- Home

- Nickel Alloys

Nickel Alloys

Nickel Alloys: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

Top Manufacturer and Global Supplier of Nickel Alloy Fittings and Flanges, offering precision-engineered Buttweld, Forged, Threaded, and Socket Weld components such as Elbows, Tees, Reducers, Stub Ends, End Caps, and Industrial Flanges designed for chemical, marine, and process industry pipelines.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a dedicated engineering and manufacturing company specializing in high-integrity piping components for critical industries. With a strong foundation in metallurgical expertise and precision forging, the company operates a well-equipped production facility adhering to international standards and strict quality control practices.

Our commitment to accuracy in dimensions, material integrity, and performance reliability allows us to support demanding operating environments across oil & gas, petrochemical, power generation, marine, and process industries.

Nickel Alloy pipe fittings and flanges are utilized in process piping systems that operate under highly corrosive and high-temperature conditions where conventional stainless steels cannot maintain stability. These alloys provide outstanding resistance to chloride stress corrosion cracking, pitting, crevice corrosion, and aggressive chemical environments, making them suitable for critical and continuous service applications.

Manufactured in accordance with ASTM B366 (buttweld fittings) and ASTM B564 (forged flanges and forged fittings), Nickel Alloys retain mechanical strength, dimensional stability, and metallurgical reliability at elevated and cryogenic temperatures. Their face-centered cubic (FCC) crystal structure allows for superior toughness, ductility, and fatigue resistance during thermal cycling or fluctuating load conditions.

Controlled alloying additions of chromium, molybdenum, iron, and copper further enhance corrosion resistance in acidic, marine, seawater, and brine-based media. Due to these properties, Nickel Alloy fittings and flanges are widely used in chemical processing equipment, desalination systems, offshore platforms, furnace assemblies, heat exchangers, and high-purity fluid handling lines, where long-term structural integrity and process reliability are critical.

Driven by technical excellence and operational efficiency, we deliver consistent quality, timely order execution, and customized engineering solutions. The company maintains a customer-centric approach backed by skilled professionals, material traceability systems, and continuous capability enhancement. Our objective is to build long-term partnerships by ensuring dependable product performance, responsible manufacturing practices, and strong service support at every stage of the supply chain.

Nickel Alloy Pipe Fittings Specifications

Size Range – (Buttweld, Forged, Flange)

Welded: 8” – 48” (200NB – 1200NB)

Socket Weld & Threaded: ½” – 4”

Flanges: ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades - Material

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Nickel Alloy Forged Fittings– Grades & Standards

| Nickel Alloy | Product Type | ASTM / ASME Standard | Notes / Applications |

|---|---|---|---|

| Nickel 200 / 201 | Buttweld Fittings | ASTM B366 / ASME SB366 | Seamless fittings: elbows, tees, reducers, caps; corrosion resistant in chemical, marine, and food processing industries. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged elbows, tees, reducers, couplings, caps; high corrosion resistance. | |

| Flanges | ASTM B462 / ASME SB462 | Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint flanges; marine and chemical applications. | |

| Monel 400 | Buttweld Fittings | ASTM B366 / ASME SB366 | Seamless and welded pipe fittings for seawater, chemical, and hydrocarbon service. |

| Forged Fittings | ASTM B564 / ASME SB564 | High corrosion resistance; marine and chemical industries. | |

| Flanges | ASTM B462 / ASME SB462 | Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint flanges; seawater and chemical applications. | |

| Monel K500 | Buttweld Fittings | ASTM B366 / ASME SB366 | High-strength buttweld fittings for marine, aerospace, and high-pressure systems. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged fittings with high mechanical strength. | |

| Flanges | ASTM B462 / ASME SB462 | High-pressure and corrosion-resistant flanges. | |

| Inconel 600 | Buttweld Fittings | ASTM B366 / ASME SB366 | Seamless and welded fittings for heat and corrosion resistance; chemical and nuclear industries. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged elbows, tees, reducers for high-temperature and chemical service. | |

| Flanges | ASTM B564 / ASME SB564 | Weld Neck, Slip-On, Blind, Socket Weld, Threaded flanges; chemical, aerospace, nuclear applications. | |

