- Home

- Forged Fittings

- Forged Swage Nipple

Forged Swage Nipple

Swage Nipple : Specifications | Materials | Dimensions | Weight Chart | Tolerances | FAQ

Reliable Exporter & Manufacturer of ASME B16.11 Swage Nipples – Sizes ½” to 4”, Class 2000#, 3000#, 6000#, 9000#, Stainless Steel, Carbon Steel, Alloy Steel, and High Nickel Alloys, Supplying to Germany, France, USA, UAE, and Australia

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a trusted manufacturer, supplier, and exporter of high-quality forged fittings for critical piping systems across industries such as oil & gas, petrochemical, refineries, and power plants. With a focus on precision, reliability, and adherence to international standards, Our specializes in delivering ASME B16.11 compliant forged fittings, including Swage Nipples.

Midland Forge maintains strict quality control protocols including hydrostatic testing, non-destructive testing, PMI (Positive Material Identification), and dimensional inspections to ensure each product meets global standards. Our commitment to innovation, timely delivery, and customer-centric solutions makes them a preferred partner for industries worldwide.

An ASME B16.11 Swage Nipple is a short, forged fitting designed to connect pipes of different diameters while ensuring smooth fluid flow and structural integrity under high pressure and temperature conditions. Machined from a single forged piece, Swage Nipples eliminate seams or welds that are prone to failure and provide enhanced fatigue strength due to aligned grain flow. Available in materials like Carbon Steel, Stainless Steel (304, 316, 316L), Alloy Steel, and High Nickel Alloys, these fittings are suitable for high-temperature, cryogenic, and corrosive media. The compact design allows for tight installations in confined spaces, making it ideal for auxiliary piping, vents, drains, and instrumentation connections.

Swage Nipples come in two main types: Concentric and Eccentric, depending on whether the pipe axes are aligned or offset. They are manufactured in pressure classes 2000#, 3000#, 6000#, and 9000#, and in sizes ranging from ½” to 4” to accommodate varying pipe diameters. Concentric Swage Nipples provide a smooth diameter transition with minimal turbulence, while Eccentric Swage Nipples are used when piping alignment or slope requirements exist.

Threaded Swage Nipple Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Concentric Swage Nipple – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

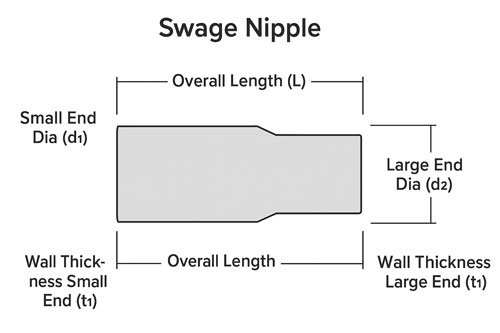

Dimensions of ASME B16.11 Swage Nipple

| Nominal Pipe Size | Pressure Class | Small End Dia (d1) | Large End Dia (d2) | Overall Length (L) | Socket Depth / Engagement (H) | Wall Thickness Small End (t1) | Wall Thickness Large End (t2) |

|---|---|---|---|---|---|---|---|

| ½” | 2000# | 0.84″ | 0.84″ | 2.00″ | 0.50″ | 0.15″ | 0.18″ |

| ½” | 3000# | 0.84″ | 0.84″ | 2.25″ | 0.55″ | 0.19″ | 0.22″ |

| 1” | 2000# | 1.05″ | 1.05″ | 2.50″ | 0.60″ | 0.17″ | 0.20″ |

| 1” | 3000# | 1.05″ | 1.05″ | 2.75″ | 0.65″ | 0.22″ | 0.25″ |

| 2” | 2000# | 2.11″ | 2.11″ | 3.50″ | 0.85″ | 0.28″ | 0.32″ |

| 2” | 6000# | 2.11″ | 2.11″ | 3.75″ | 0.90″ | 0.44″ | 0.50″ |

| 3” | 3000# | 3.15″ | 3.15″ | 4.25″ | 1.10″ | 0.36″ | 0.42″ |

| 3” | 9000# | 3.15″ | 3.15″ | 4.50″ | 1.15″ | 0.54″ | 0.60″ |

| 4” | 3000# | 4.21″ | 4.21″ | 4.75″ | 1.20″ | 0.44″ | 0.50″ |

| 4” | 9000# | 4.21″ | 4.21″ | 5.00″ | 1.25″ | 0.60″ | 0.66″ |

Weight Chart: ASME B16.11 Swage Nipple – Socket Weld / Threaded

| NPS (Small End) x NPS (Large End) | Class 2000 (kg) | Class 3000 (kg) | Class 6000 (kg) | Class 9000 (kg) |

