- Home

- Nickel Alloys

- Inconel 600 / 625 / 718

Inconel 600 / 625 / 718

Inconel 600 / 625 / 718: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Trusted Manufacturer, Stockist & Global Exporter of ASTM B366 Inconel Forged fittings, ASTM B564 Inconel flanges, Alloy 600/718 fittings, UNS N06600/N06625 Pipe Fittings, Inconel 718 Pipe Fittings, including Buttweld, Forged, Threaded, and Socket Weld configurations for extreme temperature and corrosion-resistant applications.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer and exporter of high-performance piping components, delivering precision-engineered solutions to global industries. With a modern manufacturing facility and a strong focus on quality, we produce a wide range of Pipe Fittings, Flanges, and Customized Fabricated Components that meet international standards and demanding service requirements.

Our expertise lies in handling Inconel and Special Grade Materials, enabling us to cater to diverse sectors including Oil & Gas, Petrochemicals, Refining, Power Generation, Marine, and Heavy Engineering.

Driven by innovation, technical excellence, and a customer-first approach, we ensure consistency in material quality, dimensional accuracy, and reliable performance under extreme temperature and pressure environments. We maintain strict quality assurance practices supported by advanced testing equipment, certified raw materials, and a skilled engineering workforce. With a strong distribution network and commitment to timely delivery, we continue to build long-term partnerships with clients across India and worldwide.

Inconel 600 (UNS N06600) is a nickel-chromium alloy designed for high-temperature oxidation and corrosion resistance, particularly in environments involving carburizing and chloride stress corrosion. It maintains structural stability and mechanical strength even at elevated temperatures up to 1090°C, making it suitable for furnace components, heat exchanger tubing, superheaters, and chemical processing equipment. Its balanced composition provides excellent resistance to dry and wet chlorine, hydrogen chloride, and caustic alkalis, which makes it highly reliable in harsh chemical process environments.

Inconel 625 (UNS N06625) is a solid solution-strengthened nickel-chromium-molybdenum alloy with exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking, especially in chloride-bearing environments. The presence of molybdenum and niobium enhances its strength and creep resistance across a wide temperature range from cryogenic conditions up to 980°C. Inconel 625 is widely used in seawater applications, offshore oil & gas production, pollution control equipment, chemical reactors, and aerospace exhaust systems, where high corrosion resistance and durability are critical.

Inconel 718 (UNS N07718) is a precipitation-hardened nickel-chromium alloy known for its outstanding tensile strength, fatigue strength, creep resistance, and exceptional weldability. Its strengthening mechanism comes from gamma prime (γ′) and gamma double prime (γ″) precipitates formed during heat treatment, enabling it to retain mechanical stability up to 700°C under sustained loading. Due to its superior high-temperature mechanical performance, Inconel 718 is extensively used in gas turbine engine components, aircraft propulsion systems, high-pressure fasteners, cryogenic storage tanks, and high-temperature bolting.

ASTM B366 Inconel 600 Pipe fittings Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Inconel 600 / 625 / 718

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Inconel 625 Industrial Flanges – Grades & Standards

| Nickel Alloy | Product Type | ASTM / ASME Standard | Applications |

|---|---|---|---|

| Inconel 600 | Buttweld Fittings | ASTM B366 / ASME SB366 | Seamless elbows, tees, reducers, end caps; excellent high-temperature oxidation and corrosion resistance; ideal for chemical, marine, and high-temp process piping. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged elbows, tees, reducers, couplings, caps; high strength and corrosion resistance for chemical, marine, and industrial piping systems. |

|

| Flanges | ASTM B564 / ASME SB564 | Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint flanges; suitable for high-pressure and corrosive service in offshore, chemical, and marine applications. |

|

| Inconel 625 | Buttweld Fittings | ASTM B443 / ASME SB443 | Seamless elbows, tees, reducers, end caps; superior resistance to pitting, crevice corrosion, and chloride stress corrosion cracking; offshore, chemical, and seawater applications. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged elbows, tees, reducers, couplings, caps; excellent mechanical strength and corrosion resistance for high-pressure piping systems. |

|

| Flanges | ASTM B564 / ASME SB564 | Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint flanges; engineered for chemical processing, marine, and offshore applications. |

|

| Inconel 718 | Buttweld Fittings | ASTM B670 / ASME SB670 | Seamless elbows, tees, reducers, end caps; precipitation-hardened for superior tensile, fatigue, and creep strength; used in aerospace, gas turbines, and high-pressure piping. |

| Forged Fittings | ASTM B462 / ASME SB462 | Forged elbows, tees, reducers, couplings, caps; maintains mechanical stability under high pressure and temperature; ideal for power generation, cryogenic, and industrial piping. |

|

| Flanges | ASTM B564 / ASME SB564 | Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint flanges; high-strength flanges for high-pressure, high-temperature, and corrosive applications. |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Inconel Alloys Products

