- Home

- Nickel Alloys

- Inconel X750

Inconel X750

Inconel X750: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Trusted Manufacturer, Stockist & Global Exporter of ASTM B366 Inconel X750 Buttweld Fittings and ASTM B564 Alloy X750 Forged Fittings & Flanges, available in Seamless, Welded, Threaded, and Socket Weld configurations for extreme high-temperature, high-stress, and corrosion-resistant service conditions.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a technologically driven manufacturer specializing in high-performance piping components for critical industrial applications. With a fully integrated production setup and advanced CNC machining facilities, the company delivers precision-engineered buttweld fittings, forged fittings, flanges, and specially fabricated components in Inconel grades.

Consistent quality control, adherence to global standards, and a strong focus on dimensional accuracy allow Midland Forge and Fittings to meet the demanding requirements of refineries, petrochemical plants, power generation, marine, oil & gas, and process industries worldwide.

Inconel X750 pipe fittings and flanges are manufactured from a precipitation-hardenable nickel-chromium alloy containing titanium and aluminum for enhanced creep resistance and mechanical stability at elevated temperatures. The alloy exhibits excellent oxidation and corrosion resistance in high-temperature and high-pressure environments ranging from cryogenic conditions up to 1300°F (704°C). Inconel X750 offers high tensile strength, fatigue resistance, and stress-rupture performance, making it suitable for cyclic loading and thermal shock conditions encountered in aerospace turbine systems, high-temperature furnace equipment, nuclear reactors, and petrochemical processing lines.

Inconel X750 buttweld fittings, forged fittings, and flanges are produced under ASTM B366 / ASME SB366 and ASTM B564 / ASME SB564 standards, ensuring uniform metallurgical properties and dimensional accuracy. These components are available in Seamless, Welded, Socket Weld, and Threaded configurations with schedule ranges from SCH 5S to XXS, meeting ASME B16.5, B16.9, B16.11, MSS-SP and DIN/EN dimensional requirements. The alloy’s precipitation hardening capability provides sustained strength during prolonged exposure to high service temperatures, making Inconel X750 a preferred material for steam turbine piping, chemical reactor loops, heat treatment fixtures, and high-pressure valve components.

Driven by innovation, reliability, and customer-centric service, we maintain an extensive inventory, ensure timely deliveries, and support customized engineering solutions for both standard and non-standard specifications. Every product is manufactured under stringent inspection and certified to comply with ASTM, ASME, API, DIN, BS, and EN norms. With a reputation built on trust, transparent business ethics, and consistent performance, the company continues strengthening its global presence as a dependable partner for high-quality piping solutions.

ASTM B366 Inconel X750 Buttweld Fittings Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Inconel X750

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

ASTM B564 Inconel X750 Flanges – Grades & Standards

| Product Type | Material Grade | ASTM / ASME Standard | Manufacturing Type | Dimensional Standards |

|---|---|---|---|---|

| Buttweld Pipe Fittings | Inconel X-750 | ASTM B366 / ASME SB366 | Seamless / Welded | ASME B16.9, MSS-SP-43, DIN / EN |

| Forged Pipe Fittings | Inconel X-750 | ASTM B564 / ASME SB564 (Also Covers Forged Products) ASTM B637 (Bars / Forging Stock) |

Socket Weld / Threaded | ASME B16.11, MSS-SP-83, MSS-SP-95 |

| Flanges | Inconel X-750 | ASTM B564 / ASME SB564 | Forged / CNC Machined | ASME B16.5, ASME B16.47, DIN / EN 1092-1, MSS-SP-44 |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Inconel X750 Products

