- Home

- Forged Fittings

- Socket weld & Threaded Cross

Socket weld & Threaded Cross

Forged Cross : Specifications | Materials | Types | Dimensions | Weight Chart | Tolerances | FAQ

Manufacturer and Supplier of ASME B16.11 Forged Cross – Socket Weld and Threaded, Equal and Unequal Types, Sizes ½” to 4”, Class 3000# and 6000#, Stainless Steel, Carbon Steel, Alloy Steel and High Nickel Alloys, Exporting to India, Canada, UK, Saudi Arabia and South Africa

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd. is a trusted manufacturer and supplier of high-quality piping solutions, specializing in forged fittings for industrial applications. With years of experience in engineering and fabrication, the company ensures every product meets global standards for performance, durability, and safety. Committed to excellence, we cater to a wide range of industries, delivering solutions that withstand high pressure, and corrosive environments.

We offer high-quality ASME B16.11 forged crosses, available in equal and unequal types to suit all piping configurations. Equal crosses have branches of the same diameter, perfect for symmetrical pipelines, while unequal crosses feature branches of different diameters, allowing connection of pipes with varying sizes in complex systems.

These forged crosses are designed for both socket weld and threaded connections, providing versatility for different installation methods. Manufactured from premium stainless steel, carbon steel, alloy steel, and high nickel alloys, they ensure exceptional strength, leak-proof joints, and resistance to corrosion and wear. Engineered to meet stringent quality standards and high-pressure classes, Midland’s forged crosses deliver reliable performance for demanding industrial applications.

Midland Forge not only serves the domestic market but also exports forged crosses to countries including India, Canada, UK, Saudi Arabia, and South Africa. Every product undergoes stringent inspection and testing to ensure compliance with international standards. With a focus on innovation, timely delivery, and customer satisfaction, Midland Forge continues to be a preferred partner for companies seeking dependable and high-performance forged cross fittings worldwide.

Forged Equal Cross Specifications

Size Range – (Socket weld & Screwed-Threaded)

Pressure Rating

Marking

Fitting Types

Thread/MTC

Manufacturing Standards

Materials

Dimensional Standards

Testing

Surface Finish

Threaded Unequal Cross – Materials, Grades & Standards

| Material Category | Grade | Standards (ASTM / ASME) | Typical Use / Application |

|---|---|---|---|

| Stainless Steel | 304 / 304L / 304H | ASTM A182 F304 / F304L / F304H | General purpose, corrosion resistance |

| 316 / 316L / 316H | ASTM A182 F316 / F316L / F316H | Marine, chemical, and food processing | |

| 317 / 317L | ASTM A182 F317 / F317L | High corrosion resistance | |

| 321 / 321H | ASTM A182 F321 / F321H | High temperature, stabilized service | |

| 347 / 347H | ASTM A182 F347 / F347H | High-temp, pressure systems | |

| 904L | ASTM A182 F904L | Acid handling, sulfuric environments | |

| 254 SMO | ASTM A182 F44 | High chloride & seawater applications | |

| Carbon Steel | A105 | ASTM A105 | Pressure piping & general industries |

| A350 LF2 | ASTM A350 LF2 | Low temperature services | |

| A694 F42 / F46 / F52 / F56 / F60 / F65 / F70 | ASTM A694 | High-pressure pipelines, oil & gas | |

| Alloy Steel | F1 / F5 / F9 | ASTM A182 F1 / F5 / F9 | High-temp & pressure pipelines |

| F11 / F22 | ASTM A182 F11 / F22 | Steam lines & refineries | |

| F91 | ASTM A182 F91 | Power generation, high performance | |

| Duplex Steel | UNS S31803 / S32205 | ASTM A182 F51 / F60 | Corrosion resistance, high strength |

| Super Duplex Steel | UNS S32750 / S32760 | ASTM A182 F53 / F55 | Offshore, seawater applications |

