- Home

- Nickel Alloys

- Incoloy 800 / 825

Incoloy 800 / 825

Incoloy 800 / 825: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Manufacturer & Supplier of Seamless, Welded, Threaded, and Socket Weld Incoloy 800/825 Buttweld & Forged Fittings and Flanges, ASTM certified, serving USA, Europe, and Middle East.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer, supplier, and global exporter of high-quality Incoloy 800/825 pipe fittings and flanges. With decades of experience, the company specializes in premium alloys. Our state-of-the-art manufacturing facilities ensure precision, durability, and compliance with international standards such as ASTM, ASME, DIN, JIS, and EN, catering to the needs of chemical, petrochemical, oil & gas, power, and marine industries.

We follow a structured work methodology that integrates advanced production technology, stringent quality control, and timely delivery. Our dedicated team of engineers, quality inspectors, and logistics experts ensures that every product meets strict mechanical, chemical, and dimensional specifications. We employ rigorous testing protocols, including PMI analysis, hydrostatic testing, hardness tests, and intergranular corrosion checks, to guarantee reliable, long-lasting, and high-performance fittings and flanges.

Incoloy 800 and 825 are high-performance nickel-iron-chromium alloys engineered for extreme temperature and corrosion-resistant applications. Incoloy 800 provides excellent resistance to oxidation, carburization, and stress-relaxation cracking at elevated temperatures, making it ideal for high-temperature industrial piping systems.

Incoloy 825, with its higher nickel and molybdenum content, offers enhanced resistance to strong reducing and oxidizing environments, including acid and chloride attack. These alloys are widely used in chemical, petrochemical, oil & gas, power generation, and marine industries where long-term durability and corrosion resistance are critical.

Incoloy 800/825 fittings and flanges exhibit superior resistance to intergranular attack, pitting, and stress-corrosion cracking in harsh chemical environments. Each component undergoes rigorous quality control tests, including chemical composition analysis, hydrostatic pressure testing, hardness tests, and non-destructive inspections, to ensure reliability and performance. These alloys maintain structural integrity under continuous exposure to temperatures up to 1100°C (for 800 °C) and in aggressive chemical solutions (for 825 °C), making them highly suitable for refinery, power, desalination, and offshore applications.

Our vision is to be a globally recognized leader in high-performance industrial piping solutions by consistently delivering innovation, quality, and customer satisfaction. We continue to expand our international footprint, supplying reliable pipe fittings and flanges to markets across the USA, Europe, the Middle East, and Asia. Committed to sustainable growth, technological advancement, and service excellence, we aim to set industry benchmarks for precision, durability, and corrosion-resistant solutions.

Incoloy 800 pipe fittings ASTM B366 Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Incoloy 800/825

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Incoloy 825 flanges ASTM B564 – Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Nickel Alloy | Incoloy 800 | ASTM B366 / SB366 (Buttweld Fittings), , ASTM B564 / SB564 (Forged Fittings & Flanges) |

High-temperature piping, furnace components, chemical & petrochemical plants |

| Nickel Alloy | Incoloy 800H | ASTM B366 / SB366 (Buttweld Fittings), ASTM B564 / SB564 (Forged Fittings & Flanges) |

High-temp service with enhanced creep and tensile strength |

| Nickel Alloy | Incoloy 800HT | ASTM B366 / SB366 (Buttweld Fittings), ASTM B564 / SB564 (Forged Fittings & Flanges) |

Long-term high-temperature pipelines and chemical applications |

| Nickel Alloy | Incoloy 825 | ASTM B366 / SB366 (Buttweld Fittings), ASTM B564 / SB564 (Forged Fittings & Flanges) |

Petrochemical, chemical, offshore pipelines, seawater, and chloride-rich environments |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Incoloy 800/825 Products

