- Home

- Nickel Alloys

- 254 SMO

254 SMO

254 SMO : Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Manufacturers and exporters of 254 SMO Stainless Steel Fittings & Flanges, offering Seamless, Welded, Forged, and Socket Weld types. Made under ASTM A182 / ASME SA182, shipped globally to India, China, Australia, and the United Kingdom.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a specialized manufacturer and global exporter of precision-engineered pipe fittings, flanges, and forged components. With deep expertise in high-performance alloys, 254 SMO stainless steels, the company delivers solutions designed for high-corrosion, high-temperature, and high-pressure industrial environments.

Each product undergoes stringent dimensional, chemical, and mechanical testing, ensuring compliance with ASTM, ASME, and international standards, while guaranteeing long-term reliability in critical chemical, petrochemical, and offshore applications.

Our commitment to precision, material quality, and engineering excellence enables us to serve a wide range of global clients, providing components that perform reliably in corrosive environments, seawater exposure, and extreme industrial conditions. With a focus on innovative solutions, timely delivery, and superior engineered performance, we earned a reputation as a dependable partner for high-performance piping and process systems worldwide.

254 SMO (UNS S31254 / WNR 1.4547) is a super-austenitic stainless steel alloy designed for exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in chloride-rich and aggressive chemical environments. It combines high chromium, molybdenum, and nitrogen content to provide superior mechanical strength and corrosion resistance compared to conventional austenitic stainless steels like 316L.

SMO 254 is widely used in pipe fittings, flanges, valves, and other critical components for chemical processing, offshore, marine, and desalination applications. Available in seamless, welded, and forged forms, it conforms to ASTM A182 / ASME SA182 standards, offering excellent weldability, dimensional stability, and long-term performance in high-temperature and highly corrosive conditions.

254 SMO super-austenitic stainless steel flanges Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

ASTM/ASME A182 / SA182

SMO 254

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

High-performance 254 SMO stainless steel fittings – Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Nickel Alloy | 254 SMO (UNS S31254 / WNR 1.4547) |

ASTM A403 / ASME SA403 (Buttweld Fittings), ASTM A182 / ASME SA182 (Forged Fittings & Flanges) |

Highly corrosion-resistant applications in chloride-rich and aggressive chemical environments, including chemical processing, desalination, marine, offshore, and pharmaceutical industries. Used for pipe fittings, flanges, valves, and other critical components requiring superior pitting, crevice, and stress corrosion cracking resistance. |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

