- Home

- Nickel Alloys

- Hastelloy B2

Hastelloy B2

Hastelloy B2: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Seamless, Welded, Threaded & Socket Weld Hastelloy B2 Buttweld & Forged Fittings and Flanges, ASTM B366 / B564 certified, supplied globally to Europe, Middle East & North America.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a premier manufacturer and global supplier of high-quality Hastelloy B2 Pipe fittings and flanges, and specialty piping components. We deliver precision-engineered products that meet stringent ASTM, ASME, EN, and DIN standards. Our solutions are designed to perform reliably under extreme industrial, chemical, and offshore conditions.

Our extensive product range includes seamless, welded, threaded, and socket weld fittings and flanges, catering to diverse applications in petrochemical, marine, chemical processing, power generation, and pollution control industries. By combining advanced manufacturing techniques with rigorous quality control, we ensure every component provides superior durability, corrosion resistance, and mechanical strength.

Hastelloy B2 (UNS N10665) is a nickel-molybdenum alloy with excellent resistance to strong reducing acids like hydrochloric and sulfuric acids. Available in buttweld and forged fittings & flanges, it meets ASTM B366 / B564 and ASME SB366 / SB564 standards. Its chemical composition—Ni 65–70%, Mo 28–34%, Fe ≤1.5%, C ≤0.03%—ensures superior resistance to pitting, crevice, and stress corrosion cracking. Mechanically, B2 offers yield strength 30–35 ksi, tensile strength 80–90 ksi, and elongation 35–40%, making it ideal for high-pressure, high-temperature chemical, petrochemical, and offshore piping systems.

Committed to excellence and customer satisfaction, we serve clients across the USA, Europe, the Middle East, and Asia. We provide not only top-quality products but also technical support and customized solutions, making us a trusted partner for critical piping systems and complex industrial projects worldwide.

UNS N10665 pipe fittings Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Hastelloy B2

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

High-pressure Hastelloy B2 flanges – Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Nickel Alloy | Hastelloy B2 | ASTM B366 / SB366 (Buttweld Fittings), , ASTM B564 / SB564 (Forged Fittings & Flanges) |

Highly corrosive reducing environments, hydrochloric and sulfuric acids, chemical processing, petrochemical, offshore piping, high-pressure and high-temperature systems |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Hastelloy B2 Products

Nickel-molybdenum B2 alloy fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Material Category | Grade | UNS Number | EN / DIN | Werkstoff | JIS | Standards (ASTM / ASME) |

|---|---|---|---|---|---|---|

| Nickel Alloy | Hastelloy B2 | N10665 | 2.4603 | 2.4603 | SUS N10665 | ASTM B366 / SB366 (Buttweld Fittings), ASTM B564 / SB564 (Forged Fittings & Flanges) |

