- Home

- Titanium

Titanium

Titanium: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Titanium Pipe Fittings and Flanges Manufacturer | Buttweld & Forged. High-quality Elbows, Tees, Reducers, End Caps, and Industrial Flanges engineered to ASTM B363/B381/B367 standards for international markets.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading Manufacturer and supplier of high-quality industrial pipe fittings, flanges, and forged components. With a strong focus on precision engineering and adherence to international standards, our products are trusted across oil & gas, chemical, marine, power, and industrial sectors worldwide.

Committed to excellence, we ensure every product meets stringent quality standards through advanced manufacturing processes, rigorous testing, and certification compliance, such as ASTM, ASME, and ISO. Our global reach and customer-centric approach make us a reliable partner for projects requiring durable, corrosion-resistant, and high-performance piping solutions.

Titanium pipe fittings and flanges are designed for high-performance applications in corrosive and high-temperature environments. Offered in both buttweld and forged forms, our range—including elbows, tees, reducers, and end caps—is manufactured from commercially pure titanium (Grades 1–4) and titanium alloys (e.g., Grade 5 / Ti-6Al-4V). These fittings provide outstanding corrosion resistance against seawater, chemicals, and acidic media, along with a superior strength-to-weight ratio.

All Titanium flanges and fittings are precision-engineered to meet ASTM B337 and B381 standards, ensuring dimensional accuracy, uniform wall thickness, and dependable sealing performance. Our products undergo strict quality checks, including Positive Material Identification (PMI), hydrostatic testing, and non-destructive testing (UT/RT), making them ideal for marine, chemical, petrochemical, and aerospace piping systems.

Titanium seamless pipe fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

CP-Ti (Grade 1–4), Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI, Ti-3Al-2.5V, Ti-6Al-2Sn-4Zr-2Mo

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Additional Considerations

High-performance titanium flanges– Grades & Standards

| Material / Alloy |

Grade / UNS |

ASTM / ASME Standard |

Product Type |

Typical Applications |

|---|---|---|---|---|

| Titanium (CP-Ti) | Grade 1 | ASTM B265 / B348 (Buttweld), ASTM B367 / B381 (Forged & Flanges) |

Buttweld, Forged, Flanges | Seawater pipelines, chemical processing, desalination plants, marine systems |

| Titanium (CP-Ti) | Grade 2 | ASTM B265 / B348 (Buttweld), ASTM B367 / B381 (Forged & Flanges) |

Buttweld, Forged, Flanges | Industrial piping, marine piping, chemical plants, power plants |

| Titanium (CP-Ti) | Grade 3 | ASTM B265 / B348 (Buttweld), ASTM B367 / B381 (Forged & Flanges) |

Buttweld, Forged, Flanges | High-strength piping, offshore pipelines, chemical processing |

| Titanium (CP-Ti) | Grade 4 | ASTM B265 / B348 (Buttweld), ASTM B367 / B381 (Forged & Flanges) |

Buttweld, Forged, Flanges | High-pressure piping, marine and offshore applications, chemical plants |

| Titanium Alloy | Ti-6Al-4V (Grade 5) | ASTM B348 / B381 (Buttweld, Forged & Flanges) | Buttweld, Forged, Flanges | Aerospace, chemical, marine, high-temperature & high-pressure piping systems |

| Titanium Alloy | Ti-6Al-4V ELI | ASTM B348 / B381 (Buttweld, Forged & Flanges) | Buttweld, Forged, Flanges | Critical aerospace, medical implants, high-strength chemical piping |

| Titanium Alloy | Ti-3Al-2.5V | ASTM B348 / B381 (Buttweld, Forged & Flanges) | Buttweld, Forged, Flanges | Marine piping, industrial systems, corrosion-resistant piping |

| Titanium Alloy | Ti-6Al-2Sn-4Zr-2Mo | ASTM B348 / B381 (Buttweld, Forged & Flanges) | Buttweld, Forged, Flanges | High-temperature and high-pressure applications, aerospace, chemical plants |

Explore Titanium Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Titanium Products

