ASME B16.11 Threaded Fittings : Specifications | Materials | Dimensions | Pressure Class | Weight Chart | Tolerances | FAQ

ASME B16.11 Forged Fittings Manufacturer – Socket Weld & Threaded Elbows, Tees, Couplings, and End Caps – Available in Carbon, Stainless & Alloy Steel, High Nickel Alloy – ½”–4” Sizes, 2000# & 3000# Pressure Ratings – Serving France, Italy, Japan, South Africa & UAE

Best Export Prices: sales@midlandforgefittings.com

We are a trusted manufacturer and exporter of ASME B16.11 Forged Fittings, offering socket weld and threaded elbows, tees, couplings, and caps in carbon steel, stainless steel, and alloy steel. Sizes range from ½” to 4” with pressure classes 2000# & 3000#, engineered to meet ASME standards for high-pressure, high-temperature, and corrosion-resistant performance.

Our company follows a quality-driven, customer-focused approach, with strict inspection at every stage, timely delivery, and technical support. We prioritize ethical practices, innovation, and international compliance, ensuring reliable, precise, and durable piping solutions.

ASME B16.11 Fittings are manufactured using high-grade alloys that provide excellent tensile and yield strength, ensuring durability under dynamic and cyclic loads. The forging process eliminates porosity and internal defects, resulting in uniform grain structure and enhanced fatigue resistance. Materials are selected based on corrosion resistance, temperature rating, and chemical compatibility, making these fittings suitable for highly demanding process environments.

These fittings are engineered to precise tolerances for socket, thread, and face dimensions, ensuring interchangeability and leak-free connections. They strictly conform to ASME B16.11 dimensions, ASTM material specifications, and NPT/Socket weld thread standards. Dimensional accuracy includes center-to-end length, bore alignment, and socket depth, allowing smooth welding or threading operations without misalignment or stress concentration.

B16.11 are ideal for high-pressure, high-temperature, and corrosive piping systems in refineries, chemical plants, power stations, and offshore platforms. The combination of precise forging, controlled heat treatment, and high-strength materials provides superior resistance to erosion, cracking, and thermal expansion stresses. These fittings are designed to maintain structural integrity under transient pressures and vibration, ensuring long-term system reliability and safety.

At our company, we prioritize long-term partnerships and customer satisfaction. Our team of experts works closely with clients to provide customized solutions, expert guidance, and prompt after-sales support. With a focus on precision manufacturing, global logistics, and sustainable practices, we have become a preferred supplier of ASME B16.11 Forged Fittings for markets in UAE, USA, UK, India, Germany, and Australia.

ASME B16.11 Fittings Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Screwed / Threaded Fittings - Materials, Grades & Standards

| Material Category | Standards (ASTM / ASME) Grades | Typical Use / Application |

|---|---|---|

| Stainless Steel | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| ASTM A182 F317 / F317L | High corrosion resistance | |

| ASTM A182 F321 / F321H | High temperature, stabilized service | |

| ASTM A182 F347 / F347H | High-temp, pressure systems | |

| ASTM A182 F904L | Acid handling, sulfuric environments | |

| ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | ASTM A105 | Pressure piping & general industries |

| ASTM A350 LF2 | Low temperature services | |

| ASTM A694F42 / F46 / F52 / F56 / F60 / F65 / F70 | High-pressure pipelines, oil & gas | |

| Alloy Steel | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| ASTM A182 F11 / F22 | Steam lines & refineries | |

| ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | ASTM A182 F51 / F60, UNS S31803 / S32205 | Corrosion resistance, high strength |

| Super Duplex Steel | ASTM A182 F53 / F55, UNS S32750 / S32760 | Offshore, seawater applications |

| Nickel Alloys | ASTM B564 Nickel 200 / 201 | Alkali & chemical processing |

| ASTM B564 Inconel 600 / 625 / 718 | Heat exchangers, aerospace | |

| ASTM B564 Incoloy 800 / 825 | Petrochemical & chemical processing | |

| ASTM B564 Hastelloy C22 / C276 | Severe corrosion resistance | |

| ASTM B564 Monel 400 / K500 | Seawater, marine engineering | |

| ASTM B564 Alloy 20 | Sulfuric acid services | |

| ASTM B564 / B637 Nimonic 75 / 80A | High-temp aerospace & turbines | |

| Copper Nickel | ASTM B151 / B467 Cu-Ni 90/10 / 70/30 | Marine systems, seawater service |

