GOST Standard Flange: Specifications | Materials | Dimensions | Weight Chart | Tolerances | FAQ

GOST Flanges Manufacturer and Supplier in Russia, USA, Germany, UAE, India, and South Korea, offering Weld Neck, Slip-On, Blind, Threaded, and Lap Joint flanges in Carbon Steel, Stainless Steel, and Alloy Steel as per GOST 12820-80, GOST 12821-80, and GOST 12822-80 standards for industrial, oil & gas, petrochemical, chemical, and power plant piping systems.

Best Export Prices: sales@midlandforgefittings.com

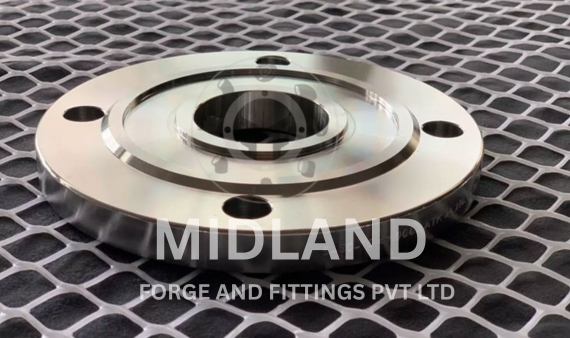

Midland Forge Fittings is a leading manufacturer and global supplier of precision-engineered GOST Standard Flanges. With a commitment to quality and innovation, we specialize in delivering high-performance flanges, forged fittings, and piping solutions that meet stringent international standards. Our manufacturing processes integrate advanced forging and machining technologies, ensuring consistent dimensional accuracy, mechanical strength all products.

Backed by decades of industry expertise, We serves critical sectors including oil & gas, petrochemical, chemical, power generation, and industrial process systems. Our team emphasizes meticulous quality control, full traceability, and timely delivery, making us a trusted partner for complex pipeline projects worldwide.

Our GOST 12820-80 flanges are manufactured strictly according to GOST 12820-80, 12821-80, and 12822-80 standards, ensuring high accuracy in dimensions, bolt alignment, and pressure containment. Available in Weld Neck, Slip-On, Blind, Threaded, and Lap Joint types, these flanges are suitable for high-pressure and high-temperature industrial applications, including oil & gas, petrochemical, chemical, and power plant pipelines.

Slip-On GOST Flanges from Midland Forge Fittings are offered in Carbon Steel, Stainless Steel, and Alloy Steel, providing superior strength, corrosion resistance, and durability. Each flange undergoes strict dimensional inspection, material verification, and tolerance checks, ensuring leak-proof connections and long-term operational reliability in demanding piping systems.

We are dedicated to innovation and customization, offering tailor-made solutions that cater to specific client requirements. Our focus on precision, reliability, and compliance with global standards positions Midland Forge Fittings as a preferred choice for engineering and industrial enterprises demanding excellence in piping components.

Threaded GOST Flanges - Specifications

Size Range

Pressure Ratings

Facing Type

Connection

Flange Types

Material Grades

Surface Finish

Dimensional Standards

Manufacturing Method

Certification

Lap Joint GOST Flanges - Materials, Grades & Standards

| Material | GOST / EN Equivalent | Grade / Specification | Applications |

|---|---|---|---|

| Carbon Steel | GOST 1050, 20, 09G2S | S235JR, S275JR, S355JR, P265GH, P355GH |

General industrial, oil & gas, chemical, power plants |

| Stainless Steel | 12X18H10T, 08X17H13M2 | EN 1.4301, EN 1.4404 | Corrosive environments, chemical, food, marine applications |

| Alloy Steel | 15CrMo, 10CrMo9-10 | GOST / EN Alloy Steel Grades |

High temperature & pressure applications in refineries, power plants |

| Low Alloy Steel | 20Cr, 35CrMo | EN 1.7709, EN 1.7225 | Critical pipelines with high stress and fatigue resistance |

| Duplex / Super Duplex | 1.4462, 1.4501 | EN 1.4462, EN 1.4501 | Highly corrosive environments, offshore, chemical industries |

Explore All Standards

- Standards

- ASME B16.5 Flanges

- ASME B16.47 Large Diameter Flanges

- ASME B16.9 Buttweld Fittings

- ASME B16.11 Forged Fittings

- ASME B16.28 Wrought Steel Elbows

- MSS SP-43 Stainless Steel Buttweld Fittings

- MSS SP-75 High Strength Butt Weld Fittings

- DIN Flanges

- EN Flanges

- GOST Flanges

- JIS Flanges

- MSS SP-95 – Swage Nipples & Bull Plugs

- MSS SP-97 – Integrally Reinforced Branch Outlets

- API 6A – Wellhead Flanges & Equipment

- API 605 – Large Diameter Flanges (replaced by ASME B16.47)

