- Home

- Copper Alloys

- Aluminium Bronze

Aluminium Bronze

Aluminium Bronze : Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Top-Quality Aluminium Bronze Fittings & Flanges – Elbows, Tees, Reducers, Caps. Precision-manufactured in Germany according to ASTM B148/B462 and ASME B16/B16.18 standards for corrosion and wear resistance. Exported worldwide: USA, UK, Italy, France, UAE, Japan, Canada, Australia, Singapore & South Africa.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd is a leading manufacturer of high-quality pipe fittings and flanges, specializing in Aluminum Bronze products. We maintain strict quality control across all stages of production, from forging and machining to finishing, ensuring that every product meets ASTM, ASME, and international standards. Our team of skilled professionals ensures precision engineering and timely order fulfillment for clients worldwide.

To guarantee safe and reliable delivery, we use robust packaging solutions, including wooden crates, reinforced cartons, and protective coatings for sensitive surfaces. We coordinate efficient shipping through trusted international carriers, offering full documentation and tracking to countries across North America, Europe, the Middle East, and Asia. Our streamlined logistics ensure that products reach customers in perfect condition, on time, every time.

Aluminium Bronze Pipe Fittings and Flanges are high-performance components engineered for demanding industrial applications. Made primarily from a copper-aluminium alloy, these fittings and flanges exhibit excellent corrosion resistance, particularly against seawater, brine, and acidic or alkaline environments. They offer superior mechanical strength, wear resistance, and fatigue durability, making them ideal for use in marine, petrochemical, chemical processing, and desalination plants.

Manufactured according to ASTM B148 / B462 and ASME B16/B16.18 standards, these components are available in various types, including elbows, tees, reducers, caps, and custom headers. They are produced through precision forging and machining processes, ensuring tight dimensional tolerances, smooth surface finish, and compatibility with both welded and flanged piping systems.

Aluminium Bronze Buttweld Fittings - Specifications

Size Range – (Forged, Flange)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

Surface & Finish

ASTM / ASME - Grades - Material

BRONZE ALLOYS – Aluminium BRONZE

C95800: Aluminium Bronze

C95500 / C95510: Aluminium Bronze

C62300: Aluminium Bronze

Manufacturing Process

Dimensional Standards

Forms

Applications

Key Features

Aluminium Bronze Forged Elbows – Grades & Standards

| Product Type | Material / Alloy | ASTM / ASME Standard | Availability | Typical Applications |

|---|---|---|---|---|

| Forged Fittings | Aluminium Bronze (C95500, C95800) | ASTM B462 / ASME B462 | Available | Marine, offshore, and chemical piping; high-strength corrosion-resistant systems |

| Threaded Fittings | Aluminium Bronze (C95500, C95800) | ASTM B462 | Available | Low- to medium-pressure piping systems; valves, pumps, meters |

| Socket Weld Fittings | Aluminium Bronze (C95500, C95800) | ASTM B462 | Available | Industrial and marine piping; high corrosion resistance required |

| Buttweld Fittings | Aluminium Bronze (C95500, C95800) | Limited / Custom | Limited | Rarely used; mainly in specialized applications due to forging challenges |

| Cast Flanges | Aluminium Bronze (C95800) | ASTM B148 | Available | Corrosion-resistant piping in water, oil, and chemical industries |

| Forged Flanges | Aluminium Bronze (C95500, C95800) | ASTM B462 | Available | Marine and chemical piping systems; high-pressure industrial piping |

| Custom Fabricated Headers | Aluminium Bronze (C95500, C95800) | ASTM B462 / Client Spec | Available | Specialized piping systems in chemical, petrochemical, and marine industries |

