- Home

- Super Duplex Steel

- UNS S32750 / S32760

UNS S32750 / S32760

UNS S32750 / S32760 : Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

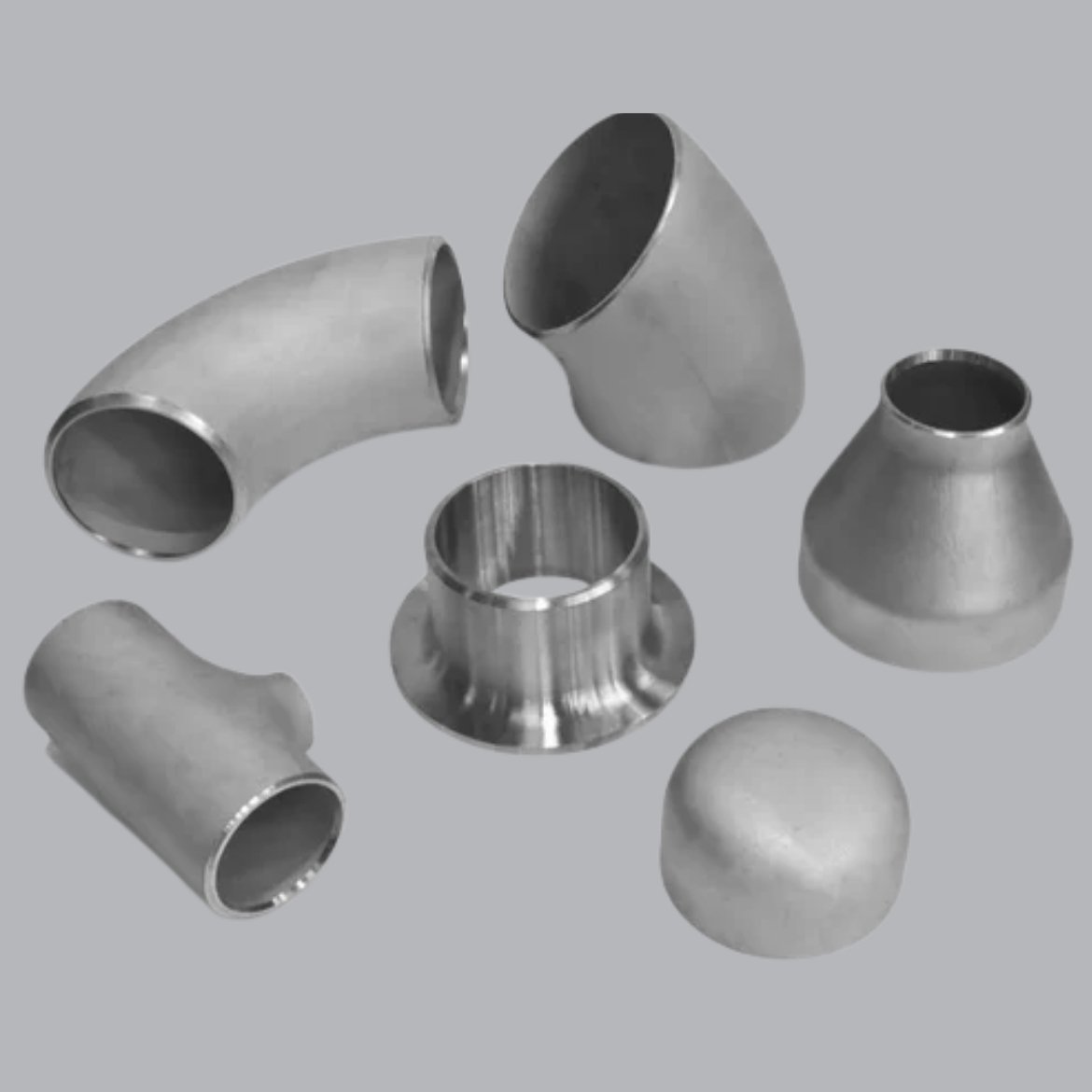

UNS S32750 / S32760 Super Duplex Stainless Steel Fittings & Flanges – Reliable Manufacturer & Supplier offering Elbows, Tees, Reducers, Caps, and full range of Buttweld, Forged, and Socket Weld Flanges for critical piping projects.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a trusted manufacturer and exporter of high-quality industrial UNS S32750 / S32760 pipe fittings and flanges. With decades of experience, we provide precision-engineered solutions in carbon steel, alloy steel, stainless steel, duplex, and super duplex, catering to demanding sectors including oil & gas, petrochemical, marine, and power industries.