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Industrial Piping GOST Flanges – Dimensions

| DN / NB |

Flange Type |

Outside Diameter (OD mm) |

Flange Thickness (mm) |

Bolt Circle Diameter (BCD mm) |

Number of Bolt Holes |

Bolt Hole Diameter (mm) |

Face Type |

PN Rating |

|---|---|---|---|---|---|---|---|---|

| 15 (1/2″) | WN, SO, BL, TH, LJ | 95 | 14 | 65 | 4 | 14 | RF / FF | PN 6–PN 40 |

| 20 (3/4″) | WN, SO, BL, TH, LJ | 105 | 16 | 75 | 4 | 14 | RF / FF | PN 6–PN 40 |

| 25 (1″) | WN, SO, BL, TH, LJ | 115 | 16 | 85 | 4 | 14 | RF / FF | PN 6–PN 40 |

| 32 (1 1/4″) | WN, SO, BL, TH, LJ | 140 | 18 | 100 | 4 | 14 | RF / FF | PN 6–PN 40 |

| 40 (1 1/2″) | WN, SO, BL, TH, LJ | 150 | 18 | 110 | 4 | 14 | RF / FF | PN 6–PN 40 |

| 50 (2″) | WN, SO, BL, TH, LJ | 165 | 20 | 125 | 4 | 18 | RF / FF | PN 6–PN 40 |

| 65 (2 1/2″) | WN, SO, BL, TH, LJ | 185 | 20 | 145 | 4 | 18 | RF / FF | PN 6–PN 40 |

| 80 (3″) | WN, SO, BL, TH, LJ | 200 | 22 | 160 | 8 | 18 | RF / FF | PN 6–PN 40 |

| 100 (4″) | WN, SO, BL, TH, LJ | 220 | 24 | 180 | 8 | 18 | RF / FF | PN 6–PN 40 |

| 150 (6″) | WN, SO, BL, TH, LJ | 285 | 28 | 240 | 8 | 22 | RF / FF | PN 6–PN 40 |

| 200 (8″) | WN, SO, BL, TH, LJ | 340 | 32 | 295 | 12 | 22 | RF / FF | PN 6–PN 40 |

| 250 (10″) | WN, SO, BL, TH, LJ | 405 | 34 | 355 | 12 | 26 | RF / FF | PN 6–PN 40 |

| 300 (12″) | WN, SO, BL, TH, LJ | 465 | 36 | 410 | 12 | 26 | RF / FF | PN 6–PN 40 |

| 400 (16″) | WN, SO, BL, TH, LJ | 585 | 42 | 525 | 16 | 30 | RF / FF | PN 6–PN 40 |

| 500 (20″) | WN, SO, BL, TH, LJ | 705 | 48 | 645 | 20 | 30 | RF / FF | PN 6–PN 40 |

| 600 (24″) | WN, SO, BL, TH, LJ | 840 | 54 | 770 | 24 | 34 | RF / FF | PN 6–PN 40 |

| 800 (32″) | WN, SO, BL, TH, LJ | 1040 | 70 | 950 | 28 | 36 | RF / FF | PN 6–PN 40 |

| 1000 (40″) | WN, SO, BL, TH, LJ | 1250 | 80 | 1140 | 32 | 39 | RF / FF | PN 6–PN 40 |

| 1200 (48″) | WN, SO, BL, TH, LJ | 1450 | 90 | 1320 | 36 | 42 | RF / FF | PN 6–PN 40 |

GOST 12822-80 Flanges - Weight Chart

| DN / NB | Flange Type | PN Rating | Approx. Weight (kg) |

|---|---|---|---|

| 15 (1/2″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 1.5 – 2.5 |

| 20 (3/4″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 1.8 – 3.0 |

| 25 (1″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 2.0 – 3.5 |

| 32 (1 1/4″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 2.5 – 4.0 |

| 40 (1 1/2″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 3.0 – 4.5 |

| 50 (2″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 5 – 8 |

| 65 (2 1/2″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 7 – 10 |

| 80 (3″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 9 – 14 |

| 100 (4″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 15 – 25 |

| 150 (6″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 28 – 45 |

| 200 (8″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 50 – 80 |

| 250 (10″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 80 – 120 |

| 300 (12″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 120 – 180 |

| 400 (16″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 200 – 300 |

| 500 (20″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 350 – 500 |

| 600 (24″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 500 – 750 |

| 800 (32″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 1000 – 1500 |

| 1000 (40″) | WN, SO, BL, TH, LJ | PN 6–PN 40 | 1800 – 2500 |

| 1200 (48″) | WN, SO, BL, TH, LJ |

Slip-On GOST Flanges - Tolerances

| Parameter | Tolerance / Limit | Remarks |

|---|---|---|

| Outside Diameter (OD) | ±1% | Ensures proper mating with adjoining flanges |

| Flange Thickness | +12.5% / -0% | Maintains minimum wall strength |

| Bolt Circle Diameter (BCD) | ±1% | Ensures uniform bolt alignment |

