- Home

- Aluminium Alloys

- Aluminium 7075

Aluminium 7075

Aluminium 7075: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

High-performance Aluminium 7075 pipe fittings and flanges made to ASTM B361/B247/B209. Perfect for durable, corrosion-resistant piping systems across USA, UK, Germany, Canada, and Australia.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd is a leading manufacturer and supplier of premium aluminum 7075 pipe fittings and flanges. Our products are precision-engineered to meet ASTM, ASME, and international standards, ensuring durability, performance, and corrosion resistance.

Quality and customer satisfaction are our top priorities at Midland Forge. With advanced manufacturing facilities and rigorous quality checks such as PMI, hydrostatic testing, and dimensional inspections, we deliver reliable products. Supported by a skilled team of engineers, we provide tailored solutions, making us a trusted partner for high-performance piping solutions worldwide.

Aluminium 7075 pipe fittings and flanges are high-strength, lightweight components engineered for demanding piping systems where durability, corrosion resistance, and mechanical performance are critical. Alloy 7075, a zinc-based aluminium alloy, offers superior tensile and yield strength compared to conventional aluminium grades, making it ideal for pressure-rated, structural, and aerospace piping applications.

These fittings and flanges are precision-manufactured to meet ASTM B209, B221, B241, and B247 standards, ensuring consistent dimensions, reliability, and long service life. With excellent fatigue resistance and the ability to withstand harsh environmental conditions, Aluminium 7075 fittings and flanges are widely used in industrial, marine, aerospace, and high-performance process systems.

Aluminium 7075 pipe fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Alloys: 5083, 6061, 6063, 6082, 7075, 1100

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Aluminium 7075 forged fittings– Grades & Standards

| Material / Alloy | Grade / UNS | ASTM / ASME Standard | Product Type | Typical Applications |

|---|---|---|---|---|

| Aluminium Alloy | 7075 | ASTM B209 / B221 / B241 (Buttweld), ASTM B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | High-strength piping, aerospace applications, structural and industrial systems, pressure-rated piping, specialized marine and offshore piping |

Explore Aluminium Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Materials

Explore All Products

Aluminium 7075 Products

Aluminium 7075 industrial flanges - Equivalent Grades

| Material / Alloy | UNS Number | EN / DIN | JIS | GOST / Russian | ASTM / ASME Standards |

|---|---|---|---|---|---|

| Aluminium 7075 | A97075 | EN AW-7075 | A7075 | 1580 | ASTM B209 / B221 / B241 (Buttweld), ASTM B247 (Forged & Flanges) |

Aluminium 7075 high-strength fittings - Chemical Composition

| Aluminium Alloy | Zn | Mg | Cu | Cr | Fe | Si | Ti | Mn | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| 7075 | 5.1–6.1 | 2.1–2.9 | 1.2–2.0 | 0.18–0.28 | ≤0.5 | ≤0.4 | ≤0.2 | ≤0.3 | Balance |

Aluminium 7075 low-pressure flanges - Mechanical Properties

| Aluminium Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Brinell Hardness (HB) | Fatigue Strength (MPa) |

