- Home

- Forged Fittings

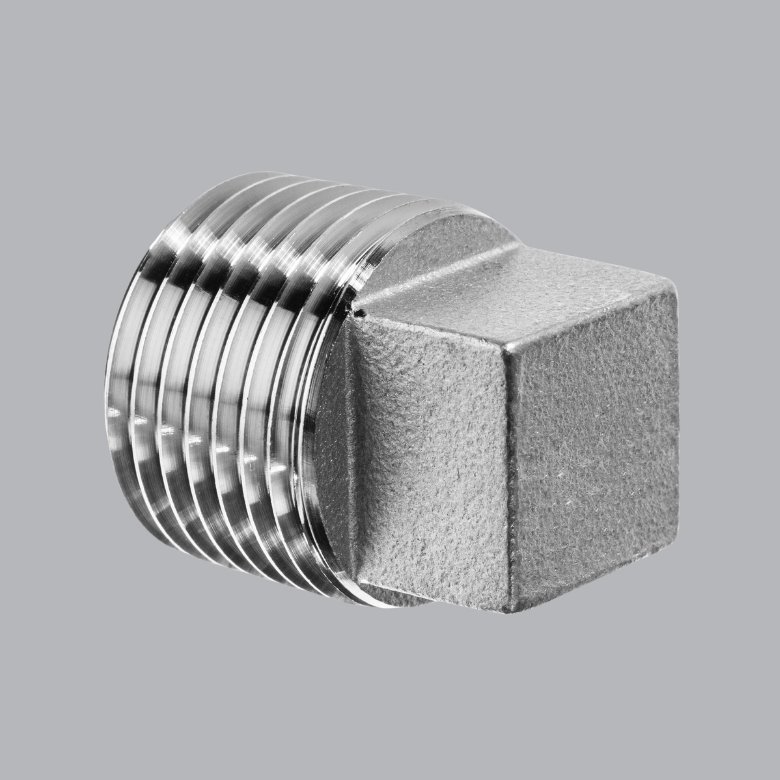

- Threaded Plug

Threaded Plug

Forged Plug : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

ASME B16.11 Forged Plugs – Socket Weld, Threaded, NPT, Hex Head, Square Head & Round Head Manufacturer | Stainless Steel, Carbon Steel & Alloy Steel & High Nickel Alloys | Export to Germany, USA, UAE, Australia & African Countries

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer and exporter specializing in high-quality forged plugs for industrial piping systems. With years of experience in precision forging, our company has earned a reputation for delivering durable and reliable products that comply with international standards such as ASME B16.11. We focus on engineering excellence, ensuring each forged plug meets strict dimensional, material, and pressure requirements.

Our range of forged plugs includes Socket Weld, Threaded, NPT, Hex Head, Square Head, and Round Head types, crafted from stainless steel, carbon steel, and alloy steel. Each product is designed to provide a secure and leak-proof closure for pipelines across industries. We combines advanced forging techniques with rigorous quality checks to ensure every plug withstands high pressure, temperature, and corrosive environments.

At Midland Forge and Fittings, we prioritize customer satisfaction by offering customized solutions, timely delivery, and technical support for all piping needs. Our global export network spans India, USA, UAE, Germany, and beyond, allowing clients worldwide to access premium ASME B16.11 forged plugs. By blending innovation, reliability, and industry expertise, we continue to set benchmarks in high-performance forged fittings and maintain our position as a trusted partner for engineers and procurement teams globally.

