- Home

- Stainless steel

- SS 316 / 316L / 316H

SS 316 / 316L / 316H

SS 316 / 316L / 316H: Specifications | Grades & Standards | Product Types | Equivalent | Chemical | Mechanical | BW Fittings | Forged Fittings | Flanges | FAQ

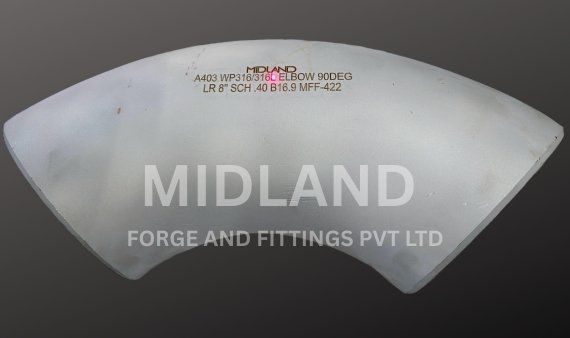

Leading Manufacturers & Suppliers of SS 316 Pipe Fittings, 316L Flanges, SS 316H Forged Fittings, SS 316 Buttweld Elbows, Tees, Reducers, UNS S31600 / S31603 Pipe Fittings & Flanges – ASTM A182 / A403 Certified, Corrosion-Resistant, High-Performance Piping Solutions Exported Worldwide.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer and supplier of premium SS 316, 316L, and 316H pipe fittings and flanges, offering a comprehensive range of buttweld, forged, and specialty flanges. Every flange and fitting is manufactured to meet ASTM A182 / A403 standards, ensuring consistent quality and reliability for critical piping projects worldwide.

With a strong focus on innovation, quality, and customer satisfaction, we serve clients across Europe, North America, the Middle East, Australia, South Africa, and Asia. We combine advanced manufacturing techniques with skilled craftsmanship to deliver customized SS 316 series flanges and fittings that meet each project’s unique requirements.

Stainless Steel 316 is an austenitic stainless steel known for its excellent corrosion resistance, mechanical strength, and versatility. Our 316 buttweld and forged flanges and fittings are precision-engineered to withstand high-pressure, high-temperature, and chemically aggressive environments, making them ideal for applications in marine, chemical, and industrial piping systems. Manufactured to meet ASTM A182 and A403 standards, these fittings and flanges ensure tight dimensional tolerances, high durability, and resistance to pitting and crevice corrosion, providing reliable performance in long-term service.

SS 316L is a low-carbon variant of 316 stainless steel, specifically designed to prevent sensitization during welding. Our 316L buttweld and forged flanges and fittings offer superior corrosion resistance in chloride-rich and acidic environments, making them suitable for chemical processing, pharmaceuticals, and seawater applications. Engineered with precision, these products comply with ASTM and ASME standards, ensuring uniform wall thickness, seamless finish, and long-term structural integrity, even in critical high-purity or high-temperature systems.

SS 316H is a high-carbon austenitic stainless steel variant optimized for elevated temperature applications. Our 316H buttweld and forged flange fittings are designed to maintain mechanical strength and creep resistance at high temperatures, making them suitable for power plants, chemical reactors, and high-temperature piping networks. Manufactured according to ASTM A182 / A403 standards, these fittings provide excellent corrosion resistance, dimensional accuracy, and superior performance under thermal stress, ensuring reliability in demanding industrial environments.

316 / 316L / 316H Stainless Steel - Specifications

Size Range – (Buttweld, Forged, Flange)

Pressure Rating/ Wall Thickness

Applications

ASTM / ASME

ASTM/ASME A403/SA403

Grades, EN, UNS

316L – S31603, X2CrNiMo17-12-2,

316H – S31609, X6CrNiMo17-12-2

Quality Certifications

Dimensional Standards

Forms

Surface Finish

SS 316/316L/316H – Grades & Standards

| Grade | Buttweld Fittings Standards | Forged Fittings Standards | Flanges Standards |

|---|---|---|---|

| 316 | ASTM A403 / ASME B16.9 / MSS-SP-43 | ASTM A182 / ASME B16.11 | ASTM A182 / ASME B16.5 / B16.47 |

| 316L | ASTM A403 / ASME B16.9 / MSS-SP-43 | ASTM A182 / ASME B16.11 | ASTM A182 / ASME B16.5 / B16.47 |

| 316H | ASTM A403 / ASME B16.9 / MSS-SP-43 | ASTM A182 / ASME B16.11 | ASTM A182 / ASME B16.5 / B16.47 |

SS 316 Series – Industrial Flanges, Fittings & Piping Products

SS 316 Threaded Fittings ASTM A182 - Equivalent Grades

| Grade | UNS | ASTM | EN (DIN) | JIS | GOST | BS | AFNOR |

|---|---|---|---|---|---|---|---|

| 316 | S31600 | A240 / A276 | 1.4401 (X5CrNiMo17-12-2) | SUS316 | 08Х17Н13М2 (08X17H13M2) | 316S31 | Z6CND17-11-02 |

| 316L | S31603 | A240 / A276 | 1.4404 (X2CrNiMo17-12-2) | SUS316L | 03Х17Н14М3 (03X17H14M3) | 316S11 / 316S12 | Z2CND17-12 |