| Number of Bolt Holes | Exact as per standard | Proper bolting and load distribution |

| Bolt Hole Diameter | ±0.5 mm | Allows smooth bolt insertion |

| Raised Face (RF) Height | ±1 mm | Proper gasket sealing |

| Flatness (Flange Face) | ≤0.5 mm | Ensures leak-proof connection |

| Out-of-Roundness | ≤1.5% of nominal OD | Prevents misalignment and stress concentration |

| Surface Finish | Ra 3.2 μm or as per customer requirement | Smooth contact for gaskets |

| Centering Hole / Bore Diameter | ±0.5 mm | Ensures correct pipe fit for slip-on connection |

What are GOST 12820-80, 12821-80, and 12822-80 Flanges?

1. GOST 12820-80

- Scope: Applies primarily to Weld Neck (WN) flanges, designed for high-pressure and high-temperature pipelines.

- Key Features:

- Provides gradual stress transition from flange to pipe.

- Suitable for critical industrial applications such as oil & gas, power generation, and chemical transport.

- Available in DN 15–1200 mm with PN 6–PN 40 pressure ratings.

- Material Options: Carbon Steel, Stainless Steel, Alloy Steel, and Duplex Steel.

- Applications: High-pressure, high-temperature systems where leak-proof connections are essential.

2. GOST 12821-80

- Scope: Covers Blind (BL), Threaded (TH), and specialty flanges.

- Key Features:

- Blind flanges: Close the ends of piping systems and allow pressure testing.

- Threaded flanges: Enable non-welded connections, suitable for low-pressure systems.

- Specialty flanges: Designed for unique industrial needs.

- Size & Pressure Ratings: DN 15–1200 mm, PN 6–PN 40.

- Materials: Carbon Steel, Stainless Steel, and Alloy Steel.

- Applications: Low-to-high-pressure pipelines, temporary installations, and pipelines requiring future maintenance or testing.

3. GOST 12822-80

- Scope: Focused on Slip-On (SO) and Lap Joint (LJ) flanges, designed for easy installation and alignment flexibility.

- Key Features:

- Slip-On flanges: Slide over pipe and welded at the hub; suitable for low-to-medium pressure systems.

- Lap Joint flanges: Used with stub ends, allowing rotation for precise alignment.

- Size & Pressure Ratings: DN 15–1200 mm, PN 6–PN 40.

- Material Options: Carbon Steel, Stainless Steel, and Alloy Steel.

- Applications: Industrial pipelines, chemical transport, large-diameter pipelines, and systems requiring frequent dismantling or maintenance.

What types of GOST Flanges are available?

GOST Flanges come in several types to meet specific operational requirements:

Weld Neck (WN):

- Designed for high-pressure and high-temperature applications.

- The long tapered hub allows gradual stress transfer from flange to pipe.

- Suitable for critical pipelines in oil, gas, and petrochemical plants.

Slip-On (SO):

- Easier to install than WN, less expensive.

- Suitable for low-to-medium pressure systems.

- Installed by sliding over the pipe and welding around the hub.

Blind (BL):

- Used to close the ends of piping systems.

- Allows for pressure testing and future expansion or maintenance.

Threaded (TH):

- Can be connected without welding.

- Ideal for low-pressure systems, often in gas distribution or small pipelines.

Lap Joint (LJ):

- Used with stub ends, allows rotation for alignment.

- Cost-effective in large-diameter pipes and frequent dismantling applications.

How do GOST Flanges differ from EN or ASME flanges?

Standards: GOST follows Russian GOST 12820-80 series, EN flanges follow EN 1092-1, and ASME flanges follow ASME B16.5 / B16.47.

Dimensional Differences: Slight variations in OD, BCD, thickness, and PN ratings.

Global Usage:

- GOST: Russia, CIS countries, and select international projects.

- EN / ASME: Widely used globally in industrial, oil & gas, and power plant systems.