|---|---|---|---|---|

| 1/4 x 1/8 | 0.04 | 0.05 | 0.07 | 0.09 |

| 3/8 x 1/8 | 0.05 | 0.06 | 0.08 | 0.10 |

| 3/8 x 1/4 | 0.06 | 0.08 | 0.10 | 0.13 |

| 1/2 x 1/4 | 0.07 | 0.09 | 0.12 | 0.15 |

| 1/2 x 3/8 | 0.08 | 0.10 | 0.13 | 0.16 |

| 1/2 x 1/2 | 0.09 | 0.11 | 0.14 | 0.18 |

| 3/4 x 1/2 | 0.11 | 0.14 | 0.18 | 0.22 |

| 3/4 x 3/4 | 0.13 | 0.16 | 0.20 | 0.25 |

| 1 x 3/4 | 0.16 | 0.20 | 0.25 | 0.31 |

| 1 x 1 | 0.18 | 0.22 | 0.28 | 0.35 |

| 1 1/4 x 1 | 0.22 | 0.27 | 0.34 | 0.43 |

| 1 1/4 x 1 1/4 | 0.25 | 0.31 | 0.38 | 0.47 |

| 1 1/2 x 1 1/4 | 0.28 | 0.34 | 0.43 | 0.53 |

| 1 1/2 x 1 1/2 | 0.32 | 0.39 | 0.49 | 0.60 |

| 2 x 1 1/2 | 0.40 | 0.49 | 0.61 | 0.75 |

| 2 x 2 | 0.45 | 0.55 | 0.69 | 0.85 |

| 2 1/2 x 2 | 0.55 | 0.67 | 0.83 | 1.02 |

| 2 1/2 x 2 1/2 | 0.63 | 0.77 | 0.96 | 1.18 |

| 3 x 2 1/2 | 0.72 | 0.88 | 1.10 | 1.35 |

| 3 x 3 | 0.80 | 0.98 | 1.22 | 1.50 |

| 4 x 3 | 1.00 | 1.23 | 1.53 | 1.88 |

| 4 x 4 | 1.10 | 1.35 | 1.68 | 2.06 |

| 6 x 4 | 1.40 | 1.72 | 2.15 | 2.65 |

| 6 x 6 | 1.50 | 1.85 | 2.30 | 2.85 |

Eccentric Swage Nipples Tolerances as per ASME B16.11

| NPS (Small x Large) | OD Tolerance | Socket Depth Tolerance | Wall Thickness Tolerance |

|---|---|---|---|

| 1/4 x 1/8 | ±1.6 mm | ±1 mm | ±12.5% |

| 1/2 x 1/4 | ±1.6 mm | ±1 mm | ±12.5% |

| 3/4 x 1/2 | ±1.6 mm | ±1 mm | ±12.5% |

| 1 x 3/4 | ±1.6 mm | ±1 mm | ±12.5% |

| 1 1/2 x 1 1/4 | ±2 mm | ±1 mm | ±12.5% |

| 2 x 1 1/2 | ±2 mm | ±1 mm | ±12.5% |

| 3 x 2 1/2 | ±2.4 mm | ±1.2 mm | ±12.5% |

| 4 x 3 | ±2.4 mm | ±1 |

How does a swage nipple differ from a regular reducing nipple?

- Swage Nipple: Usually socket weld or threaded, reinforced at the small end to withstand welding stresses and maintain pressure integrity.

- Regular Reducing Nipple: Typically just a short pipe with differing diameters, less precise in thickness, often used in low-pressure or non-critical services.

- Swage nipples are forged, ensuring grain continuity, while ordinary reducing nipples may be welded or machined from pipes, which can reduce strength.

Why is forging important for swage nipples?

-

Forging ensures continuous metal grain structure, enhancing:

- Strength under high pressure.

- Resistance to cracking or deformation.

- Fatigue life in dynamic or thermal applications.

- Unlike cast or welded fittings, forged swage nipples are less prone to internal defects, making them suitable for critical pipelines.

How is a swage nipple installed?

-

Socket Weld Type:

- Insert the pipe into the socket depth, leaving a small gap for welding.

- Weld around the socket to ensure a pressure-tight joint.

-

Threaded Type:

- Apply a suitable thread sealant and screw into mating threaded pipe or fitting.

- Proper installation ensures maximum pressure integrity and leak-proof service.