With state-of-the-art manufacturing capabilities, stringent quality control, and adherence to international standards, we deliver products with superior reliability and performance. Our technical expertise, global supply network, and commitment to timely delivery make us a preferred partner for clients worldwide. We also offer customized solutions and dedicated customer support to meet the most challenging industrial and offshore piping requirements.

UNS S32750 / S32760 Super Duplex Fittings and Flanges are designed for critical piping applications that require exceptional strength and corrosion resistance. These grades exhibit outstanding resistance to chloride stress corrosion cracking, pitting, and crevice corrosion, making them ideal for offshore, marine, chemical processing, and desalination industries. The fittings include elbows, tees, reducers, and caps, while flanges are available in buttweld, forged, and socket weld forms.

UNS S32750 / S32760 are high-performance super duplex stainless steels with high tensile and yield strength, superior toughness, and excellent fatigue resistance. They are manufactured in compliance with ASTM A182 and ASTM A815 for fittings and flanges, and meet dimensional and pressure standards such as ASME B16.5, B16.9, and B16.11. These components are produced in seamless and welded forms, ensuring precise tolerances, high durability, and reliable performance under demanding conditions.

Super Duplex fittings and flanges undergo stringent quality tests including hydrostatic testing, intergranular corrosion testing (ASTM A262 Practice E), hardness testing (HBW/HRB), impact testing (Charpy V-notch), and chemical composition verification via PMI or spectro analysis. The high ferrite content (typically 70:30 ±5) ensures a balance between strength and corrosion resistance, making UNS S32750 / S32760 components suitable for highly corrosive, high-pressure, and high-temperature piping systems.

UNS S32750 pipe fittings Specifications

Size Range – (Buttweld, Forged, Flange)

½” – 4” (Socket Weld & Threaded), ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades

ASTM A182 / SA182

Super Duplex 2507, UNS S32750 / S32760

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

ASTM A182 UNS S32760 Flanges - Grades & Standards

| Grade | UNS Number | ASTM / ASME Standards | Material Type | Typical Applications |

|---|---|---|---|---|

| Super Duplex F51 | S32750 | ASTM A182 / A815 | Forged / Buttweld Flange | Oil & Gas, Petrochemical, Offshore |

| Super Duplex F53 | S32760 | ASTM A182 / A815 | Forged / Buttweld Flange | Chemical Processing, Desalination Plants |

| Super Duplex F55 | S32550 | ASTM A182 / A815 | Forged / Buttweld Flange | High-Pressure Piping, Marine Applications |

| Super Duplex F61 | S32900 | ASTM A182 / A815 | Forged / Buttweld Flange | Corrosive Environment Pipelines |

| Super Duplex F55 (Alternative) | S32760 | ASTM B564 / ASME B16.5 | Weld Neck / Slip-On / Blind Flanges | Offshore, Marine, High Chloride Water Systems |

Explore Super Duplex Steel

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

UNS S32750 / S32760 Super Duplex Steel Products

ASTM A815 UNS S32750 Super Duplex fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Material / Grade | UNS Number | EN / DIN | ASTM / ASME | JIS | GOST / Russian |

