- Home

- Copper Alloys

- Brass

Brass

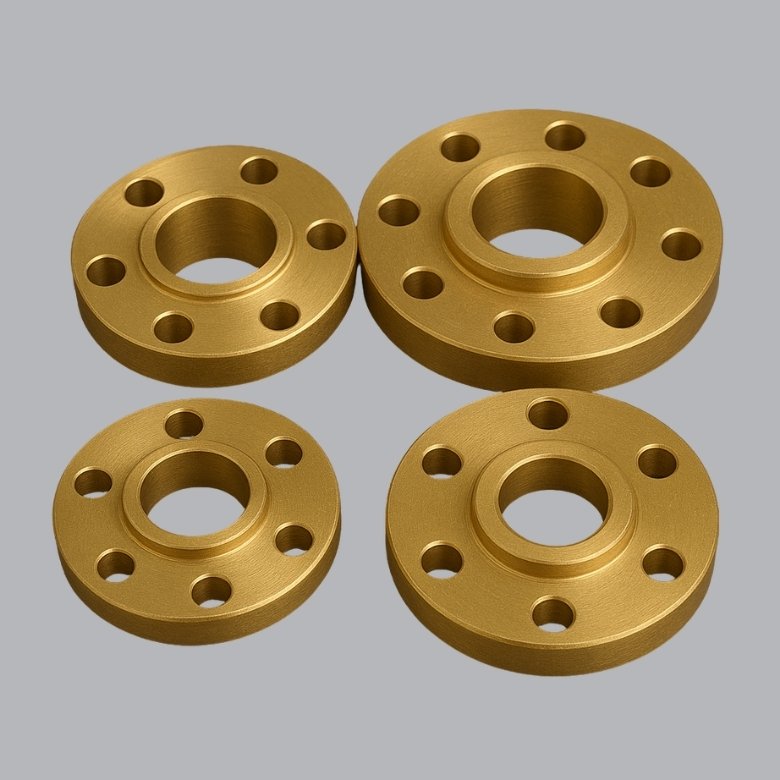

Global Supplier of Brass Industrial Fittings & Flanges, featuring Buttweld Elbows, Tees, Reducers, Caps & Custom Fabricated Headers. Built to ASTM B16, B62, and B16.18 for durable, corrosion-resistant performance. Supplying to USA, UK, Germany, Italy, UAE, Saudi Arabia, Qatar, Singapore, Malaysia & Australia.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd stands out as a pioneer in precision-engineered industrial brass fittings and flanges, delivering solutions tailored to complex piping systems worldwide. With a focus on both standard and customized components, the company leverages advanced forging, machining, and fabrication technologies to produce products that meet stringent industry specifications.

Midland’s commitment to metallurgical excellence ensures durability, corrosion resistance, and performance in critical applications across oil & gas, chemical, power, and marine industries.

Beyond manufacturing, we prioritize close technical collaboration with our clients, offering engineering support and expert consultation to deliver optimized piping solutions. Our product range includes seamless and welded buttweld fittings, forged flanges, and custom-fabricated headers, all manufactured under strict quality standards, including PMI, hydrostatic testing, and NDT inspections. Serving clients across the USA, Europe, the Middle East, and Asia, we have established ourselves as a trusted partner for industrial projects that require precision, safety, and on-time delivery.

Brass pipe fittings and flanges are precision-engineered components for fluid handling systems, providing superior corrosion resistance, machinability, and durability. Manufactured from high-quality copper-zinc alloys, these fittings are suitable for potable water, HVAC, marine, and industrial applications. Brass buttweld fittings deliver leak-proof joints under high pressure, while forged fittings ensure enhanced mechanical strength and dimensional accuracy.

Flanges, available in threaded, slip-on, and welded types, enable secure connections and convenient maintenance access. All products are manufactured in compliance with ASTM standards such as B16.18, B16.22, and B62, guaranteeing consistent material composition, wall thickness, and pressure ratings. Additionally, brass fittings exhibit excellent thermal conductivity, resistance to dezincification, and long service life under varying temperature and chemical conditions.

ASTM B16.18 brass buttweld fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48”

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

Surface & Finish

ASTM / ASME - Grades - Material

C36000 (Free-Cutting Brass), C37700 (Red Brass), C46400 (Naval Brass), C46500 (Architectural Bronze), C69300 (High Strength Brass), C83600 (Lead-Free Brass)