| Nickel Alloys | Nickel 200 / 201 | ASTM B564 | Alkali & chemical processing |

| Inconel 600 / 625 / 718 | ASTM B564 | Heat exchangers, aerospace | |

| Incoloy 800 / 825 | ASTM B564 | Petrochemical & chemical processing | |

| Hastelloy C22 / C276 | ASTM B564 | Severe corrosion resistance | |

| Monel 400 / K500 | ASTM B564 | Seawater, marine engineering | |

| Alloy 20 | ASTM B564 | Sulfuric acid services | |

| Nimonic 75 / 80A | ASTM B564 / B637 | High-temp aerospace & turbines | |

| Copper Nickel | Cu-Ni 90/10 / 70/30 | ASTM B151 / B467 | Marine systems, seawater service |

| Titanium | Grade 2 / Grade 5 | ASTM B381 | Lightweight, corrosion resistance |

| Aluminium | 6061 / 5083 | ASTM B247 | Low-pressure, non-corrosive piping |

Explore Forged Fittings

- Forged Fitting

- Elbow (Threaded / Socket Weld)

- Tee (Threaded / Socket Weld)

- Union (Threaded / Socket Weld)

- Coupling (Threaded / Socket Weld)

- Plug (Threaded / Socket Weld)

- Bushing (Threaded / Socket Weld)

- Cap (Threaded / Socket Weld)

- Cross (Threaded / Socket Weld)

- Nipple (Threaded / Socket Weld)

