- Home

- Nickel Alloys

- Nickel 200 / 201

Nickel 200 / 201

Nickel 200 / 201: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Nickel 200/201 Pipe Fittings and Flanges – Leading Manufacturer and Exporter of premium Buttweld, Forged, Threaded, and Socket Weld components including Elbows, Tees, Reducers, Stub Ends, End Caps, and Industrial Flanges, engineered for chemical, marine, and process piping applications.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer, supplier, and exporter of high-quality industrial piping solutions. With years of expertise in the field, we specialize in delivering precision-engineered Buttweld, Forged, Threaded, and Socket Weld fittings and flanges, catering to a wide range of industries, including chemical, petrochemical, marine, and process piping systems.

Committed to excellence, we focus on providing durable, reliable, and corrosion-resistant solutions. Our dedicated team of professionals combines technical expertise with innovative manufacturing processes to offer customized solutions for clients worldwide. As a trusted partner in the global piping industry, we pride ourselves on delivering superior products, timely services, and consistent customer satisfaction.

Nickel 200/201 pipe fittings and flanges are high-purity nickel alloys engineered for exceptional corrosion resistance in reducing environments, including chemical, marine, and industrial applications. These alloys offer superior resistance to alkalis, caustics, and organic acids, making them ideal for piping systems handling corrosive media. Available in Buttweld, Forged, Threaded, and Socket Weld configurations, these fittings and flanges are suitable for high-pressure and high-temperature conditions, ensuring long-term reliability and performance.

Nickel 200/201 fittings maintain excellent mechanical properties, including high tensile and yield strength, good ductility, and impact resistance, which allow them to withstand thermal expansion and mechanical stresses in piping systems. The low-carbon variant, Nickel 201, provides enhanced resistance to intergranular corrosion, particularly after welding. These alloys are manufactured as seamless or welded components, conforming to ASME B16.9, B16.11, B16.5, and ASTM standards, and are suitable for demanding applications in chemical processing, seawater systems, and industrial process pipelines.

ASTM B366 Nickel 200/201 Buttweld fittings Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Nickel 200 / 201

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Nickel 200/201 high-pressure fittings– Grades & Standards

| Nickel Alloy | Product Type | ASTM / ASME Standard | Notes / Applications |

|---|---|---|---|

| Nickel 200 / 201 | Buttweld Fittings | ASTM B366 / ASME SB366 | Seamless fittings: elbows, tees, reducers, caps; corrosion resistant in chemical, marine, and food processing industries. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged elbows, tees, reducers, couplings, caps; high corrosion resistance. |

|

| Flanges | ASTM B462 / ASME SB462 | Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint flanges; marine and chemical applications. |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Nickel Alloys 200/201 Products

ASTM B366 Nickel 200/201 fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Product Type | Alloy | UNS | ASTM / ASME Standard | EN / DIN | JIS | GOST | BS | AFNOR / NF |

|---|---|---|---|---|---|---|---|---|

| Buttweld Fittings | Nickel 200 | N02200 | ASME B16.9 | 2.4066 | NC2 | HN1 | 2.4066 | ZN2 |

| Nickel 201 | N02201 | ASME B16.9 | 2.4066 | NC2 | HN1 | 2.4066 | ZN2 | |

| Forged Fittings (Socket / Threaded) | Nickel 200 | N02200 | ASME B16.11 | 2.4066 | NC2 | HN1 | 2.4066 | ZN2 |

| Nickel 201 | N02201 | ASME B16.11 | 2.4066 | NC2 | HN1 | 2.4066 | ZN2 | |

| Flanges | Nickel 200 | N02200 | ASME B16.5 / B16.47 | 2.4066 | NC2 | HN1 | 2.4066 | ZN2 |

| Nickel 201 | N02201 | ASME B16.5 / B16.47 | 2.4066 | NC2 | HN1 | 2.4066 | ZN2 |

ASTM B564 Nickel 200/201 flanges - Chemical Composition

| Alloy | Nickel (Ni) | Carbon (C) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Silicon (Si) | Sulfur (S) |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 99.0 min | 0.15 max | 0.35 max | 0.30 max | 0.35 max | 0.25 max | 0.015 max |

| Nickel 201 | 99.0 min | 0.03 max | 0.35 max | 0.30 max | 0.35 max | 0.25 max | 0.015 max |

Nickel UNS N02200 / N02201 forged fittings - Mechanical Properties

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| Nickel 200 | 485–690 | 150–300 | 40–50 | 80–140 |