| Titanium | ASTM B381 Grade 2 / Grade 5 | Lightweight, corrosion resistance |

| Aluminium | ASTM B247 6061 / 5083 | Low-pressure, non-corrosive piping |

Explore All Standards

- Standards

- ASME B16.5 Flanges

- ASME B16.47 Large Diameter Flanges

- ASME B16.9 Buttweld Fittings

- ASME B16.11 Forged Fittings

- ASME B16.28 Wrought Steel Elbows

- MSS SP-43 Stainless Steel Buttweld Fittings

- MSS SP-75 High Strength Butt Weld Fittings

- DIN Flanges

- EN Flanges

- GOST Flanges

- JIS Flanges

- MSS SP-95 – Swage Nipples & Bull Plugs

- MSS SP-97 – Integrally Reinforced Branch Outlets

- API 6A – Wellhead Flanges & Equipment

- API 605 – Large Diameter Flanges (replaced by ASME B16.47)

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

ANSI/ASME B16.11 Socket Weld Fittings– Size Range & Dimensions

| Nom, Pipe Size | Depth of Sock, Min | Sock, Bore Diameter B | Bore Diameter of Fitting D | Wall Thickness Minimum | entre to Bottom of Socket | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 90º Elbows, Tee & Crosses | 45º Elbows | |||||||||||

| A | A | |||||||||||

| 3000# | 6000# | Sock, C | Body G | Sock C | Body G | 3000# | 6000# | 3000# | 6000# | |||

| 1/8” | 3/8 | .420 .430 | .254 .284 | .141 | .125 | .095 | .135 | .124 | 7/16 | 7/16 | 5/16 | 5/16 |

| 1/4 | 3/8 | .555 .565 | .349 .379 | .235 | .130 | .119 | .158 | .145 | 7/16 | 17/32 | 5/16 | 5/16 |

| 3/8 | 3/8 | .690 .700 | .478 .508 | .344 | .138 | .126 | .172 | .158 | 17/32 | 5/8 | 5/16 | 7/16 |

| 1/2 | 3/8 | .855 .865 | .607 .637 | .451 | .161 | .147 | .204 | .188 | 5/8 | 3/4 | 7/16 | 1/2 |

| 3/4 | 1/2 | 1.065 1.075 | .809 .839 | .599 | .168 | .154 | .238 | .219 | 3/4 | 7/8 | 1/2 | 9/16 |

| 1 | 1/2 | 1.330 1.340 | 1.034 1.064 | .800 | .196 | .179 | .273 | .250 | 7/8 | 1-1/16 | 9/16 | 11/16 |

| 1-1/4 | 1/2 | 1.675 1.685 | 1.365 1.395 | 1.145 | .208 | .191 | .273 | .250 | 1-1/16 | 1-1/4 | 11/16 | 13/16 |

| 1-1/2 | 1/2 | 1.915 1.925 | 1.595 1.625 | 1.323 | .218 | .200 | .307 | .281 | 1-1/4 | 1-1/2 | 13/16 | 1 |

| 2 | 5/8 | 2.406 2.416 | 2.052 2.082 | 1.674 | .238 | .218 | .374 | .344 | 1-1/2 | 1-5/8 | 1 | 1-1/8 |

| 2-1/2 | 5/8 | 2.906 2.921 | 2.439 2.499 | .301 | .276 | .375 | 1-5/8 | 1-1/8 | ||||

| 3 | 5/8 | 3.535 3.550 | 3.038 3.098 | .327 | .300 | .438 | 2-1/4 | 1-1/4 | ||||

| 4 | 3/4 | 4.545 4.560 | 3.996 4.055 | .368 | .337 | .531 | 2-5/8 | 1-5/8 | ||||

