- Home

- Aluminium Alloys

- Aluminium 1060 / 5052 / 6061

Aluminium 1060 / 5052 / 6061

Aluminium 1060/5052/6061: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Premium Aluminium pipe fittings and flanges (1060, 5052, 6061) manufactured to ASTM B361/B247/B209. Ideal for durable, corrosion-resistant piping systems in India, UAE, Saudi Arabia, Malaysia, Bahrain.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. specializes in the manufacturing and supply of high-precision aluminum pipe fittings and flanges in grades 1060, 5052, and 6061. Our products are engineered to meet stringent ASTM B361/B247/B209 standards, ensuring exceptional corrosion resistance, lightweight performance, and durability for demanding industrial applications across oil & gas, chemical processing.

Leveraging advanced forging and buttweld fabrication technologies, we deliver dimensionally accurate, corrosion-resistant, and high-performance aluminum solutions. With a strong focus on quality, consistency, and timely delivery, we serve clients across India, Oman, Qatar, Kuwait, Singapore, and Europe, establishing ourselves as a trusted partner for critical piping systems.

Aluminum 1060, 5052, and 6061 pipe fittings and flanges are precision-engineered components designed for corrosion resistance, high strength-to-weight ratio, and dimensional accuracy in piping systems. Grade 1060 offers excellent corrosion resistance and formability, making it suitable for low-pressure applications, while 5052 provides superior marine-grade corrosion resistance and moderate strength for industrial piping. Grade 6061 combines high tensile strength with excellent corrosion resistance and weldability, ideal for high-pressure and structural applications.

These fittings and flanges are manufactured using advanced forging and buttweld techniques to meet ASTM B361/B247/B209 standards, ensuring consistent wall thickness, precise tolerances, and reliable performance in chemical, petrochemical, water treatment, and power generation industries.

aluminium 1060 pipe fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

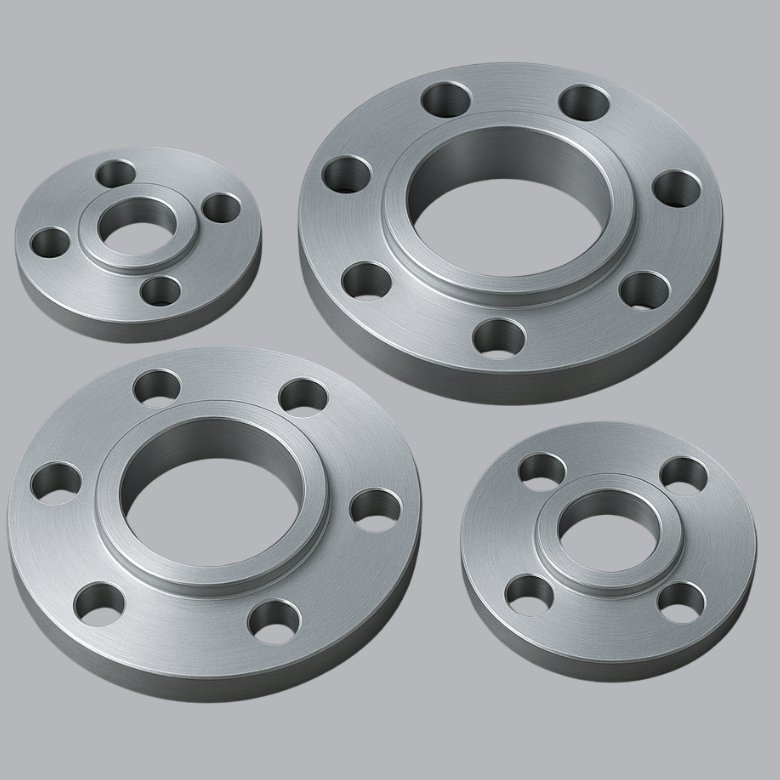

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Alloys: 5083, 6061, 6063, 6082, 7075, 1100

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

aluminium 5052 forged fittings– Grades & Standards

| Material / Alloy | Grade / UNS | ASTM / ASME Standard | Product Type | Typical Applications |

|---|---|---|---|---|

| Aluminium Alloy | 1060 | ASTM B209 / B221 / B241 (Buttweld), ASTM B361 (Forged & Flanges) |

Buttweld, Forged, Flanges | Low-pressure piping, water distribution, corrosion-resistant piping, chemical plants |

| Aluminium Alloy | 5052 | ASTM B209 / B211 / B241 (Buttweld), ASTM B361 / B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | Marine pipelines, offshore installations, medium-pressure industrial piping, chemical processing |

| Aluminium Alloy | 6061 | ASTM B209 / B221 / B241 (Buttweld), ASTM B361 / B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | High-strength piping, structural and industrial applications, pressure-rated systems, offshore installations |

