- Home

- Super Duplex Steel

Super Duplex Steel

Super Duplex : Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

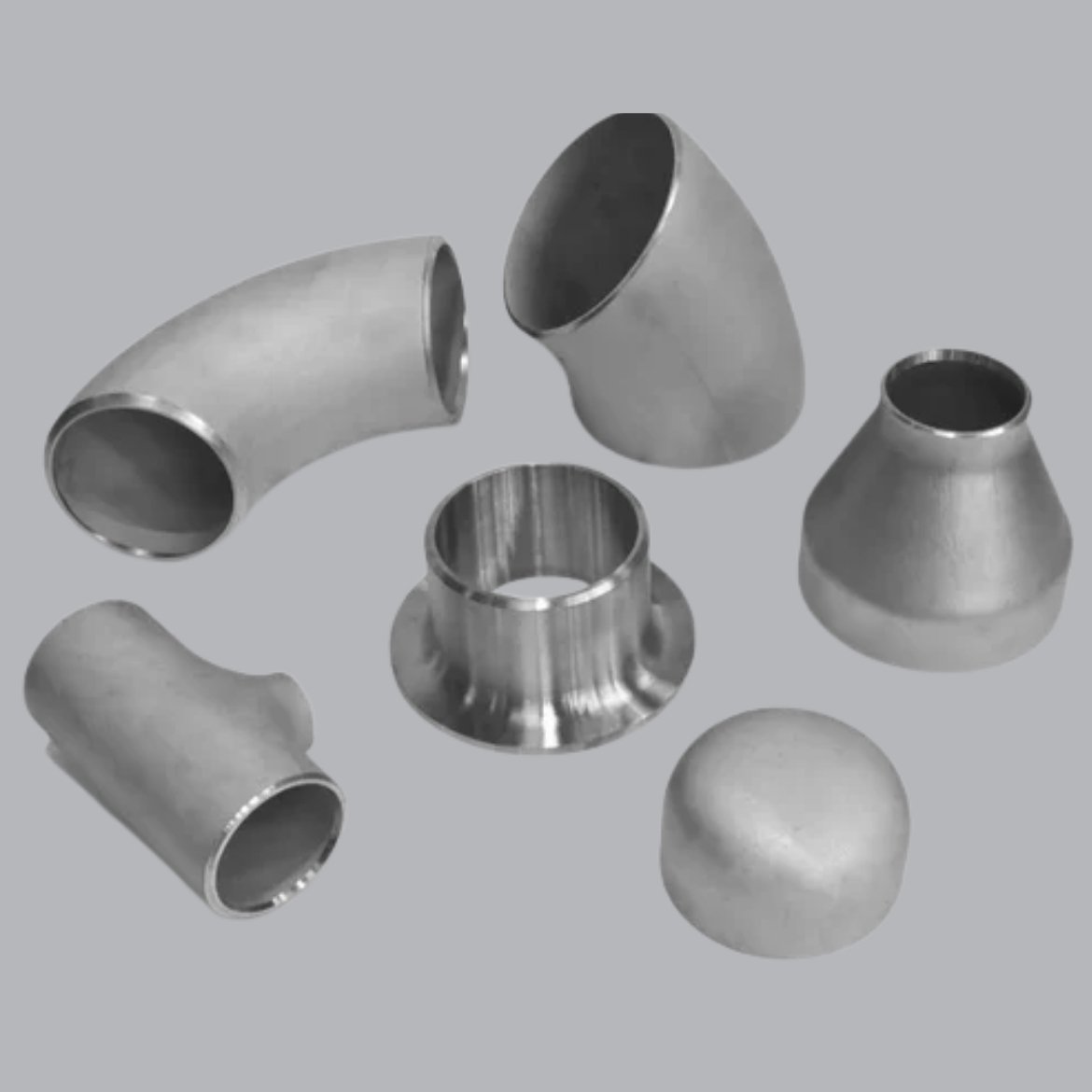

High-Quality Super Duplex Stainless Steel Pipe Fittings & Flanges (ASTM A182 / A815 F51 / F53) – Manufacturer & Exporter providing Elbows, Tees, Reducers, Caps, and a full range of Buttweld, Forged, and Socket Weld Flanges for critical piping networks.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a premier manufacturer and supplier of high-quality Super Duplex pipe fittings and flanges, including buttweld, forged, and socket weld fittings. Known for precision engineering and adherence to international standards, the company delivers products that ensure durability, reliability, and superior performance in critical piping systems.

