- Home

- Nickel Alloys

- Nimonic 75 / 80A

Nimonic 75 / 80A

Nimonic 75 / 80A : Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Premium quality Nimonic 75 / 80A Pipe Fittings & Flanges suitable for boilers, gas turbines, chemical reactors, and furnace systems. Manufactured in Seamless, Welded, and Forged construction with ANSI / DIN / BS / EN dimensional standards. Supplying to UK, Qatar, Egypt, Thailand, and Vietnam.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a dedicated manufacturer of high-performance industrial piping components, specializing in precision-engineered fittings and flanges for critical service environments. Our operations are driven by stringent metallurgical control, CNC-based machining accuracy, and adherence to international quality standards, ensuring dimensional stability and long service reliability in demanding applications.

We maintain an optimized manufacturing workflow supported by advanced inspection facilities, heat treatment systems, and controlled surface finishing lines. With a clear focus on traceability, certification, and material integrity, we deliver consistent product performance to OEMs, EPC contractors, and global industry sectors, including energy, petrochemical, marine, and high-temperature processing.

Nimonic 75 (UNS N06075, W. Nr. 2.4951/2.4630) is a nickel-chromium alloy containing approximately 80% nickel and 20% chromium, with controlled additions of titanium and carbon. It offers excellent oxidation and scaling resistance at elevated temperatures, retaining stable mechanical properties in oxidizing atmospheres up to around 1100°C. In pipe fittings and flanges, Nimonic 75 is used where moderate high-temperature strength, good weldability, and formability are required. Its nickel-chromium matrix forms a protective oxide layer that enhances resistance to creep, corrosion, and thermal degradation in furnace systems, heat-treatment equipment, and aerospace-derived high-temperature service environments.

Nimonic 80A (UNS N07080, W. Nr. 2.4952/2.4631) is a wrought, age-hardenable nickel-chromium alloy containing titanium and aluminium to develop high strength at elevated temperatures. It typically contains 18–21% chromium with controlled additions of titanium and aluminium to enable precipitation hardening. Nimonic 80A provides excellent creep-rupture strength, thermal fatigue resistance, and long-term stability at service temperatures up to approximately 815°C. In pipe fittings and flanges, it is preferred for applications involving high stress and prolonged exposure to elevated temperatures, such as gas turbine systems, superheated steam lines, and high-temperature chemical processing units. Heat treatment cycles involving solution annealing and aging enable consistent mechanical properties and reliable joint integrity during fabrication.

Nimonic 75 Pipe Fittings - Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48”

Forged: ½” – 4”

Flanges: ½” – 48”

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Material: Nimonic 75 / Nimonic 80A