SMO 254 Products

UNS S31254 fittings and flanges - Equivalent Grades

| Standard / Organization | Equivalent Grade |

|---|---|

| UNS | S31254 |

| WNR / EN / DIN | 1.4547 |

| ASTM / ASME | ASTM A182 / A403, ASME SA182 / SA403 |

| JIS | SUS32750 |

| Carpenter Technology | 254 SMO |

| GOST (Russian) | — |

SMO 254 welded fittings - Chemical Composition

| Element | Composition (wt%) |

|---|---|

| Chromium (Cr) | 20 – 22 |

| Nickel (Ni) | 18 – 20 |

| Molybdenum (Mo) | 6 – 6.5 |

| Nitrogen (N) | 0.2 – 0.3 |

| Iron (Fe) | Balance |

| Carbon (C) | ≤ 0.03 |

| Manganese (Mn) | ≤ 1 |

| Silicon (Si) | ≤ 1 |

| Phosphorus (P) | ≤ 0.03 |

| Sulfur (S) | ≤ 0.01 |

254 SMO corrosion-resistant pipe fittings - Mechanical Properties

| Property | Value / Range |

|---|---|

| Tensile Strength (MPa) | 690 – 850 |

| Yield Strength (MPa) | 275 – 450 |

| Elongation (%) | 35 – 45 |

| Hardness (HB) | 150 – 200 |

| Modulus of Elasticity (GPa) | ~200 |

| Density (g/cm³) | 7.8 – 8.0 |

| Melting Range (°C) | 1390 – 1425 |

| Thermal Conductivity (W/m·K) | 0.12 – 0.14 |

| Coefficient of Thermal Expansion (µm/m·°C) | 16 – 17 |

ASTM A403 SMO 254 Buttweld Fittings – High-Quality Seamless & Welded

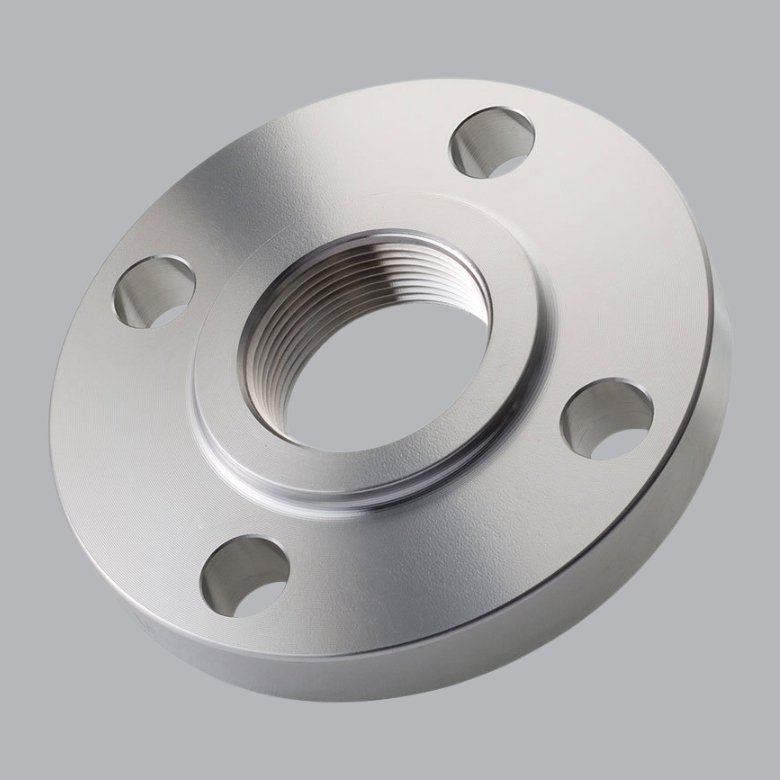

ASTM A182 254 SMO Flanges – industrial piping solutions

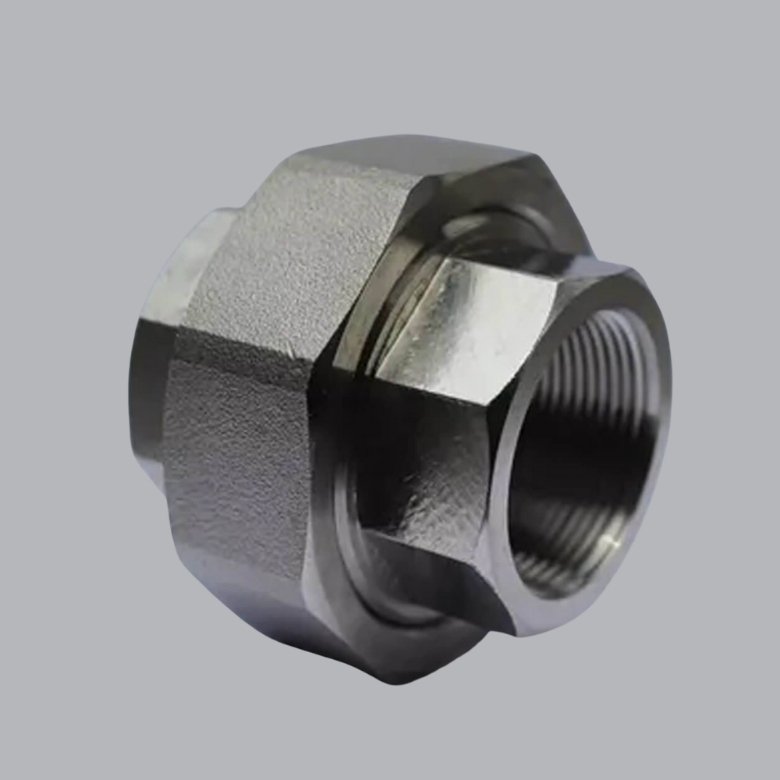

A182 SMO 254 Threaded and Socket Weld Fittings

What is 254 SMO stainless steel and what are its key characteristics?

254 SMO (UNS S31254 / WNR 1.4547) is a super-austenitic stainless steel alloy designed for exceptional corrosion resistance, particularly in chloride-rich and aggressive chemical environments.

It contains high levels of chromium (20–22%), molybdenum (6%), nickel (18–20%), and nitrogen (0.2–0.3%), which enhance its resistance to pitting, crevice corrosion, and stress corrosion cracking.

Compared to conventional austenitic stainless steels like 316L, 254 SMO provides higher mechanical strength and long-term durability in harsh industrial applications.

How does 254 SMO compare to 316L stainless steel?

Corrosion Resistance: 254 SMO resists pitting and crevice corrosion far better than 316L in chloride-rich environments.

Mechanical Strength: Higher tensile and yield strength at room and elevated temperatures.

Stress Corrosion Cracking (SCC) Resistance: Alloy design significantly reduces SCC in chloride-containing media.

Long-Term Durability: Ideal for high-performance chemical, marine, and offshore applications where 316L would degrade faster.

Can 254 SMO be welded and machined easily?

Welding: Excellent weldability using TIG, MIG, and resistance welding, with compatible filler metals for super-austenitic stainless steel.

Machining: Can be machined using standard austenitic stainless steel techniques, though it is work-hardening prone, requiring sharp tools and proper cooling.

Fabrication: Available in seamless, welded, and forged forms, enabling custom piping and process system solutions.