Incoloy 800 Werkstoff 1.4876 fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Alloy | UNS | Werkstoff (Germany) | EN / DIN | JIS (Japan) |

|---|---|---|---|---|

| Incoloy 800 | N08800 | 1.4876 | X8CrNiNb19-9 | SUS 800 |

| Incoloy 800H | N08810 | 1.4958 | X8CrNiNb19-11 | SUS 800H |

| Incoloy 800HT | N08811 | 1.4958 | X8CrNiNb19-11 | SUS 800HT |

| Incoloy 825 | N08825 | 2.4858 | X10NiCrAlMo32-20-2 | SUS 825 |

Incoloy UNS N08800/N08825 Pipe fittings - Chemical Composition

| Element | Incoloy 800 (%) | Incoloy 825 (%) |

|---|---|---|

| Nickel (Ni) | 30–35 | 38–46 |

| Chromium (Cr) | 19–23 | 19.5–23.5 |

| Iron (Fe) | Balance | Balance |

| Molybdenum (Mo) | – | 2.5–3.5 |

| Copper (Cu) | – | 1.5–3.0 |

| Carbon (C) | ≤0.10 | ≤0.05 |

| Manganese (Mn) | ≤1.0 | ≤1.0 |

| Silicon (Si) | ≤1.0 | ≤0.5 |

| Aluminum (Al) | 0.15–0.60 | 0.2 max |

| Titanium (Ti) | 0.15–0.60 | 0.6 max |

| Sulfur (S) | ≤0.015 | ≤0.03 |

| Phosphorus (P) | ≤0.03 | ≤0.03 |

| Cobalt (Co) | – | ≤0.5 |

| Nitrogen (N) | – | ≤0.1 |

Alloy 825 Threaded Fittings - Mechanical Properties

| Property | Incoloy 800 | Incoloy 825 |

|---|---|---|

| Tensile Strength (MPa) |

585–690 | 550–690 |

| Yield Strength (MPa) |

275–380 | 275–415 |

| Elongation (%) | 30–40 | 30–40 |

| Hardness (HBW) | 150–210 | 150–200 |

| Creep Resistance | Excellent up to 1100°C | Good up to 870°C |

| Modulus of Elasticity (GPa) |

~200 | ~200 |

| Impact Toughness (Charpy V-notch, J) |

≥40 at room temp | ≥40 at room temp |

| Corrosion Resistance | Oxidation, scaling, moderate acid | Excellent against oxidizing/ reducing acids,chlorides |

