- Home

- Forged Fittings

- Socket Weld & Threaded Union

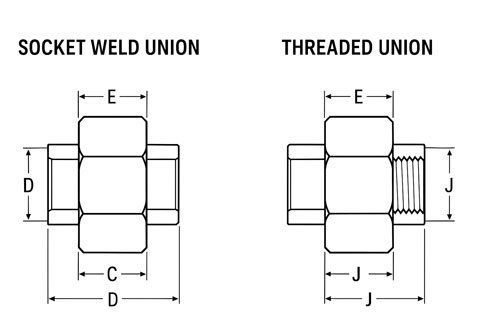

Socket Weld & Threaded Union

Forged Union : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

High-Quality ASME B16.11 Forged Socket Weld & Threaded Unions – Leading Manufacturer & Exporter in Stainless Steel, Carbon Steel, Alloy Steel & Nickel Alloys | India, Singapore & Canada

Best Export Prices: sales@midlandforgefittings.com

At Midland Forge and Fittings Pvt. Ltd., we pride ourselves on being a trusted manufacturer and supplier of forged fittings that meet international standards of safety, reliability, and performance. Our commitment to engineering excellence ensures that every product is crafted with precision and durability to withstand demanding operating conditions.

Our company follows a strict quality-first policy, supported by advanced manufacturing facilities and rigorous testing procedures. We believe in delivering not just products but complete solutions that add value to our client’s projects. By adhering to ethical business practices, on-time delivery schedules, and customer-focused service, Midland Forge continues to build long-term partnerships worldwide.

Among our specialized products, Forged Unions play a vital role in connecting two pipes while allowing easy disassembly when required. Available in a wide range of sizes (½” to 4”) and pressure classes (2000lb, 3000lb, 6000lb), these unions are designed and manufactured in compliance with ASME B16.11 standards for reliability and durability.

Socket Weld Unions are ideal for high-pressure applications, providing a strong, leak-proof joint with excellent mechanical strength. They are widely used in pipelines where secure welding and permanent sealing are essential.

Threaded Unions offer easy installation and disassembly without welding, making them perfect for maintenance, temporary connections, or low to medium pressure systems. They provide flexibility, strong performance, and long service life.

Forged Union Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Socket Weld Union– Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Types of ASME B16.11 Forged Union Fittings

Dimensions of ASME B16.11 Socket weld Union (Class 3000)

| NPS (DN) | End to End (E) | OD of Band (H) | Bore Diameter (D) | Socket Depth (C) |

|---|---|---|---|---|

| 1/2″ (15) | 79 | 35 | 16.6 | 14.7 |

| 3/4″ (20) | 95 | 41 | 21.7 | 19.1 |

| 1″ (25) | 111 | 51 | 27.4 | 22.4 |

| 1-1/4″ (32) | 127 | 60 | 36.6 | 28.4 |

| 1-1/2″ (40) | 143 | 67 | 42.1 | 31.8 |

| 2″ (50) | 159 | 83 | 52.5 | 38.1 |

| 2-1/2″ (65) | 175 | 95 | 62.7 | 44.5 |

| 3″ (80) | 191 | 108 | 77.9 | 47.8 |

| 4″ (100) | 229 | 140 | 103.9 | 57.2 |

Dimensions of ASME B16.11 Threaded Union (Class 3000)

| NPS (DN) | End to End (E) | OD of Band (H) | Min. Thread Length (J) |

|---|---|---|---|

| 1/2″ (15) | 79 | 35 | 10.9 |

| 3/4″ (20) | 95 | 41 | 12.7 |

| 1″ (25) | 111 | 51 | 14.7 |

| 1-1/4″ (32) | 127 | 60 | 17.0 |

| 1-1/2″ (40) | 143 | 67 | 17.8 |

| 2″ (50) | 159 | 83 | 19.0 |

| 2-1/2″ (65) | 175 | 95 | 23.6 |

| 3″ (80) | 191 | 108 | 25.4 |

| 4″ (100) | 229 | 140 | 27.0 |

Weight Chart: ASME B16.11 Forged Union (Class 3000, Socket Weld & Threaded, Carbon Steel / Stainless Steel)

| NPS (inches) | DN | Approx. Weight (kg) |

|---|---|---|

| 1/2″ | 15 | 0.40 – 0.45 |

| 3/4″ | 20 | 0.55 – 0.60 |

| 1″ | 25 | 0.85 – 0.95 |

| 1-1/4″ | 32 | 1.40 – 1.50 |

| 1-1/2″ | 40 | 1.70 – 1.90 |

| 2″ | 50 | 2.60 – 2.90 |

| 2-1/2″ | 65 | 4.20 – 4.50 |

| 3″ | 80 | 5.50 – 6.00 |

| 4″ | 100 | 9.00 – 9.80 |

Forged Union Tolerances as per ASME B16.11

| Parameter / Dimension | Tolerance (mm) / Note |

|---|---|

| End-to-End (E) / Overall Length | ±1.5 mm (≤ 60 mm length) / ±2.0 mm (> 60 mm length) |

| Outside Diameter of Band (H) | ±1% or ±1.5 mm (whichever is greater) |

| Socket Bore (D) | +0.3 mm / –0.0 mm (no undersize permitted) |

| Socket Depth (C) | ±1.0 mm |

| Thread Length (J) – Threaded Unions | ±0.8 mm |

| Thread Standard | NPT as per ASME B1.20.1 |

| Concentricity of Bore | Max. 0.8 mm deviation in 100 mm length |

| Alignment of Union Seats | Male & female seats must match smoothly, no visible offset |

What is the primary function of a Forged Union in a piping system?

- A forged union is a detachable pipe fitting that connects two pipes.

- It allows disconnection without cutting or damaging the pipeline.

- Unlike welded joints, it enables repeated assembly and disassembly.

- Ensures a leak-proof connection during operation.

- Highly useful in high-pressure, high-temperature, and corrosive environments.

- Facilitates easy inspection and replacement of pipe sections.

How does a Forged Union maintain sealing integrity under high pressure?

- Designed with metal-to-metal seating surfaces between male and female ends.

- Tightening the nut causes the seating faces to compress together, forming a secure seal.

- Often features precision-machined taper seats or cone-to-cone designs.

- Ensures even stress distribution to prevent leaks.

- Capable of withstanding Class 2000, 3000, and 6000 pressure ratings (ASME B16.11).

What inspection and testing requirements apply to Forged Unions?

- Hydrostatic testing – pressure tightness check

- NDT methods – such as MPI or DPI for detecting surface defects

- Dimensional inspection – performed as per ASME B16.11 tolerances

- Material testing – chemical and mechanical properties checked according to ASTM/ASME codes.

This ensures unions meet the required safety and reliability standards for critical piping applications.