Fabrication / Welding

Advantages

Dimensional Standards

Forms

Applications

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Nimonic 75 / 80A Products

UNS N06075 Pipe Fittings and flanges - Equivalent Grades

| Property / Standard | Nimonic 75 | Nimonic 80A |

|---|---|---|

| UNS | N06075 | N07080 |

| W. Nr. / DIN | 2.4951 / 2.4630 | 2.4952 / 2.4631 |

| ASTM | B637 (bars, plates, rods) | B637 (bars, plates, rods) |

| EN / ISO | ISO 513 | ISO 513 |

| BS (British Standard) | BS 3070 | BS 3070 |

| JIS (Japanese Standard) | SUS-N06075 | SUS-N07080 |

| Werkstoff No. | 2.4951 / 2.4630 | 2.4952 / 2.4631 |

| Other Designations | Alloy 75 | Alloy 80A |

Nimonic 75 Socket Weld Fittings - Chemical Composition

| Element | Nimonic 75 (UNS N06075) | Nimonic 80A (UNS N07080) |

|---|---|---|

| Nickel (Ni) | ~80% | Balance (~76–78%) |

| Chromium (Cr) | ~20% | 18–21% |

| Titanium (Ti) | 0.2–0.6% | 1.8–2.7% |

| Aluminium (Al) | – | 1.0–1.8% |

| Carbon (C) | 0.08–0.15% | ≤0.10% |

| Iron (Fe) | ≤1.0% | ≤1.0% |

| Cobalt (Co) | ≤0.5% | ≤0.5% |

| Manganese (Mn) | ≤0.5% | ≤0.5% |

| Silicon (Si) | ≤0.5% | ≤0.5% |

WNR 2.4951 Nimonic Alloy Fittings - Mechanical Properties

| Property | Nimonic 75 (UNS N06075) | Nimonic 80A (UNS N07080) |

|---|---|---|

| Ultimate Tensile Strength (MPa) | 650–700 | 850–900 |

| Yield Strength (0.2% Offset, MPa) | 300–350 | 500–550 |

| Elongation (%) | 20–25 | 15–20 |

| Reduction of Area (%) | 40–45 | 35–40 |

| Hardness (HRB) | 85–95 | 90–100 |

| Creep Rupture Strength | Moderate, up to 1100°C | High, up to 815°C |

| Service Temperature | Up to ~1100°C (oxidizing atmosphere) | Up to ~815°C (continuous service) |

| Fatigue Resistance | Good | Excellent under cyclic high-temperature conditions |

| Oxidation Resistance | Excellent | Superior, due to Ti-Al precipitation hardening |

| Fabrication / Weldability | Good, readily formed and welded | Good, requires solution annealing + aging after welding for full strength |

