- Home

- Copper Alloys

- Bronze

Bronze

Bronze: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Manufacturer & Exporter of Bronze Industrial Fittings & Flanges, featuring Buttweld Elbows, Tees, Reducers, Caps & Custom Fabricated Headers. Engineered to ASTM B62, B16, and B16.18 standards for superior strength and corrosion resistance. Exporting to the USA, UK, Germany, Italy, UAE, Saudi Arabia, Qatar, Singapore, Australia, & Malaysia.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a specialized manufacturer and global supplier of precision-engineered bronze pipe fittings and flanges. With a focus on metallurgical integrity and dimensional accuracy, every product is forged, machined, and inspected to meet stringent international standards, including ASTM, ASME, ANSI, and EN.

Combining innovation with decades of manufacturing expertise, we offer precision-engineered solutions in bronze, non-ferrous materials. Our dedication to consistent quality, timely delivery, and global customer trust defines our strength in engineered piping solutions.

Bronze Pipe Fittings and Flanges are precision-engineered components manufactured from high-strength copper-based alloys containing tin and other elements for enhanced durability and corrosion resistance. These fittings and flanges exhibit excellent resistance to seawater, steam, and various corrosive media, making them ideal for marine, hydraulic, and industrial fluid-handling systems. Produced as per ASTM B62, ASME B16.5, and B16.18 standards, bronze fittings are available in buttweld, forged, and flanged configurations, including elbows, tees, reducers, couplings, caps, and headers.

The material’s superior machinability, thermal conductivity, and pressure retention capabilities ensure reliable performance in high-temperature and moderate-pressure applications. Each component is precisely machined, hydrostatically tested, and finished to meet tight dimensional tolerances, ensuring leak-proof and long-lasting connections. Bronze pipe fittings and flanges are widely used in marine, oil & gas, desalination, HVAC, and process industries, where consistent mechanical strength and corrosion resistance are critical.

ASTM B62 bronze fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48”

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

Surface & Finish

ASTM / ASME - Grades - Material

Bronze Alloys

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Key Features

Bronze alloy pipe fittings ASTM B62 – Grades & Standards

| Material / Alloy | Grade / UNS |

ASTM / ASME Standard |

Product Type | Typical Applications |

|---|---|---|---|---|

| Bronze – Tin Bronze | C83600 | ASTM B62 / ASME B16.18 |

Buttweld, Forged, Flanges | Marine piping, potable water, general industrial piping, seawater systems |

| Phosphor Bronze | C51000 | ASTM B111 / ASME B16.18 |

Buttweld, Forged, Flanges | Hydraulic systems, valves, marine hardware, corrosion-resistant piping |

| Aluminum Bronze | C95500 | ASTM B148 / ASME B16.5 |

Buttweld, Forged, Flanges | High-pressure seawater, chemical plants, offshore piping, industrial process lines |

| Silicon Bronze | C65500 | ASTM B505 / ASME B16.18 |

Buttweld, Forged, Flanges | Corrosion-resistant piping, seawater systems, industrial fluids, HVAC applications |

| Leaded Bronze (Machinable Bronze) | C54400 | ASTM B505 / B505M |

Buttweld, Forged, Flanges | Low-pressure piping, general plumbing, bearings, threaded connections |

| Naval Bronze (Copper-Tin-Zinc) | C46400 | ASTM B148 / ASTM B62 |

Buttweld, Forged, Flanges | Marine, offshore, and seawater pipelines, corrosion-resistant industrial applications |

Explore Copper Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Materials

Explore All Products

bronze Products

ASTM B62 bronze flanges - Equivalent Grades

| Material / Alloy | UNS / Alloy No. | ASTM / ASME Standard | DIN / EN | JIS | BS / AFNOR |

|---|---|---|---|---|---|

| Tin Bronze (Cu-Sn) | C83600 | ASTM B62 (Cast Fittings), B16.18 (Flanges) | CuSn10 | C3771 | CZ102 |

| Phosphor Bronze (Cu-Sn-P) | C51000 | ASTM B111 (Pipe Fittings), B16.18 (Flanges) | CuSn8P | C5101 | CZ121 |

| Silicon Bronze (Cu-Si) | C65500 | ASTM B505 (Forged Fittings), B16.18 (Flanges) | CuSi3 | C6551 | CZ114 |

| Naval Bronze (Cu-Sn-Zn) | C46400 | ASTM B148 (Forged Fittings & Flanges) | CuSn6Zn6Pb3 | C4641 | CZ101 |