BS / British |

AFNOR / French |

|---|---|---|---|---|---|---|---|

| Super Duplex Stainless Steel | UNS S32750 | EN 1.4410 / X2CrNiMoN25-7-4 |

ASTM A182 F51 / A815 F51 |

SUS329J4L | 08Х25Н6М3Т | 329S32 | Z3CN25-07 |

| Super Duplex Stainless Steel | UNS S32760 | EN 1.4501 / X2CrNiMoN25-6-3 |

ASTM A182 F53 / A815 F53 |

SUS329J3L | 08Х26Н6М3Т | 329S31 | Z3CN25-06 |

UNS S32760 pipe fittings - Chemical Composition

| Element (wt%) | UNS S32750 (F51) | UNS S32760 (F53) |

|---|---|---|

| Carbon (C) | ≤ 0.03 | ≤ 0.03 |

| Manganese (Mn) | ≤ 2.0 | ≤ 2.0 |

| Phosphorus (P) | ≤ 0.03 | ≤ 0.03 |

| Sulfur (S) | ≤ 0.02 | ≤ 0.02 |

| Silicon (Si) | 0.5–1.0 | 0.5–1.0 |

| Chromium (Cr) | 24–26 | 25–26 |

| Nickel (Ni) | 6–8 | 7–9 |

| Molybdenum (Mo) | 3–5 | 3–5 |

| Nitrogen (N) | 0.2–0.22 | 0.24–0.32 |

| Iron (Fe) | Balance | Balance |

Forged fittings UNS S32750 - Mechanical Properties

| Property | UNS S32750 (F51) | UNS S32760 (F53) |

|---|---|---|

| Tensile Strength (MPa) | 830–1000 | 850–1050 |

| Yield Strength (0.2% offset, MPa) | 550–750 | 570–780 |

| Elongation (%) | 25–30 | 25–30 |

| Hardness (HBW) | 280–320 | 280–320 |

| Impact Toughness (Charpy V-notch, J) | 80–150 | 80–150 |

| Ferrite Content (%) | 65–75 | 65–75 |

| Modulus of Elasticity (GPa) | ~200 | ~200 |

| Poisson’s Ratio | 0.27 | 0.27 |

UNS S32750 / S32760 Buttweld Fittings – Available in Seamless and Welded

UNS S32750 / S32760 Flanges – Trusted Industrial Piping Solutions

UNS S32750 / S32760 Threaded & Socket Weld Fittings – ASME / ANSI Certified

What makes UNS S32760 better than S32750?

Enhanced Chemical Composition:

UNS S32760 contains higher levels of nickel, molybdenum, and nitrogen compared to S32750.

Increased nickel improves overall corrosion resistance and toughness.

Higher molybdenum content enhances resistance to pitting and crevice corrosion in chloride-containing environments.

Elevated nitrogen contributes to improved yield strength and stabilizes the duplex microstructure, maintaining a proper balance between ferrite and austenite.

Superior Corrosion Resistance:

S32760 is more resistant to chloride stress corrosion cracking (CSCC) and aggressive acidic or saline environments.

This makes it ideal for offshore, seawater, and chemical applications where S32750 may be vulnerable to localized corrosion.

High-Performance in Extreme Conditions:

Designed to perform reliably under high pressure, high temperature, and highly corrosive conditions.

Preferred for marine piping systems, offshore oil & gas platforms, and chemical processing lines where long-term durability is critical.

Long-Term Reliability:

The improved composition and corrosion resistance reduce maintenance requirements and extend the service life of piping systems in challenging environments.

Why should UNS S32750 / S32760 be chosen over standard stainless steel grades?

Superior Strength and Toughness:

Both grades provide higher tensile and yield strength than conventional austenitic stainless steels (like 304 or 316L).

High toughness ensures resistance to cracking and mechanical failure, even at low temperatures.

Exceptional Corrosion Resistance:

Resistant to chloride-induced stress corrosion cracking, pitting, and crevice corrosion.

Suitable for seawater, chemical processing, and aggressive industrial environments, where standard grades like 316L or 904L may fail.

Durability in Harsh Environments:

Offers long-term reliability and reduces the need for frequent maintenance.

High performance in offshore, desalination, chemical, and power plant applications ensures consistent operational efficiency.

Compatibility with High-Pressure, High-Temperature Systems:

It can be safely used in high-pressure pipelines and high-temperature processes, unlike conventional stainless steels, which have lower mechanical strength.

Balanced Microstructure:

The duplex structure (ferrite + austenite) provides an optimal combination of corrosion resistance, mechanical strength, and fatigue resistance, making these grades superior to standard austenitic stainless steels.

How are UNS S32750 / S32760 fittings and flanges tested?

Hydrostatic Pressure Test: Verifies pressure rating and leak-tightness.

Intergranular Corrosion Test (ASTM A262, Practice E): Checks resistance to intergranular attack.

Hardness Test (HBW / HRB): Ensures mechanical strength.

Impact Test (Charpy V-notch): Measures toughness at low temperatures.

Ferrite Content Test (70:30 ±5): Confirms duplex microstructure balance.

PMI / Spectro Analysis: Verifies chemical composition and alloy grade.

Dimensional & Visual Inspection: Ensures conformity to ASME/ASTM standards.