With years of industry expertise, we combine advanced manufacturing capabilities with strict quality control to provide robust, corrosion-resistant, and high-performance products. Our commitment to excellence makes us a trusted partner for clients in oil & gas, chemical, petrochemical, power, and marine industries worldwide.

Super Duplex Stainless Steel Pipe Fittings and Flanges are engineered from a dual-phase microstructure composed of roughly equal proportions of austenite and ferrite, providing an exceptional combination of high mechanical strength and corrosion resistance. These fittings and flanges exhibit yield strength nearly twice that of conventional austenitic stainless steels, allowing for thinner wall sections and lighter piping systems without compromising safety. The alloy’s chemistry—high chromium (22–23%), nickel (4.5–6.5%), molybdenum (3–5%), and nitrogen (0.14–0.20%)—ensures superior resistance to pitting, crevice, and stress corrosion cracking, particularly in chloride-rich environments such as offshore platforms, desalination plants, and chemical process industries.

Super Duplex fittings and flanges are manufactured in compliance with ASTM A182 / A815 standards for forged and seamless components, offering Buttweld, Forged, and Socket Weld configurations including elbows, tees, reducers, caps, and flanges. The low thermal expansion coefficient and high toughness of Super Duplex steel allow it to withstand high-pressure, high-temperature applications while maintaining excellent weldability and formability. These technical attributes make Super Duplex pipe fittings and flanges ideal for critical industrial piping systems where both strength and long-term corrosion resistance are essential.

Super Duplex Stainless Steel Fittings Specifications

Size Range – (Buttweld, Forged, Flange)

½” – 4” (Socket Weld & Threaded), ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

ASTM / ASME - Grades

ASTM A182 / SA182

Duplex 2507,

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Super Duplex Flanges– Grades & Standards

| Grade | UNS Number | ASTM / ASME Standards | Material Type | Typical Applications |

|---|---|---|---|---|

| Super Duplex F51 | S32750 | ASTM A182 / A815 | Forged / Buttweld Flange | Oil & Gas, Petrochemical, Offshore |

| Super Duplex F53 | S32760 | ASTM A182 / A815 | Forged / Buttweld Flange | Chemical Processing, Desalination Plants |

| Super Duplex F55 | S32550 | ASTM A182 / A815 | Forged / Buttweld Flange | High-Pressure Piping, Marine Applications |

| Super Duplex F61 | S32900 | ASTM A182 / A815 | Forged / Buttweld Flange | Corrosive Environment Pipelines |

| Super Duplex F55 (Alternative) | S32760 | ASTM B564 / ASME B16.5 | Weld Neck / Slip-On / Blind Flanges | Offshore, Marine, High Chloride Water Systems |

Explore Super Duplex Steel

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Super Duplex Steel Products

Super Duplex Forged Fittings Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Super Duplex Grade | UNS Number | EN / DIN | JIS | BS | AFNOR / NF | ASTM / ASME |

|---|---|---|---|---|---|---|

| F51 | S32750 | EN 1.4410 | SUS32750 | BS S32750 | Z3CN25-06 | ASTM A182 / A815 |

| F53 | S32760 | EN 1.4501 | SUS32760 | BS S32760 | Z3CND25-06 | ASTM A182 / A815 |

| F55 | S32550 | EN 1.4507 | SUS32550 | BS S32550 | Z3CND30-06 | ASTM A182 / A815 |

| F61 | S32900 | EN 1.4501 | SUS32900 | BS S32900 | Z3CND35-06 | ASTM A182 / A815 |

| F55 (alternative) | S32760 | EN 1.4501 | SUS32760 | BS S32760 | Z3CND25-06 | ASTM A182 / A815 |

