- Home

- Aluminium Alloys

Aluminium Alloys

Aluminium Alloys: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Aluminium Alloys Pipe Fittings and Flanges Manufacturer | Buttweld & Forged. Precision-engineered Elbows, Tees, Reducers, and Flanges manufactured to ASTM B361/B247/B209 standards for industries in India, UAE, Saudi Arabia, Oman, Qatar, Kuwait, and Europe.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a forward-driven engineering company specializing in the design and manufacture of high-performance forged fittings and flanges for critical piping systems. Leveraging modern forging facilities, CNC machining centers, and advanced metallurgical controls, the company delivers components that integrate precision, consistency, and durability.

Every product is developed with a clear focus on functionality and endurance — ensuring superior performance in high-pressure, corrosive, and high-temperature environments.

Built on an integrity and technical mastery foundation, we serve a global clientele in the oil and gas, desalination, offshore, power, and heavy industrial sectors. Its strength lies in combining in-depth material knowledge with an adaptive manufacturing approach, enabling swift customization without compromising quality. By aligning with international codes and client specifications, we continue to set new benchmarks in reliability, engineering excellence, and customer satisfaction within the forged components industry.

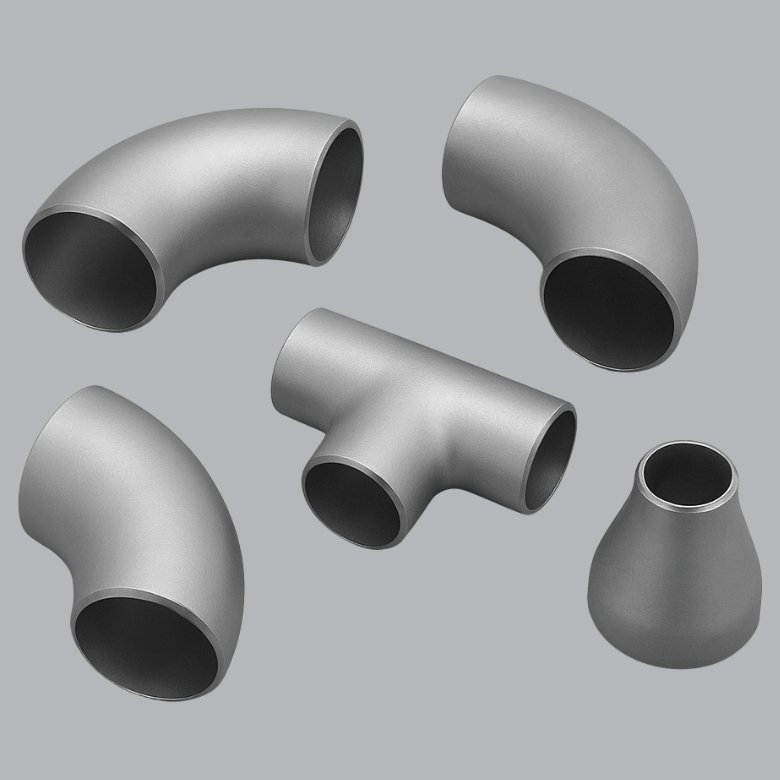

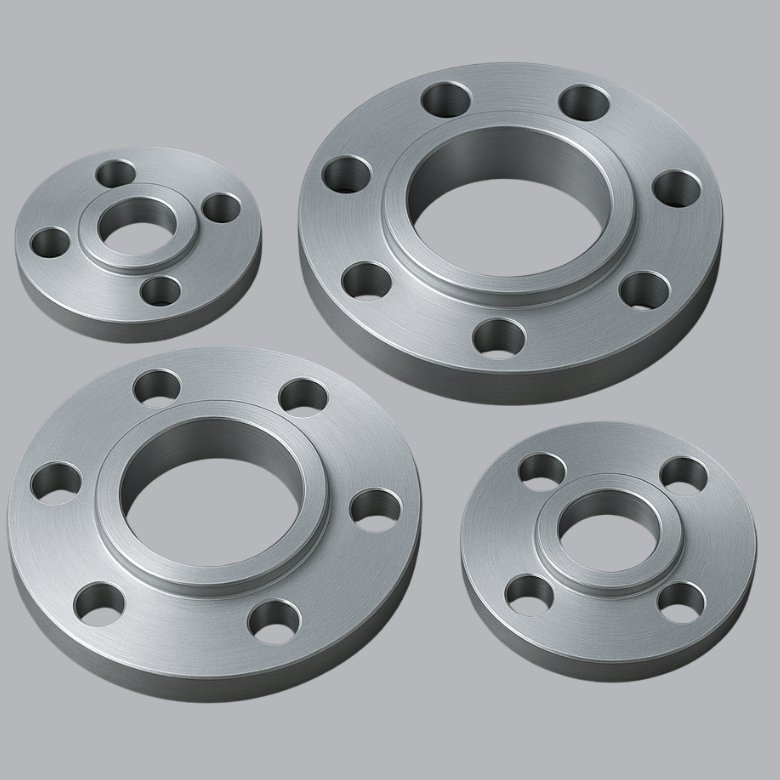

Aluminium Alloys Pipe Fittings and Flanges are engineered from wrought and heat-treated grades conforming to ASTM B361, B247, and B564 standards. These components exhibit a superior strength-to-weight ratio, excellent corrosion resistance in marine and chemical environments, and high thermal conductivity. The alloys commonly used include 5083, 6061, 6063, and 6082, each offering distinct combinations of mechanical strength, weldability, and formability.