| Inconel 625 | Buttweld Fittings | ASTM B366 / ASME SB366 | Corrosion and heat resistant seamless fittings. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged fittings for chemical, petrochemical, and marine applications. | |

| Flanges | ASTM B564 / ASME SB564 | Corrosion and heat resistant flanges. | |

| Inconel 718 | Buttweld Fittings | ASTM B366 / ASME SB366 | High-strength seamless fittings for elevated temperatures; gas turbines and aerospace. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged high-strength fittings. | |

| Flanges | ASTM B564 / ASME SB564 | High-strength flanges for aerospace and power generation. | |

| Inconel X750 | Buttweld Fittings | ASTM B366 / ASME SB366 | Heat and corrosion resistant seamless fittings. |

| Forged Fittings | ASTM B564 / ASME SB564 | Heat-treated forged fittings. | |

| Flanges | ASTM B564 / ASME SB564 | High-temperature flanges for aerospace and nuclear service. | |

| Inconel 783 | Buttweld Fittings | ASTM B366 / ASME SB366 | Seamless high-strength fittings for chemical & aerospace. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged fittings for heat and chemical resistance. | |

| Flanges | ASTM B564 / ASME SB564 | Flanges for high-temperature chemical applications. | |

| Inconel 690 | Buttweld Fittings | ASTM B366 / ASME SB366 | Corrosion resistant fittings for nuclear & chemical service. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged high-temperature corrosion resistant fittings. | |

| Flanges | ASTM B564 / ASME SB564 | Weld Neck, Slip-On, Blind, Socket Weld flanges. | |

| Incoloy 800 / 800H / 800HT | Buttweld Fittings | ASTM B366 / ASME SB366 | High-temperature chemical resistant fittings. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged elbows, tees, reducers for furnace & heat exchanger service. | |

| Flanges | ASTM B564 / ASME SB564 | Weld Neck, Slip-On, Blind flanges for chemical & high-temp applications. | |

| Incoloy 825 | Buttweld Fittings | ASTM B366 / ASME SB366 | Corrosion resistant seamless fittings in acidic/reducing environments. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged fittings for marine and chemical industries. | |

| Flanges | ASTM B564 / ASME SB564 | Corrosion resistant flanges. | |

| Incoloy 925 | Buttweld Fittings | ASTM B366 / ASME SB366 | Stress corrosion resistant seamless fittings. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged high-strength corrosion resistant fittings. | |

| Flanges | ASTM B564 / ASME SB564 | High-strength flanges for chemical and marine service. | |

| Hastelloy C276 | Buttweld Fittings | ASTM B366 / ASME SB366 | Seamless chemical resistant fittings for oxidizing/reducing environments. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged chemical resistant fittings. | |

| Flanges | ASTM B564 / ASME SB564 | Chemical resistant flanges for harsh conditions. | |

| Hastelloy C22 | Buttweld Fittings | ASTM B366 / ASME SB366 | Corrosion resistant seamless fittings. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged fittings for aggressive chemical service. | |

| Flanges | ASTM B564 / ASME SB564 | Corrosion resistant flanges. | |

| Hastelloy C4 | Buttweld Fittings | ASTM B366 / ASME SB366 | Seamless fittings for oxidizing/reducing agents. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged fittings for chemical processing. | |

| Flanges | ASTM B564 / ASME SB564 | Flanges resistant to chemical corrosion. | |

| Hastelloy C2000 | Buttweld Fittings | ASTM B366 / ASME SB366 | High-strength seamless fittings for chemical processing. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged fittings for chemical and high-temp service. | |

| Flanges | ASTM B564 / ASME SB564 | High-strength flanges for chemical and industrial applications. | |

| Hastelloy B2 | Buttweld Fittings | ASTM B366 / ASME SB366 | Fittings resistant to hydrochloric acid & reducing media. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged chemical resistant fittings. | |

| Flanges | ASTM B564 / ASME SB564 | Acid resistant flanges. | |

| Hastelloy B3 | Buttweld Fittings | ASTM B366 / ASME SB366 | Improved acid-resistant seamless fittings. |

| Forged Fittings | ASTM B564 / ASME SB564 | Forged improved B2 alloy fittings. | |

| Flanges | ASTM B564 / ASME SB564 | Acid resistant flanges. | |

| Hastelloy X | Buttweld Fittings | ASTM B366 / ASME SB366 | Heat & oxidation resistant seamless fittings. |

| Forged Fittings | ASTM B564 / ASME SB564 | High-temp forged fittings. | |

| Flanges | ASTM B564 / ASME SB564 | High-temperature flanges for aerospace, gas turbines. |

