- Home

- Duplex Steel

Duplex Steel

Duplex Steel: Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | BW Fittings | Forged Fittings | Flanges | FAQ

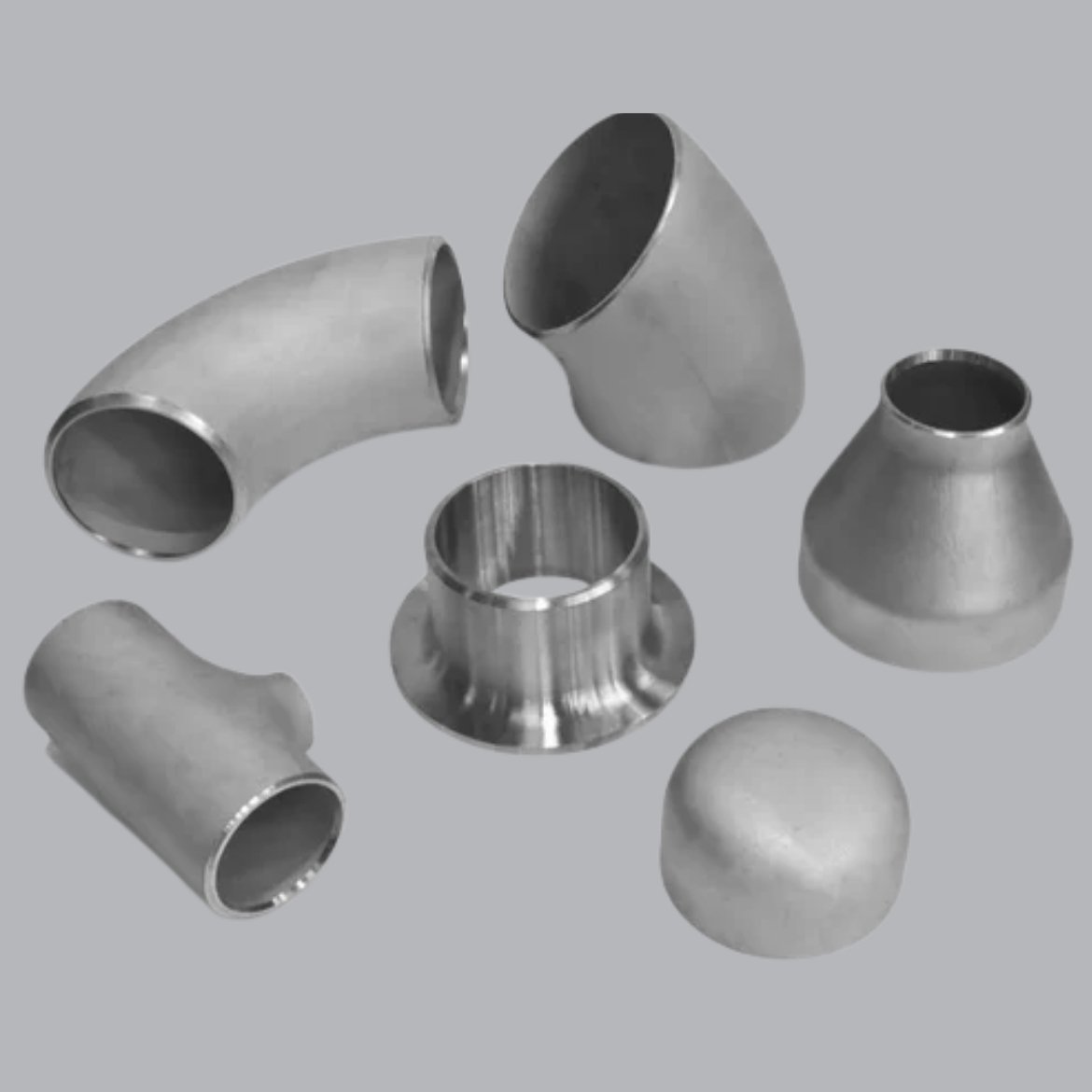

Leading Manufacturer and Exporter of Duplex Stainless Steel Pipe Fittings & Flanges, offering a complete range of Buttweld, Forged, and Socket Weld Fittings such as Elbows, Tees, Reducers, Caps, and various Flange Types for critical piping applications.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a trusted and globally recognized manufacturer and supplier of high-quality industrial piping solutions, specializing in Buttweld Fittings, Forged Fittings, and Flanges. With years of engineering excellence and a strong focus on innovation, we have built a reputation for delivering products that meet the most demanding international standards, including ASME, ASTM, DIN, EN, and ISO.

Our advanced manufacturing infrastructure, equipped with precision machining and testing facilities, enables us to produce components that ensure superior performance, durability, and reliability across a wide range of industries such as oil & gas, petrochemical, power generation, marine, and process equipment.

Duplex Steel Pipe Fittings and Flanges are engineered from a dual-phase microstructure consisting of approximately equal proportions of austenite and ferrite. This balanced metallurgical structure imparts a unique combination of high mechanical strength and exceptional corrosion resistance. The dual-phase nature of Duplex Stainless Steel enhances its resistance to localized corrosion mechanisms such as stress corrosion cracking (SCC), pitting, and crevice corrosion, making it superior to conventional austenitic stainless steels in aggressive service environments.

The material’s high yield strength—typically twice that of standard stainless steels—allows for thinner wall sections and reduced weight while maintaining excellent pressure retention capabilities. Duplex steel fittings and flanges also exhibit outstanding weldability and formability due to their optimized nitrogen content and balanced alloy composition of chromium (21–23%), nickel (4.5–6.5%), and molybdenum (2.5–3.5%). These properties ensure dimensional stability and mechanical integrity under cyclic loading and elevated temperature conditions.

