- Home

- Nickel Alloys

- Monel 400 / K500

Monel 400 / K500

Monel 400 / K500: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Premium Monel 400 and K500 Buttweld & Forged Fittings and Flanges, Seamless, Welded, Threaded & Socket Weld, ASTM B366 / B564 certified, delivered globally including Europe, Middle East & North America.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer and supplier of high-quality industrial fittings and flanges, specializing in nickel alloys Monel and other premium materials. With years of expertise in precision forging and buttweld fabrication, Our commitment to quality ensures reliable performance across industrial piping applications.

Equipped with advanced manufacturing facilities and a skilled technical team, serving clients globally, we provide customized solutions to meet diverse industrial requirements, ensuring timely delivery and unmatched customer support across Europe, the Middle East, North America, and other international markets.

Monel 400 and K500 are high-performance nickel-copper alloys widely used for buttweld and forged fittings and flanges due to their exceptional corrosion resistance, high strength, and durability in harsh environments.

Monel 400 offers superior resistance to seawater, chemical processing fluids, and acidic conditions, making it ideal for marine, offshore, and chemical industries.

Monel K500, a precipitation-hardened variant, combines the excellent corrosion resistance of Monel 400 with higher tensile strength and hardness, making it suitable for high-pressure applications.

These fittings and flanges are available in seamless, welded, threaded, and socket weld configurations, manufactured in compliance with ASTM B366 / B564 standards. Monel 400 and K500 components are engineered to withstand extreme operating conditions, including high-temperature, high-pressure, and corrosive environments, ensuring long-term reliability and performance in critical piping systems.

UNS N04400 pipe fittings and flanges Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Monel 400 / K500

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Werkstoff 2.4360 / 2.4375 forged fittings – Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Nickel Alloy | Monel 400 (UNS N04400) | ASTM B366 / ASME SB366 (Buttweld Fittings) ASTM B564 / ASME SB564 (Forged Fittings & Flanges) |

Marine & seawater systems, heat exchangers, desalination plants, petroleum refining, chemical processing, pump & valve components exposed to brine |

| Nickel Alloy | Monel K500 (UNS N05500) | ASTM B366 / ASME SB366 (Buttweld Fittings) ASTM B564 / ASME SB564 (Forged Fittings & Flanges) |

High-pressure & high-strength applications, offshore oil & gas, subsea tools, pump shafts, turbine blades, sour gas service, and components requiring superior mechanical strength with corrosion resistance. |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Monel 400/k500 Products

ASTM B366 Monel 400 buttweld fittings - Equivalent Grades

| Material | UNS | Werkstoff Nr. (WNR) | EN Standard | JIS | BS | GOST / Russian | AFNOR |

|---|---|---|---|---|---|---|---|

| Monel 400 | N04400 | 2.4360 / 2.4361 | NiCu30Fe | NW 4400 | NA 13 | МНЖМц 28-2.5-1.5 | NU-30M |

| Monel K500 | N05500 | 2.4375 | NiCu30Al | NW 4401 | NA 18 | МНЖКТ 30-1-1 | NU-30K |

ASTM B564 Monel K500 Flanges - Chemical Composition

| Element | Monel 400 (UNS N04400) | Monel K500 (UNS N05500) |

|---|---|---|

| Nickel (Ni) | 63.0 min (Usually 63–70) | 63.0 min (Typically 63–70) |

| Copper (Cu) | 28.0 – 34.0 | 27.0 – 33.0 |

| Iron (Fe) | ≤ 2.5 | ≤ 2.0 |

| Manganese (Mn) | ≤ 2.0 | ≤ 1.5 |

| Silicon (Si) | ≤ 0.50 | ≤ 0.50 |

| Carbon (C) | ≤ 0.30 | ≤ 0.25 |

| Sulfur (S) | ≤ 0.024 | ≤ 0.010 |

| Titanium (Ti) | — | 0.35 – 0.85 |

| Aluminum (Al) | — | 2.30 – 3.15 |

Monel 400 elbows, tees, reducers, caps - Mechanical Properties

| Property | Monel 400 (UNS N04400) | Monel K500 (UNS N05500) |

|---|---|---|

| Tensile Strength (MPa / ksi) | 480 – 620 MPa (70 – 90 ksi) | 965 – 1100 MPa (140 – 160 ksi) |

| Yield Strength 0.2% Proof (MPa / ksi) | 170 – 345 MPa (25 – 50 ksi) | 690 – 795 MPa (100 – 115 ksi) |

| Elongation (% in 50 mm) | 30 – 45% | 15 – 25% |

| Hardness (Brinell HB) | 100 – 150 HB | 220 – 300 HB (Age Hardened) |

| Density | 8.80 g/cm³ | 8.44 g/cm³ |

| Melting Range | 1300 – 1350°C | 1315 – 1350°C |

| Modulus of Elasticity (Elastic Modulus) | 179 GPa | 179 GPa |

| Impact Strength | Excellent (No Ductile-Brittle Transition) | High, slightly reduced at cold temperatures |

| Service Temperature Range | Cryogenic to ~480°C | Cryogenic to ~480°C (Strength retention better than 400) |