2507 Super Duplex Blind Flange - Chemical Composition

| Element | F51 (S32750) | F53 (S32760) | F55 (S32550) |

|---|---|---|---|

| Carbon (C) | ≤ 0.03% | ≤ 0.02% | ≤ 0.03% |

| Chromium (Cr) | 21–23% | 23–25% | 24–26% |

| Nickel (Ni) | 4.5–6.5% | 6–8% | 5–7% |

| Molybdenum (Mo) | 3–5% | 3–5% | 3–5% |

| Nitrogen (N) | 0.14–0.20% | 0.18–0.25% | 0.22–0.30% |

| Manganese (Mn) | ≤ 2% | ≤ 2% | ≤ 2% |

| Silicon (Si) | ≤ 1% | ≤ 1% | ≤ 1% |

| Phosphorus (P) | ≤ 0.03% | ≤ 0.03% | ≤ 0.03% |

| Sulfur (S) | ≤ 0.02% | ≤ 0.02% | ≤ 0.02% |

| Iron (Fe) | Balance | Balance | Balance |

Super Duplex Steel Buttweld Fittings - Mechanical Properties

| Property | F51 (S32750) | F53 (S32760) | F55 (S32550) |

|---|---|---|---|

| Tensile Strength (MPa) | 830–950 | 830–950 | 850–1000 |

| Yield Strength (0.2% Proof, MPa) | 550–700 | 550–700 | 600–750 |

| Elongation (%) | 25–30 | 25–30 | 20–25 |

| Hardness (HB) | 250–300 | 250–300 | 260–310 |

| Impact Toughness (J, at -50°C) | ≥ 100 | ≥ 100 | ≥ 90 |

| Density (g/cm³) | 7.8 | 7.8 | 7.8 |

| Modulus of Elasticity (GPa) | 200 | 200 | 200 |

| Thermal Conductivity (W/m·K) | 15 | 15 | 15 |

| Coefficient of Thermal Expansion (10⁻⁶ /°C) | 13 | 13 | 13 |

Super Duplex 2507 Buttweld Fittings – Available in Seamless and Welded

ANSI / ASME Approved Super Duplex 2507 Flanges – Trusted Industrial Piping Solutions

- Super Duplex 2507 Slip On Flange

- Super Duplex 2507 Weld Neck Flange

- Super Duplex 2507 Socket Weld Flange

- Super Duplex 2507 Threaded Flange

- Super Duplex 2507 Lap Joint Flange

- Super Duplex 2507 Blind Flange

- Super Duplex 2507 Long Weld Neck Flange

- Super Duplex 2507 Reducing Flange

- Super Duplex 2507 RTJ Flange

2507 Super Duplex Steel Threaded & Socket Weld Fittings – ASME / ANSI Certified

What is Super Duplex Stainless Steel and why is it used in pipe fittings and flanges?

Super Duplex Stainless Steel is a dual-phase stainless steel consisting of roughly 50% austenite and 50% ferrite, offering a unique combination of high mechanical strength and corrosion resistance.

It is widely used in pipe fittings and flanges because it can withstand high-pressure, high-temperature, and highly corrosive environments, such as offshore platforms, desalination plants, chemical processing, and oil & gas pipelines.

The balanced microstructure ensures resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) in chloride-rich environments, outperforming standard austenitic stainless steels.

How does Super Duplex stainless steel resist corrosion?

The high chromium, molybdenum, and nitrogen content in the duplex structure enhances pitting and crevice corrosion resistance.

The ferritic phase provides stress corrosion cracking resistance, while the austenitic phase contributes to toughness and ductility.

Ideal for chloride-rich and aggressive chemical environments, such as offshore seawater applications, desalination plants, and chemical reactors.

What is the advantage of Super Duplex over standard austenitic stainless steel fittings?

Higher Strength: ~2x the yield strength, allowing thinner walls.

Superior Corrosion Resistance: Especially in chloride and high-stress environments.

High Toughness: Maintains impact resistance at low temperatures.

Cost Efficiency: Reduced material usage due to higher strength while maintaining performance.