ASTM B367 Titanium forged fittings - Equivalent Grades

| Titanium Grade | ASTM / ASME | UNS | ISO / EN |

|---|---|---|---|

| Grade 1 (CP-Ti) | ASTM B363, B367, B381 | R50250 | ISO 5832-2 |

| Grade 2 (CP-Ti) | ASTM B363, B367, B381 | R50400 | ISO 5832-3 |

| Grade 3 (CP-Ti) | ASTM B363, B367, B381 | R50550 | ISO 5832-4 |

| Grade 4 (CP-Ti) | ASTM B363, B367, B381 | R50650 | ISO 5832-5 |

| Ti-6Al-4V (Grade 5) | ASTM B363, B367, B381 | R56400 | ISO 5832-3 |

| Ti-6Al-4V ELI | ASTM B363, B367, B381 | R56401 | ISO 5832-3 |

| Ti-3Al-2.5V | ASTM B363, B367, B381 | R56320 | ISO 5832-3 |

| Ti-6Al-2Sn-4Zr-2Mo | ASTM B363, B367, B381 | R58400 | ISO 5832-3 |

Titanium alloy fittings - Chemical Composition

| Titanium Grade |

Carbon (C) % |

Iron (Fe) % |

Oxygen (O) % |

Nitrogen (N) % |

Hydrogen (H) % |

Titanium (Ti) % |

Other Alloying Elements |

|---|---|---|---|---|---|---|---|

| Grade 1 (CP-Ti) | 0.08 max | 0.20 max | 0.18 max | 0.03 max | 0.015 max | Balance | – |

| Grade 2 (CP-Ti) | 0.08 max | 0.30 max | 0.25 max | 0.03 max | 0.015 max | Balance | – |

| Grade 3 (CP-Ti) | 0.08 max | 0.30 max | 0.35 max | 0.03 max | 0.015 max | Balance | – |

| Grade 4 (CP-Ti) | 0.08 max | 0.50 max | 0.40 max | 0.03 max | 0.015 max | Balance | – |

| Ti-6Al-4V (Grade 5) | 0.08 max | 0.25 max | 0.20 max | 0.05 max | 0.015 max | Balance | Al 6%, V 4% |

| Ti-6Al-4V ELI | 0.08 max | 0.25 max | 0.13 max | 0.03 max | 0.012 max | Balance | Al 6%, V 4% |

| Ti-3Al-2.5V | 0.08 max | 0.30 max | 0.20 max | 0.03 max | 0.015 max | Balance | Al 3%, V 2.5% |

| Ti-6Al-2Sn-4Zr-2Mo | 0.08 max | 0.30 max | 0.20 max | 0.03 max | 0.015 max | Balance | Al 6%, Sn 2%, Zr 4%, Mo 2% |