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Nickel Alloys Products

Nickel alloy buttweld elbow, tee fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Alloy | UNS | EN / DIN | JIS | GOST | Notes |

|---|---|---|---|---|---|

| Nickel 200 | N02200 | 2.4066 | Ni200 | Н02200 | Pure Nickel, Excellent Corrosion Resistance |

| Nickel 201 | N02201 | 2.4066 | Ni201 | Н02201 | Low Carbon Nickel, Improved Weldability |

| Monel 400 | N04400 | 2.4360 | NiCu30 | Н04400 | Copper-Nickel Alloy, High Strength & Corrosion Resistance |

| Monel K500 | N05500 | – | – | – | Precipitation-Hardened Monel, High Strength |

| Inconel 600 | N06600 | 2.4816 | NiCr15Fe | 06H15N9M2 | Excellent Oxidation and Corrosion Resistance |

| Inconel 625 | N06625 | – | NiCr22Mo9Nb | – | High Strength, High Temperature Resistance |

| Inconel 718 | N07718 | – | NiCr19NbMo | – | Age-Hardenable, Cryogenic Toughness |

| Hastelloy C276 | N10276 | 2.4819 | NiMo16Cr15W | – | Excellent Resistance to Oxidizing and Reducing Environments |

| Hastelloy C22 | N06022 | 2.4602 | NiCr21Mo14W | – | High Resistance to Corrosion in Acids |

| Alloy 20 | N08020 | – | NiCr19FeNb | – | Corrosion-Resistant Nickel-Iron-Chromium Alloy |

Weld neck nickel alloy flanges - Chemical Composition

| Alloy | Ni (%) | Cr (%) | Fe (%) | Cu (%) | Mo (%) | C (%) | Mn (%) | Si (%) | Nb+Ta (%) | Ti (%) | W (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nickel 200 | 99 min | – | 0.35 max | 0.30 max | – | 0.15 max | 0.35 max | – | – | – | – |

| Nickel 201 | 99 min | – | 0.35 max | 0.30 max | – | 0.03 max | 0.35 max | – | – | – | – |

| Monel 400 | 63 min | – | 2.5 max | 28–34 | – | 0.30 max | 2 max | – | – | – | – |

| Monel K500 | 63 min | – | 2.5 max | 28–34 | – | 0.20 max | 2 max | – | – | 0.45–0.85 | – |

| Inconel 600 | 72 min | 14–17 | 6–10 | 0.5 max | – | 0.15 max | 0.5 max | 0.5 max | – | – | – |

| Inconel 625 | 58 min | 20–23 | 5 max | 0.50 max | 8–10 | 0.10 max | 0.50 max | 0.50 max | 3.15–4.15 | – | – |

| Incoloy 800 | 30–35 | 19–23 | 39.5 min | 0.75 max | – | 0.10 max | 1 max | 1 max | – | – | – |

| Incoloy 800H | 30–35 | 19–23 | 39.5 min | 0.75 max | – | 0.05–0.10 | 1 max | 1 max | – | – | – |

| Incoloy 800HT | 30–35 | 19–23 | 39.5 min | 0.75 max | – | 0.05–0.10 | 1 max | 1 max | – | – | – |

| Incoloy 825 | 38–46 | 19.5–23.5 | 28–34 | 1.5–3.0 | 2.5–3.5 | 0.05 max | 1 max | 1 max | – | 0.6 max | – |

| Hastelloy C276 | 57 min | 15.5–16.5 | 4 max | 0.5 max | 15–17 | 0.01 max | 1 max | 0.08–0.50 | – | – | 3–4.5 |

| Hastelloy C22 | 56 min | 20–22 | 3 max | 1 max | 13–15 | 0.02 max | 1 max | 0.5 max | – | – | 2–4 |

| Hastelloy C4 | 65 min | 16–18 | 4 max | 0.5 max | 15–17 | 0.03 max | 1 max | 0.5 max | – | – | 4 |

