MSS SP-95 Nipple & Plug Fittings : Specifications | Materials | Dimensions | Weight Chart | Tolerances | FAQ

High-Quality MSS SP-95 Swage Nipples & Bull Plugs – Manufactured & Supplied for Global Piping Needs – Class 150 & 300, Sizes ½” to 24” – Delivered to Canada, UAE, Germany, Malaysia & Brazil.

Best Export Prices: sales@midlandforgefittings.com

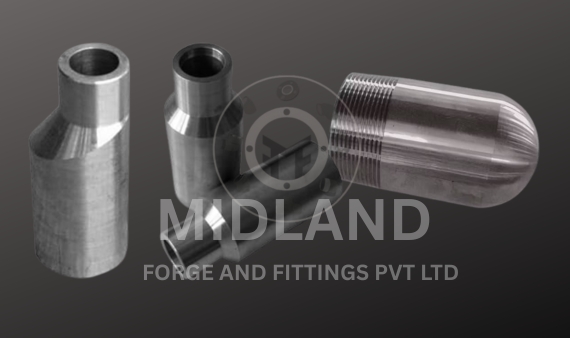

As a trusted manufacturer and supplier of Swage Nipples & Bull Plugs, we specialize in delivering high-quality fittings that meet stringent industry standards. Our products are engineered for durability, precision, and reliable performance in Class 150 and 300 piping systems. By combining advanced manufacturing techniques with rigorous quality control, we ensure every Swage Nipple and Bull Plug provides a perfect fit and long-lasting service across diverse industrial applications.

With a commitment to excellence and global supply, our Swage Nipples & Bull Plugs support projects across chemical, mechanical, and industrial piping systems. We offer a wide range of sizes, materials, and specifications to meet diverse requirements, delivering products that ensure strength, reliability, and compliance with international standards, making them a preferred choice for engineers and contractors worldwide.

MSS SP-95 Swage Nipples & Bull Plugs are engineered to provide precise dimensional conformity and high mechanical strength required for pressure piping systems. Swage nipples are designed with optimized reducer profiles to maintain laminar flow while minimizing pressure drops, whereas bull plugs are forged to exact tolerances to ensure leak-proof sealing at pipe ends or branch connections. Both products undergo stringent testing for hardness, impact resistance, and surface integrity to meet industrial performance requirements.

These fittings are compatible with a wide range of piping schedules and materials, including carbon steel, stainless steel, and alloy steel, making them suitable for corrosive and high-temperature environments. Machining and forging processes are closely controlled to achieve smooth internal finishes, concentricity, and thread accuracy (where applicable), which enhances fatigue resistance and reduces the risk of stress corrosion cracking during service.

MSS SP-95 Swage Nipples & Bull Plugs are widely used in applications requiring reliable flow transitions, branch terminations, or line closures in process plants, refineries, and high-pressure piping networks. Their design supports both welded and threaded connections while ensuring structural integrity under internal pressure, vibration, and thermal cycling, providing engineers with a robust solution for complex piping configurations.

Swage Nipples & Bull Plugs

Size Range

Pressure Ratings

Testing & Inspection

Fitting Types

End Connections

Material Grades

Dimensional Standards

Manufacturing Process

Applications

High-Pressure Swage Nipples & Bull Plugs - Materials, Grades & Standards

| Material Type | Grades / Standards | Notes |

|---|---|---|

| Carbon Steel | ASTM A105, A350 LF2, A234 WPB | Suitable for high-pressure applications |

| Alloy Steel | ASTM A182 F11, F22, F91 | High-temperature and corrosion-resistant |

| Stainless Steel | ASTM A182 F304/304L, F316/316L, F321, F347 | Corrosion-resistant, widely used in industry |

| Nickel Alloys | Inconel, Incoloy, Monel, Hastelloy | High temperature & corrosive environments |

| Duplex / Super Duplex | UNS S31803, S32750 | Excellent corrosion resistance & strength |

Explore All Standards

- Standards

- ASME B16.5 Flanges

- ASME B16.47 Large Diameter Flanges

- ASME B16.9 Buttweld Fittings

- ASME B16.11 Forged Fittings

- ASME B16.28 Wrought Steel Elbows

- MSS SP-43 Stainless Steel Buttweld Fittings

- MSS SP-75 High Strength Butt Weld Fittings

- DIN Flanges

- EN Flanges

- GOST Flanges

- JIS Flanges

- MSS SP-95 – Swage Nipples & Bull Plugs

- MSS SP-97 – Integrally Reinforced Branch Outlets

- API 6A – Wellhead Flanges & Equipment

- API 605 – Large Diameter Flanges (replaced by ASME B16.47)

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Swage Nipples & Bull Plugs MSS SP-95 – Dimensions

| Fitting Type | Run Pipe NPS (in) |

Branch Pipe NPS (in) |

Overall Length (mm / in) |

Wall Thickness (Sch / mm) |

Class |

|---|---|---|---|---|---|

| Swage Nipple (Concentric) | ½” | ½” | 60 / 2.36 | Sch 40 / 3.68 | 150 / 300 |

| 1” | ½” | 65 / 2.56 | Sch 40 / 3.68 | 150 / 300 | |

| 1½” | 1” | 75 / 2.95 | Sch 40 / 4.55 | 150 / 300 | |

| 2” | 1½” | 90 / 3.54 | Sch 40 / 4.85 | 150 / 300 | |

| 3” | 2” | 110 / 4.33 | Sch 40 / 5.49 | 150 / 300 | |

| 4” | 3” | 140 / 5.51 | Sch 40 / 6.02 | 150 / 300 | |

| 6” | 4” | 190 / 7.48 | Sch 40 / 7.11 | 150 / 300 | |

| 8” | 6” | 250 / 9.84 | Sch 40 / 8.18 | 150 / 300 | |

| Swage Nipple (Eccentric) | ½” – 24” | ½” – 12” | Varies (see standard) | Sch 40 – Sch XXS | 150 / 300 |

