- Home

- Nickel Alloys

- Hastelloy C22 / C276

Hastelloy C22 / C276

Hastelloy C22/C276: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Global Manufacturer & Supplier of Hastelloy C22/C276 Buttweld & Forged Fittings and Flanges, Seamless, Welded, Threaded, Socket Weld, ASTM/ASME certified for USA, Europe & Middle East.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a premier Manufacturer and Supplier of high-quality Hastelloy forged and buttweld fittings, flanges, and industrial piping solutions. With a focus on precision engineering and stringent quality standards, our products are manufactured in compliance with ASTM, ASME, and other international standards, ensuring durability, reliability, and optimal performance in critical applications.

We combine advanced manufacturing technologies with a customer-centric approach to deliver both standard and customized piping solutions. Our commitment to excellence, timely delivery, and technical support makes us a trusted partner for global clients seeking high-performance fittings and flanges for complex industrial systems.

Hastelloy C22 is engineered for maximum resistance to oxidizing environments and strong reducing agents. Its unique alloying with nickel, chromium, and molybdenum provides superior resistance to localized corrosion, including pitting and crevice attack. C22 is particularly suitable for handling nitric, phosphoric, and acetic acids, as well as seawater and halogenated compounds. The alloy exhibits excellent weldability and maintains mechanical integrity under high-temperature operations, making it ideal for chemical reactors, heat exchangers, and offshore piping systems. C22 fittings and flanges are available in forged and seamless forms, conforming to ASTM/ASME standards.

Hastelloy C276 is a versatile nickel-molybdenum-chromium-tungsten alloy specifically designed for highly aggressive chemical environments. It provides outstanding resistance to both oxidizing and reducing media, including sulfuric, hydrochloric, and nitric acids, as well as chlorides and hypochlorites. C276 maintains excellent dimensional stability at elevated temperatures and offers high creep and fatigue resistance, making it suitable for pressure vessels, process piping, and flue gas scrubbers. Its seamless and forged buttweld fittings and flanges, produced to ASTM/ASME standards, ensure reliable performance in critical industrial and chemical processing systems.

Hastelloy Buttweld Pipe Fittings Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Hastelloy C22 / C276

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Hastelloy C22 welded fittings – Grades & Standards

| Material Category |

Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Nickel Alloy | Hastelloy C22 | ASTM B366 / SB366 (Buttweld Fittings), ASTM B564 / SB564 (Forged Fittings & Flanges) |

Chemical processing, marine, offshore piping, high-temperature and oxidizing/reducing environments |

| Nickel Alloy | Hastelloy C276 | ASTM B366 / SB366 (Buttweld Fittings), ASTM B564 / SB564 (Forged Fittings & Flanges) |

Highly corrosive chemical environments, petrochemical, pollution control, acid-resistant piping, offshore and marine systems |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Hastelloy C22/C276 Products

Hastelloy C22 socket weld fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Alloy | UNS Number | ASTM Specification | ASME Standard | EN / DIN Number | Werkstoff No. | JIS Equivalent |