|---|---|---|---|---|---|

| 7075 | 510–570 | 430–500 | 5–11 | 150–170 | 160–180 |

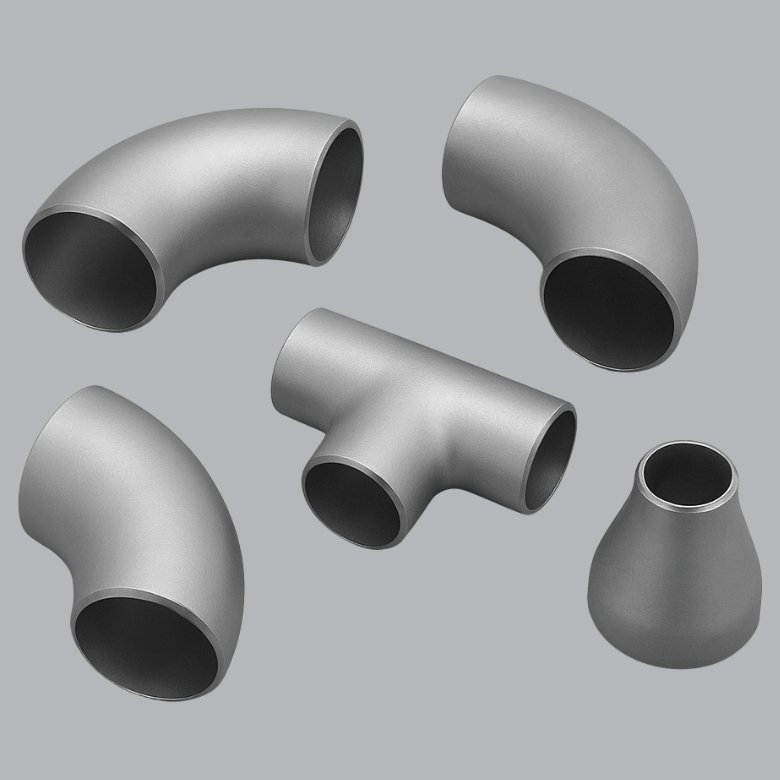

Aluminium alloy buttweld fittings – 7075

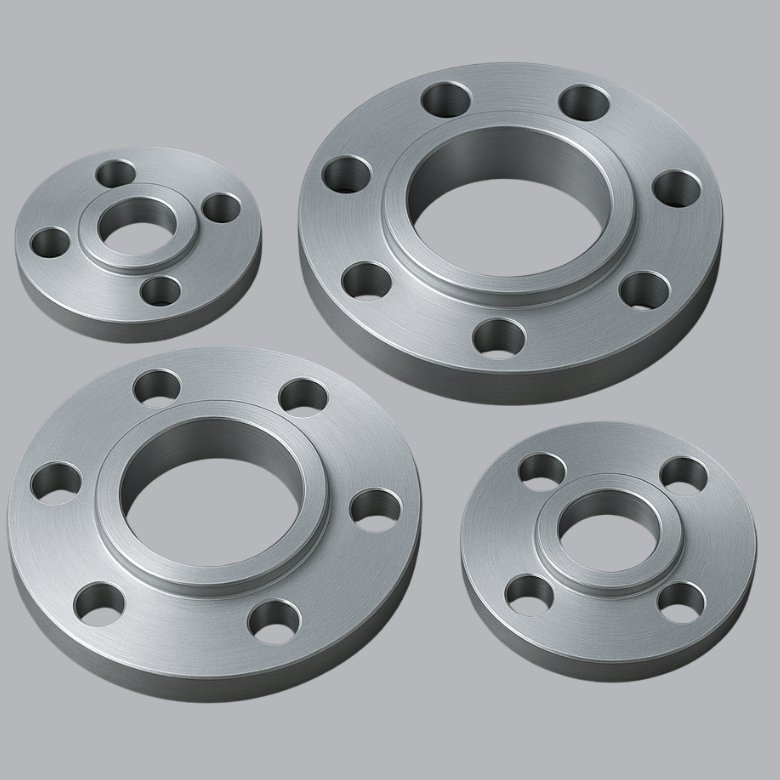

Aluminium alloy flanges – 7075

Aluminium alloy forged fittings – 7075 socket weld and threaded

What are the fabrication considerations for Aluminium 7075 fittings and flanges?

Welding:

7075 is not easily weldable using conventional methods due to zinc content.

Specialized techniques such as friction stir welding are preferred.

Machining:

Excellent machinability due to high strength and uniform grain structure.

Requires sharp cutting tools and proper cooling to avoid heat-induced weakening.

Forming:

Limited ductility means forming must be carefully controlled, typically using T6 temper material for better strength.

Design Implication: 7075 fittings are often forged or machined rather than heavily formed, ensuring structural integrity under high pressure.

How do Aluminium 7075 fittings and flanges perform under pressure?

7075 is capable of handling high-pressure systems, outperforming most standard aluminium alloys.

Wall thickness and flange design must be calculated according to ASME B16.5 / ASTM specifications to ensure safe operation.

Fatigue and cyclic loading: High fatigue strength allows long-term operation in pulsating or variable pressure piping systems.

What testing and quality checks are recommended for Aluminium 7075 pipe fittings and flanges?

Mechanical Testing: Tensile, yield, elongation, and hardness tests per ASTM standards.

Non-Destructive Testing (NDT): Ultrasonic testing or dye penetrant inspection for detecting surface and subsurface defects.

Dimensional Inspection: Ensure compliance with ASTM B209/B221/B241/B247 for pipe, fittings, and flanges.

Surface Treatment Verification: Confirm anodizing or coating thickness for corrosion protection.

Pressure Testing: Hydrostatic or pneumatic testing for pressure-rated systems.