Explore Aluminium Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Materials

Explore All Products

Aluminium 1060 / 5052 / 6061 Products

aluminium 6061 industrial flanges - Equivalent Grades

| Aluminium Alloy | UNS Number | EN / DIN | JIS | GOST / Russian | ASTM / ASME |

|---|---|---|---|---|---|

| 1060 | A91060 | EN AW-1060 | A1050 | 1350 | B209 / B221 / B241 / B361 |

| 5052 | A95052 | EN AW-5052 | A5052 | 5757 | B209 / B211 / B241 / B361 / B247 |

| 6061 | A96061 | EN AW-6061 | A6061 | 1576 | B209 / B221 / B241 / B361 / B247 |

aluminium 6061 high-strength fittings - Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| 1060 | 0.25 max | 0.35 max | 0.05 max | 0.03 max | 0.03 max | – | 0.05 max | 0.03 max | 99.6 min |

| 5052 | 0.25 max | 0.40 max | 0.10 max | 0.10 max | 2.2–2.8 | 0.15–0.35 | 0.10 max | 0.03 max | Balance |

| 6061 | 0.40–0.8 | 0.70 max | 0.15–0.40 | 0.15 max | 0.8–1.2 | 0.04–0.35 | 0.25 max | 0.15 max | Balance |

aluminium 1060 low-pressure flanges - Mechanical Properties

| Alloy | Temper / Condition | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| 1060 | H14 (cold-worked) | 90–125 | 35–55 | 12–22 | 25–40 |

| 5052 | H32 (strain-hardened & stabilized) | 210–240 | 90–160 | 10–12 | 50–60 |

| 6061 | T6 (solution heat-treated & artificially aged) | 290–310 | 240–270 | 8–12 | 95–105 |

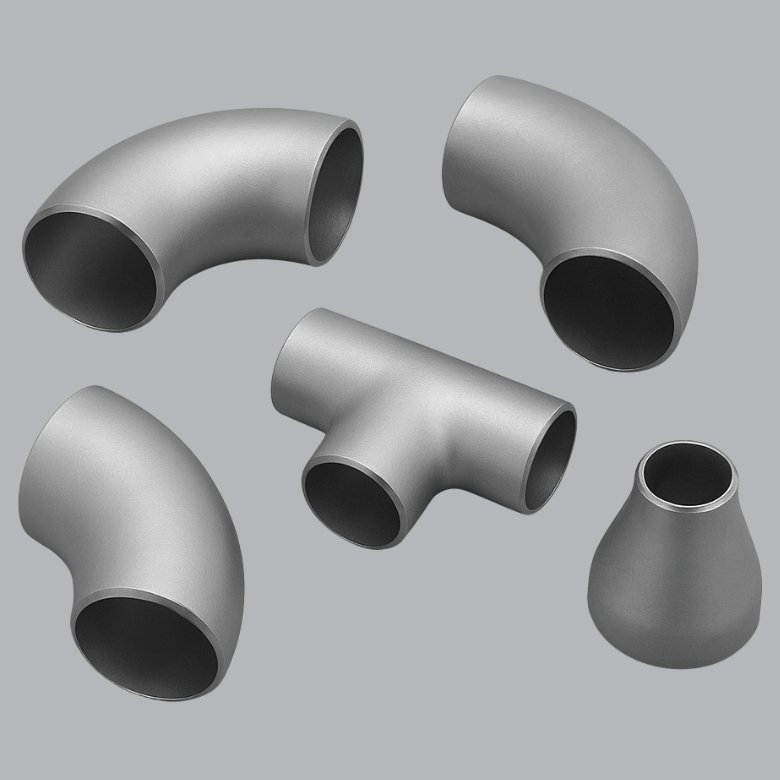

Aluminium alloy buttweld fittings – 1060, 5052, 6061

Aluminium alloy flanges – 1060, 5052, 6061

Aluminium alloy forged fittings – 1060 / 5052 / 6061 socket weld and threaded

What are the differences in between Aluminium 1060, 5052, and 6061 for pipe fittings and flanges?

Aluminium 1060:

Commercially pure aluminium (≥99.6% Al).

Tensile strength: ~70–125 MPa.

Yield strength: ~35–55 MPa.

Excellent ductility and formability, ideal for low-pressure piping systems.

Limited strength, not suitable for high-pressure applications.

Aluminium 5052:

Aluminium-magnesium alloy with moderate strength.

Tensile strength: ~190–240 MPa.

Yield strength: ~90–160 MPa.

Excellent corrosion resistance, especially in marine and chemical environments.

Suitable for medium-pressure piping systems and industrial fittings.

Aluminium 6061:

Aluminium-magnesium-silicon alloy with high strength.

Tensile strength: ~290–310 MPa.

Yield strength: ~240–270 MPa.

Excellent weldability, corrosion resistance, and pressure handling capability.

Ideal for high-pressure piping, structural, and industrial applications.

What are the fabrication considerations for Aluminium 1060 / 5052 / 6061 fittings and flanges?

Welding:

6061 and 5052 are highly weldable using TIG, MIG, and friction stir welding; post-weld strength reduction must be considered for 6061.

1060 has excellent weldability but is limited in high-pressure applications.

Forming:

1060 is highly ductile and easy to form into elbows, tees, and reducers.

5052 has moderate formability, suitable for bends and shaped fittings.

6061 requires heat treatment (T6 temper) and controlled forming due to higher strength.

Machining:

All three alloys are machinable, but 6061 is preferred for precision machined flanges due to dimensional stability.

Are Aluminium 1060 / 5052 / 6061 fittings compatible with other piping materials?

Electrical/galvanic considerations:

Aluminum fittings must be isolated from steel or copper to prevent galvanic corrosion.

Use insulating gaskets, sleeves, or coatings if joining dissimilar metals.

Thermal compatibility:

Aluminium has higher thermal expansion than steel; allowances must be made in pipe design to prevent stress on flanges/fittings.