Corrosion-resistant titanium fittings - Mechanical Properties

| Titanium Grade |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

Hardness (HRB / HRC) |

Density (g/cm³) |

Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|---|

| Grade 1 (CP-Ti) | 170 min | 240–350 | 24–28 | 70 HRB | 4.51 | 105–110 |

| Grade 2 (CP-Ti) | 275 min | 345–450 | 20–25 | 80 HRB | 4.51 | 105–110 |

| Grade 3 (CP-Ti) | 380 min | 450–600 | 18–22 | 90 HRB | 4.51 | 105–110 |

| Grade 4 (CP-Ti) | 480 min | 550–700 | 15–20 | 95 HRB | 4.51 | 105–110 |

| Ti-6Al-4V (Grade 5) | 828–880 | 895–950 | 10–15 | HRC 36–38 | 4.43 | 110 |

| Ti-6Al-4V ELI | 795–825 | 860–895 | 10–15 | HRC 36–38 | 4.43 | 110 |

| Ti-3Al-2.5V | 620–690 | 655–725 | 12–15 | HRC 33–36 | 4.45 | 105–110 |

| Ti-6Al-2Sn-4Zr-2Mo | 880–950 | 950–1000 | 8–12 | HRC 38–40 | 4.48 | 110–115 |

ASTM B363 Titanium Buttweld Fittings

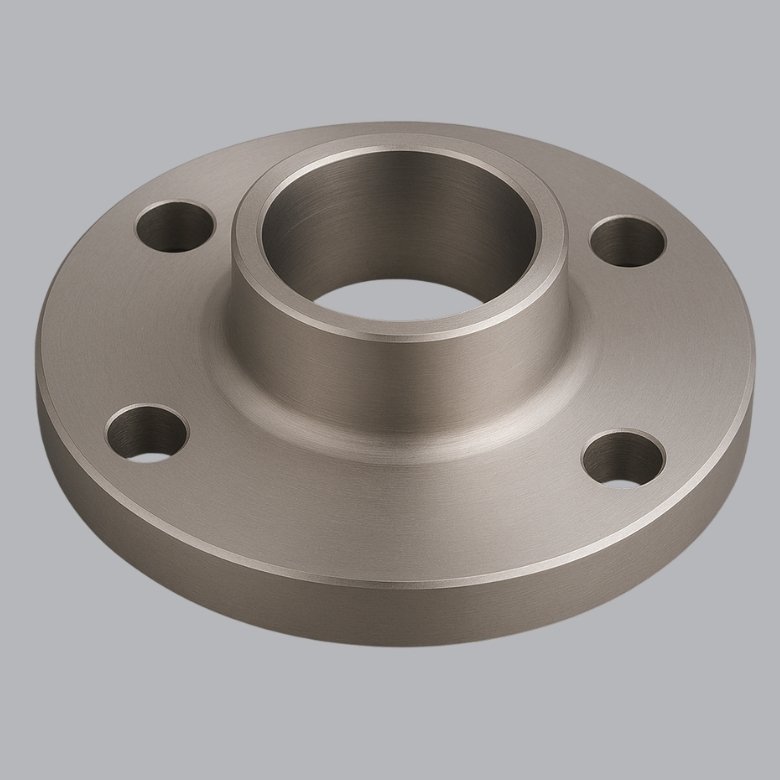

ASTM B381 Titanium Flanges

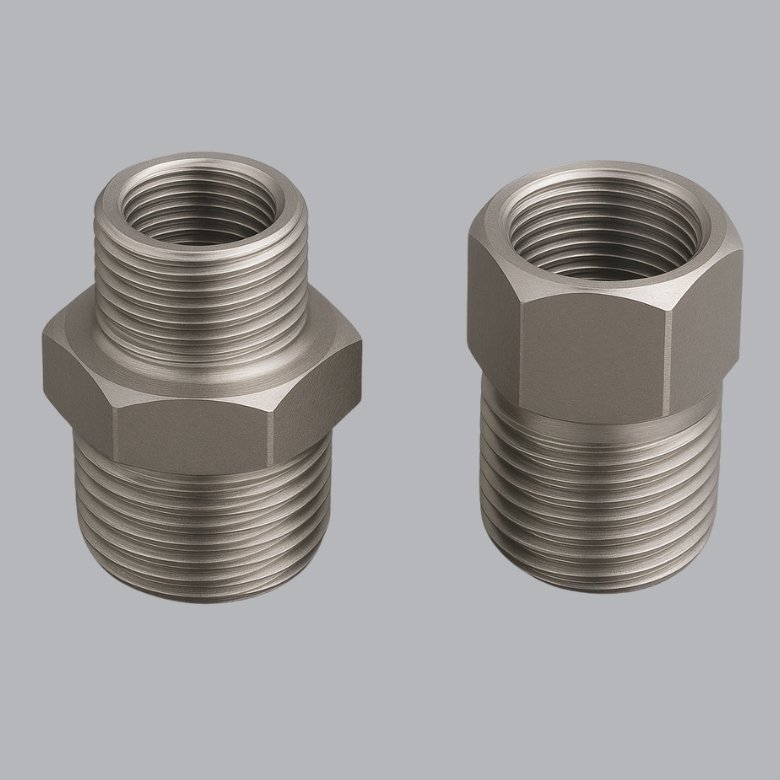

Precision Titanium Forged Fittings

What materials are used in Titanium pipe fittings and flanges?

Titanium pipe fittings and flanges are manufactured from commercially pure titanium (Grades 1–4) or titanium alloys (commonly Grade 5 / Ti-6Al-4V).

Grade 1: Excellent corrosion resistance, low strength, used in seawater and chemical applications.

Grade 2: Slightly higher strength than Grade 1, widely used for piping and marine applications.

Grade 5 (Ti-6Al-4V): High strength-to-weight ratio, suitable for high-temperature and high-pressure applications, including aerospace and chemical industries.

All materials comply with ASTM standards like B337, B363, B367, and B381, ensuring consistent mechanical and chemical properties.

What are the advantages of Titanium fittings and flanges over other materials?

Exceptional Corrosion Resistance: Against seawater, chemicals, and acidic media.

High Strength-to-Weight Ratio: Strong yet lightweight compared to stainless steel or carbon steel.

Temperature Resistance: Suitable for high-temperature applications up to ~600°C (for Grade 5 alloys).

Durability & Longevity: Reduced maintenance costs due to extended service life.

Non-Magnetic: Ideal for specialized applications in medical, aerospace, and electronics industries.

What factors should be considered when selecting Titanium fittings and flanges?

Grade of Titanium: Depending on corrosion, pressure, and temperature requirements.

Pipe Size & Schedule: Ensure compatibility with existing piping.

Type of Fitting: Elbow, tee, reducer, flange type (weld neck, slip-on, blind, etc.).

Pressure & Temperature Rating: Must comply with application requirements.

Standards Compliance: ASTM/ASME standards ensure material and dimensional integrity.