- Home

- Duplex Steel

- UNS S31803 / S32205

UNS S31803 / S32205

UNS S31803 / S32205 Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

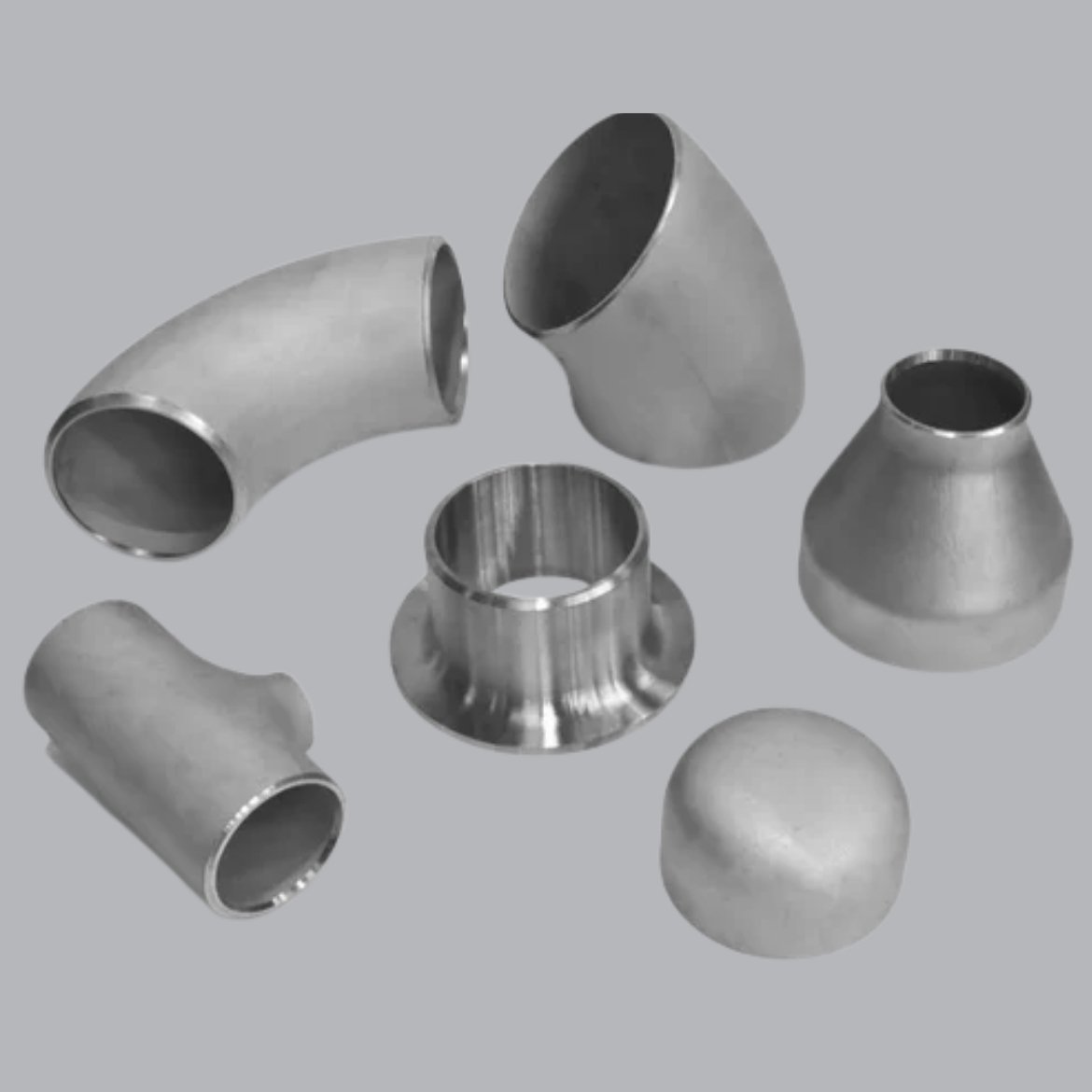

UNS S31803 / S32205 Duplex Steel Pipe Fittings & Flanges from a leading manufacturer and exporter, offering a full range of Buttweld, Forged, and Socket Weld Fittings for high-pressure, corrosion-resistant applications.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a pioneering manufacturer and supplier of high-quality industrial piping solutions, specializing in UNS S31803 / S32205 pipe fittings and flanges. With decades of expertise, the company combines state-of-the-art manufacturing processes, precision engineering, and stringent quality control to deliver products that meet international standards.

Our commitment to technical excellence, durability, and performance ensures that every fitting and flange we produce is optimized for high-pressure, high-temperature, and corrosive environments.

UNS S31803 / S32205 Duplex Steel Pipe Fittings and Flanges are engineered with a dual-phase microstructure comprising approximately equal proportions of austenite and ferrite. This microstructure provides a unique combination of high mechanical strength and superior corrosion resistance, making these components suitable for high-pressure, high-temperature, and chloride-rich environments. The alloy composition, including 21–23% Chromium, 4.5–6.5% Nickel, 2.5–3.5% Molybdenum, and 0.08–0.20% Nitrogen, ensures excellent resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC). These fittings and flanges also exhibit yield strength nearly twice that of standard austenitic stainless steels, enabling reduced wall thickness while maintaining structural integrity in critical piping systems.

Manufactured in accordance with standards such as ASTM A182, ASTM A815, ASME B16.9, B16.11, and B16.5, UNS S31803 / S32205 fittings and flanges are available in buttweld, forged, socket weld, threaded, slip-on, weld neck, blind, and orifice types. The alloy’s controlled nitrogen content and ferrite-austenite balance provide excellent weldability and formability, allowing for precision fabrication and joining in complex piping networks. These components are widely employed in offshore platforms, chemical and petrochemical plants, desalination systems, heat exchangers, and industrial pipelines where long-term mechanical reliability and corrosion resistance are essential.