ASTM B366 Inconel 718 Pipe Fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Alloy / Grade | UNS Number | ASTM / ASME | EN / DIN | JIS | Werkstoff |

|---|---|---|---|---|---|

| Inconel 600 | N06600 | ASTM B166 / B564 / ASME SB166 / SB564 | 2.4816 (NiCr15Fe) | NCF601 | 2.4816 |

| Inconel 625 | N06625 | ASTM B443 / B564 / ASME SB443 / SB564 | 2.4856 (NiCr22Mo9Nb) | NCF625 | 2.4856 |

| Inconel 718 | N07718 | ASTM B670 / B564 / ASME SB670 / SB564 | 2.4668 (NiCr19Fe19Nb) | NCF718 | 2.4668 |

Inconel Werkstoff 2.4816 fittings - Chemical Composition

| Alloy / Grade | Ni | Cr | Fe | Mo | Nb+Ta | Ti | Al | C | Mn | Si |

|---|---|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 72 min | 14–17 | 6–10 | – | – | – | – | 0.15 max | 1 max | 0.5 max |

| Inconel 625 | 58 min | 20–23 | 5 max | 8–10 | 3.15–4.15 | – | – | 0.1 max | 0.5 max | 0.5 max |

| Inconel 718 | 50–55 | 17–21 | 17 max | 2.8–3.3 | 4.75–5.5 | 0.65–1.15 | 0.2–0.8 | 0.08 max | 0.35 max | 0.35 max |

buttweld Inconel fittings - Mechanical Properties

| Alloy / Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness | Service Temperature |