Aluminum buttweld fittings are produced through extrusion and subsequent solution heat treatment, ensuring uniform grain structure and dimensional stability. Forged aluminum flanges are manufactured via precision forging and controlled aging to enhance fatigue resistance and hardness. Their lightweight nature significantly reduces piping system loads while maintaining pressure integrity across a wide temperature range. These fittings and flanges are widely used in applications requiring low density, corrosion resistance, and efficient thermal transfer, such as desalination, cryogenic, and aerospace-grade piping systems.

aluminium butt‑weld pipe fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Alloys: 5083, 6061, 6063, 6082, 7075, 1100

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

aluminium alloy forged pipe fittings– Grades & Standards

| Material / Alloy |

Grade / UNS |

ASTM / ASME Standard |

Product Type |

Typical Applications |

|---|---|---|---|---|

| Aluminium Alloy | 5083 | ASTM B209 / B221 / B241 (Buttweld), ASTM B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | Marine pipelines, chemical processing, cryogenic systems, seawater applications |

| Aluminium Alloy | 6061 | ASTM B209 / B221 / B241 (Buttweld), ASTM B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | Industrial piping, structural piping, medium-pressure systems, offshore installations |

| Aluminium Alloy | 6063 | ASTM B209 / B221 / B241 (Buttweld), ASTM B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | Lightweight piping, architectural piping, low-to-medium pressure industrial systems |

| Aluminium Alloy | 6082 | ASTM B209 / B221 / B241 (Buttweld), ASTM B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | High-strength piping, marine and offshore systems, chemical plants |

| Aluminium Alloy | 7075 | ASTM B209 / B221 / B241 (Buttweld), ASTM B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | Aerospace-grade piping, high-strength industrial piping, critical pressure systems |

| Aluminium Alloy | 1100 | ASTM B209 / B221 / B241 (Buttweld), ASTM B247 (Forged & Flanges) |

Buttweld, Forged, Flanges | Low-pressure piping, water distribution systems, corrosion-resistant piping |

