- Home

- Forged Fittings

- Threaded Nipple

Threaded Nipple

Forged Nipple : Specifications | Materials | Dimensions | Weight Chart | Tolerances | FAQ

Leading Manufacturer & Supplier of ASME B16.11 Forged socket weld & Threaded Nipple – Sizes ½” to 4”, Class 2000#, 3000#, 6000#, and 9000#, Stainless Steel, Carbon Steel, Alloy Steel, and High Nickel Alloys, Exporting to USA, Germany, UAE, Australia, and Singapore.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a leading manufacturer and supplier of premium piping solutions, committed to delivering high-quality products that meet international standards. With a focus on precision, reliability, and customer satisfaction,

The company adheres to strict quality control procedures and testing protocols. Our policy emphasizes timely delivery, ethical practices, and continuous innovation, ensuring that every client receives products that are durable, efficient, and tailored for critical industrial applications.

ASME B16.11 Forged Nipples are available in threaded and socket weld types, designed for sizes ranging from ½” to 4” and pressure classes from 2000# to 9000#. Manufactured from stainless steel, carbon steel, alloy steel, and high nickel alloys, these nipples provide exceptional strength, corrosion resistance, and durability. They are ideal for oil & gas, petrochemical, power generation, and chemical industries, offering reliable connections in high-pressure and high-temperature systems while ensuring leak-proof performance.

At Midland Forge, we not only manufacture high-quality forged nipples but also provide customized solutions to meet diverse client requirements. With a strong export network to countries like USA, Germany, UAE, Australia, and Singapore, we ensure timely delivery and consistent product quality. Our dedicated team works closely with clients to provide technical support, compliance documentation, and after-sales service, reinforcing our commitment to reliability, performance, and long-term partnerships in the global piping industry.

Forged Pipe Nipple Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Threaded Hex Nipple – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

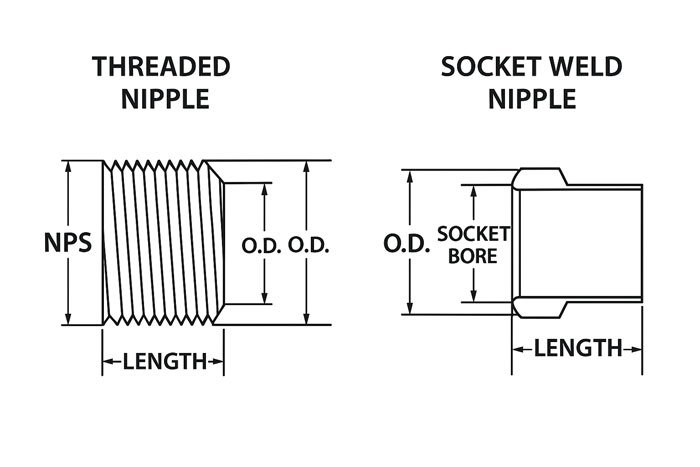

Dimensions of ASME B16.11 Forged Socket Weld Nipple(Class 2000#, 3000#, 6000#, 9000#)

| NPS | DN (mm) | Class | Outside Dia. (mm) | Socket Bore (mm) | Length – Full (mm) | Length – Half (mm) |

