ASME B16.9 Fittings : Specifications | Materials | Dimensions | Wall Thickness | Weight Chart | Tolerances | FAQ

Top Exporter of ASME B16.9 Buttweld Fittings – Seamless & Welded Elbows, Tees, Reducers, and Caps – Offered in Carbon Steel, Stainless Steel, Alloy Steel & Nickel – Sizes ½”–48”, Available in Various Pipe Schedules (Sch 5S–Sch XXS) – Delivering to UAE, India, UK, Mexico & Australia

Best Export Prices: sales@midlandforgefittings.com

At Midland Forge and Fittings, we manufacture and supply ASME B16.9 Buttweld Fittings, including elbows, tees, reducers, and caps. Each fitting is precision-engineered using advanced forging techniques to meet strict dimensional tolerances, pressure ratings, and material standards for industrial pipelines in oil & gas, petrochemical, power, and water treatment sectors.

Our production follows a rigorous quality system, with material verification, dimensional inspection, and hydrostatic testing at every stage. We ensure safe handling, accurate welding, and precise measurements for leak-proof performance and long-term durability under high-pressure and high-temperature conditions.

ASME B16.9 is the recognized standard for buttweld fittings used in piping systems, covering dimensions, tolerances, and pressure ratings for fittings ranging from ½” to 48” NPS. It ensures uniformity across elbows, tees, reducers, and caps, allowing seamless integration in industrial pipelines. The standard defines wall thickness, bend radius, center-to-end dimensions, and weight charts, which are critical for accurate stress calculations and pipeline design.

The standard specifies material requirements to accommodate different industrial environments. Carbon Steel, Stainless Steel, Alloy Steel, and Nickel Alloys are included, each with defined mechanical properties, corrosion resistance, and temperature ratings. ASME B16.9 also provides guidelines for tolerances on OD, BCD, wall thickness, and end preparation, ensuring leak-proof connections and structural integrity under high-pressure and high-temperature conditions.

ASME B16.9 covers fitting types and geometrical specifications to suit different pipeline layouts. Long-radius and short-radius elbows, concentric and eccentric reducers, and caps are standardized to facilitate proper flow dynamics, reduced turbulence, and stress distribution. Compliance with B16.9 ensures fittings are interchangeable, reliable, and compatible with other piping components across global industrial applications.

We believe in client collaboration and transparency. Our team works directly with customers to understand their unique requirements, recommend the right material grade—be it Carbon Steel, Stainless Steel, Alloy Steel, or Nickel—and suggest the most suitable fitting type. Our company culture prioritizes timely delivery, efficient project management, and a skilled workforce, making us a trusted partner for global clients seeking high-quality ASME B16.9 Buttweld Fittings.

ASME B16.9 Fittings Specifications

Size Range – Seamless

Wall Thickness

Marking

Fitting Types

Size Range – Welded

Ends Connection

Manufacturing Standards for ASTM

Materials

Size Range – Fabricated

Dimensional Standards

Testing

Surface Finish

Pipe Fittings - Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use/Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A403 WP304/304L/304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A403 WP316/316L/316H | Marine & chemical applications | |

| 317 / 317L | ASTM A403 WP317/317L | High corrosion resistance | |

| 321 / 321H | ASTM A403 WP321/321H | High temperature, stabilized | |

| 347 / 347H | ASTM A403 WP347/347H | High-temp pressure systems | |

| 904L | ASTM A403 WP904L / B625 | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A403 / B366 | High chloride environments | |

| Carbon Steel | A234 WPB / WPC | ASTM A234 | Pressure piping & general piping systems |

| A420 WPL6 | ASTM A420 | Low temperature services | |

| Alloy Steel | A234 WP1 / WP5 / WP9 | ASTM A234 | High-temp & pressure pipelines |

| A234 WP11 / WP22 | ASTM A234 | Steam lines & refineries | |

| A234 WP91 | ASTM A234 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A815 / A790 | Corrosion & high strength use |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A815 / A790 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B366 / B162 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B366 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B366 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B366 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B366 | Seawater, chemical industries | |

| Alloy 20 | ASTM B366 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B366 / B637 | High-temp applications | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B466 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B363 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B361 | Low-pressure, non-corrosive piping |