Explore Aluminium Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Materials

Explore All Products

Aluminium Alloys Products

ASTM B361 aluminium pipe fittings - Equivalent Grades

| Product / Alloy | ASTM | EN (European) | JIS (Japanese) | UNS (USA) |

|---|---|---|---|---|

| Aluminium 5083 | B209 / B241 / B221 / B247 / B316 | EN AW-5083 | A9505 | A95083 |

| Aluminium 6061 | B209 / B221 / B241 / B247 / B316 | EN AW-6061 | A96061 | A96061 |

| Aluminium 6063 | B209 / B221 / B241 / B316 | EN AW-6063 | A96063 | A96063 |

| Aluminium 6082 | B209 / B221 / B241 / B247 | EN AW-6082 | A96082 | A96082 |

| Aluminium 7075 | B209 / B221 / B241 | EN AW-7075 | A97075 | A97075 |

| Aluminium 1100 | B209 / B221 / B241 | EN AW-1100 | A91100 | A91100 |

aluminium alloy flanges - Chemical Composition

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) |

|---|---|---|---|---|---|---|---|---|

| 5083 | 0.4 | 0.4 | 0.1 | 0.4–1.0 | 4.0–4.9 | 0.05–0.25 | 0.25 | 0.15 |

| 6061 | 0.4–0.8 | 0.7 | 0.15–0.4 | 0.15 | 0.8–1.2 | 0.04–0.35 | 0.25 | 0.15 |

| 6063 | 0.2–0.6 | 0.35 | 0.1 | 0.1 | 0.45–0.9 | 0.1 | 0.1 | 0.1 |

| 6082 | 0.7–1.3 | 0.5 | 0.1 | 0.4–1.0 | 0.6–1.2 | 0.25 | 0.2 | 0.1 |

| 7075 | 0.4 | 0.5 | 1.2–2.0 | 0.3 | 2.1–2.9 | 0.18–0.28 | 5.1–6.1 | 0.2 |

| 1100 | 0.95 | 0.95 | 0.05 | 0.05 | 0.05–0.2 | 0.1 | 0.1 | 0.05 |

aluminium forged flanges pressure class 150‑2500 - Mechanical Properties

| Alloy | Temper / Condition |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

Brinell Hardness (HB) |

Density (g/cm³) |

|---|---|---|---|---|---|---|

| 5083 | H321 / H116 | 275–345 | 145–215 | 12–18 | 60–95 | 2.66 |

| 6061 | T6 | 290–310 | 240–270 | 12–17 | 95–105 | 2.70 |

| 6063 | T6 | 215–240 | 145–170 | 8–12 | 65–75 | 2.70 |

| 6082 | T6 | 310–340 | 260–290 | 10–14 | 100–120 | 2.70 |

| 7075 | T6 | 540–570 | 480–500 | 10–12 | 150–160 | 2.81 |

| 1100 | O (annealed) | 90–110 | 35–50 | 35–45 | 25–30 | 2.71 |

astm b361 aluminium Buttweld Fittings

ASTM B247 Aluminium Flanges

ASTM B247 Aluminium Socket weld & threaded fittings

What types of aluminium alloys are used in fittings and flanges?

5xxx series (e.g., 5083): Excellent corrosion resistance, moderate strength, commonly used in marine and chemical applications.

6xxx series (e.g., 6061, 6063, 6082): Heat-treatable alloys offering higher strength and good corrosion resistance.

7xxx series (e.g., 7075) (rare): Very high strength, primarily for aerospace or high-performance applications.

Selection depends on operating conditions like pressure, temperature, and exposure to corrosive media.

What are the advantages of aluminium alloy pipe fittings and flanges?

Lightweight: Reduces piping system loads and foundation requirements.

Corrosion resistance: High resistance to seawater, chemicals, and atmospheric corrosion.

High thermal conductivity: Suitable for heat exchangers and systems requiring efficient thermal transfer.

Strength-to-weight ratio: Can withstand high pressures while being lighter than steel.

Easy fabrication: Good weldability, formability, and machinability for custom applications.

What are the limitations of aluminium alloy fittings?

Temperature limitations: Most aluminium alloys are suitable up to ~150–200°C; higher temperatures may reduce strength.

Lower hardness vs steel: Aluminium may deform more under extreme mechanical loads.

Cost: Premium alloys like 5083 or 6061 can be costlier than standard carbon steel fittings.