| Typical Applications | High-temp piping, furnace components, chemical plants |

Petrochemical, chemical, offshore pipelines, seawater applications |

Incoloy 800/825 Buttweld Fittings – High-Quality Seamless & Welded

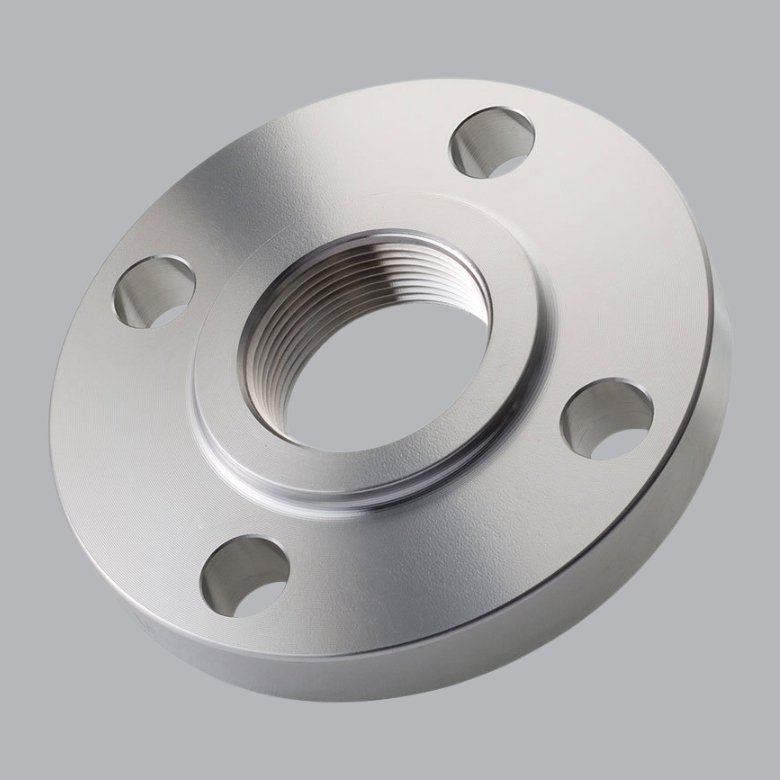

Incoloy 800/825 Flanges – industrial piping solutions

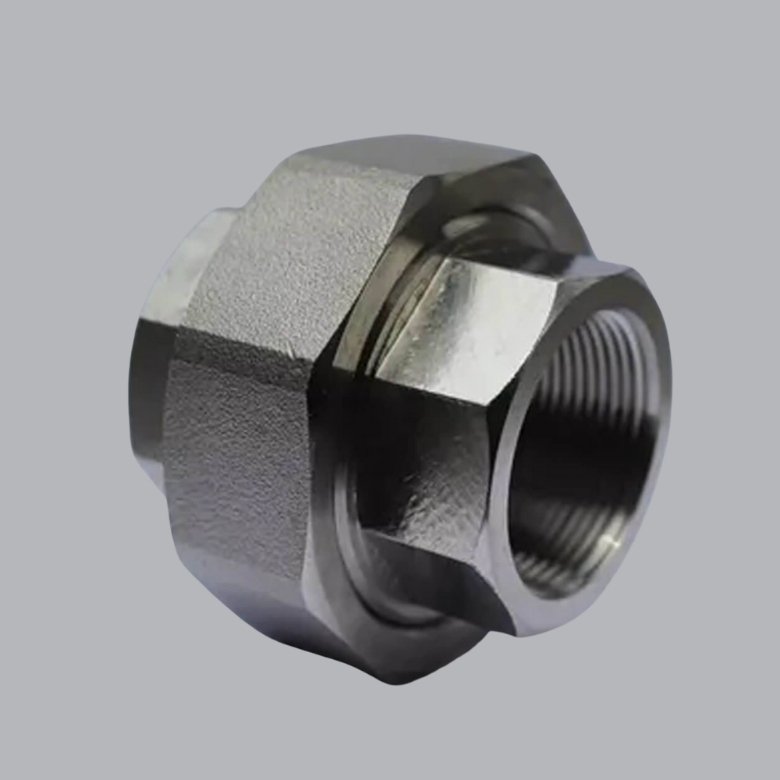

Incoloy 800/825 Threaded and Socket Weld Fittings – chemical and marine grade fittings

How does Incoloy 800 differ from Incoloy 825 in terms of corrosion resistance for pipe fittings and flanges?

Incoloy 800: Excellent resistance to oxidation and scaling in high-temperature air and gases; moderately resistant to acid solutions.

Incoloy 825: Superior resistance to strong oxidizing and reducing acids, chloride-containing environments, and seawater; highly suitable for chemical and petrochemical plants.

Application Implication: Use Incoloy 800 for high-temperature, low-corrosion environments; choose Incoloy 825 for aggressive chemical exposure and chloride-rich conditions.

What are the key advantages of using Incoloy 800/825 pipe fittings and flanges over standard stainless steel?

Superior high-temperature creep and oxidation resistance.

Better resistance to both reducing and oxidizing acids (especially Incoloy 825).

Enhanced stress-corrosion cracking resistance in chloride environments.

Longer service life in harsh chemical, marine, and petrochemical applications.

What inspection and certification are provided with Incoloy 800/825 fittings and flanges?

Inspection: Dimensional inspection, NDT, chemical analysis, and mechanical testing.

Certifications: Mill Test Certificates (MTC), ASTM/ASME compliance certificates, UNS and Werkstoff grade confirmation.

Purpose: Ensures traceability, reliability, and compliance with global industrial standards for high-performance piping systems.