Explore All Standards

- Standards

- ASME B16.5 Flanges

- ASME B16.47 Large Diameter Flanges

- ASME B16.9 Buttweld Fittings

- ASME B16.11 Forged Fittings

- ASME B16.28 Wrought Steel Elbows

- MSS SP-43 Stainless Steel Buttweld Fittings

- MSS SP-75 High Strength Butt Weld Fittings

- DIN Flanges

- EN Flanges

- GOST Flanges

- JIS Flanges

- MSS SP-95 – Swage Nipples & Bull Plugs

- MSS SP-97 – Integrally Reinforced Branch Outlets

- API 6A – Wellhead Flanges & Equipment

- API 605 – Large Diameter Flanges (replaced by ASME B16.47)

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

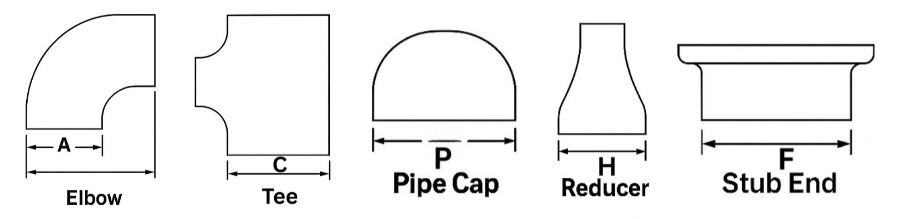

ANSI/ASME B16.9 Fittings– Size Range & Dimensions

| NPS (in) | Elbow (90°) A (mm) | Tee C (mm) | Reducer H (mm) | End Cap P (mm) | Stub End F (mm) |