| 316H | S31609 | A240 / A276 | 1.4919 (X6CrNiMoTi17-12-2) | SUS316H | 08Х17Н13М2Т (08X17H13M2T) | 316S51 | Z6CND17-12 |

ASTM A403 SS 316L Buttweld Pipe Fittings - Chemical Composition

| Grade | C (%) | Cr (%) | Ni (%) | Mo (%) | Mn (%) | Si (%) | P (%) | S (%) | N (%) | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| 316 | ≤ 0.08 | 16.0 – 18.0 | 10.0 – 14.0 | 2.00 – 3.00 | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | ≤ 0.10 | – |

| 316L | ≤ 0.03 | 16.0 – 18.0 | 10.0 – 14.0 | 2.00 – 3.00 | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | ≤ 0.10 | – |

| 316H | 0.04 – 0.10 | 16.0 – 18.0 | 10.0 – 14.0 | 2.00 – 3.00 | ≤ 2.00 | ≤ 0.75 | ≤ 0.045 | ≤ 0.03 | ≤ 0.10 | – |

SS 316H ASME SA182 Flanges - Mechanical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HB) | Hardness (HRB) | Hardness (HRC) |

|---|---|---|---|---|---|---|

| 316 | 515 – 760 | ≥ 205 | ≥ 40 | ≤ 217 | ≤ 95 | ≤ 22 |

| 316L | 485 – 700 | ≥ 170 | ≥ 40 | ≤ 217 | ≤ 95 | ≤ 22 |

| 316H | 515 – 760 | ≥ 205 | ≥ 40 | ≤ 217 | ≤ 95 | ≤ 22 |

SS 316/316L/316H Buttweld Fittings – Seamless, Welded & Fabricated Types

Types of Stainless Steel 316/316L/316H Flanges for Piping Systems

- SS 316/316L/316H Slip On Flange

- SS 316/316L/316H Weld Neck Flange

- SS 316/316L/316H Socket Weld Flange

- SS 316/316L/316H Threaded Flange

- SS 316/316L/316H Lap Joint Flange

- SS 316/316L/316H Blind Flange

- SS 316/316L/316H Long Weld Neck Flange

- SS 316/316L/316H Reducing Flange

- SS 316/316L/316H RTJ Flange

- SS 316/316L/316H Plate Flange

Stainless Steel 316/316L/316H Forged Fittings – Complete Guide

What are the main differences between Stainless Steel 316, 316L, and 316H grades?

The primary difference lies in their carbon content, which affects their mechanical strength, corrosion resistance, and temperature suitability:

SS 316: Standard grade with moderate carbon content (≤0.08%), offering excellent corrosion resistance and strength.

SS 316L: Low-carbon version (≤0.03%) that minimizes carbide precipitation during welding—ideal for welded piping systems and environments prone to intergranular corrosion.

SS 316H: High-carbon version (0.04–0.10%) that provides greater tensile strength and creep resistance at elevated temperatures, making it suitable for high-temperature and pressure services.

In short:

Use 316L for corrosion resistance and weldability.

Use 316H for high-temperature strength.

Use 316 for general-purpose industrial applications.

Why is Molybdenum (Mo) added in SS 316 grades and what are its benefits?

Molybdenum (2–3%) plays a crucial role in enhancing corrosion resistance, especially against chloride environments:

Improves pitting and crevice corrosion resistance in marine and chemical environments.

Enhances performance in acidic and saline conditions.

Increases high-temperature oxidation resistance.

Provides greater tensile and creep strength at elevated service temperatures.

This makes SS 316 series ideal for chemical processing, seawater piping, heat exchangers, and food industry equipment.

How does SS 316L prevent intergranular corrosion during welding?

316L’s low carbon content (≤0.03%) prevents chromium carbide precipitation during welding.

This ensures:

Maximum corrosion resistance in the heat-affected zone (HAZ).

No need for post-weld annealing in thin sections.

Longer life in chemical, pharmaceutical, and food industries where cleanliness and weld integrity are critical.