Monel 400/k500 Buttweld Fittings – High-Quality Seamless & Welded

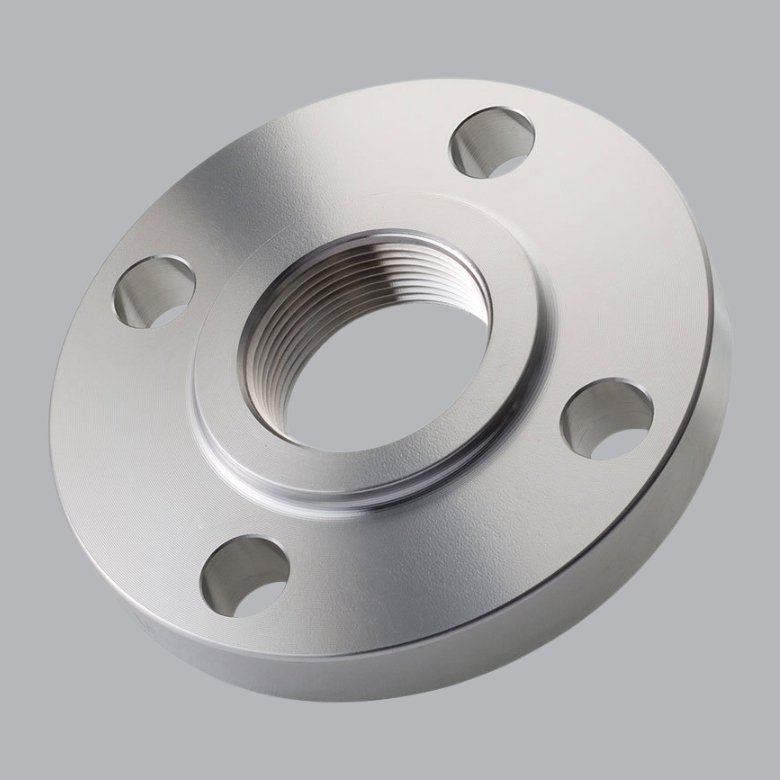

Monel 400/k500 Flanges – industrial piping solutions

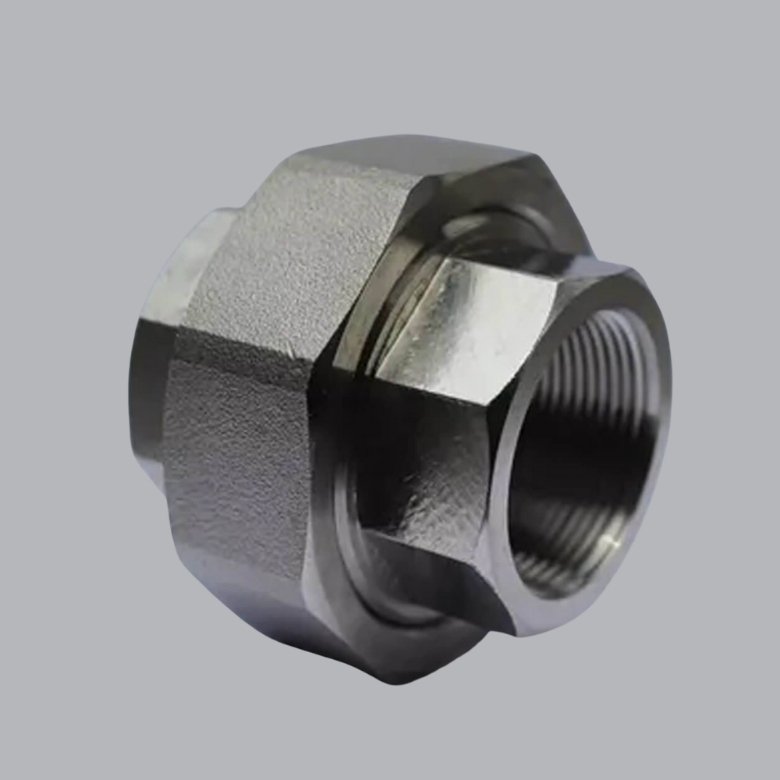

Monel 400/k500 Threaded and Socket Weld Fittings

What are the key differences between Monel 400 and Monel K500 in fittings and flanges?

Chemical Composition:

Both are nickel-copper alloys (~63% Ni, ~28–34% Cu).

K500 contains Titanium (Ti) and Aluminum (Al) for precipitation hardening.

Mechanical Strength:

Monel 400: Solid-solution strengthened, moderate strength.

Monel K500: Higher tensile and yield strength due to age-hardening treatment.

Hardness:

K500 exhibits significantly higher hardness, making it suitable for high-wear environments.

Corrosion Resistance:

Both offer excellent resistance to seawater, neutral/alkaline salts, and non-oxidizing acids.

K500 may show stress-corrosion cracking in certain conditions if not annealed properly.

Applications:

Monel 400: General marine and chemical service.

Monel K500: High-pressure, high-tension offshore and valve components.

What manufacturing forms are available for Monel 400/K500 fittings and flanges?

Buttweld Fittings: Seamless, Welded (Elbows, Tees, Reducers, Caps).

Forged Fittings: Threaded (NPT), Socket Weld (SW), Class 3000/6000/9000.

Flanges: WN (Weld Neck), SO (Slip-On), BL (Blind), SW (Socket Weld), RTJ, Orifice, Lap-Joint.

Heat Treatments:

Monel 400: Annealed for improved ductility.

K500: Solution annealed + age hardened for high strength.

Are Monel 400 and K500 suitable for welding in pipeline fabrication?

Weldability:

Monel 400: Excellent weldability using ERNiCu-7 filler.

K500: Weldable but requires post-weld age hardening to restore strength.

Precautions:

Control heat input to avoid grain growth.

Use inert shielding gas for TIG to prevent oxidation.

Post-Weld Treatment:

Stress-relieving recommended in critical pressure service.