| Bull Plug (Forged) | ½” | N/A | 40 / 1.57 | Sch 40 / 3.68 | 150 / 300 |

| 1” | N/A | 50 / 1.97 | Sch 40 / 3.68 | 150 / 300 | |

| 2” | N/A | 60 / 2.36 | Sch 40 / 4.85 | 150 / 300 | |

| 3” | N/A | 75 / 2.95 | Sch 40 / 5.49 | 150 / 300 | |

| 4” | N/A | 90 / 3.54 | Sch 40 / 6.02 | 150 / 300 | |

| 6” | N/A | 120 / 4.72 | Sch 40 / 7.11 | 150 / 300 | |

| 8” | N/A | 150 / 5.91 | Sch 40 / 8.18 | 150 / 300 | |

| Bull Plug (Machined) | ½” – 24” | N/A | Equal to NPS OD | Sch 40 – Sch XXS | 150 / 300 |

Swage Nipples & Bull Plugs - Weight Chart as per MSS SP - 95

| Fitting Type | Run Pipe NPS (in) | Branch Pipe NPS (in) | Wall Thickness (Sch / mm) | Approx. Weight (kg / lb) |

|---|---|---|---|---|

| Swage Nipple (Concentric) | ½” | ½” | Sch 40 / 3.68 | 0.25 / 0.55 |

| 1” | ½” | Sch 40 / 3.68 | 0.35 / 0.77 | |

| 1½” | 1” | Sch 40 / 4.55 | 0.55 / 1.21 | |

| 2” | 1½” | Sch 40 / 4.85 | 0.80 / 1.76 | |

| 3” | 2” | Sch 40 / 5.49 | 1.25 / 2.75 | |

| 4” | 3” | Sch 40 / 6.02 | 2.10 / 4.63 | |

| 6” | 4” | Sch 40 / 7.11 | 3.80 / 8.38 | |

| 8” | 6” | Sch 40 / 8.18 | 6.50 / 14.33 | |

| Swage Nipple (Eccentric) | ½” – 24” | ½” – 12” | Sch 40 – Sch XXS | Varies with size |

| Bull Plug (Forged) | ½” | N/A | Sch 40 / 3.68 | 0.20 / 0.44 |

| 1” | N/A | Sch 40 / 3.68 | 0.35 / 0.77 | |

| 2” | N/A | Sch 40 / 4.85 | 0.60 / 1.32 | |

| 3” | N/A | Sch 40 / 5.49 | 1.00 / 2.20 | |

| 4” | N/A | Sch 40 / 6.02 | 1.50 / 3.31 | |

| 6” | N/A | Sch 40 / 7.11 | 2.80 / 6.17 | |

| 8” | N/A | Sch 40 / 8.18 | 4.50 / 9.92 | |

| Bull Plug (Machined) | ½” – 24” | N/A | Sch 40 – Sch XXS | Varies with size |

MSS SP-95 Pipe Fittings – Swage Nipples & Bull Plugs Tolerances

| Parameter | Tolerance / Specification |

|---|---|

| Outside Diameter (OD) | ±1.5% of nominal OD |

| Wall Thickness | +12.5% / -0% of nominal thickness to ensure minimum pressure rating |

| Concentricity (Swage Nipples) | Max 1.5% deviation from nominal centerline for concentric nipples |

| Eccentricity (Swage Nipples) | Branch offset tolerance: ±3° or ±1.5% of OD (depending on NPS and manufacturer) |

| Overall Length | ±3% of nominal length |

| End Preparation (Bevel/Chamfer) | As per MSS SP-95, suitable for welding (butt weld or socket weld) |

| Thread Tolerance (if threaded) | As per ASME B1.20.1 (NPT) |

| Out-of-Roundness | ≤1.5% of nominal OD for all fittings |

| Surface Finish (Internal) | Smooth, free from burrs, cracks, or discontinuities to reduce turbulence |

| Surface Finish (External) | Suitable for painting, coating, or insulation |

What is MSS SP-95 and how does it relate to Swage Nipples & Bull Plugs?

- MSS SP-95 is a standard issued by the Manufacturers Standardization Society for Swage Nipples and Bull Plugs, specifying dimensional, material, and pressure requirements.

- It ensures that all Swage Nipples and Bull Plugs are compatible with standard piping systems, conform to Class 150 and Class 300 pressure ratings, and can be safely installed in industrial, chemical, oil & gas, and mechanical piping networks.

- Compliance with MSS SP-95 guarantees mechanical integrity, proper wall thickness, and reliable sealing, which are critical for maintaining leak-proof branch connections.

What types of Swage Nipples & Bull Plugs are covered under MSS SP-95?

- Swage Nipples: Used for connecting pipes of different diameters; available in concentric and eccentric types. Concentric nipples maintain a smooth axis, while eccentric nipples allow offset connections to prevent sag or maintain alignment in piping systems.

- Bull Plugs: Serve as end closures for pipelines, vessels, or branch connections. They can be forged or machined, designed to match pipe wall thicknesses and withstand the same internal pressures as the main pipeline.

- MSS SP-95 defines all critical dimensions, tolerances, and wall thickness requirements for both types of fittings.

Are MSS SP-95 fittings compatible with other standards?

- Yes, they are generally compatible with ASME B16.9 & B16.11 dimensions, allowing integration with standard elbows, tees, and reducers.

- Threaded outlets follow ASME B1.20.1 (NPT), ensuring interchangeability with standard piping components.