|---|---|---|---|---|---|

| 1/2 | 38 | 25 | 76 | 25 | 16 |

| 3/4 | 38 | 29 | 76 | 29 | 19 |

| 1 | 38 | 38 | 89 | 38 | 22 |

| 1 1/4 | 48 | 48 | 102 | 48 | 25 |

| 1 1/2 | 57 | 57 | 114 | 57 | 29 |

| 2 | 76 | 64 | 127 | 64 | 32 |

| 2 1/2 | 95 | 76 | 140 | 76 | 35 |

| 3 | 114 | 86 | 152 | 86 | 38 |

| 3 1/2 | 133 | 95 | 165 | 95 | 41 |

| 4 | 152 | 105 | 178 | 105 | 44 |

| 5 | 190 | 127 | 203 | 127 | 48 |

| 6 | 229 | 152 | 229 | 152 | 51 |

| 8 | 305 | 203 | 254 | 203 | 57 |

| 10 | 381 | 254 | 305 | 254 | 64 |

| 12 | 457 | 305 | 356 | 305 | 70 |

| 14 | 533 | 337 | 381 | 337 | 76 |

| 16 | 610 | 386 | 406 | 386 | 83 |

| 18 | 686 | 419 | 457 | 419 | 89 |

| 20 | 762 | 457 | 508 | 457 | 95 |

| 22 | 838 | 495 | 559 | 495 | 102 |

| 24 | 914 | 521 | 610 | 521 | 108 |

| 26 | 991 | 559 | 660 | 559 | 114 |

| 28 | 1067 | 597 | 711 | 597 | 121 |

| 30 | 1143 | 635 | 762 | 635 | 127 |

| 32 | 1219 | 673 | 813 | 673 | 133 |

| 34 | 1295 | 711 | 864 | 711 | 140 |

| 36 | 1372 | 749 | 914 | 749 | 146 |

| 38 | 1448 | 787 | 965 | 787 | 152 |

| 40 | 1524 | 825 | 1016 | 825 | 159 |

| 42 | 1600 | 864 | 1067 | 864 | 165 |

| 44 | 1676 | 902 | 1118 | 902 | 172 |

| 46 | 1753 | 940 | 1168 | 940 | 178 |

| 48 | 1829 | 978 | 1219 | 978 | 184 |

ASME B16.9 – Wall Thickness SCH 5 - SCH XXS

| Nominal Pipe Size (NPS) |

Outside Diameter (OD, mm) |

Schedule 5S / 5 / 10S / 10 (mm) |

Schedule 40S / 40 (mm) |

Schedule 80S / 80 (mm) |

Schedule 160 / XXS (mm) |

|---|---|---|---|---|---|

| ½″ | 21.3 | 2.77 | 2.87 | 3.91 | 5.16 |

| ¾″ | 26.7 | 2.77 | 2.87 | 3.91 | 5.16 |

| 1″ | 33.4 | 2.87 | 3.38 | 4.55 | 6.02 |

| 1½″ | 48.3 | 3.05 | 3.68 | 5.16 | 7.11 |

| 2″ | 60.3 | 3.05 | 3.91 | 5.49 | 7.62 |

| 3″ | 88.9 | 3.91 | 5.49 | 7.11 | 11.13 |

| 4″ | 114.3 | 3.91 | 6.02 | 8.56 | 12.70 |

| 6″ | 168.3 | 4.19 | 7.11 | 10.97 | 15.09 |

| 8″ | 219.1 | 4.57 | 8.18 | 12.70 | 18.26 |

| 10″ | 273.0 | 4.78 | 9.27 | 15.09 | 20.77 |

| 12″ | 323.9 | 4.88 | 10.97 | 16.13 | 22.23 |

| 14″ | 355.6 | 4.88 | 12.70 | 17.48 | 24.64 |

| 16″ | 406.4 | 5.16 | 12.70 | 19.05 | 26.67 |

| 18″ | 457.0 | 5.49 | 14.27 | 20.77 | 29.21 |

| 20″ | 508.0 | 5.49 | 15.09 | 22.23 | 31.75 |

| 24″ | 610.0 | 5.72 | 16.13 | 25.40 | 38.10 |

ASME B16.9 Pipe Fittings – Weight Chart

| Size (Inches) | 90° Elbow (kg) | 45° Elbow (kg) | 180° Return (kg) | Equal Tee (kg) | Concentric Reducer (kg) | Cap (kg) |

