- Home

- Copper Alloys

- Cu-Ni 90/10 / 70/30

Cu-Ni 90/10 / 70/30

Cu-Ni 90/10 & 70/30: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Trusted Manufacturer of Cu-Ni 90/10 Pipe Fittings & Cu-Ni 70/30 Industrial Flanges, including Elbows, Tees, Reducers, Caps & Custom Fabricated Headers. Produced in accordance with ASTM B111 / B151 / B466, supplying to USA, UK, Germany, Italy, UAE, Saudi Arabia, Qatar, Singapore, Malaysia & Australia.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a specialized manufacturer of Cu-Ni 90/10 pipe fittings and flanges designed for demanding industrial environments. With advanced forging, heat-treatment, and CNC machining capabilities, we deliver products engineered for dimensional accuracy, corrosion resistance, and long-term reliability. Every component is produced under strict quality systems, with full material traceability and compliance with global standards.

Our product portfolio covers Cu-Ni 70/30 buttweld fittings, forged fittings, specialty flanges, and custom-fabricated piping solutions for marine, petrochemical, offshore, desalination, power generation, and process plant applications. Backed by technical expertise, responsive service, and an export-oriented supply network, we stand as a trusted partner for EPC contractors, OEMs, and global pipeline projects.

Cu-Ni 90/10 and Cu-Ni 70/30 are copper-nickel alloys formulated for marine fluid handling systems, where stable corrosion performance in chloride-rich seawater is required. Cu-Ni 90/10 offers controlled iron and manganese additions to improve resistance to general corrosion and localized attack in continuous seawater exposure.

Cu-Ni 70/30, with a higher nickel content, provides increased mechanical strength and superior resistance to flow-induced erosion in high-velocity piping circuits. Both grades maintain consistent metallurgical structure and thermal stability, making them suitable for heat transfer operations.

Fabrication and welding are straightforward when using matching Cu-Ni filler metals, and no post-weld heat treatment is required. Production is carried out in accordance with ASTM B111, B151, and B466, ensuring dimensional uniformity, controlled grain refinement, and material integrity for long-service pipeline reliability.

Copper Nickel 90/10 pipe fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

Surface & Finish

ASTM / ASME - Grades - Material

Cu-Ni 90/10, Cu-Ni 70/30

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Additional Considerations

Cupro Nickel 70/30 flanges– Grades & Standards

| Material / Alloy | Grade / UNS | ASTM / ASME Standard | Product Type | Typical Applications |

|---|---|---|---|---|

| Copper Nickel 90/10, (CuNi 90/10) | C70600 | ASTM B111 / ASME SB111 ASTM B466 / B151 / ASME SB466 |

Buttweld, Forged, Flanges | Marine piping, seawater systems, offshore pipelines, desalination plants |

| Copper Nickel 70/30 (CuNi 70/30) | C71500 | ASTM B111 / ASME SB111 ASTM B466 / B151 / ASME SB466 |

Buttweld, Forged, Flanges | High-strength seawater pipelines, offshore platforms, chemical systems |

Explore Copper Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Materials

Explore All Products

Cu-Ni 90/10 / 70/30 Products

Copper Nickel 90/10 fittings - Equivalent Grades

| Material / Alloy | ASTM / ASME | UNS | EN / DIN | JIS | BS / UK |

|---|---|---|---|---|---|

| Copper Nickel 90/10 (CuNi 90/10) |

ASTM B111 (Buttweld), ASTM B466 / B151 (Forged & Flanges) |

C70600 | DIN 2.0876 | CuNi10Fe1Mn | BS 2870 |

| Copper Nickel 70/30 (CuNi 70/30) |

ASTM B111 (Buttweld), ASTM B466 / B151 (Forged & Flanges) |

C71500 | DIN 2.0880 | CuNi30Fe1Mn | BS 2871 |

ASTM B151 Cu-Ni 90/10 Forged fittings- Chemical Composition

| Alloy / Material | Cu (%) | Ni (%) | Sn (%) | Zn (%) | Al (%) | Fe (%) | Mn (%) | Pb (%) | Other Elements (%) |

|---|---|---|---|---|---|---|---|---|---|

| Copper Nickel 90/10 (C70600) | 89–91 | 9–10 | – | – | – | 0.3 max | 0.5 max | – | – |

| Copper Nickel 70/30 (C71500) | 69–71 | 29–30 | – | – | – | 0.3 max | 0.5 max | – | – |

Seamless Cu-Ni 90/10 fittings - Mechanical Properties

| Alloy / Material | Tensile Strength (MPa / psi) |

Yield Strength (MPa / psi) |

Elongation (%) | Hardness (HB / Brinell) |

Impact Strength |

|---|---|---|---|---|---|

| Copper Nickel 90/10 (C70600) |

310–450 MPa (45–65 ksi) | 140–250 MPa (20–36 ksi) | 30–40 | 90–120 HB | Good, tough in seawater |

| Copper Nickel 70/30 (C71500) |

400–550 MPa (58–80 ksi) | 200–280 MPa (29–41 ksi) | 25–35 | 100–130 HB | High toughness |