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Key Features

UNS C36000 brass forged flanges – Grades & Standards

| Material / Alloy |

Grade / UNS |

ASTM / ASME Standard |

Product Type |

Typical Applications |

|---|---|---|---|---|

| Brass C36000 (Free-Cutting Brass) |

C36000 | ASTM B16.18 / B16.22 / B62 | Buttweld, Forged, Flanges | Threaded fittings, valves, general-purpose industrial piping, HVAC systems |

| Brass C37700 (Red Brass) |

C37700 | ASTM B16.18 / B16.22 / B62 | Buttweld, Forged, Flanges | Plumbing, HVAC, marine systems, water distribution pipelines |

| Brass C46400 (Naval Brass) |

C46400 | ASTM B111 / ASTM B62 | Buttweld, Forged, Flanges | Marine piping, corrosion-resistant industrial applications, seawater systems |

| Brass C46500 (Architectural Bronze) |

C46500 | ASTM B584 | Forged, Flanges | Decorative fittings, architectural hardware, custom piping components |

| Brass C69300 (High Strength Brass) |

C69300 | ASTM B21 / B16.22 | Buttweld, Forged, Flanges | High-strength industrial piping, critical process lines |

| Brass C83600 (Lead-Free Brass) |

C83600 | ASTM B62 / NSF 61 | Buttweld, Forged, Flanges | Potable water systems, drinking water pipelines, plumbing applications |

Explore Copper Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Materials

Explore All Products

Brass Products

Brass Forged Fittings - Equivalent Grades

| Material Name / Type | UNS Number | ASTM Standard | EN / DIN | JIS | GOST / Russian Standard |

|---|---|---|---|---|---|

| Brass C36000 (Free-Cutting Brass) | C36000 | ASTM B16.18 / B16.22 / B62 | CW614N | C3771 | Л63 |

| Brass C37700 (Red Brass) | C37700 | ASTM B16.18 / B16.22 / B62 | CW614R | C3772 | Л68 |

| Brass C46500 (Architectural Bronze) | C46500 | ASTM B584 | CW508L | – | – |

| Brass C69300 (High Strength Brass) | C69300 | ASTM B21 / B16.22 | CW617N | – | – |

| Brass C46400 (Naval Brass) | C46400 | ASTM B111 | CW307G | – | – |

| Brass C83600 (Lead-Free Brass) | C83600 | NSF 61 / ASTM B62 | CW602N | – | – |

Brass Pipe Fittings - Chemical Composition

| Brass Grade | UNS Number | Cu (%) | Zn (%) | Pb (%) | Sn (%) | Fe (%) | Other Elements |

|---|---|---|---|---|---|---|---|

| C36000 (Free-Cutting Brass) | C36000 | 61–63 | 35–37 | 2.5 max | – | 0.5 max | Trace |

| C37700 (Red Brass) | C37700 | 85 | 5–7 | – | 5–7 | 1 | Trace |

| C46400 (Naval Brass) | C46400 | 60 | 39 | – | 1 | – | Trace |

| C46500 (Architectural Bronze) | C46500 | 60 | 39 | – | 1 | – | Trace |

| C69300 (High Strength Brass) | C69300 | 60 | 37–39 | – | 1 | – | Trace |

| C83600 (Lead-Free Brass) | C83600 | 60 | 39 | – | – | – | Trace |

Brass Threaded Fittings - Mechanical Properties

| Brass Grade | UNS Number | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| C36000 (Free-Cutting Brass) | C36000 | 360–410 | 220–250 | 30–40 | 90–110 |

| C37700 (Red Brass) | C37700 | 345–380 | 200–220 | 20–35 | 85–100 |

| C46400 (Naval Brass) | C46400 | 380–420 | 230–260 | 25–35 | 95–110 |

| C46500 (Architectural Bronze) | C46500 | 350–400 | 200–240 | 20–30 | 85–105 |

| C69300 (High Strength Brass) | C69300 | 400–450 | 250–280 | 15–25 | 100–120 |

| C83600 (Lead-Free Brass) | C83600 | 330–370 | 180–220 | 25–35 | 80–100 |

High-Quality Brass Buttweld Fittings

ASTM-Compliant Brass Flanges (B16.18 / B16.22 / B62)

Industrial Brass Forged Pipe Fittings

What grades of Brass are commonly used for pipe fittings and flanges?

C36000 (Free-Cutting Brass): High machinability, used for threaded and general-purpose fittings.

C37700 (Red Brass): Excellent corrosion resistance, used in plumbing and marine applications.

C46400 (Naval Brass): High resistance to dezincification, ideal for seawater and marine piping.

C46500 (Architectural Bronze): Used for decorative and specialty applications.

C69300 (High Strength Brass): Suitable for high-pressure industrial pipelines.

C83600 (Lead-Free Brass): Used for potable water and drinking water systems to meet safety standards.

What are the ASTM / ASME standards applicable to Brass Fittings and Flanges?

ASTM B16.18: Wrought copper and copper alloy solder-joint pressure fittings.

ASTM B16.22: Wrought copper and copper alloy brazed fittings.

ASTM B62: Composition bronze castings for valves, flanges, and fittings.

ASTM B111: Naval brass pipe, tubing, and fittings for marine applications.

ASTM B584: Copper alloy sand castings for industrial use.

NSF 61 / Lead-Free standards: For potable water systems.

How to select the right Brass Fitting or Flange for a project?

Determine pressure and temperature requirements.

Select the appropriate alloy grade (C36000, C37700, C46400, etc.) based on corrosion and dezincification resistance.

Choose the product type: buttweld, forged, threaded, or flanged.

Ensure ASTM/ASME compliance for safety and reliability.

Consider the installation environment, e.g., potable water, seawater, or industrial chemicals.