- Home

- Alloy Steel

Alloy Steel

Alloy Steel: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Global Supplier & Manufacturer of Alloy Steel Buttweld, Forged Fittings & Flanges including – Elbows, Tees, Reducers, Crosses, Caps, Weld Neck, Slip-On, Blind, Threaded & Orifice Flanges for High-Pressure Piping.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is committed to delivering excellence in the manufacturing and supply of high-quality industrial components, including alloy steel pipe fittings and flanges. With a strong focus on precision, quality, and innovation, we implement stringent quality management systems and adhere to international standards to ensure every product meets the highest performance and safety requirements.

Our policies emphasize sustainability, ethical business practices, and continuous process improvement, enabling us to consistently provide reliable solutions for demanding industrial applications worldwide.

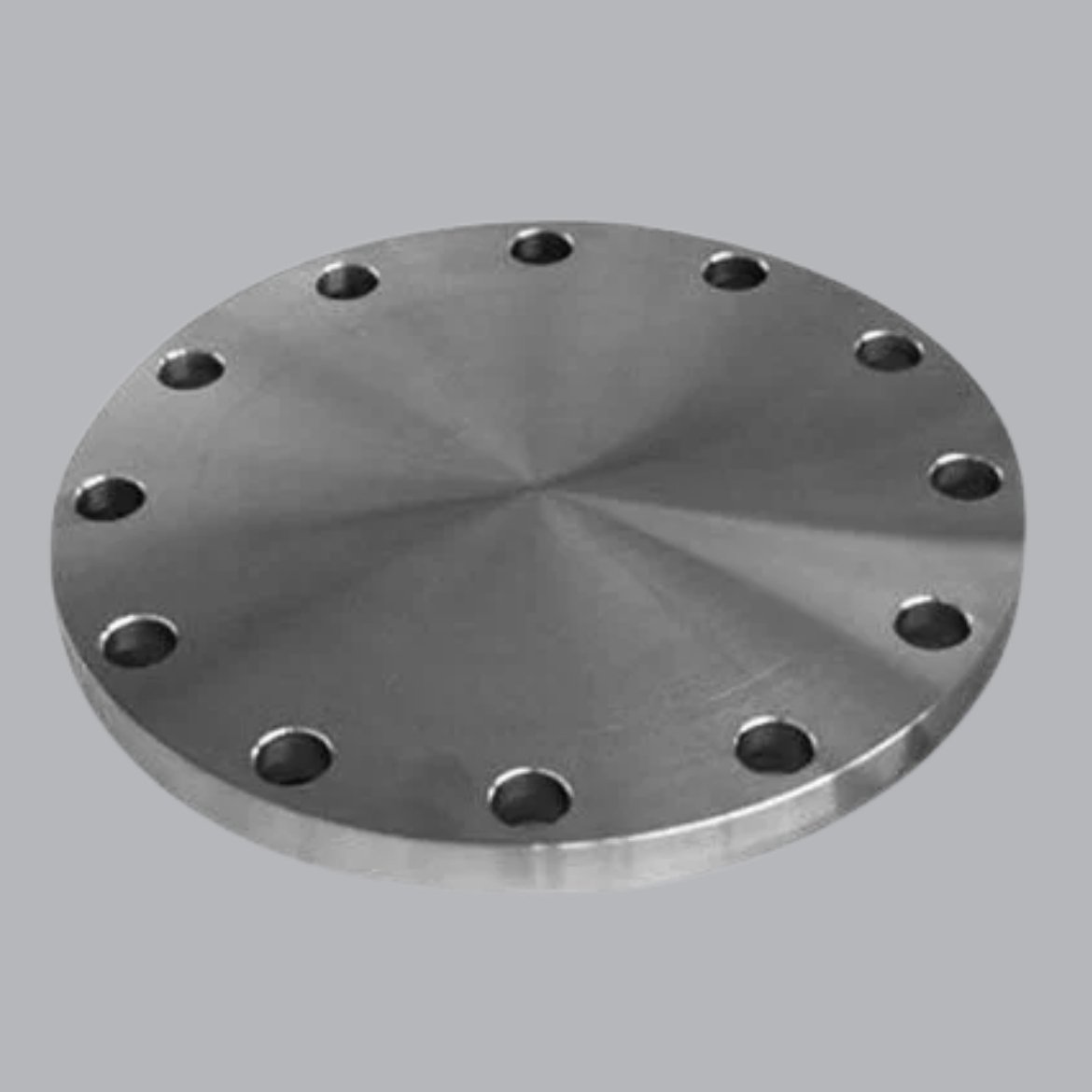

Alloy steel pipe fittings and flanges are engineered for high-strength, high-pressure, and high-temperature industrial piping systems. Manufactured using precision forging and fabrication techniques, these components provide superior mechanical properties, including enhanced tensile strength, yield strength, impact toughness, and fatigue resistance. Available in various types such as elbows, tees, reducers, crosses, slip-on, weld neck, threaded, and blind flanges, alloy steel fittings ensure dimensional accuracy, leak-proof connections, and long-term reliability. With strict adherence to ASTM, ASME, and API standards, these flanges and fittings are ideal for oil & gas, petrochemical, power, and chemical process industries, delivering consistent performance under extreme operating conditions.