Threaded Hex Head Plug Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Forged Threaded Square Head Plug– Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Types of ASME B16.11 Forged Plug Fittings

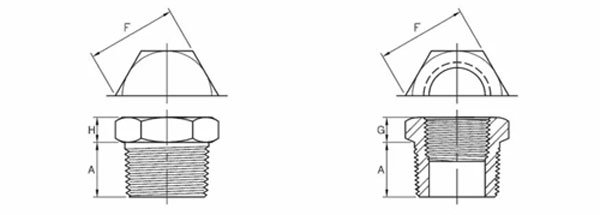

Dimensions of ASME B16.11 Hex Head Plug

| Hex Head Plug | ||||

|---|---|---|---|---|

| DN | Nom. Pipe Size | A (Min) | F (Nom) | H (Min) |

| 6 | 1/8 | 10 | 11.11 | 6 |

| 8 | 1/4 | 11 | 15.88 | 6 |

| 10 | 3/8 | 13 | 17.46 | 8 |

| 15 | 1/2 | 14 | 22.23 | 8 |

| 20 | 3/4 | 16 | 26.99 | 10 |

| 25 | 1 | 19 | 34.93 | 10 |

| 32 | 1-1/4 | 21 | 44.45 | 14 |

| 40 | 1-1/2 | 21 | 50.80 | 16 |

| 50 | 2 | 22 | 63.50 | 18 |

| 65 | 2-1/2 | 27 | 76.20 | 19 |

| 80 | 3 | 28 | 88.90 | 21 |

| 100 | 4 | 32 | 117.48 | 25 |

| Hex Head Gushing | ||||

|---|---|---|---|---|

| DN | Nom. Pipe Size | A (Min) | F (Nom) | G (Min) |

| 8 | 1/4 | 11 | 15.88 | 3 |

| 10 | 3/8 | 13 | 17.46 | 4 |

| 15 | 1/2 | 14 | 22.23 | 5 |

| 20 | 3/4 | 16 | 26.99 | 6 |

| 25 | 1 | 19 | 34.93 | 6 |

| 32 | 1-1/4 | 21 | 44.45 | 7 |

| 40 | 1-1/2 | 21 | 50.80 | 8 |

| 50 | 2 | 22 | 63.50 | 9 |

| 65 | 2-1/2 | 27 | 76.20 | 10 |

| 80 | 3 | 28 | 88.90 | 10 |

| 100 | 4 | 32 | 117.48 | 13 |

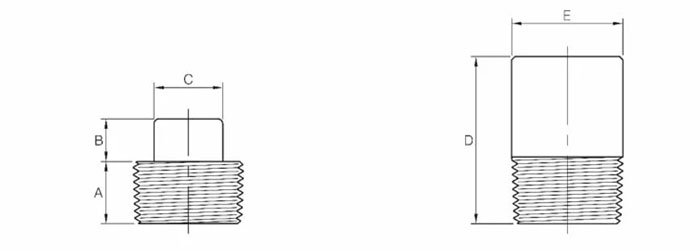

Dimensions of ASME B16.11 Square Head Plug

| Square Head Plug | ||||

|---|---|---|---|---|

| DN | Nom. Pipe Size | A (Min) | B (Min) | C (Min) |

| 6 | 1/8 | 10 | 6 | 7.15 |

| 8 | 1/4 | 11 | 6 | 9.55 |

| 10 | 3/8 | 13 | 8 | 11.11 |

| 15 | 1/2 | 14 | 10 | 14.29 |

| 20 | 3/4 | 16 | 11 | 15.88 |

| 25 | 1 | 19 | 13 | 20.64 |

| 32 | 1-1/4 | 21 | 14 | 23.81 |

| 40 | 1-1/2 | 21 | 16 | 28.58 |

| 50 | 2 | 22 | 18 | 33.27 |

| 65 | 2-1/2 | 27 | 19 | 38.10 |

| 80 | 3 | 28 | 21 | 42.86 |

| 100 | 4 | 32 | 25 | 63.50 |

Dimensions of ASME B16.11 Round Head Plug

| Round Head Plug | |||

|---|---|---|---|

| DN | Nom. Pipe Size | E (Nom) | D (Min) |

| 6 | 1/8 | 10 | 35 |

| 8 | 1/4 | 14 | 41 |

| 10 | 3/8 | 18 | 41 |

| 15 | 1/2 | 21 | 44 |

| 20 | 3/4 | 27 | 44 |

| 25 | 1 | 33 | 51 |

| 32 | 1-1/4 | 43 | 51 |

| 40 | 1-1/2 | 48 | 51 |

| 50 | 2 | 60 | 64 |

| 65 | 2-1/2 | 73 | 70 |

| 80 | 3 | 89 | 70 |

| 100 | 4 | 114 | 76 |

Weight Chart: ASME B16.11 Forged Socket weld Plug

| NPS (in) | DN (mm) | Type | Weight Approx. (kg) |

|---|---|---|---|

| ½” | 15 | SW | 0.20 |

| ½” | 15 | THD | 0.18 |

| ¾” | 20 | SW | 0.25 |

| ¾” | 20 | THD | 0.22 |

| 1″ | 25 | SW | 0.35 |

| 1″ | 25 | THD | 0.30 |

| 1¼” | 32 | SW | 0.50 |

| 1¼” | 32 | THD | 0.45 |

| 1½” | 40 | SW | 0.65 |

| 1½” | 40 | THD | 0.60 |

| 2″ | 50 | SW | 0.95 |