| Hastelloy C2000 | 59 min | 22–25 | 2–5 | 1 max | 15–17 | 0.03 max | 1 max | 0.5 max | – | – | 4 |

| Hastelloy B2 | 63 min | – | 4 max | 0.5 max | 27–31 | 0.02 max | 1 max | 0.5 max | – | – | – |

| Hastelloy B3 | 63 min | – | 4 max | 0.5 max | 29–33 | 0.02 max | 1 max | 0.5 max | – | – | – |

| Hastelloy X | 47–50 | 20–23 | 18–20 | 0.5 max | 9–10 | 0.15 max | 1 max | 0.5 max | – | – | 0.5–1.5 |

Seamless nickel alloy fittings - Mechanical Properties

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|

| Nickel 200 | 550–750 | 200–300 | 40–50 | 90–150 |

| Nickel 201 | 550–750 | 200–300 | 40–50 | 90–150 |

| Monel 400 | 580–690 | 250–350 | 30–45 | 120–200 |

| Monel K500 | 690–900 | 450–600 | 20–35 | 180–250 |

| Inconel 600 | 550–760 | 220–380 | 30–40 | 160–200 |

| Inconel 625 | 690–930 | 275–550 | 30–40 | 180–220 |

| Incoloy 800 | 480–620 | 205–275 | 30–40 | 130–180 |

| Incoloy 800H | 550–700 | 275–415 | 30–40 | 140–190 |

| Incoloy 800HT | 550–700 | 275–415 | 30–40 | 140–190 |

| Incoloy 825 | 550–690 | 205–310 | 30–40 | 150–190 |

| Hastelloy C276 | 550–690 | 240–360 | 35–45 | 180–220 |

| Hastelloy C22 | 550–690 | 240–360 | 35–45 | 180–220 |

| Hastelloy C4 | 550–690 | 240–360 | 35–45 | 180–220 |

| Hastelloy C2000 | 600–750 | 260–400 | 30–40 | 180–220 |

| Hastelloy B2 | 480–620 | 205–275 | 30–40 | 140–180 |

| Hastelloy B3 | 500–650 | 220–300 | 30–40 | 140–180 |

| Hastelloy X | 700–900 | 275–450 | 25–35 | 200–240 |

Nickel Alloy Buttweld Fittings – High-Quality Seamless & Welded

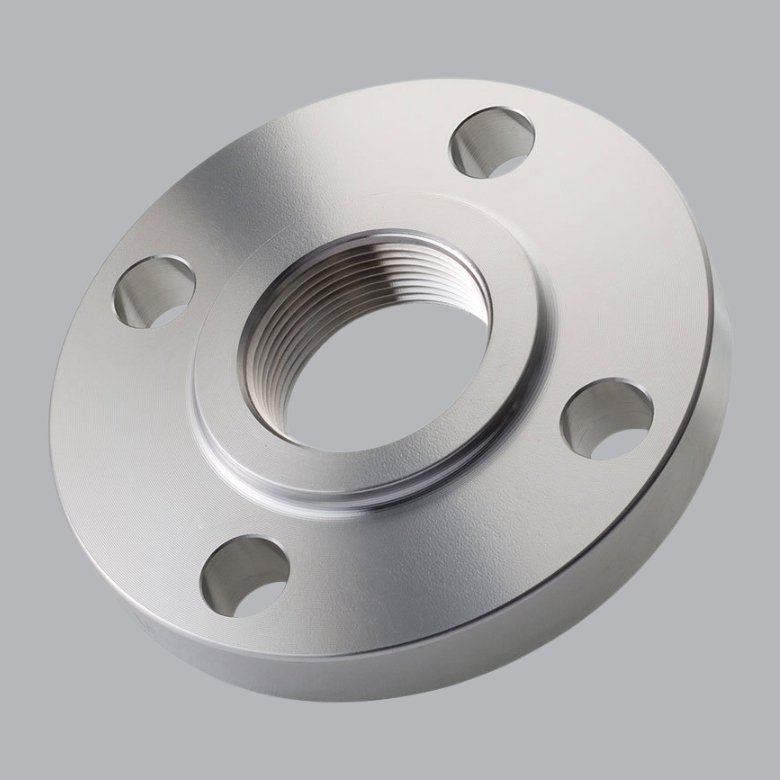

Industrial-Grade Nickel Alloy Flanges – Superior Piping Solutions

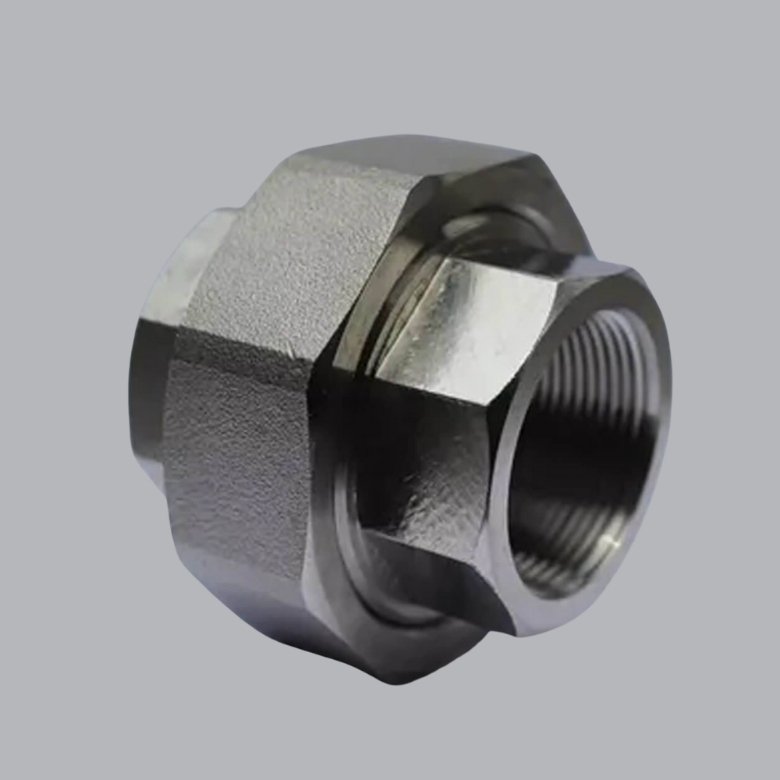

Nickel Alloy Threaded and Socket Weld Fittings – Certified ASME / ANSI Quality

What are the differences between seamless and welded nickel alloy fittings?

Seamless (SMLS): Manufactured from a solid billet, offering superior strength, uniform grain structure, and better pressure rating. Ideal for high-pressure and critical systems.