|---|---|---|---|---|---|---|

| ½” | 15 | 2000# | 21.3 | 14.3 | 50 | 25 |

| ½” | 15 | 3000# | 26.7 | 14.3 | 55 | 27 |

| ½” | 15 | 6000# | 33.4 | 14.3 | 60 | 30 |

| ½” | 15 | 9000# | 42.2 | 14.3 | 65 | 32 |

| ¾” | 20 | 2000# | 26.7 | 19.0 | 55 | 27 |

| ¾” | 20 | 3000# | 33.4 | 19.0 | 60 | 30 |

| ¾” | 20 | 6000# | 42.2 | 19.0 | 65 | 32 |

| ¾” | 20 | 9000# | 48.3 | 19.0 | 70 | 35 |

| 1” | 25 | 2000# | 33.4 | 25.4 | 60 | 30 |

| 1” | 25 | 3000# | 42.2 | 25.4 | 65 | 32 |

| 1” | 25 | 6000# | 48.3 | 25.4 | 70 | 35 |

| 1” | 25 | 9000# | 60.3 | 25.4 | 75 | 38 |

| 1¼” | 32 | 2000# | 42.2 | 31.8 | 65 | 32 |

| 1¼” | 32 | 3000# | 48.3 | 31.8 | 70 | 35 |

| 1¼” | 32 | 6000# | 60.3 | 31.8 | 75 | 38 |

| 1¼” | 32 | 9000# | 73.0 | 31.8 | 90 | 45 |

| 1½” | 40 | 2000# | 48.3 | 38.1 | 70 | 35 |

| 1½” | 40 | 3000# | 60.3 | 38.1 | 75 | 38 |

| 1½” | 40 | 6000# | 73.0 | 38.1 | 90 | 45 |

| 1½” | 40 | 9000# | 88.9 | 38.1 | 100 | 50 |

| 2” | 50 | 2000# | 60.3 | 50.8 | 75 | 38 |

| 2” | 50 | 3000# | 73.0 | 50.8 | 90 | 45 |

| 2” | 50 | 6000# | 88.9 | 50.8 | 100 | 50 |

| 2” | 50 | 9000# | 101.6 | 50.8 | 120 | 60 |

| 2½” | 65 | 2000# | 73.0 | 63.5 | 90 | 45 |

| 2½” | 65 | 3000# | 88.9 | 63.5 | 100 | 50 |

| 2½” | 65 | 6000# | 101.6 | 63.5 | 120 | 60 |

| 2½” | 65 | 9000# | 114.3 | 63.5 | 140 | 70 |

| 3” | 80 | 2000# | 88.9 | 76.2 | 100 | 50 |

| 3” | 80 | 3000# | 101.6 | 76.2 | 120 | 60 |

| 3” | 80 | 6000# | 114.3 | 76.2 | 140 | 70 |

| 3” | 80 | 9000# | 139.7 | 76.2 | 160 | 80 |

| 4” | 100 | 2000# | 114.3 | 101.6 | 120 | 60 |

| 4” | 100 | 3000# | 127.0 | 101.6 | 140 | 70 |

| 4” | 100 | 6000# | 139.7 | 101.6 | 160 | 80 |

| 4” | 100 | 9000# | 168.3 | 101.6 | 180 | 90 |

Dimensions of ASME B16.11 Forged Threaded Nipple(2000#, 3000#, 6000#, 9000#)