Hastelloy B2 forged fittings - Chemical Composition

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 65–70 |

| Molybdenum (Mo) | 28–34 |

| Iron (Fe) | ≤1.5 |

| Carbon (C) | ≤0.03 |

| Manganese (Mn) | ≤1 |

| Silicon (Si) | ≤0.35 |

| Phosphorus (P) | ≤0.04 |

| Sulfur (S) | ≤0.03 |

| Boron (B) | ≤0.01 |

| Nitrogen (N) | ≤0.03 |

ASTM B366 Hastelloy B2 Fittings - Mechanical Properties

| Property | Value / Range |

|---|---|

| Yield Strength | 30–35 ksi (207–241 MPa) |

| Tensile Strength | 80–90 ksi (550–620 MPa) |

| Elongation | 35–40% |

| Hardness (Brinell) | Max 180 HB |

| Density | 8.89 g/cm³ |

| Melting Point | 1290–1350°C |

Hastelloy B2 Buttweld Fittings – High-Quality Seamless & Welded

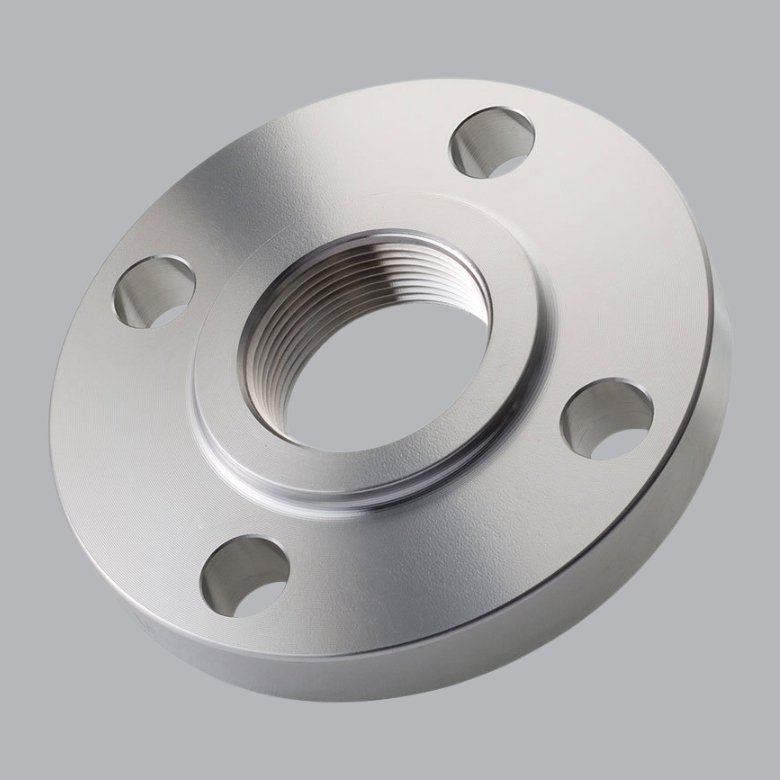

Hastelloy B2 Flanges – industrial piping solutions

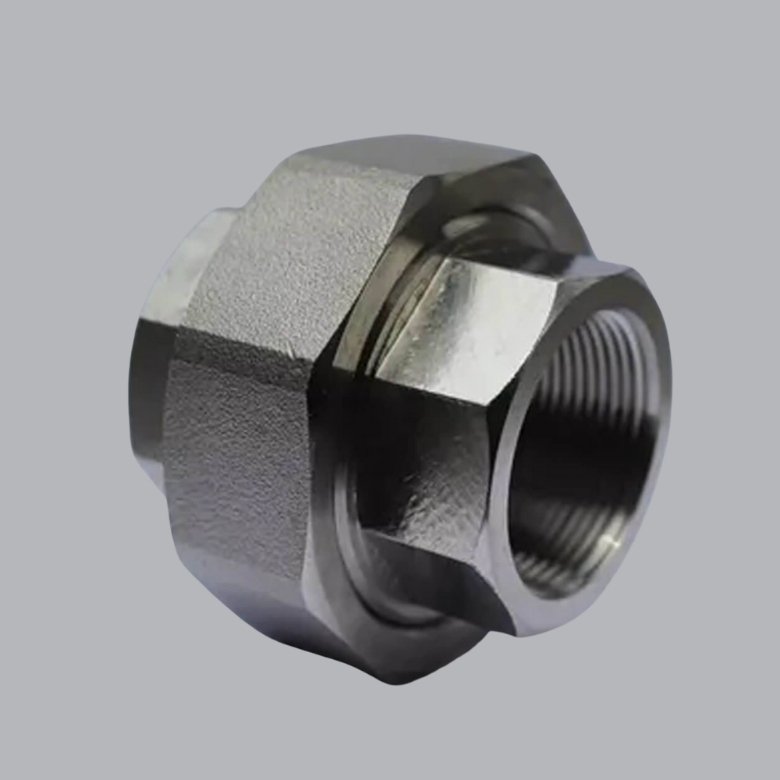

Hastelloy B2 Threaded and Socket Weld Fittings

How does Hastelloy B2 differ from other nickel alloys like C22 or C276?

B2: Optimized for reducing acids; superior resistance to hydrochloric and sulfuric acids.

C22/C276: Optimized for oxidizing or mixed oxidizing/reducing environments; higher chromium and molybdenum for pitting and crevice resistance.

Selection depends on the specific chemical environment, temperature, and pressure conditions of the application.

Can Hastelloy B2 fittings and flanges be welded?

Yes, using compatible Hastelloy B2 filler rods to maintain corrosion resistance.

Preheating is generally not required, but stress relief may be considered for thick sections.

Proper welding ensures mechanical strength and chemical resistance across welded joints.

What types of testing are performed on Hastelloy B2 fittings and flanges?

Material Test Certificates (MTC) as per ASTM/ASME standards.

Chemical Composition Verification – Spectrochemical analysis or PMI.

Mechanical Testing – Tensile, hardness, and impact tests.

Non-Destructive Testing (NDT) – Radiography, ultrasonic, or dye-penetrant testing.

Hydrostatic & Pressure Testing – Ensures reliability in high-pressure piping systems.