ASTM B62 bronze fittings - Chemical Composition

| Bronze Alloy / Grade | Cu (%) | Sn (%) | Pb (%) | Zn (%) | Al (%) | P (%) | Ni (%) |

|---|---|---|---|---|---|---|---|

| C83600 – Tin Bronze | 83–88 | 8–10 | 2–4 | – | – | 0.03–0.35 | – |

| C51000 – Phosphor Bronze | 90–94 | 5–6 | – | – | – | 0.01–0.35 | – |

| C65500 – Silicon Bronze | 96–97 | 2–3 | – | – | – | 0.1–0.35 | – |

| C46400 – Naval Bronze | 60–65 | 3–5 | – | 1–3 | – | 0.03–0.35 | – |

Industrial bronze fittings and valves - Mechanical Properties

| Bronze Alloy / Grade | Tensile Strength (MPa / psi) | Yield Strength (MPa / psi) | Brinell Hardness (HB) | Elongation (%) |

|---|---|---|---|---|

| C83600 – Tin Bronze | 345–415 MPa (50–60 ksi) | 140–210 MPa (20–30 ksi) | 90–110 | 20–30 |

| C51000 – Phosphor Bronze | 480–620 MPa (70–90 ksi) | 275–415 MPa (40–60 ksi) | 110–140 | 10–20 |

| C65500 – Silicon Bronze | 345–415 MPa (50–60 ksi) | 140–210 MPa (20–30 ksi) | 80–110 | 15–25 |

| C46400 – Naval Bronze | 380–520 MPa (55–75 ksi) | 210–345 MPa (30–50 ksi) | 100–140 | 15–20 |

Precision-Engineered Bronze Buttweld Fittings

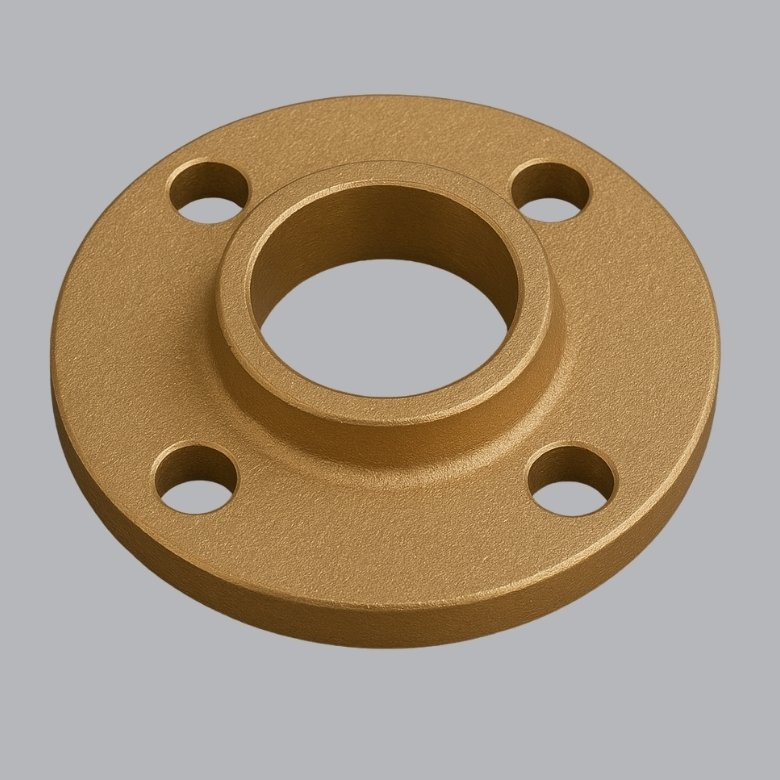

Bronze Flanges Built to ASTM B62 / ASME B16.5 Standards

Bronze Forged Fittings with Excellent Strength and Corrosion Resistance

What are the advantages of using Bronze Fittings over other materials?

Corrosion Resistance: Superior performance in marine, desalination, and chemical environments.

Durability: Long service life even under repeated thermal cycling and mechanical stress.

Machinability: Easy to machine and fabricate into custom fittings and flanges.

Leak-Proof Joints: Precision machining ensures tight tolerances for bolted flanges and socket weld joints.

Versatility: Suitable for hydraulic, marine, chemical, and industrial piping applications.

How are Bronze Pipe Fittings and Flanges tested for quality?

Hydrostatic Testing: Ensures the fitting or flange can withstand rated pressure without leakage.

Dimensional Inspection: Confirms compliance with ASME or ASTM standards.

Chemical Composition Verification: Ensures alloy meets ASTM B62 or custom specifications.

Non-Destructive Testing (NDT): For high-pressure applications, radiographic (RT) or ultrasonic testing (UT) may be conducted.

Surface Finish and Machining Tolerance Checks: Ensures proper fit, leak-free joints, and smooth internal flow.

How does thermal expansion affect Bronze flanged joints?

Bronze has a thermal expansion coefficient of ~17×10⁻⁶ /°C, higher than carbon steel.

In high-temperature systems, flanged connections must accommodate expansion using gaskets, flexible joints, or proper bolt torque.

Mismanagement of thermal expansion can lead to stress cracks, leakage, or flange warping, so engineers must account for this in design.