|---|---|---|---|---|---|---|

| ½” | 0.15 | 0.08 | 0.20 | 0.20 | 0.10 | 0.08 |

| ¾” | 0.25 | 0.13 | 0.35 | 0.30 | 0.15 | 0.12 |

| 1″ | 0.40 | 0.20 | 0.55 | 0.45 | 0.25 | 0.20 |

| 1½” | 0.90 | 0.45 | 1.20 | 1.10 | 0.70 | 0.60 |

| 2″ | 1.40 | 0.70 | 1.85 | 1.75 | 1.10 | 0.90 |

| 3″ | 3.40 | 1.70 | 4.50 | 4.30 | 2.60 | 2.30 |

| 4″ | 6.00 | 3.00 | 8.20 | 7.80 | 4.60 | 4.00 |

| 6″ | 12.00 | 6.00 | 16.50 | 15.00 | 9.60 | 8.50 |

| 8″ | 20.00 | 10.00 | 27.50 | 26.00 | 16.00 | 14.00 |

| 10″ | 31.00 | 15.50 | 42.00 | 40.00 | 24.00 | 22.00 |

| 12″ | 45.00 | 22.50 | 61.00 | 58.00 | 35.00 | 32.00 |

| 14″ | 60.00 | 30.00 | 82.00 | 78.00 | 48.00 | 43.00 |

| 16″ | 78.00 | 39.00 | 107.00 | 102.00 | 64.00 | 58.00 |

| 18″ | 100.00 | 50.00 | 137.00 | 130.00 | 82.00 | 74.00 |

| 20″ | 125.00 | 62.50 | 171.00 | 162.00 | 105.00 | 95.00 |

| 24″ | 180.00 | 90.00 | 246.00 | 230.00 | 145.00 | 130.00 |

| 26″ | 210.00 | 105.00 | 285.00 | 265.00 | 170.00 | 150.00 |

| 28″ | 240.00 | 120.00 | 325.00 | 300.00 | 195.00 | 170.00 |

| 30″ | 275.00 | 137.50 | 372.00 | 340.00 | 225.00 | 200.00 |

| 32″ | 310.00 | 155.00 | 420.00 | 380.00 | 250.00 | 225.00 |

| 36″ | 380.00 | 190.00 | 515.00 | 460.00 | 310.00 | 280.00 |

| 40″ | 460.00 | 230.00 | 620.00 | 550.00 | 380.00 | 340.00 |

| 42″ | 500.00 | 250.00 | 675.00 | 600.00 | 410.00 | 370.00 |

| 44″ | 540.00 | 270.00 | 730.00 | 645.00 | 440.00 | 400.00 |

| 48″ | 620.00 | 310.00 | 840.00 | 730.00 | 500.00 | 455.00 |

Tolerances as per ASME B16.9

| Fitting Type | Parameter | Tolerance | |

|---|---|---|---|

| Up to 4” NPS | Above 4” NPS | ||

| Elbows | Outside Diameter at Bevel | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) |

| Center-to-End (A, B) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Ovality | Shall not exceed 1% of specified OD | ||

| Tees | Center-to-End (Run & Branch) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) |

| Outside Diameter | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Reducers | Large End OD | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) |

| Small End OD | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) | |

| End-to-End Length | ±3.2 mm (1/8″) | ±6.4 mm (1/4″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Caps | Outside Diameter at Bevel | ±1.6 mm (1/16″) | ±1.6 mm (1/16″) |

| Length (H) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Stub Ends | Lap Diameter | ±0.8 mm (1/32″) | ±1.6 mm (1/16″) |

| Length | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) | |

| Wall Thickness | -12.5% (no positive tolerance) | ||

| Cross | Center-to-End (Run & Branch) | ±1.6 mm (1/16″) | ±3.2 mm (1/8″) |

| Wall Thickness | -12.5% (no positive tolerance) | ||

What formulas are used to calculate the pressure rating of ASME B16.9 fittings?

- Unlike flanges, B16.9 does not assign classes; pressure rating is derived from pipe schedule, wall thickness, and material.

-

Point-wise:

-

Basic formula:

P = (2 × S × t) / (D − 0.6 t)

Where:

- P = allowable internal pressure

- S = allowable stress of the material at design temperature

- t = wall thickness

- D = outside diameter

- Temperature derating: As temperature increases, allowable stress S decreases; thus, P reduces.

- Fitting geometry factor: For elbows and tees, the radius and branch geometry introduce stress concentration factors.

- Safety factor: Design codes (B31.1/B31.3) apply minimum safety factors for permanent welded systems.

-

Basic formula:

How are wall thicknesses for ASME B16.9 fittings determined and standardized?

-

Wall thickness in B16.9 fittings is strictly linked to pipe schedule (Sch) and material grade.

- Schedule correlation: Each schedule (Sch 5S, 10S, 40S, 80S, 160/XXS) has a defined wall thickness for each NPS.

- Dimensional matching: The OD of the fitting must match the OD of the corresponding pipe schedule.

- Pressure capability: Thicker walls increase allowable pressure; thin walls limit service pressure.

- Material adjustments: Stainless steel schedules (S suffix) differ slightly in thickness compared to carbon steel for identical pressure rating.

- Manufacturing tolerance: Wall thickness tolerances are defined to ±12.7% (as per ASTM/ASME guidance) for small sizes; larger sizes allow ±3.2 mm.

How do bending radius and fitting type affect dimensional compliance in B16.9?

Elbows, tees, and reducers have specific dimensional tolerances:

- Elbow radius: 1D (short radius) vs 1.5D (long radius) – radius affects center-to-end distance.

- Reducers: Concentric vs eccentric; center-to-end varies with diameter reduction ratio.

- Tolerances: ±1.6 mm for small OD, ±3.2 mm for larger OD on center-to-end and bend radius.

- Impact on welding: Incorrect radius or center-to-end length can cause misalignment and stress concentration during assembly.

- Flow efficiency: Long-radius elbows reduce turbulence; short-radius elbows are space-saving but increase pressure drop.