ANSI/ASME B16.11 Threaded Fittings– Size Range & Dimensions

| Nominal Pipe Size | End to End Couplings W | Outside Diameter D | End to End Caps H | End Wall Thickness G Min | |||

|---|---|---|---|---|---|---|---|

| 3000# & 6000# | 3000# | 6000# | 3000# | 6000# | 3000# | 6000# | |

| 1/8 | 1-1/4 | 5/8 | 7/8 | 3/4 | 3/16 | ||

| 1/4 | 1-3/8 | 3/4 | 1 | 1 | 1-1/16 | 3/16 | 1/4 |

| 3/8 | 1-1/2 | 7/8 | 1-1/4 | 1 | 1-1/16 | 3/16 | 1/4 |

| 1/2 | 1-7/8 | 1-1/8 | 1-1/2 | 1-1/4 | 1-5/16 | 1/4 | 5/16 |

| 3/4 | 2 | 1-3/8 | 1-3/4 | 1-7/16 | 1-1/2 | 1/4 | 5/16 |

| 1 | 2-3/8 | 1-3/4 | 2-1/4 | 1-5/8 | 1-11/16 | 3/8 | 7/16 |

| 1-1/4 | 2-5/8 | 2-1/4 | 2-1/2 | 1-3/4 | 1-13/16 | 3/8 | 7/16 |

| 1-1/2 | 3-1/8 | 2-1/2 | 3 | 1-3/4 | 1-7/8 | 7/16 | 1/2 |

| 2 | 3-3/8 | 3 | 3-5/8 | 1-7/8 | 2 | 1/2 | 5/8 |

| 2-1/2 | 3-5/8 | 3-5/8 | 4-1/4 | 2-3/8 | 2-1/2 | 5/8 | 3/4 |

| 3 | 4-1/4 | 4-1/4 | 5 | 2-9/16 | 2-11/16 | 3/4 | 7/8 |

| 4 | 4-3/4 | 5-1/2 | 6-1/4 | 2-11/16 | 2-15/16 | 7/8 | 1-1/8 |

ASME B16.11 – pressure classes (2000, 3000, 6000)

| Pressure Class | Nominal Pipe Size (NPS) Range |

Minimum Wall Thickness* |

Typical Working Pressure* |

|---|---|---|---|

| Class 2000 | ½″ – 4″ | Lightest of the series | ≈ 2000 psi (≈ 138 bar) at 100 °F |

| Class 3000 | ½″ – 4″ | Heavier than 2000 | ≈ 3000 psi (≈ 207 bar) at 100 °F |

| Class 6000 | ½″ – 2″ † | Extra-heavy wall | ≈ 6000 psi (≈ 414 bar) at 100 °F |

| Class 9000 ‡ | ½″ – 2″ † | Ultra-heavy wall | ≈ 9000 psi (≈ 620 bar) at 100 °F |

ASME B16.11 Fittings – Weight Chart

| Size (NPS) | Socket-Weld Class 3000 | Socket-Weld Class 6000 | Socket-Weld Class 9000 | Threaded Class 2000 | Threaded Class 3000 | Threaded Class 6000 |