Driven by innovation and customer-centric practices, we have built a reputation for reliability, consistency, and timely delivery in both domestic and international markets. Our robust production capabilities are complemented by a dedicated R&D and quality assurance team, ensuring that every component—from elbows and tees to forged flanges and custom fittings—meets the most stringent industrial specifications. The company’s focus on precision, material integrity, and engineering expertise positions it as a trusted partner for critical piping solutions across oil & gas, chemical, power, and desalination sectors.

S32205 duplex fittings Specifications

Size Range – (Buttweld, Forged, Flange)

½” – 4” (Socket Weld & Threaded), ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

ASTM / ASME - Grades

ASTM A182 / SA182

Duplex 2205, UNS S31803 / S32205

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

UNS S31803 pipe fittings– Grades & Standards

| Product Type | ASTM / ASME Standard | UNS Number | Common Grade Name | Applicable Type / Notes |

|---|---|---|---|---|

| Buttweld Fittings | ASTM A815 / ASME SA815 | S31803 / S32205 | Duplex 2205 | Elbows, Tees, Reducers, Caps, Crosses – Solution Annealed |

| Forged Fittings | ASTM A182 / ASME SA182 | S31803 / S32205 | Duplex 2205 | Socket Weld, Threaded, High-Pressure Applications |

| Threaded / Socket Weld Flanges | ASTM A182 / ASME SA182 | S31803 / S32205 | Duplex 2205 | Offshore, Chemical, Petrochemical Applications |

Explore Duplex Steel

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Duplex Steel Products

ASTM A815 UNS S31803 45°, 90° Elbow Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Common Name | UNS Number | ASTM / ASME | EN / DIN | JIS | GOST / Russian |

|---|---|---|---|---|---|

| Duplex 2205 | S31803 | ASTM A182 F51, ASTM A815 | 1.4462 | SUS 329J3L | 08Х22Н6Т |

| Duplex 2205 | S32205 | ASTM A182 F60, ASTM A815 | 1.4462 | SUS 329J4L | 08Х22Н6Т |

UNS S31803 WNRF Flange - Chemical Composition

| Element | UNS S31803 (%) | UNS S32205 (%) |

|---|---|---|

| Carbon (C) | ≤ 0.03 | ≤ 0.03 |

| Manganese (Mn) | 1.00 – 2.00 | 1.00 – 2.00 |

| Phosphorus (P) | ≤ 0.03 | ≤ 0.03 |

| Sulfur (S) | ≤ 0.02 | ≤ 0.02 |

| Silicon (Si) | 0.50 – 1.00 | 0.50 – 1.00 |

| Chromium (Cr) | 21.0 – 23.0 | 22.0 – 23.0 |

| Nickel (Ni) | 4.5 – 6.5 | 4.5 – 6.5 |

| Molybdenum (Mo) | 2.5 – 3.5 | 3.0 – 3.5 |

| Nitrogen (N) | 0.08 – 0.20 | 0.08 – 0.20 |

| Iron (Fe) | Balance | Balance |

ASTM A815 UNS S32205 Forged Fittings - Mechanical Properties

| Property | UNS S31803 | UNS S32205 |

|---|---|---|

| Tensile Strength (MPa) | 620 – 850 | 620 – 850 |

| Yield Strength (0.2% offset, MPa) | 450 – 550 | 450 – 550 |

| Elongation (%) | 25 – 35 | 25 – 35 |

| Hardness (HRB) | 88 – 95 | 88 – 95 |

| Impact Toughness (Charpy V-Notch, J at 0°C) | ≥ 40 | ≥ 40 |

| Modulus of Elasticity (GPa) | 200 | 200 |

| Density (g/cm³) | 7.8 | 7.8 |

| Melting Point (°C) | 1390 – 1440 | 1390 – 1440 |

Seamless and Welded UNS S31803 / S32205 Buttweld Fittings – High-Performance Duplex Steel

UNS S31803 / S32205 Flanges – ASME / ANSI Certified, Durable Piping Solutions for Industry

Duplex 2205 UNS S31803 / S32205 Threaded & Socket Weld Forged Fittings – Certified ASME / ANSI

Are UNS S31803 / S32205 fittings and flanges weldable and formable?

Excellent weldability: Suitable for TIG, MIG, SMAW, and orbital welding.

Controlled ferrite content: Prevents hot cracking during welding.

Formability: Can be bent, flanged, and fabricated for complex piping networks without microstructural damage.

Post-weld considerations: Low-carbon S32205 ensures minimal sensitization, preserving corrosion resistance at welded joints.

In which industries are UNS S31803 / S32205 pipe fittings and flanges commonly used?

Offshore and marine: High resistance to chlorides and saltwater corrosion.

Chemical and petrochemical plants: Withstands corrosive acids, chlorides, and chemical exposure.

Desalination plants: Ideal for high-chloride water processing.

Power and energy: Suitable for high-pressure and temperature piping systems.

Food, pharmaceutical, and paper industries: Where hygiene and corrosion resistance are critical.

How do UNS S31803 and UNS S32205 differ, and when should each be used?

UNS S31803: Standard duplex steel grade with balanced mechanical strength and corrosion resistance.

UNS S32205: Low-carbon, high-purity version optimized for welded applications, reducing sensitization and enhancing corrosion resistance.

Selection: Use S32205 for critical welded flanges, fittings, and high-corrosion zones, while S31803 is suitable for general duplex piping applications.