: Grade 5 is more demanding in fabrication, especially for threaded or socket weld fittings.