Duplex steel products are manufactured and standardized under international specifications such as ASTM A815 for buttweld fittings, ASTM A182 for forged flanges and fittings, and ASTM A790/A928 for seamless and welded pipes. Owing to their superior strength-to-corrosion resistance ratio, Duplex Steel Pipe Fittings and Flanges are extensively used in chloride-bearing environments like desalination units, offshore platforms, pressure vessels, heat exchangers, and chemical process equipment.

At Midland, quality and customer satisfaction are at the core of our operations. Our strength lies in our highly skilled workforce, state-of-the-art production capabilities, and commitment to continuous improvement. We maintain a large inventory of raw materials and finished products to ensure quick turnaround times and global delivery efficiency. Backed by robust quality assurance systems, technical expertise, and a customer-centric approach, we continue to strengthen our position as one of the most dependable partners for industrial piping components worldwide.

Duplex steel Pipe Fittings Specifications

Size Range – (Buttweld, Forged, Flange)

½” – 4” (Socket Weld & Threaded), ½” – 48” (Class 150 to 2500 / PN 2.5 to PN 400)

Pressure Rating/ Wall Thickness

ASTM / ASME - Grades

ASTM A182 / SA182

Duplex 2205,

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Duplex 2205 Threaded Fittings– Grades & Standards

| Product Type | ASTM / ASME Standard | UNS Number | Common Grade Name | Applicable Type / Notes |

|---|---|---|---|---|

| Buttweld Fittings | ASTM A815 / ASME SA815 | S31803 / S32205 | Duplex 2205 | Elbows, Tees, Reducers, Caps, Crosses – Solution Annealed |

| Forged Fittings | ASTM A182 / ASME SA182 | S31803 / S32205 | Duplex 2205 | Socket Weld, Threaded, High-Pressure Applications |

| Threaded / Socket Weld Flanges | ASTM A182 / ASME SA182 | S31803 / S32205 | Duplex 2205 | Offshore, Chemical, Petrochemical Applications |

Explore Duplex Steel

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Duplex Steel Products

Duplex Steel Buttweld 45°, 90° Elbow Equivalent Grades – ASTM, ASME, DIN, JIS & UNS

| Common Name | UNS Number | ASTM / ASME | EN / DIN | JIS | GOST / Russian |

|---|---|---|---|---|---|

| Duplex 2205 | S31803 | ASTM A182 F51, ASTM A815 | 1.4462 | SUS 329J3L | 08Х22Н6Т |

| Duplex 2205 | S32205 | ASTM A182 F60, ASTM A815 | 1.4462 | SUS 329J4L | 08Х22Н6Т |

2205 Duplex SORF Flange - Chemical Composition

| Element | Composition (% by weight) |

|---|---|

| Carbon (C) | ≤ 0.03 |

| Chromium (Cr) | 21.0 – 23.0 |

| Nickel (Ni) | 4.5 – 6.5 |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Nitrogen (N) | 0.08 – 0.20 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.020 |

| Iron (Fe) | Balance |

Duplex Steel Forged Fittings - Mechanical Properties

| Property | Metric | Imperial | Notes |

|---|---|---|---|

| Tensile Strength (UTS) | 620 MPa min | 90 ksi min | Maximum stress before fracture |

| Yield Strength (0.2% Proof) | 450 MPa min | 65 ksi min | Stress at which material begins to deform plastically |

| Elongation (in 50 mm gauge length) | 25% min | 25% min | Measure of ductility |

| Hardness (Brinell) | 290 HB max | 290 HB max | Surface resistance to indentation |

| Impact Toughness (Charpy V-notch, -46°C) | ≥ 100 J | ≥ 74 ft-lb | Resistance to sudden impact or shock loading |

| Modulus of Elasticity | 200 GPa | 29,000 ksi | Stiffness of material under load |

| Density | 7.8 g/cm³ | 0.28 lb/in³ | Material density |

Duplex 2205 Buttweld Fittings – Available in Seamless and Welded

ANSI / ASME Approved Duplex Steel Flanges – Trusted Industrial Piping Solutions

Duplex Steel Threaded & Socket Weld Forged Fittings – ASME / ANSI Certified

How does the dual-phase microstructure of Duplex 2205 affect its welding and heat treatment requirements?

Duplex 2205 has roughly 50% austenite and 50% ferrite.

Balanced microstructure is critical for combining high strength with corrosion resistance.

Excess ferrite in weld zones: Reduces toughness and ductility.

Excess austenite: Lowers strength and SCC resistance.

Welding controls required:

Maintain interpass temperature ≤ 150°C.

Use low heat input processes (TIG, SMAW).

Apply Duplex-specific filler metals to preserve microstructure.

Post-weld solution annealing (1020–1080°C) may be required for high-pressure systems to restore ferrite-austenite balance and corrosion resistance.

Cooling rates must be controlled to avoid formation of sigma phase, which is brittle and reduces pitting resistance.

What non-destructive tests (NDT) are essential for Duplex 2205 flanges and fittings, and why?

Ultrasonic Testing (UT): Detects internal voids, cracks, and inclusions.

Radiographic Testing (RT): Confirms weld integrity under high-pressure service.

Dye Penetrant Testing (PT): Detects surface microcracks.

Eddy Current / Ferrite Testing: Ensures proper ferrite content to maintain strength and corrosion resistance.

Hydrostatic Testing: Validates flange and fitting pressure containment.

Corrosion testing (ASTM A262): Confirms intergranular corrosion resistance.

How do cold forming and bending processes affect Duplex 2205 fittings?

Cold working can increase ferrite content, causing brittleness and microcracks.

Bends and radius fittings often require stress-relieving or solution annealing post-forming.

Excessive deformation may reduce pitting resistance in the outer bend zone.

Controlled forming parameters are critical to maintain weldability and corrosion performance.