Welded (WP/WX): Made by rolling and welding plates or strips. Cost-effective for larger sizes. Suitable for moderate pressure and temperature applications.

Mechanical & Corrosion Performance: Seamless fittings generally offer slightly higher mechanical strength and better corrosion resistance due to absence of weld seams.

Applications: Seamless for power plants, chemical reactors, and offshore pipelines; welded for large-diameter water, HVAC, or non-critical chemical piping.

How are nickel alloy fittings tested for quality and reliability?

Hydrostatic / Pressure Testing: Ensures fittings can withstand rated pressures without leakage.

Hardness Testing (HBW/HRB): Confirms mechanical strength and uniformity.

Impact Testing (Charpy V-notch): Measures toughness, especially at low temperatures.

Intergranular Corrosion Testing (ASTM A262): Confirms resistance to grain boundary attack in welded areas.

Ferrite / Microstructure Analysis: Verifies proper alloying and stabilization for duplex or high-Ni alloys.

PMI / Spectrochemical Analysis: Confirms chemical composition against ASTM standards to prevent alloy substitution.

Dimensional & Visual Inspection: Ensures conformance to ASME B16.9/B16.11/B16.5 dimensions and surface finish standards.

Which industries benefit most from nickel alloy pipe fittings and flanges?

Oil & Gas: High-pressure, high-temperature pipelines, offshore rigs, and refineries.

Chemical & Petrochemical: Corrosive media, acids, and oxidizing/reducing chemicals.

Power Generation: Boilers, heat exchangers, and nuclear plants with high-temperature fluids.

Marine & Seawater Applications: Seawater piping, desalination plants, and offshore equipment.

Pharmaceutical & Food Processing: Corrosion-resistant, non-contaminating piping systems.

Aerospace & Defense: High-temperature and corrosive hydraulic systems.