Driven by a vision to be a globally recognized leader in forged and fabricated piping solutions, our priorities are customer satisfaction, timely delivery, and technical expertise. Our mission is to innovate, optimize, and expand our capabilities while fostering a collaborative work culture that values talent, integrity, and operational excellence. By leveraging advanced technologies and skilled professionals, we ensure efficient production processes, rigorous quality checks, and seamless project execution, making us a trusted partner for clients across diverse industries.

Alloy steel Pipe Fittings Specifications

Size Range – (Buttweld, Forged, Flange)

Pressure Rating/ Wall Thickness

Applications

ASTM / ASME - Grades

ASTM A182 / SA182

Types

Quality Certifications

Dimensional Standards

Forms

Surface Finish

Alloy Steel Forged Fittings– Grades & Standards

| Alloy Steel Grade | UNS No. | Applicable Standards | Typical Products |

|---|---|---|---|

| ASTM A234 WP1 / WP5 / WP9 / WP11 / WP12 / WP22 / WP91 | K12822 – K90901 | ASTM A234/A234M, ASME B16.9, MSS-SP-75 | Seamless & Welded Buttweld Fittings including Elbows, Tees, Reducers, Crosses, Caps, Stub Ends & Pipe Bends |

| ASTM A182 F1 / F5 / F9 / F11 / F12 / F22 / F91 | K12822 – K90901 | ASTM A182/A182M, ASME B16.5, B16.11, MSS-SP-83 | Forged Fittings & Flanges including Elbows, Tees, Couplings, Unions, Weld Neck, Slip-On, Socket Weld, Threaded & Blind Flanges |

| ASTM A234 WP1 | K12822 | ASTM A234/A234M, ASME B16.9 | Buttweld Elbows, Tees, Reducers, Caps |

| ASTM A234 WP5 | K41545 | ASTM A234/A234M, ASME B16.9 | Buttweld Fittings, Pipe Bends, Stub Ends |

| ASTM A234 WP9 | K90941 | ASTM A234/A234M, ASME B16.9 | Alloy Steel Elbows, Tees, Reducers, Crosses |

| ASTM A234 WP11 | K11597 | ASTM A234/A234M, ASME B16.9 | Seamless & Welded Buttweld Fittings for High-Temperature Service |

| ASTM A234 WP22 | K21590 | ASTM A234/A234M, ASME B16.9 | Alloy Steel Pipe Fittings, Elbows, Tees, Caps |

| ASTM A234 WP91 | K90901 | ASTM A234/A234M, ASME B16.9 | High-Temperature Alloy Steel Buttweld Fittings for Power & Petrochemical Applications |

| ASTM A182 F11 / F22 | K21590 / K21595 | ASTM A182, ASME B16.5, B16.11 | Forged Fittings, Flanges, Elbows |

| ASTM A182 F5 / F9 | K21550 / K21560 | ASTM A182, ASME B16.5, B16.11 | Forged Fittings, Flanges |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Alloy Steel Products

Alloy Steel Buttweld Tee, Cross Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Alloy Steel Grade | UNS No. | DIN / EN | BS | AFNOR | JIS |

