- Home

- Nickel Alloys

- Alloy 20

Alloy 20

Alloy 20 : Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

High-performance Alloy 20 (UNS N08020 / WNR 2.4660) Pipe Fittings & Flanges, available in Seamless, Welded, and Forge-Machined designs. Manufactured to ASTM B366 / ASME SB366 and ASTM B564 / ASME SB564 standards, and supplied globally to US, Europe, UAE, and Saudi Arabia.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a pioneering manufacturer and global supplier of precision-engineered pipe fittings, flanges, and forged components. Specializing in high nickel alloys and high-performance steel solutions, the company integrates advanced forging, machining, and quality assurance technologies to deliver products that meet ASTM, ASME, and international standards.

Trusted by industries worldwide, we offer customized solutions, robust performance, and dependable delivery, catering to sectors such as chemical, petrochemical, offshore, and pharmaceutical industries with unmatched reliability and technical expertise.

Alloy 20 is a nickel-iron-chromium austenitic alloy specifically engineered for high corrosion resistance in sulfuric acid and other aggressive chemical environments. It combines the strength of stainless steel with enhanced resistance to oxidizing and reducing agents. Alloy 20 also features controlled additions of copper and molybdenum, which improve resistance to pitting, crevice corrosion, and stress corrosion cracking, particularly in sulfuric acid applications.

It is available in seamless, welded, and forged forms and is widely used for pipe fittings, flanges, valves, and other critical components, conforming to ASTM B366 / B564, ASME SB366 / SB564, and international standards. Its excellent mechanical properties, weldability, and dimensional stability under high-temperature and corrosive conditions make Alloy 20 a reliable choice for long-term industrial performance.

Alloy 20 buttweld fittings Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

ASTM/ASME B564 / SB564

Alloy 20

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

UNS N08020 pipe fittings – Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Nickel Alloy | Alloy 20 (UNS N08020 / Carpenter 20) |

ASTM B366 / ASME SB366 (Buttweld Fittings), ASTM B564 / ASME SB564 (Forged Fittings & Flanges) |

Corrosion-resistant chemical processing applications, sulfuric acid service, pharmaceutical and pulp & paper industries, valves, reactors, pipelines, and high-performance industrial components exposed to oxidizing and reducing agents. |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Alloy 20 Products

Alloy 20 forged fittings - Equivalent Grades

| Standard / Organization | Alloy 20 Equivalent |

|---|---|

| UNS | N08020 |

| WNR / EN / DIN | 2.4660 |

| Carpenter Technology | Carpenter 20 |

| JIS | SUSN08020 |

| ASTM / ASME | ASTM B366 / B564, ASME SB366 / SB564 |

| GOST (Russian) | — |

ASTM B564 Alloy 20 flanges - Chemical Composition

| Element | Composition (wt%) |

|---|---|

| Nickel (Ni) | 32 – 38 |

| Chromium (Cr) | 19 – 21 |

| Iron (Fe) | Balance |

| Copper (Cu) | 2 – 3 |

| Molybdenum (Mo) | 2 – 3 |

| Carbon (C) | ≤ 0.06 |

| Manganese (Mn) | ≤ 2 |

| Silicon (Si) | ≤ 1 |

| Sulfur (S) | ≤ 0.03 |

| Phosphorus (P) | ≤ 0.04 |

Nickel-iron-chromium Alloy 20 fittings - Mechanical Properties

| Property | Value / Range | Notes |

|---|---|---|

| Tensile Strength (MPa) | 620 – 850 | Ultimate tensile strength in standard conditions |

| Yield Strength (MPa) | 275 – 450 | 0.2% offset yield strength |

| Elongation (%) | 35 – 45 | Measured over 50 mm gauge length |

| Hardness (HB) | 150 – 200 | Brinell Hardness; depends on heat treatment and product form |