Explore Copper Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Materials

Explore All Products

Aluminium Bronze Products

ASTM B148 Aluminium Bronze Fittings - Equivalent Grades

| Material / Alloy | UNS | ASTM / ASME | EN / DIN | JIS | GOST / Russian |

Typical Product Type |

|---|---|---|---|---|---|---|

| Aluminium Bronze C95400 |

C95400 | ASTM B148 / B462, ASME B16/B16.18 |

EN 1982 CuAl10Fe5Ni5 | – | – | Pipe fittings, flanges, valves, bushings |

| Aluminium Bronze C95800 |

C95800 | ASTM B148 / B462 | EN 1982 CuAl10Fe5Ni5 | – | – | Elbows, tees, reducers, caps |

| Aluminium Bronze C95500 |

C95500 | ASTM B148 / B462 | EN 1982 CuAl10Ni5Fe3 | – | – | Forged fittings, flanges |

| Aluminium Bronze C95510 |

C95510 | ASTM B148 / B462 | EN 1982 CuAl10Ni5Fe3 | – | – | Custom headers, reducers |

| Aluminium Bronze C62300 |

C62300 | ASTM B148 / B462 | EN 1982 CuAl6Fe3 | – | – | Cast fittings, bushings |

ASME B16/B16.18 Aluminium Bronze Flanges - Chemical Composition

| Alloy / Grade | Cu | Al | Fe | Ni | Mn | Sn | Pb | Zn | Other Elements |

|---|---|---|---|---|---|---|---|---|---|

| C95400 | 78–81% | 9.0–11.0% | 5.0–6.0% | 4.0–5.0% | – | – | – | – | Balance Cu |