|---|---|---|---|---|---|

| Inconel 600 | 550–750 | 240–400 | 30–40 | 95–200 HB | Up to 1090°C |

| Inconel 625 | 620–860 | 275–550 | 30–40 | 95–270 HB | Up to 980°C |

| Inconel 718 | 1270–1380 | 1050–1200 | 12–15 | 340–400 HB | Up to 700°C |

Inconel 600/625/718 Buttweld Fittings – High-Quality Seamless & Welded

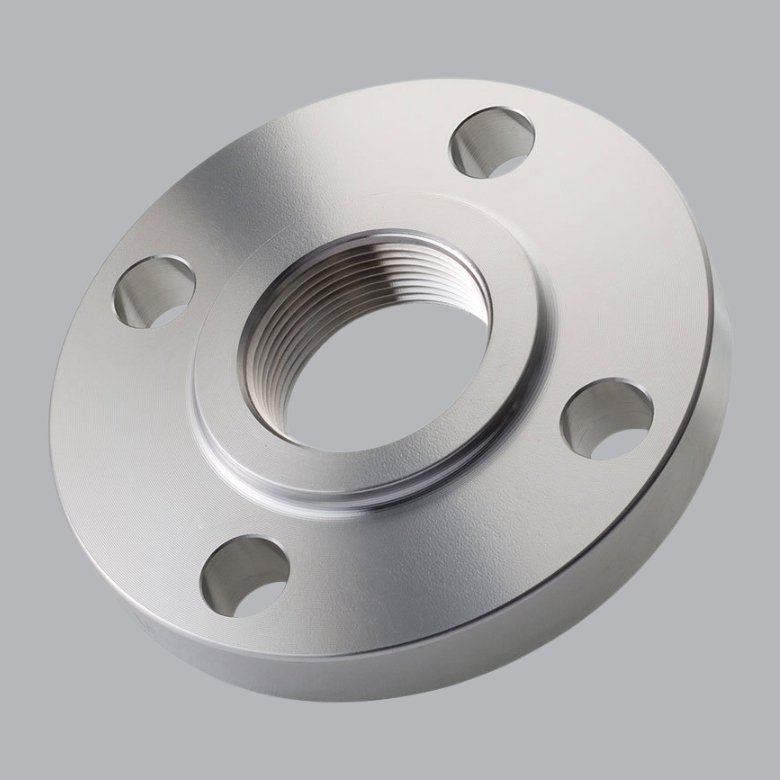

Alloy 600/625/718 Flanges – industrial piping solutions

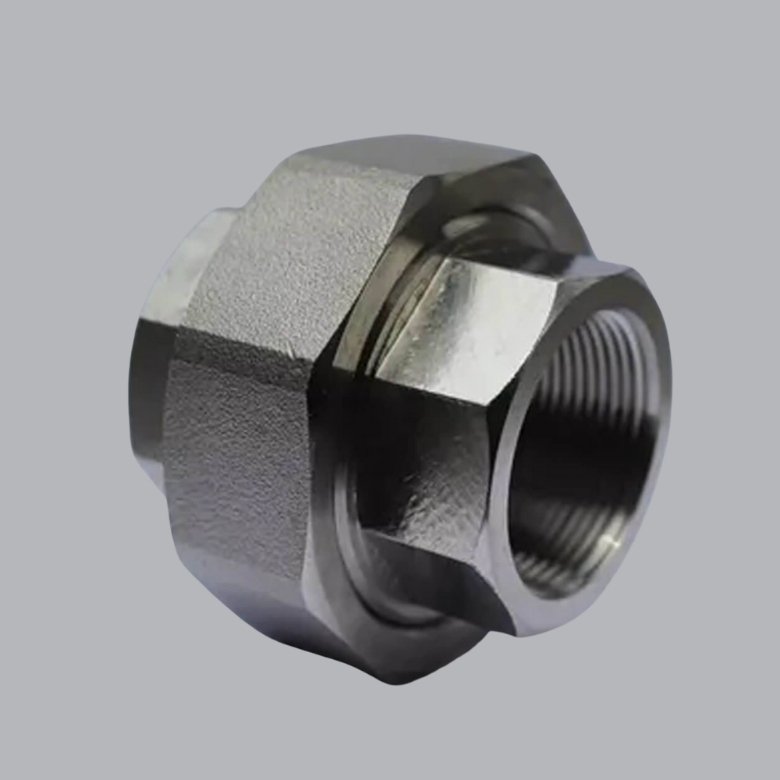

Inconel 600/625/718 Threaded and Socket Weld Fittings – chemical and marine grade fittings

What are the key differences between Inconel 600, 625, and 718 in terms of pipe fittings and flanges?

Inconel 600 (UNS N06600) – A nickel-chromium alloy optimized for oxidation and corrosion resistance. Ideal for high-temperature furnace components, heat exchangers, and chemical process piping. Maintains mechanical properties up to 1090°C. Offers good resistance to chloride stress corrosion and carburization, but moderate strength compared to 625 and 718.

Inconel 625 (UNS N06625) – A solid solution-strengthened nickel-chromium-molybdenum alloy with exceptional resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking. Provides higher tensile strength and creep resistance than 600, suitable for offshore, seawater, chemical, and aerospace applications. Service temperature up to 980°C.

Inconel 718 (UNS N07718) – A precipitation-hardened alloy offering superior mechanical strength, fatigue resistance, and creep resistance under high pressure and temperature. Can withstand 700°C under sustained load. Used in gas turbines, aerospace, high-pressure bolting, and cryogenic systems. Provides excellent weldability and dimensional stability for flanges and fittings.

Which testing standards are followed for Inconel 600 / 625 / 718 fittings and flanges?

Chemical & Mechanical Testing: ASTM B366 (600/625/718 seamless pipe), ASTM B564 (flanges), PMI (Positive Material Identification), spectro analysis for composition verification.

Mechanical Tests: Tensile test (ASTM E8), Hardness test (Rockwell B/HB), Impact test (Charpy V-notch).

Non-Destructive Tests (NDT): Radiographic testing (RT), Ultrasonic Testing (UT), and Dye Penetrant Testing (DPT) for critical welds.

Corrosion Resistance Tests: Pitting and crevice corrosion tests in chloride solutions, intergranular corrosion tests (ASTM A262), and stress corrosion cracking evaluation.

Dimensional & Visual Inspection: As per ASME B16.9 (buttweld fittings) and ASME B16.5/B16.47 (flanges) tolerances.

What types of Inconel 600 / 625 / 718 pipe fittings and flanges are commonly used?

Buttweld Fittings: Elbows (90°, 45°, 180°), Tees (equal & reducing), Reducers (concentric & eccentric), Stub Ends, End Caps, Mitered Bends, Lateral Tees.

Forged & Threaded Components: Socket weld fittings, NPT threaded elbows, tees, unions, couplings, plugs, bushings, and caps.

Flanges: Weld Neck, Slip-On, Socket Weld, Threaded, Lap Joint, Blind, Reducing, RTJ, Long Weld Neck, Spectacle Blind, Tongue & Groove, Orifice, and Male-Female Flanges.

Special Components: Weldoflange, Nipoflange, Sweldolet, Swage Nipple, Bull Plug, Barred Tee — engineered for custom piping systems in chemical, marine, and industrial applications.