|---|---|---|---|---|---|---|

| 1/8″ | 0.09 kg | 0.15 kg | — | 0.21 kg | 0.23 kg | 0.56 kg |

| 1/4″ | 0.09 kg | 0.15 kg | — | 0.24 kg | 0.30 kg | 0.58 kg |

| 3/8″ | 0.12 kg | 0.32 kg | — | 0.47 kg | 0.58 kg | 0.91 kg |

| 1/2″ | 0.26 kg | 0.40 kg | 0.85 kg | 0.73 kg | 0.91 kg | 1.54 kg |

| 3/4″ | 0.35 kg | 0.65 kg | 1.48 kg | 1.03 kg | 1.29 kg | 2.25 kg |

| 1″ | 0.52 kg | 1.25 kg | 2.20 kg | 1.46 kg | 2.02 kg | 2.84 kg |

| 1¼″ | 0.85 kg | 1.40 kg | 2.90 kg | 1.77 kg | 2.29 kg | 5.12 kg |

| 1½″ | 1.05 kg | 2.35 kg | 3.50 kg | 3.03 kg | 4.54 kg | 6.82 kg |

| 2″ | 1.75 kg | 2.96 kg | 4.35 kg | 8.07 kg | 5.26 kg | 10.28 kg |

| 2½″ | 2.80 kg | — | — | 9.46 kg | 7.83 kg | 15.00 kg |

| 3″ | 4.60 kg | — | — | 24.57 kg | 12.99 kg | 35.20 kg |

| 4″ | 9.60 kg | — | — | — | 24.75 kg | — |

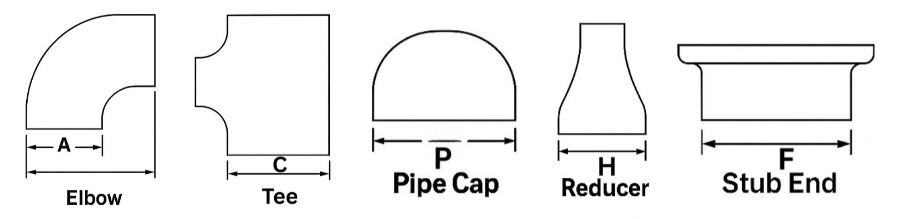

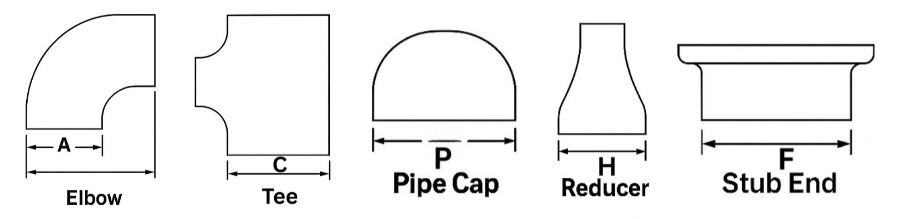

Tolerances as per ASME B16.11

| Dimension / Parameter | Tolerance | Remarks / Reference |

|---|---|---|

| Center-to-End (A, B, C) | ± 1.5 mm | For Elbows, Tees, Crosses |

| Overall Length (Couplings, Caps) | ± 1.5 mm | As per ASME B16.11 |

| Socket Bore Diameter (B) | +0.15 mm / -0.00 mm | For Socket-Weld Ends |

| Outside Diameter at Welding End | ± 1.0 mm | |

| Wall Thickness | Not less than nominal specified | Minimum per standard |

| Thread Dimensions | As per ASME B1.20.1 | NPT Taper Pipe Threads |

| Socket Depth (Minimum) | As specified in ASME B16.11 | Varies with size & class |

How does forging method influence the performance of ASME B16.11 fittings?

-

Closed-Die Forging:

- Produces a uniform grain flow that follows the contour of elbows, tees, and couplings.

- Enhances directional strength and fatigue resistance, critical for high-cycle pressure systems.

-

Upset Forging for Couplings:

- Controls wall thickness at the thread root to prevent stress concentration.

- Reduces machining allowance, ensuring dimensional repeatability.

- The standard mandates that the forging ratio (reduction of cross-section) is sufficient to eliminate centerline segregation and porosity.

How are ASME B16.11 fittings tested and inspected?

- Visual & Dimensional Inspection: 100 % verification of dimensions and surface finish.

-

Non-Destructive Examination (NDE):

- Magnetic Particle or Liquid Penetrant for surface cracks.

- Ultrasonic or Radiographic testing when ordered for critical service.

- Hydrostatic Pressure Test: Usually performed by the fabricator or end user; fittings must withstand at least 1.5 × design pressure without leakage.

- Material Test Reports (MTRs): Must show chemical analysis and mechanical properties traceable to the forging heat.

What differentiates Class 9000 threaded fittings from lower classes?

- Ultra-heavy wall thickness enabling working pressures approaching 620 bar (≈ 9000 psi) at 100 °F.

- Only manufactured in small sizes (½″–2″) to maintain machinability and thread integrity.

- Typically used in subsea manifolds, hydraulic fracturing skids, and high-pressure chemical injection lines.