| 2″ | 50 | THD | 0.85 |

| 2½” | 65 | SW | 1.35 |

| 2½” | 65 | THD | 1.25 |

| 3″ | 80 | SW | 1.85 |

| 3″ | 80 | THD | 1.70 |

| 4″ | 100 | SW | 3.00 |

| 4″ | 100 | THD | 2.80 |

| 6″ | 150 | SW | 5.50 |

| 6″ | 150 | THD | 5.00 |

Forged Threaded Plug Tolerances as per ASME B16.11

| Parameter | Socket Weld (SW) | Threaded (THD / NPT) |

|---|---|---|

| Outside Diameter (OD) | ±1.6 mm | ±1.6 mm |

| Socket Bore Diameter | ±0.3 mm | N/A |

| Socket Depth | ±0.8 mm | N/A |

| Wall Thickness | ±12.5% | ±12.5% |

| Length | ±1.5 mm | ±1.5 mm |

| Thread Tolerance | N/A | As per ASME B1.20.1 |

| Angle of Taper (for NPT) | N/A | ±0.5° |

What types of forged plugs are available under ASME B16.11?

ASME B16.11 forged plugs are available in several types, each designed for specific piping needs:

- Socket Weld (SW) Plug – Used for permanent welded connections; ideal for high-pressure pipelines where strong, leak-proof joints are required.

- Threaded (THD) Plug – Screwed into threaded fittings; suitable for temporary connections or low-to-medium pressure systems, allowing easier maintenance or replacement.

- NPT Plug – Tapered threads provide a tight, leak-proof seal, commonly used in industrial and chemical piping applications.

- Hex Head Plug – Features a hexagonal external head for wrench tightening, making it common in high-pressure installations.

- Square Head Plug – Designed to provide better grip for torque tools, making it suitable for heavy-duty pipelines.

- Round Head Plug – Smooth external surface, ideal for space-limited or aesthetic applications where protrusions need to be minimized.

What are the advantages of using these head types?

- Hex Head: Enables high-torque installation, ideal for sealing high-pressure systems. Easy to remove and reinstall.

- Square Head: Offers better torque transfer than hex heads in certain applications. Useful where vibration or torque wrench accessibility is limited.

- Round Head: Ideal for tight or restricted spaces. Reduces risk of external damage, maintains smooth pipeline appearance, and allows easy manual tightening in small-scale systems.

Why choose Hex, Square, or Round Head plugs over standard threaded plugs?

- They provide enhanced torque handling, better grip, and ease of installation in challenging environments.

- Each head type is engineered for specific technical requirements, such as space constraints, high pressure, or repeated maintenance operations.

- Allows engineers to match plug type with installation tools and operational conditions, ensuring safety and longevity.