| Modulus of Elasticity (GPa) | ~200 | Approximate for austenitic structure |

| Density (g/cm³) | 8.1 – 8.2 | Typical for Alloy 20 |

| Melting Range (°C) | 1375 – 1425 | Depends on composition and impurities |

| Thermal Conductivity (W/m·K) | 11 – 12 | At room temperature |

| Coefficient of Thermal Expansion (µm/m·°C) | 15.8 – 16.8 | 20 – 100°C |

Alloy 20 Buttweld Fittings – High-Quality Seamless & Welded

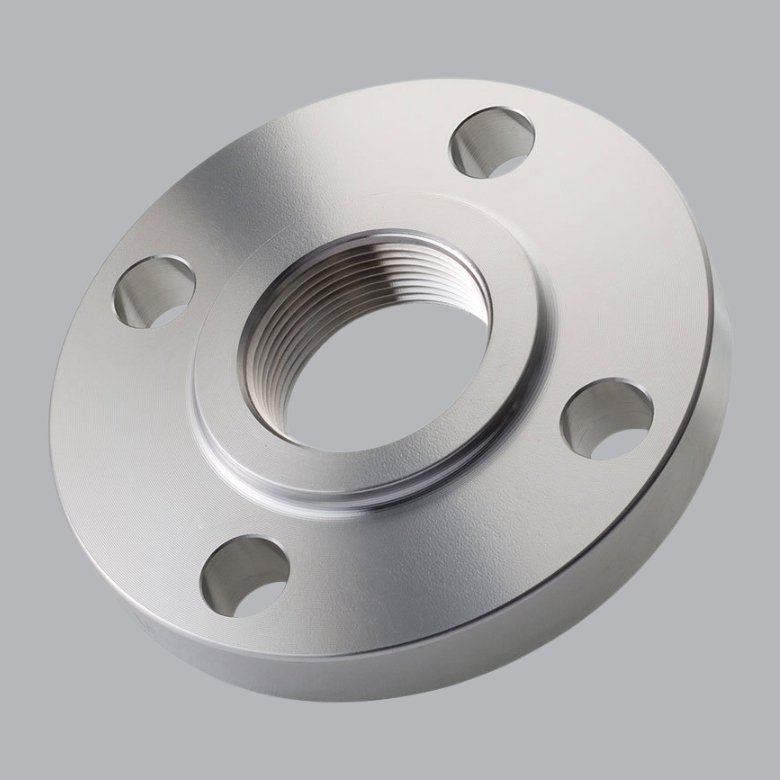

Alloy 20 Flanges – industrial piping solutions

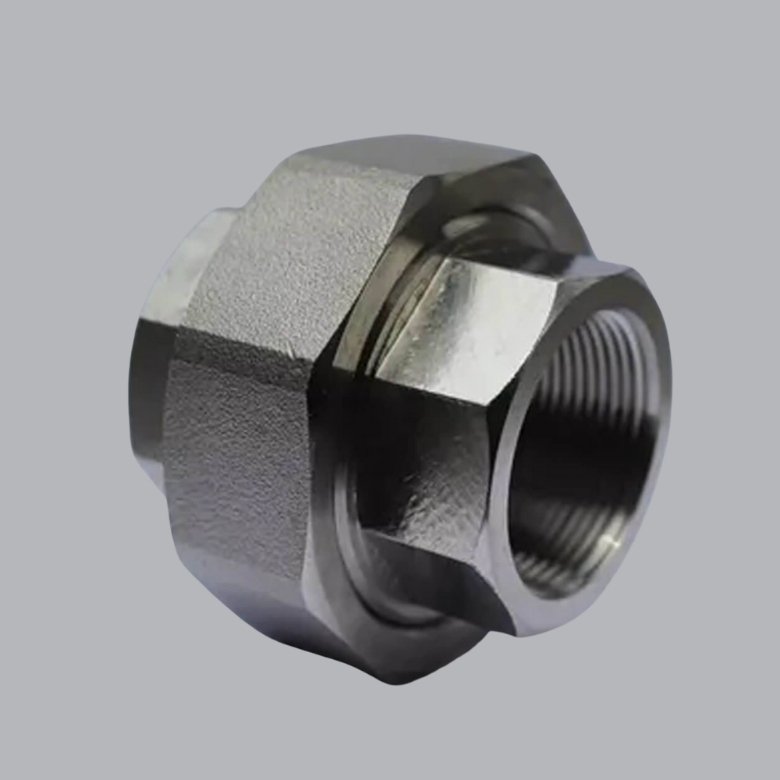

Alloy 20 Threaded and Socket Weld Fittings

What is Alloy 20 and what are its primary characteristics?

Alloy 20 (UNS N08020 / WNR 2.4660) is a nickel-iron-chromium austenitic alloy designed for excellent corrosion resistance, particularly in sulfuric acid and other aggressive chemical environments.

It has controlled additions of copper and molybdenum, which enhance resistance to pitting, crevice corrosion, and stress corrosion cracking.

The alloy combines the mechanical strength of stainless steel with superior resistance to oxidizing and reducing agents, making it ideal for industrial piping applications.

Alloy 20 is dimensionally stable, weldable, and retains mechanical properties under high temperatures, ensuring long-term performance in critical industrial applications.

What makes Alloy 20 superior to conventional stainless steels like 316 or 304?

Higher Sulfuric Acid Resistance: Alloy 20 can withstand concentrated sulfuric acid at higher temperatures, where 316 or 304 stainless steels fail.

Enhanced Crevice and Pitting Resistance: Copper and molybdenum additions minimize localized corrosion.

Stress Corrosion Cracking Resistance: Alloy 20 is specifically engineered to resist SCC, common in chloride-containing media.

Mechanical Strength Retention: Maintains tensile and yield strength under elevated temperatures.

Can Alloy 20 be welded, machined, and fabricated easily?

Welding: Excellent weldability using TIG, MIG, and resistance welding, with filler metals designed for Alloy 20.

Machining: Alloy 20 can be machined using standard austenitic stainless steel machining practices, though care must be taken due to work-hardening tendency.

Fabrication: Seamless, welded, and forged forms allow for custom fittings and flanges, enabling flexibility for complex piping systems.