|---|---|---|---|---|---|

| ASTM A234 WP1 / A182 F1 | K12822 | 1.5415 (15Mo3) | 1501-620-510 | 15D3 | STPA12 |

| ASTM A234 WP5 / A182 F5 | K41545 | 1.7362 (5Cr0.5Mo) | 620A24 | 15CD5.05 | STPA24 |

| ASTM A234 WP9 / A182 F9 | K90941 | 1.7386 (9Cr1Mo) | 620A27 | 15CrMo9 | STPA26 |

| ASTM A234 WP11 / A182 F11 | K11597 | 1.7335 (13CrMo4-5) | 621B27 | 15CD4.05 | STPA23 |

| ASTM A234 WP22 / A182 F22 | K21590 | 1.7335 / 1.7380 (10CrMo9-10) | 621B27 | 15CD4.04 | STPA24 |

| ASTM A234 WP91 / A182 F91 | K90901 | 1.4903 (X10CrMoVNb9-1) | 621B27 | 15CD9.10 | STPA28 |

Chemical Composition of Alloy Steel Threaded Elbow

| Grade | Carbon (C) |

Manganese (Mn) |

Phosphorus (P) |

Sulfur (S) |

Silicon (Si) |

Chromium (Cr) |

Molybdenum (Mo) |

Nickel (Ni) |

Vanadium (V) |

|---|---|---|---|---|---|---|---|---|---|

| WP1 / F1 | 0.10–0.20 | 0.30–0.80 | ≤0.030 | ≤0.030 | 0.10–0.50 | ≤0.30 | 0.44–0.65 | ≤0.40 | ≤0.02 |

| WP5 / F5 | 0.15 | 0.30–0.60 | ≤0.030 | ≤0.030 | 0.50–1.00 | 4.00–6.00 | 0.45–0.65 | ≤0.50 | ≤0.02 |

| WP9 / F9 | 0.15 | 0.40–0.80 | ≤0.030 | ≤0.030 | 0.50–1.00 | 8.00–10.00 | 0.90–1.10 | ≤0.50 | ≤0.25 |

| WP11 / F11 | 0.05–0.15 | 0.30–0.60 | ≤0.030 | ≤0.030 | 0.50–1.00 | 1.00–1.50 | 0.44–0.65 | ≤0.50 | ≤0.02 |

| WP22 / F22 | 0.05–0.15 | 0.30–0.60 | ≤0.030 | ≤0.030 | 0.50–1.00 | 2.00–2.50 | 0.87–1.13 | ≤0.50 | ≤0.02 |

| WP91 / F91 | 0.08–0.12 | 0.30–0.60 | ≤0.020 | ≤0.010 | 0.20–0.50 | 8.00–9.50 | 0.85–1.05 | ≤0.40 | 0.18–0.25 |

Mechanical Properties of Alloy Steel Plate Flange

| Grade | Tensile Strength (min.) MPa (ksi) |

Yield Strength (min.) MPa (ksi) |

Elongation (%) |

Hardness (HB) |

Typical Service Characteristics |

|---|---|---|---|---|---|

| WP1 / F1 | 380 (55) | 205 (30) | 22 | ≤143 | Designed for moderate temperature & pressure service; good ductility and weldability. |

| WP5 / F5 | 415 (60) | 205 (30) | 20 | ≤163 | Suitable for higher temperature applications; excellent oxidation resistance up to 600°C. |

| WP9 / F9 | 585 (85) | 380 (55) | 20 | ≤197 | High tensile and creep strength; ideal for high-pressure steam pipelines. |

| WP11 / F11 | 415 (60) | 205 (30) | 20 | ≤163 | Balanced Cr-Mo alloy; widely used in boiler, heat exchanger, and pressure vessel fabrication. |

| WP22 / F22 | 415 (60) | 205 (30) | 20 | ≤163 | Higher creep strength than F11; reliable for prolonged service at elevated temperatures. |

| WP91 / F91 | 620 (90) | 415 (60) | 18 | ≤250 | Exceptional strength, hardness, and thermal fatigue resistance; used in ultra-supercritical power systems and refineries. |

Alloy Steel Buttweld Pipe Fittings – Available in Seamless and Welded

ANSI / ASME Approved Alloy Steel Flanges – Trusted Industrial Piping Solutions

Alloy Steel Threaded & Socket Weld Forged Fittings – ASME / ANSI Certified

What grades of alloy steel are used in fittings and flanges?

1. Low Alloy Steels

Grades: ASTM A234 WP1, WP5, WP9, WP11

Features: Small amounts of Cr and Mo for moderate strength and corrosion resistance.

Temperature & Pressure: Moderate pressure; suitable up to ~427°C (800°F).

Applications: Boilers, pipelines, and pressure vessels.

2. High Alloy Steels

Grades: ASTM A182 F5, F11, F22, F91

Features: Higher Cr, Mo, and sometimes Ni; excellent high-temperature strength and creep resistance.

Temperature & Pressure: High pressure; can handle up to ~600°C (1112°F).

Applications: Power plants, superheated steam lines, refineries.

3. Chromium-Molybdenum-Nickel Alloys

Features: Optimized Cr-Mo-Ni composition for corrosion and oxidation resistance.

Temperature & Pressure: Ideal for high temperature and corrosive environments.

Applications: Chemical plants, oil refineries, and high-pressure steam lines.

4. Selection Considerations

Pressure class, temperature, corrosion resistance, environment, and welding/fabrication requirements.

What are the differences between forged and welded alloy steel fittings?

Forged Fittings:

Manufactured by hot forging; seamless structure; superior strength.

Suitable for high-pressure, high-temperature applications.

Examples: elbows, tees, reducers.

Welded (Fabricated) Fittings:

Made from plates or pipes via welding; larger sizes are more economical.

May require post-weld heat treatment (PWHT) for stress relief.

Examples: large diameter elbows, reducers, headers.

How to select the right alloy steel grade for a piping system?

Pressure & Temperature Ratings: Use ASME B16.5/B16.9 class and material ratings.

Corrosion & Environment Resistance: Consider chemical exposure, seawater, or acidic conditions.

Mechanical Properties: Yield, tensile strength, and impact resistance.

Fabrication Needs: Seamless vs. welded, ease of installation, or on-site welding requirements.

Cost Considerations: Higher alloy content increases cost but improves service life.