| NPS | DN | Class | Length of Thread (Min) | A | H | B(*) | L2(*) |

|---|---|---|---|---|---|---|---|

| 1/8 | 6 | 2000# | 6.4 | 6.7 | 21 | 22 | – |

| 1/4 | 8 | 2000# | 8.1 | 10.2 | 21 | 22 | – |

| 3/8 | 10 | 2000# | 9.1 | 10.4 | 25 | 25 | – |

| 1/2 | 15 | 2000# | 10.9 | 13.6 | 28 | 33 | – |

| 3/4 | 20 | 2000# | 12.7 | 13.9 | 33 | 38 | – |

| 1 | 25 | 2000# | 14.7 | 17.3 | 38 | 46 | – |

| 1-1/4 | 32 | 2000# | 17.0 | 18.0 | 44 | 56 | – |

| 1-1/2 | 40 | 2000# | 17.8 | 18.4 | 51 | 62 | – |

| 2 | 50 | 2000# | 19.0 | 19.2 | 60 | 75 | – |

| 2-1/2 | 65 | 2000# | 23.6 | 28.9 | 76 | 92 | – |

| 3 | 80 | 2000# | 25.9 | 30.5 | 86 | 109 | – |

| 4 | 100 | 2000# | 27.7 | 33.0 | 106 | 146 | – |

| 1/8 | 6 | 3000# | 6.4 | 6.7 | 21 | 22 | – |

| 1/4 | 8 | 3000# | 8.1 | 10.2 | 25 | 25 | – |

| 3/8 | 10 | 3000# | 9.1 | 10.4 | 28 | 33 | – |

| 1/2 | 15 | 3000# | 10.9 | 13.6 | 33 | 38 | – |

| 3/4 | 20 | 3000# | 12.7 | 13.9 | 38 | 46 | – |

| 1 | 25 | 3000# | 14.7 | 17.3 | 44 | 56 | – |

| 1-1/4 | 32 | 3000# | 17.0 | 18.0 | 51 | 62 | – |

| 1-1/2 | 40 | 3000# | 17.8 | 18.4 | 60 | 75 | – |

| 2 | 50 | 3000# | 19.0 | 19.2 | 64 | 84 | – |

| 2-1/2 | 65 | 3000# | 23.6 | 28.9 | 83 | 102 | – |

| 3 | 80 | 3000# | 25.9 | 30.5 | 95 | 121 | – |

| 4 | 100 | 3000# | 27.7 | 33.0 | 114 | 152 | – |

| 1/8 | 6 | 6000# | 6.4 | – | 6.7 | – | 25 |

| 1/4 | 8 | 6000# | 8.1 | – | 10.2 | – | 28 |

| 3/8 | 10 | 6000# | 9.1 | – | 10.4 | – | 33 |

| 1/2 | 15 | 6000# | 10.9 | – | 13.6 | – | 38 |

| 3/4 | 20 | 6000# | 12.7 | – | 13.9 | – | 44 |

| 1 | 25 | 6000# | 14.7 | – | 17.3 | – | 51 |

| 1-1/4 | 32 | 6000# | 17.0 | – | 18.0 | – | 60 |

| 1-1/2 | 40 | 6000# | 17.8 | – | 18.4 | – | 64 |

| 2 | 50 | 6000# | 19.0 | – | 19.2 | – | 83 |

| 2-1/2 | 65 | 6000# | 23.6 | – | 28.9 | – | 95 |

| 3 | 80 | 6000# | 25.9 | – | 30.5 | – | 106 |

| 4 | 100 | 6000# | 27.7 | – | 33.0 | – | 114 |

Weight Chart: ASME B16.11 Forged Nipple

| NPS (in) | DN (mm) | Length (L) mm | SW Weight (kg) | THD Weight (kg) |

|---|---|---|---|---|

| 1/8″ | 6 | 50 | 0.05 | 0.04 |

| 1/4″ | 8 | 55 | 0.07 | 0.06 |

| 3/8″ | 10 | 60 | 0.09 | 0.08 |

| 1/2″ | 15 | 65 | 0.12 | 0.10 |

| 3/4″ | 20 | 75 | 0.18 | 0.15 |

| 1″ | 25 | 80 | 0.25 | 0.20 |

| 1-1/4″ | 32 | 90 | 0.38 | 0.35 |

| 1-1/2″ | 40 | 100 | 0.50 | 0.45 |

| 2″ | 50 | 110 | 0.75 | 0.70 |

| 2-1/2″ | 65 | 125 | 1.10 | 1.00 |

| 3″ | 80 | 140 | 1.50 | 1.40 |

| 4″ | 100 | 165 | 2.50 | 2.20 |

Threaded Pipe Nipple Tolerances as per ASME B16.11

| Feature | Tolerance |

|---|---|

| Outside Diameter (OD) | ±1.6 mm (±1/16″) for sizes up to 2″ NPS; ±2.4 mm (±3/32″) for sizes above 2″ NPS |

| Length (L) | ±3.2 mm (±1/8″) for nipples up to 6″ NPS; ±4.8 mm (±3/16″) for larger sizes |

| Socket Bore (SW) | ±0.15 mm (±0.006″) for sizes up to 2″ NPS; ±0.25 mm (±0.010″) for larger sizes |

| Thread (THD) External | As per ASME B1.20.1 (Pipe Threads, General Purpose) |

| Concentricity | Max 0.8 mm (0.03″) misalignment between ends |

| Ovality (Roundness of OD) | Max 1.0 mm (0.04″) deviation from true circular shape |

How to select between Socket Weld and Threaded nipples?

| Feature | Socket Weld | Threaded |

|---|---|---|

| Max Pressure | Higher | Moderate |

| Vibration Resistance | Excellent | Moderate |

| Assembly/Disassembly | Requires welding | Easy to assemble/disassemble |

| Space Requirement | Slightly more | Compact |

| Leakage Risk | Minimal if welded properly | Slightly higher under high pressure |

How are forged nipples inspected and tested?

- Visual Inspection: Surface defects, burrs, cracks

- Dimensional Check: OD, wall thickness, length, bore diameter

- Hydrostatic / Pressure Test: To verify leak-proof performance at rated pressure

- Material Verification: PMI (Positive Material Identification) or chemical composition check

- Thread/Socket Inspection: Gauge check for proper fit

What is the purpose of a forged nipple in a piping system?

A forged nipple is a specialized pipe fitting designed for high-pressure and critical piping applications. Its purpose can be explained in the following points:

-

Connects Pipe Ends:

- Used to join two threaded (THD) or socket weld (SW) pipe ends in a pipeline.

- Provides a reliable link between piping sections, flanges, or valves.

-

High-Pressure Resistance:

- Machined from a single forged piece, giving it higher mechanical strength than welded or fabricated fittings.

- Suitable for high-pressure pipelines up to 9000# as per ASME B16.11 standards.

-

Leak-Proof Performance:

- Designed to maintain a tight seal under extreme pressure and temperature conditions.

- Socket weld and threaded ends ensure minimal leakage risk when properly installed.

-

Structural Integrity:

- Forged nipples have a uniform grain structure due to the forging process, reducing weaknesses such as seams or voids.

- Can withstand vibration, thermal expansion, and mechanical stresses better than cast or fabricated fittings.

-

Critical Service Applications:

- Widely used in industries like oil & gas, petrochemical, power plants, and chemical processing.

- Effective for high-temperature pipelines, corrosive media, and critical flow control points.

-

Compact and Versatile:

- Available in various lengths: full, half, or close nipples, allowing flexibility in tight spaces.

- Compatible with different materials including carbon steel, stainless steel, alloy steel, and nickel alloys.

-

Durability and Reliability:

- Single-piece forging prevents leakage or mechanical failure common in fabricated joints.

- Ensures long-term service life with minimal maintenance.