UNS N07750 Pipe Fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Standard / System | Grade / Designation |

|---|---|

| UNS | N07750 |

| Werkstoff Nr. | 2.4669 |

| EN | NiCr15Fe7TiAl / NiCr15FeTiAl |

| BS (British) | NA 57 |

| AFNOR (French) | NC15FeTA |

| GOST (Russia) | ЭИ437Б (EI437B) |

| JIS (Japan) | NCF750 |

| ISO | NiCr15Fe7TiAl |

| Trade Name | Inconel® X-750 |

Inconel X750 Seamless Elbow / Reducer / Tee - Chemical Composition

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Nickel (Ni) | 70.0 | — |

| Chromium (Cr) | 14.0 | 17.0 |

| Iron (Fe) | 5.0 | 9.0 |

| Titanium (Ti) | 2.25 | 2.75 |

| Aluminum (Al) | 0.40 | 1.00 |

| Niobium + Tantalum (Nb + Ta) | 0.70 | 1.20 |

| Manganese (Mn) | — | 1.00 |

| Silicon (Si) | — | 0.50 |

| Carbon (C) | — | 0.08 |

| Sulfur (S) | — | 0.01 |

| Cobalt (Co) | — | 1.00 |

| Copper (Cu) | — | 0.50 |

Inconel X750 Socket Weld Fittings - Mechanical Properties

| Condition / Heat Treatment | Yield Strength (0.2% offset) | Tensile Strength (Ultimate) | Elongation (%) |

|---|---|---|---|

| Cold‐worked 0% | ~ 393 MPa (≈ 57 ksi) | ~ 855 MPa (≈ 124 ksi) | ~ 38% |

| Cold‐worked 20% | ~ 665 MPa (≈ 95 ksi) | ~ 1007 MPa (≈ 146 ksi) | ~ 19% |

| Cold‐worked 50% | ~ 1193 MPa (≈ 173 ksi) | ~ 1303 MPa (≈ 189 ksi) | ~ 2.3% |

| Elevated‐temp performance | e.g., At ~ 540 °C (~1000 °F) → Yield ~ 725 MPa, Tensile ~ 1050 MPa |