- Forged Boss

- Forged Insert

- Swage Nipple

- Bull Plug

- Street Elbow

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Products

Types of ASME B16.11 Forged Cross Fittings

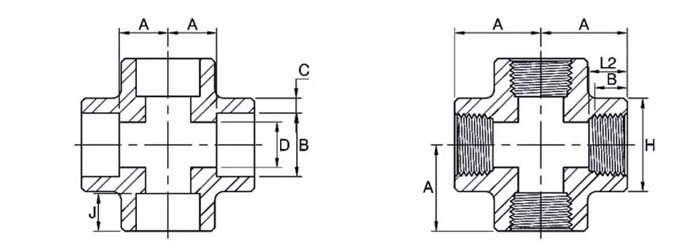

Dimensions of ASME B16.11 Forged Socket Weld Cross

| NPS | DN | Class | B(2) (Min) | C(1) (Avg) | D(2) (Min) | A(2) | J (Min) |

|---|---|---|---|---|---|---|---|

| 1/8 | 6 | 3000# | 10.8 | 3.18 | 3.18 | 6.9 | 9.5 |

| 1/4 | 8 | 3000# | 14.2 | 3.78 | 3.30 | 9.3 | 9.5 |

| 3/8 | 10 | 3000# | 17.6 | 4.01 | 3.50 | 12.6 | 9.5 |

| 1/2 | 15 | 3000# | 21.8 | 4.67 | 4.09 | 15.8 | 9.5 |

| 3/4 | 20 | 3000# | 27.2 | 4.90 | 4.27 | 21.0 | 12.5 |

| 1 | 25 | 3000# | 33.9 | 5.69 | 4.98 | 26.7 | 12.5 |

| 1-1/4 | 32 | 3000# | 42.7 | 6.07 | 5.28 | 35.1 | 12.5 |

| 1-1/2 | 40 | 3000# | 48.8 | 6.35 | 5.54 | 40.9 | 12.5 |

| 2 | 50 | 3000# | 61.2 | 6.93 | 6.04 | 52.5 | 16.0 |

| 2-1/2 | 65 | 3000# | 73.9 | 8.76 | 7.67 | 62.7 | 16.0 |

| 3 | 80 | 3000# | 89.8 | 9.52 | 8.30 | 78.0 | 16.0 |

| 4 | 100 | 3000# | 115.2 | 10.69 | 9.35 | 102.3 | 19.0 |

| 1/8 | 16 | 6000# | 10.8 | 3.96 | 3.43 | 4.0 | 9.5 |

| 1/4 | 8 | 6000# | 14.2 | 4.60 | 4.01 | 6.4 | 9.5 |

| 3/8 | 10 | 6000# | 17.6 | 5.03 | 4.37 | 9.2 | 9.5 |

| 1/2 | 15 | 6000# | 21.8 | 5.97 | 5.18 | 11.8 | 9.5 |

| 3/4 | 20 | 6000# | 27.2 | 6.96 | 6.04 | 15.6 | 12.5 |

| 1 | 25 | 6000# | 33.9 | 7.92 | 6.93 | 20.7 | 12.5 |

| 1-1/4 | 32 | 6000# | 42.7 | 7.92 | 6.93 | 29.5 | 12.5 |

| 1-1/2 | 40 | 6000# | 48.8 | 8.92 | 7.80 | 34.0 | 12.5 |

| 2 | 50 | 6000# | 61.2 | 10.92 | 9.50 | 42.9 | 16.0 |

| 1/2 | 15 | 9000# | 21.8 | 9.35 | 8.18 | 6.4 | 9.5 |

| 3/4 | 20 | 9000# | 27.2 | 9.78 | 8.56 | 11.1 | 12.5 |

| 1 | 25 | 9000# | 33.9 | 11.38 | 9.96 | 15.2 | 12.5 |

| 1-1/4 | 32 | 9000# | 42.7 | 12.14 | 10.62 | 22.8 | 12.5 |

| 1-1/2 | 40 | 9000# | 48.8 | 12.70 | 11.12 | 28.0 | 12.5 |

| 2 | 50 | 9000# | 61.2 | 13.84 | 12.12 | 38.2 | 16.0 |

Dimensions of ASME B16.11 Forged Threaded Cross

| NPS | DN | Class | Length of Thread (Min) | A | H | B(*) | L2(*) |

|---|---|---|---|---|---|---|---|

| 1/8 | 6 | 2000# | 6.4 | 6.7 | 21 | 22 | – |

| 1/4 | 8 | 2000# | 8.1 | 10.2 | 21 | 22 | – |

| 3/8 | 10 | 2000# | 9.1 | 10.4 | 25 | 25 | – |

| 1/2 | 15 | 2000# | 10.9 | 13.6 | 28 | 33 | – |

| 3/4 | 20 | 2000# | 12.7 | 13.9 | 33 | 38 | – |

| 1 | 25 | 2000# | 14.7 | 17.3 | 38 | 46 | – |

| 1-1/4 | 32 | 2000# | 17.0 | 18.0 | 44 | 56 | – |

| 1-1/2 | 40 | 2000# | 17.8 | 18.4 | 51 | 62 | – |

| 2 | 50 | 2000# | 19.0 | 19.2 | 60 | 75 | – |

| 2-1/2 | 65 | 2000# | 23.6 | 28.9 | 76 | 92 | – |

| 3 | 80 | 2000# | 25.9 | 30.5 | 86 | 109 | – |

| 4 | 100 | 2000# | 27.7 | 33.0 | 106 | 146 | – |

| 1/8 | 6 | 3000# | 6.4 | 6.7 | 21 | 22 | – |

| 1/4 | 8 | 3000# | 8.1 | 10.2 | 25 | 25 | – |

| 3/8 | 10 | 3000# | 9.1 | 10.4 | 28 | 33 | – |

| 1/2 | 15 | 3000# | 10.9 | 13.6 | 33 | 38 | – |

| 3/4 | 20 | 3000# | 12.7 | 13.9 | 38 | 46 | – |

| 1 | 25 | 3000# | 14.7 | 17.3 | 44 | 56 | – |

| 1-1/4 | 32 | 3000# | 17.0 | 18.0 | 51 | 62 | – |

| 1-1/2 | 40 | 3000# | 17.8 | 18.4 | 60 | 75 | – |

| 2 | 50 | 3000# | 19.0 | 19.2 | 64 | 84 | – |

| 2-1/2 | 65 | 3000# | 23.6 | 28.9 | 83 | 102 | – |

| 3 | 80 | 3000# | 25.9 | 30.5 | 95 | 121 | – |