Nimonic 75 / 80A Buttweld Fittings – High-Quality Seamless & Welded

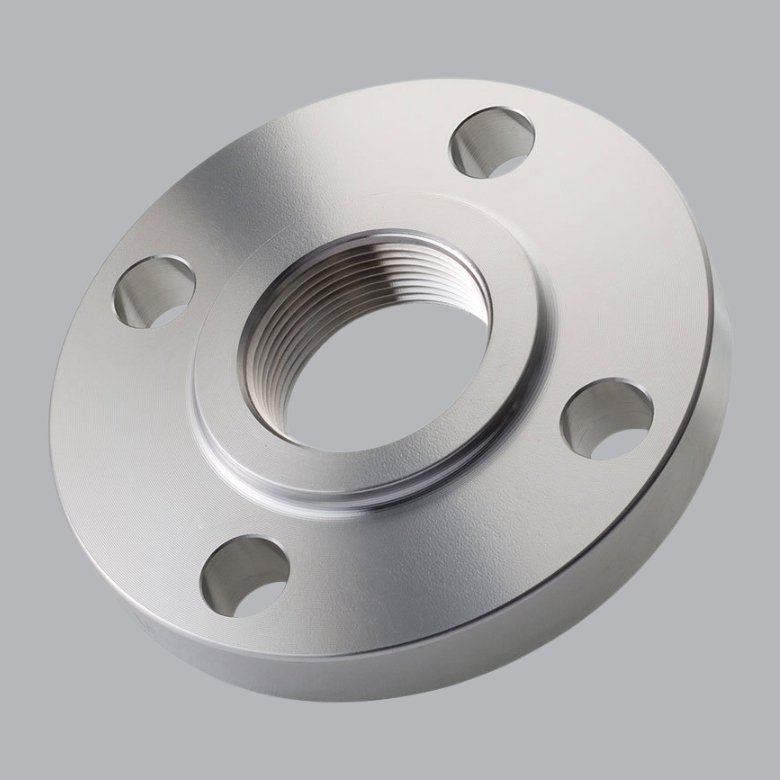

Nimonic 75 / 80A Flanges – industrial piping solutions

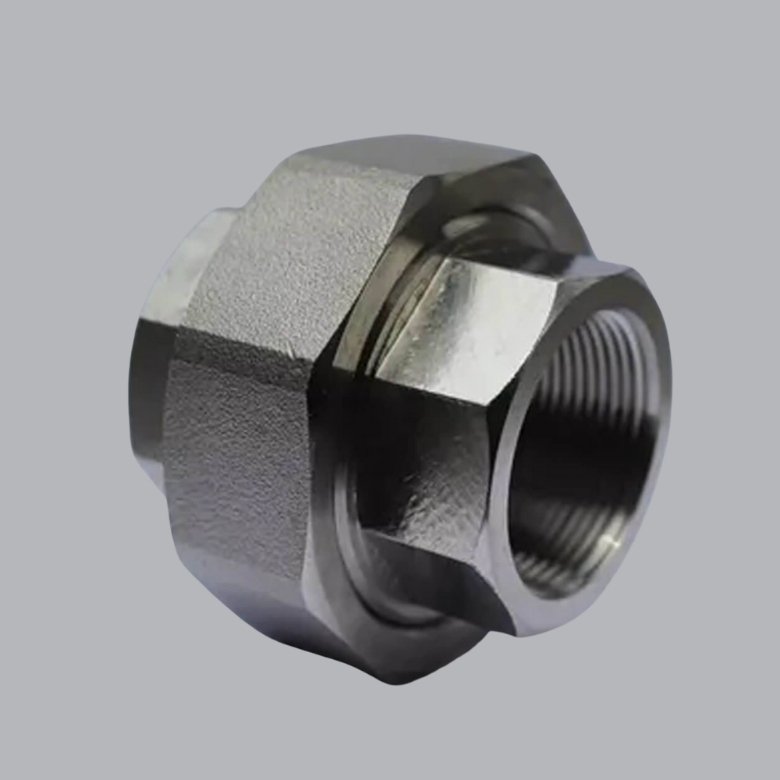

Nimonic 75 / 80A Forged Fittings

What is the main difference between Nimonic 75 and Nimonic 80A?

Composition Difference:

Nimonic 75: ~80% Nickel, 20% Chromium, with small amounts of Titanium (0.2–0.6%) and Carbon (0.08–0.15%).

Nimonic 80A: ~76–78% Nickel, 18–21% Chromium, with higher Titanium (1.8–2.7%) and Aluminium (1.0–1.8%), and low Carbon ≤0.10%.

Strength and Hardening:

Nimonic 75 is a moderately strong alloy, mostly solid-solution strengthened.

Nimonic 80A is age-hardenable, providing higher tensile and creep strength at elevated temperatures.

Service Temperature:

Nimonic 75 – usable up to ~1100°C in oxidizing atmospheres.

Nimonic 80A – suitable for ~815°C continuous service, optimized for mechanical stability under stress.

Mechanical Properties:

Nimonic 75 – moderate tensile and yield strength with good ductility (elongation ~20–25%).

Nimonic 80A – higher tensile strength (~850–900 MPa) and yield strength (~500–550 MPa) with slightly lower elongation (~15–20%) but superior creep resistance.

Applications:

Nimonic 75 – furnaces, general high-temperature piping, oxidizing atmospheres.

Nimonic 80A – high-stress applications like gas turbines, superheated steam lines, and chemical reactors.

Why choose Nimonic 75 / 80A for pipe fittings and flanges?

High-Temperature Resistance:

Both alloys retain mechanical integrity and resist scaling in high-temperature environments.

Nimonic 75 is suitable for oxidizing atmospheres up to 1100°C; 80A provides superior creep resistance in dynamic high-temperature service.

Creep and Fatigue Resistance:

Nimonic 75 resists creep moderately, ideal for thermal processing or furnace piping.

Nimonic 80A has enhanced creep rupture strength and excellent fatigue life under cyclic thermal stress.

Corrosion and Oxidation Resistance:

Chromium in both alloys forms a protective oxide layer.

Nimonic 80A’s Ti-Al additions further stabilize the protective film under prolonged high-temperature service.

Fabrication & Weldability:

Both alloys can be forged, formed, and welded using TIG, SMAW, or electron beam techniques.

Post-weld heat treatment ensures full mechanical properties, particularly for age-hardened Nimonic 80A.

Versatile Industrial Applications:

Nimonic 75 – furnace components, boiler piping, and heat treatment systems.

Nimonic 80A – aerospace turbines, chemical reactors, superheated steam lines, and high-stress industrial piping.

How to select between Nimonic 75 and 80A for a project?

Temperature Requirement: Use Nimonic 75 if operating temperature is near or above 1000°C in oxidizing conditions.

Stress & Creep Requirement: Choose Nimonic 80A for high-stress, cyclic, or creep-critical applications.

Fabrication Method: Both alloys are suitable for forged and seamless fittings; 80A may require precise aging heat treatment for optimal properties.

Cost & Availability: Nimonic 75 is generally more economical; 80A provides higher strength at premium cost.