| C95800 | 79–82% | 9.0–11.0% | 4.0–5.0% | 4.0–5.0% | – | – | – | – | – |

| C95500 | 79–82% | 9.0–11% | 4.0–5% | 4.0–5% | – | – | – | – | – |

| C95510 | 78–81% | 9.0–10% | 4.5–5.5% | 4.0–5.0% | – | – | – | – | – |

| C62300 | 91–93% | 6.0–7.5% | 2.0–3.5% | – | – | – | – | – | – |

ASTM B462 Aluminium Bronze Flanges - Mechanical Properties

| Alloy / Grade |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

Hardness (HB) |

Impact Strength (J) |

Operating Temperature (°C) |

|---|---|---|---|---|---|---|

| C95400 | 620–750 | 350–500 | 12–20 | 180–220 | 35–50 | Up to 550 |

| C95800 | 600–740 | 350–480 | 10–18 | 175–215 | 30–45 | Up to 550 |

| C95500 | 610–730 | 360–500 | 12–20 | 180–220 | 35–50 | Up to 550 |

| C95510 | 600–720 | 350–480 | 10–18 | 175–215 | 30–45 | Up to 550 |

| C62300 | 400–500 | 200–300 | 15–25 | 140–160 | 25–35 | Up to 300 |

High-Quality Aluminium Bronze Buttweld Pipe Fittings

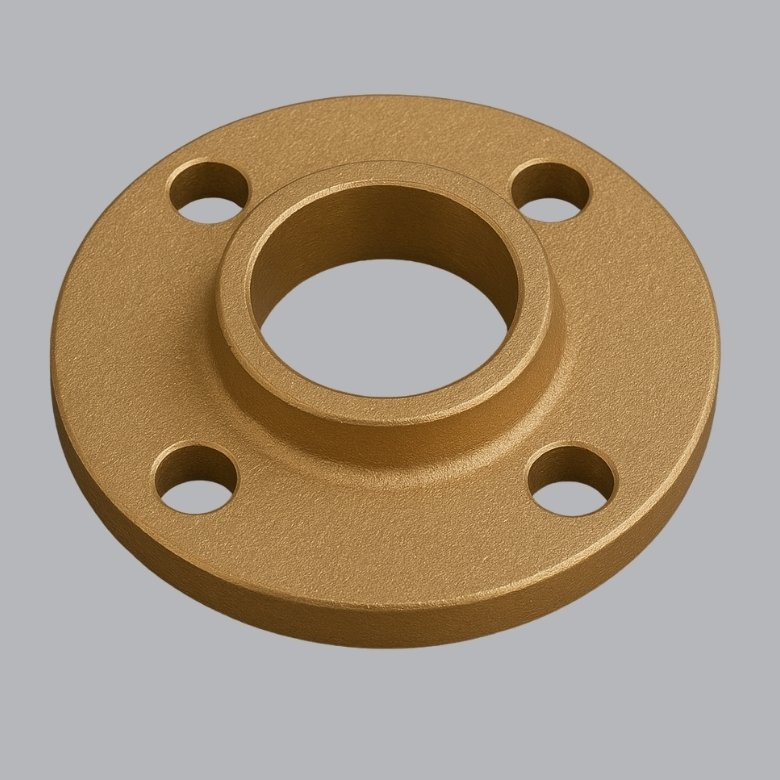

ASTM / ASME Standard Aluminium Bronze Flanges - Forged & Cast Flanges

- Aluminium Bronze Slip On Flange

- Aluminium Bronze Weld Neck Flange

- Aluminium Bronze Socket Weld Flange

- Aluminium Bronze Threaded Flange

- Aluminium Bronze Lap Joint Flange

- Aluminium Bronze Blind Flange

- Aluminium Bronze Long Weld Neck Flange

- Aluminium Bronze Reducing Flange

- Aluminium Bronze RTJ Flange

- Aluminium Bronze Plate Flange

Heavy-Duty Aluminium Bronze Forged Fittings

What is the difference between cast and forged Aluminium Bronze fittings?

Aluminium Bronze fittings can be manufactured either by casting or forging, and each process imparts distinct properties and advantages. The differences are explained in detail below:

Manufacturing Process:

Cast Fittings: Produced by pouring molten aluminum bronze alloy into molds or patterns, allowing the creation of complex shapes, large components, or intricate geometries. This process is ideal when dimensional flexibility is required.

Forged Fittings: Produced by compressing or hammering the alloy under high pressure using closed-die or open-die forging techniques. This results in a denser and more uniform metal structure.

Mechanical Strength:

Cast Fittings: Have adequate mechanical strength for moderate pressure applications but may contain minor porosity or internal cavities depending on the casting quality.

Forged Fittings: Exhibit superior tensile strength, yield strength, and fatigue resistance due to the compact, uniform grain structure developed during forging.

Durability and Reliability:

Cast Fittings: Suitable for general-purpose applications where high pressure or extreme mechanical stress is not expected. They are cost-effective and efficient for medium-duty pipelines.

Forged Fittings: Highly durable and reliable in high-pressure, high-stress, or harsh marine environments. The forging process reduces the risk of internal defects and improves resistance to cracking, erosion, and wear.

Surface and Dimensional Accuracy:

Cast Fittings: May require additional machining to achieve precise dimensions and smooth surfaces, especially for flanges or threaded connections.

Forged Fittings: Offer closer dimensional tolerances and smoother surfaces directly after forging, reducing the need for extensive post-processing.

Applications:

Cast Fittings: Typically used in chemical processing, desalination plants, or low-to-medium pressure industrial pipelines where complex shapes are required.

Forged Fittings: Preferred in marine, offshore, petrochemical, and high-pressure piping systems, where mechanical strength and long-term reliability are critical.

Cost Considerations:

Cast Fittings: Generally more economical for large volumes or complex geometries.

Forged Fittings: Higher production costs due to the forging process, but the investment is justified for high-performance applications requiring longevity and safety.

How does Aluminium Bronze compare with other copper alloys?

Strength: Aluminium Bronze offers higher tensile and yield strength.

Corrosion Resistance: Superior resistance to seawater, brine, and chemical exposure.

Wear Resistance: Better erosion and galling resistance in moving parts and high-flow systems.

It is preferred in marine, chemical, and high-pressure industrial systems where both durability and corrosion resistance are critical.

How are Aluminium Bronze flanges connected to piping systems?

Welding: Butt-welded or socket-welded connections provide permanent, high-strength joints.

Bolting: Slip-on, weld neck, or blind flanges use bolts and gaskets for flange-to-flange connections.

Threading or Soldering: Smaller fittings can be threaded or soldered in systems where welding is not feasible.

This flexibility ensures compatibility with various piping materials and industrial standards.