|---|---|---|---|---|---|---|

| Hastelloy C22 | N06022 | ASTM B366 (Seamless/Buttweld), ASTM B564 (Forged) |

ASME SB366 / SB564 | EN 2.4602 / DIN 17750:2021 | 2.4602 | SUS 6622 |

| Hastelloy C276 | N10276 | ASTM B366 (Seamless/Buttweld), ASTM B564 (Forged) |

ASME SB366 / SB564 | EN 2.4819 / DIN 17751 | 2.4819 | SUS 6276 |

UNS N06022 Forged Fittings - Chemical Composition

| Element | Hastelloy C22 (UNS N06022) | Hastelloy C276 (UNS N10276) |

|---|---|---|

| Nickel (Ni) | 56.0 – 63.0 | 57.0 min |

| Chromium (Cr) | 20.0 – 22.0 | 14.5 – 16.5 |

| Molybdenum (Mo) | 12.0 – 14.0 | 15.0 – 17.0 |

| Tungsten (W) | 2.5 – 3.5 | 3.0 – 4.0 |

| Iron (Fe) | 2.5 max | 6.0 max |

| Carbon (C) | 0.015 max | 0.02 max |

| Manganese (Mn) | 1.0 max | 1.0 max |

| Silicon (Si) | 0.08 – 0.25 | 0.08 – 0.25 |

| Cobalt (Co) | 1.0 max | 1.0 max |

| Copper (Cu) | 0.5 max | 0.5 max |

| Phosphorus (P) | 0.04 max | 0.04 max |

| Sulfur (S) | 0.03 max | 0.03 max |

| Boron (B) | 0.006 max | 0.006 max |

| Nitrogen (N) | 0.03 max | 0.03 max |

Hastelloy C276 buttweld caps and elbows - Mechanical Properties

| Property | Hastelloy C22 (UNS N06022) | Hastelloy C276 (UNS N10276) |

|---|---|---|

| Yield Strength (0.2% offset) | 35 ksi (241 MPa) min | 35 ksi (241 MPa) min |

| Tensile Strength | 90 ksi (620 MPa) min | 85–95 ksi (585–655 MPa) |

| Elongation (in 2 in / 50 mm) | 40% min | 35–40% min |

| Hardness (Brinell) | 180 HB max | 180 HB max |

| Modulus of Elasticity | 28 × 10³ ksi (193 GPa) | 28 × 10³ ksi (193 GPa) |

| Density | 8.94 g/cm³ | 8.89 g/cm³ |

| Melting Range | 1320–1360°C | 1290–1350°C |

| Poisson’s Ratio | 0.31 | 0.31 |

Hastelloy C22 / C276 Buttweld Fittings – High-Quality Seamless & Welded

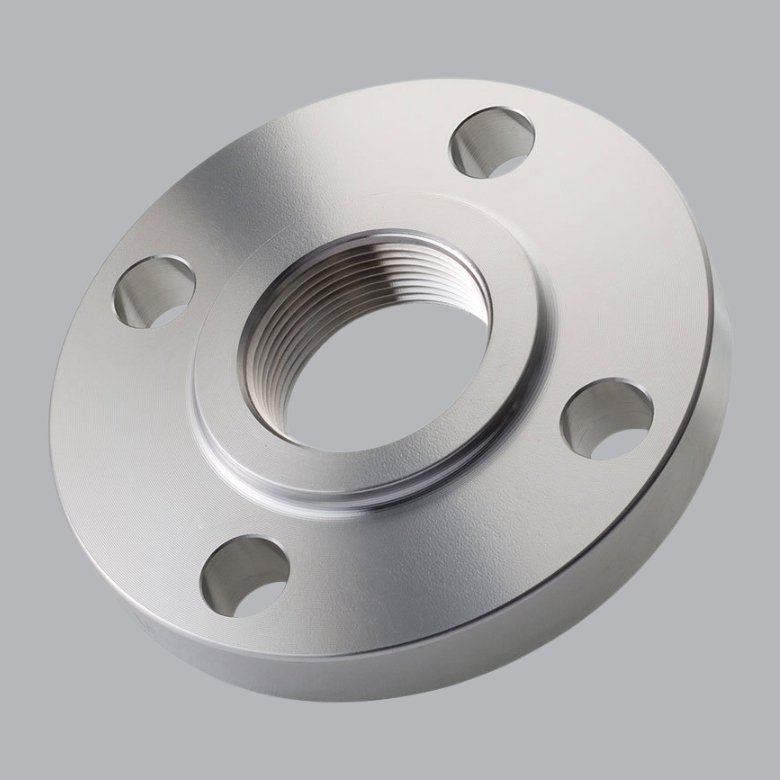

Hastelloy C22 / C276 Flanges – industrial piping solutions

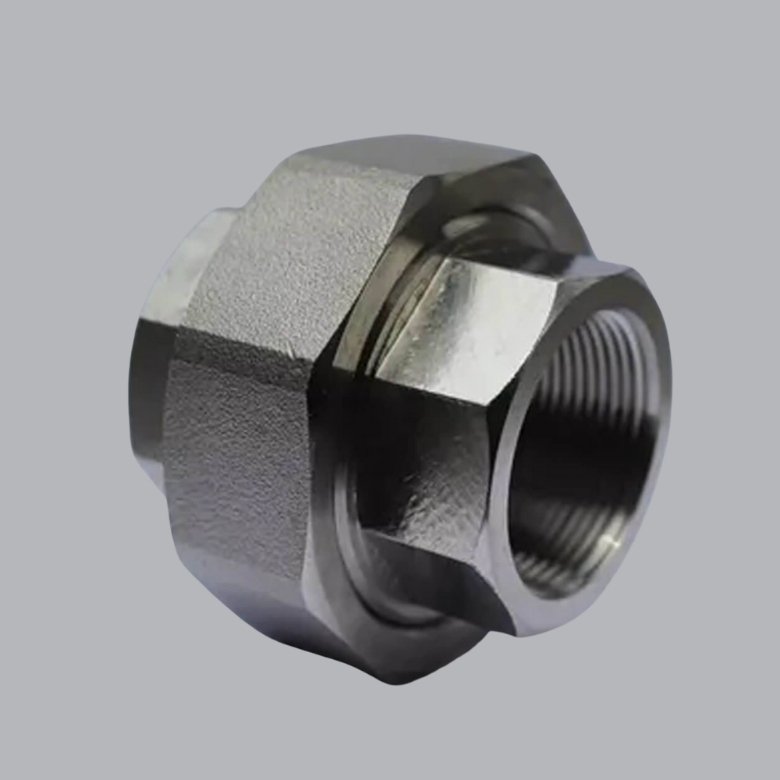

Hastelloy C22 / C276 Threaded and Socket Weld Fittings

How does Hastelloy C22 differ from C276?

C22: Optimized for oxidizing environments; slightly higher chromium content improves resistance to nitric and other oxidizing acids.

C276: Optimized for mixed oxidizing and reducing environments; higher molybdenum and tungsten content enhance resistance to pitting, crevice corrosion, and chloride-induced corrosion.

a C22 is often preferred for pure chemical environments, while C276 is used for highly aggressive or mixed chemical processes.

What types of corrosion are Hastelloy C22 and C276 resistant to?

Pitting Corrosion – Both alloys resist localized attack in chlorides and oxidizing acids.

Crevice Corrosion – Excellent resistance due to high nickel, molybdenum, and tungsten content.

Stress Corrosion Cracking (SCC) – High resistance in chloride environments under tensile stress.

Oxidizing Acids – C22 excels in nitric, sulfuric, and phosphoric acid conditions.

Mixed Acid / Reducing Media – C276 shows superior resistance in combined oxidizing/reducing environments.

How does the UNS number help in selecting Hastelloy materials?

UNS (Unified Numbering System) uniquely identifies alloys for traceability and specification compliance.

C22 → N06022, C276 → N10276.

Engineers use UNS numbers to ensure the correct alloy is specified for chemical resistance, mechanical strength, and temperature requirements.

Also improves international communication, reducing errors in procurement and engineering documentation.