— | ~ 26% |

| Suggested service limit | — | — | — |

Inconel X750 Buttweld Fittings – High-Quality Seamless & Welded

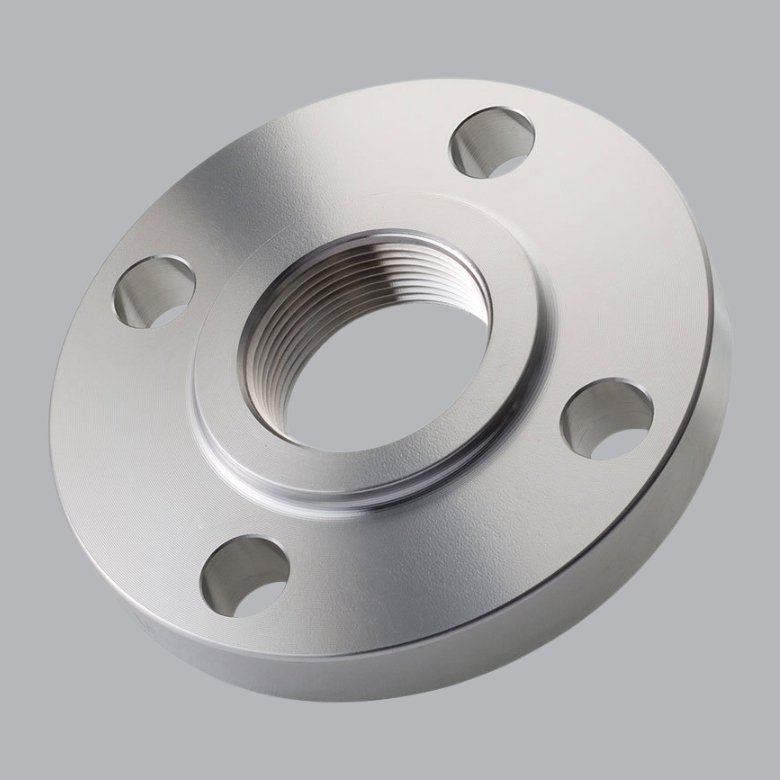

Alloy X750 Flanges – industrial piping solutions

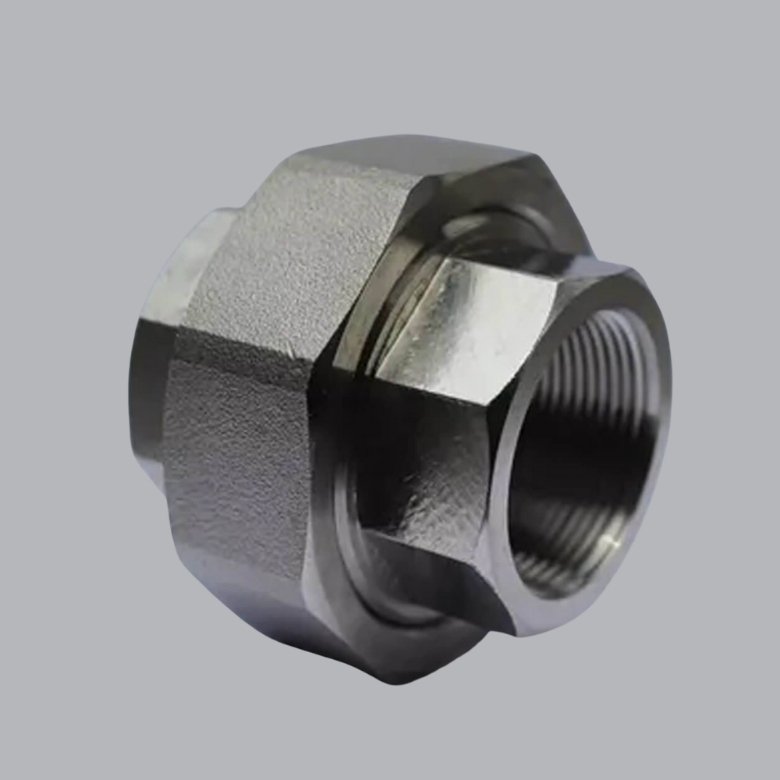

Inconel X750 Threaded and Socket Weld Fittings – chemical and marine grade fittings

How do we ensure the quality of Inconel X750 fittings and flanges?

Material Certification: Verify ASTM/ASME compliance and UNS N07750 designation.

Inspection Tests: Hardness test (HB/HRB), dimensional inspection, impact (Charpy V-notch), and intergranular corrosion (ASTM A262).

PMI & Spectro Analysis: Confirm chemical composition matches UNS N07750.

Hydrostatic & Pressure Tests: Validate mechanical integrity for high-pressure service.

Proper handling and storage prevent surface oxidation and contamination, preserving material performance before installation.

What heat treatment process is used for Inconel X750 fittings and flanges?

The typical process includes solution annealing followed by stabilization and age hardening (precipitation hardening).

Solution Annealing: Heat to 980–1150 °C to dissolve precipitates and achieve a homogeneous microstructure.

Stabilization: Heat at 730–760 °C to reduce the risk of carbide precipitation along grain boundaries.

Age Hardening: Final heat treatment at 700–760 °C for several hours forms gamma-prime precipitates, giving the alloy high creep strength and tensile properties.

Heat treatment parameters are critical; improper cycles can lead to reduced high-temperature strength or stress corrosion susceptibility.

What are the mechanical limitations of Inconel X750?

While X750 has excellent high-temperature strength, ductility decreases significantly after high cold work or age hardening, particularly in forged fittings.

It is susceptible to overaging if exposed to sustained temperatures above 760 °C for long durations, which can reduce creep strength.

Not recommended for highly reducing environments without proper surface protection, as certain halide salts may cause localized attack.

Fatigue life is excellent under cyclic thermal loads, but thermal shock should be minimized in brittle, fully hardened conditions.