| Nickel 201 | 485–690 | 150–300 | 40–50 | 80–140 |

Nickel 200/201 Buttweld Fittings – High-Quality Seamless & Welded

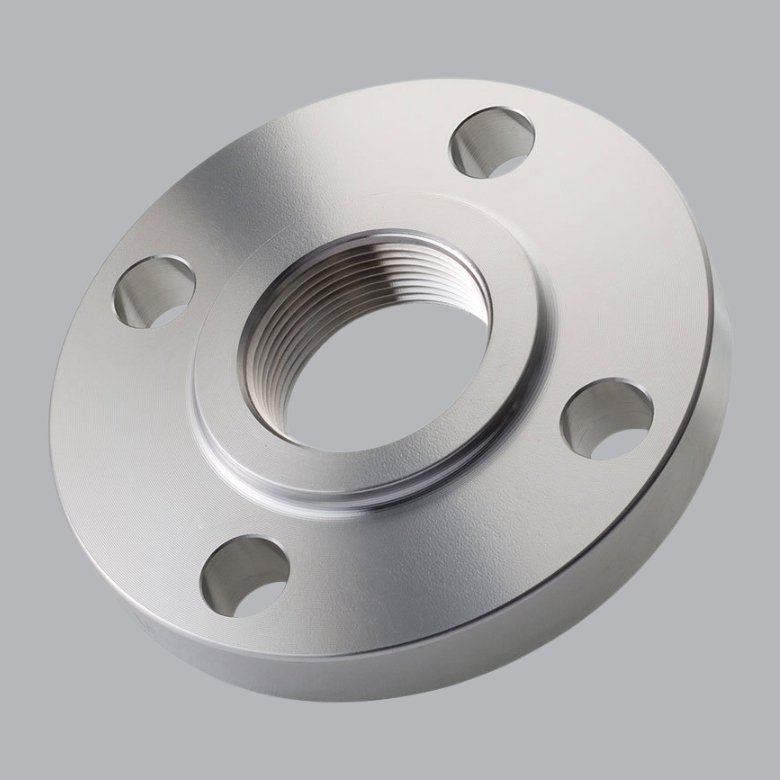

Nickel 200/201 Flanges – industrial piping solutions

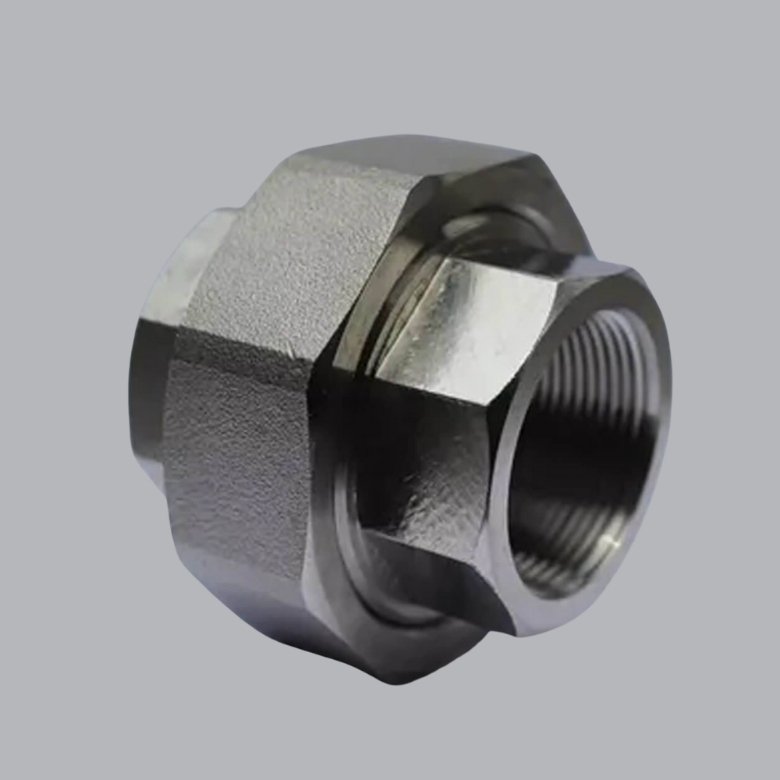

Nickel 200/201 Threaded and Socket Weld Fittings – chemical and marine grade fittings

What is the primary difference between Nickel 200 and Nickel 201 in piping applications?

Nickel 200 and Nickel 201 are both commercially pure nickel, but differ mainly in carbon content.

Nickel 200 contains higher carbon (≤0.15%), which provides higher tensile strength but may lead to graphitization at temperatures above 315°C.

Nickel 201 has lower carbon (≤0.03%), preventing graphitization and making it suitable for high-temperature and welded applications.

Therefore, Nickel 200 is preferred for general corrosion environments, whereas Nickel 201 is chosen when fittings and flanges will be welded or operate at elevated temperatures to avoid intergranular cracking.

Why is Nickel 201 recommended for welded pipe fittings and flanges?

Nickel 201’s low carbon content minimizes carbide precipitation during welding.

This prevents intergranular corrosion which can occur in Nickel 200 when exposed to heat during welding.

Nickel 201 maintains structural stability and ductility across the heat-affected zone (HAZ).

It provides long-term resistance to stress corrosion cracking in chemical, alkaline, and reducing environments.

How does Nickel 200/201 behave during welding and fabrication of fittings and flanges?

Nickel 200/201 has excellent weldability using GTAW / TIG, SMAW, and GMAW.

Nickel filler metals (e.g., ENi-1 electrodes) are recommended.

Post-weld heat treatment is generally not required.

The alloy remains ductile and does not harden during welding.

This ensures:

Leak-free joint formation

High structural integrity in pressure piping systems