ASTM B111 / B466 Cu-Ni 90/10 & 70/30 Buttweld Fittings

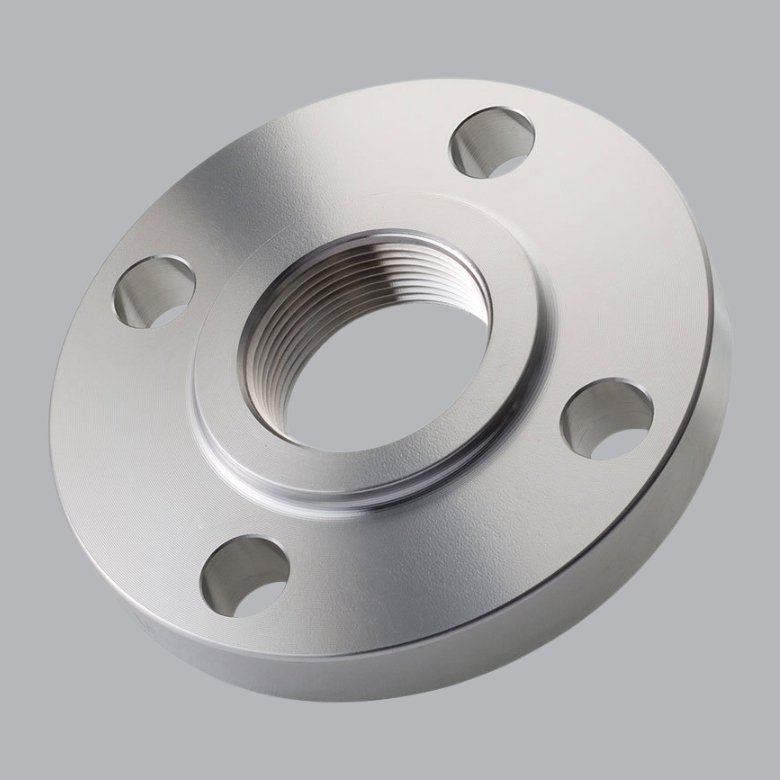

ASTM B151 / B466 Cu-Ni 70/30 & 90/10 Flanges

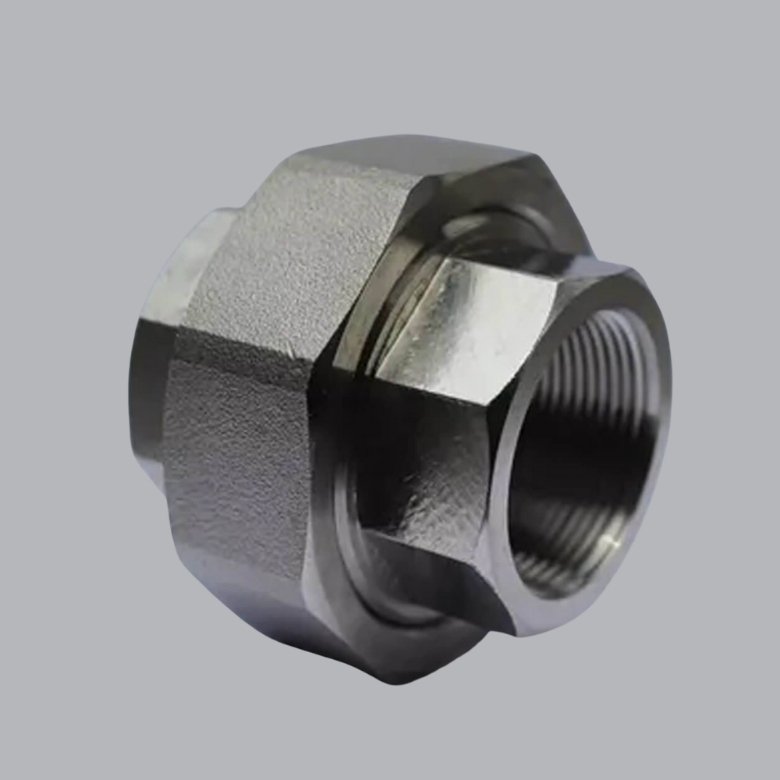

ASTM B466 Cu-Ni 70/30 & 90/10 Forged Pipe Components

What is the difference between Cu-Ni 90/10 and 70/30 in service?

Cu-Ni 90/10: Lower nickel content, ideal for moderate seawater velocity, lower stress applications, and general marine piping.

Cu-Ni 70/30: Higher nickel content, preferred for high-velocity seawater pipelines, heat exchangers, and offshore systems where erosion-corrosion is a concern.

Selection depends on flow rate, chloride concentration, temperature, and expected service life.

How is the quality of Cu-Ni 90/10 and 70/30 pipe fittings and flanges ensured?

Material testing: Chemical composition, PMI (Positive Material Identification).

Mechanical testing: Tensile, yield, elongation, and hardness.

Non-destructive testing (NDT): Ultrasonic (UT), radiographic (RT), and dye-penetrant (PT) inspections for defect detection.

Pressure testing: Hydrostatic and pneumatic tests to verify leak-tightness.

Certification: Supplied with test certificates complying with ASTM standards and international specifications.

How corrosion-resistant are Cu-Ni 90/10 and 70/30 fittings and flanges?

Both grades resist uniform and localized corrosion in seawater, brackish water, and cooling water.

Cu-Ni 90/10: Suitable for moderate seawater velocities and less aggressive chloride environments.

Cu-Ni 70/30: Higher nickel content provides improved resistance in high-velocity seawater lines, preventing erosion-corrosion and impingement attack.

Both grades resist biofouling, pitting, and crevice corrosion due to natural passivation of the alloy surface in chloride-rich media.