| 4 | 100 | 3000# | 27.7 | 33.0 | 114 | 152 | – |

| 1/8 | 6 | 6000# | 6.4 | – | 6.7 | – | 25 |

| 1/4 | 8 | 6000# | 8.1 | – | 10.2 | – | 28 |

| 3/8 | 10 | 6000# | 9.1 | – | 10.4 | – | 33 |

| 1/2 | 15 | 6000# | 10.9 | – | 13.6 | – | 38 |

| 3/4 | 20 | 6000# | 12.7 | – | 13.9 | – | 44 |

| 1 | 25 | 6000# | 14.7 | – | 17.3 | – | 51 |

| 1-1/4 | 32 | 6000# | 17.0 | – | 18.0 | – | 60 |

| 1-1/2 | 40 | 6000# | 17.8 | – | 18.4 | – | 64 |

| 2 | 50 | 6000# | 19.0 | – | 19.2 | – | 83 |

| 2-1/2 | 65 | 6000# | 23.6 | – | 28.9 | – | 95 |

| 3 | 80 | 6000# | 25.9 | – | 30.5 | – | 106 |

| 4 | 100 | 6000# | 27.7 | – | 33.0 | – | 114 |

Weight Chart: ASME B16.11 Socket weld Unequal Cross

| NPS | DN (mm) | Type | Connection | Weight (kg) |

|---|---|---|---|---|

| ½” | 15 | Equal | SW | 0.45 |

| ½” | 15 | Equal | THD | 0.40 |

| ½” | 15 | Unequal | SW | 0.50 |

| ½” | 15 | Unequal | THD | 0.45 |

| ¾” | 20 | Equal | SW | 0.70 |

| ¾” | 20 | Equal | THD | 0.65 |

| ¾” | 20 | Unequal | SW | 0.75 |

| ¾” | 20 | Unequal | THD | 0.70 |

| 1” | 25 | Equal | SW | 1.20 |

| 1” | 25 | Equal | THD | 1.10 |

| 1” | 25 | Unequal | SW | 1.25 |

| 1” | 25 | Unequal | THD | 1.15 |

| 2” | 50 | Equal | SW | 3.60 |

| 2” | 50 | Equal | THD | 3.30 |

| 2” | 50 | Unequal | SW | 3.80 |

| 2” | 50 | Unequal | THD | 3.50 |

| 4” | 100 | Equal | SW | 12.5 |

| 4” | 100 | Equal | THD | 11.8 |

| 4” | 100 | Unequal | SW | 13.0 |

| 4” | 100 | Unequal | THD | 12.2 |

Threaded Equal Cross Tolerances as per ASME B16.11

| Parameter | Tolerance | Notes |

|---|---|---|

| Outside Diameter (OD) | ±1% of nominal OD | Applies to all material grades (CS, SS, Alloy Steel, High Nickel Alloys) |

| Wall Thickness (SW) | +0.38 mm / -0.0 mm | Ensures proper strength for socket weld connections |

| Wall Thickness (THD) | As per thread fit | Matches ASME B1.20.1 internal/external thread tolerances |

| Face-to-Face / Overall Length | ±1.5% of nominal length | Applies to both equal and unequal crosses |

| Socket Depth (SW) | +0.25 mm / -0.13 mm | Ensures proper pipe insertion and leak-proof joint |

| Thread Fit (THD) | Per ASME B1.20.1, Class 2A/2B | Standard pitch and diameter tolerance |

| Branch Angle | 90° ±1° | Applies to both equal and unequal types to maintain alignment |

| Unequal Branch Difference | ±1 mm | Dimensional tolerance between different branch sizes |

What distinguishes equal and unequal forged crosses?

- Equal Forged Cross: All four branches have the same nominal diameter, ensuring uniform flow and symmetrical piping layouts. Ideal for systems where pressure drop needs to be consistent across all branches.

- Unequal Forged Cross: Branch diameters differ, allowing connection of pipes of varying sizes. This design accommodates complex piping networks where flow distribution or pressure requirements vary. Unequal crosses are often used in process lines, where main pipelines feed multiple branch lines of different sizes.

What are the key differences between socket weld and threaded forged crosses?

- Socket Weld (SW): The pipe is inserted into the socket end and fillet-welded externally. Provides a high-strength, leak-proof joint suitable for high-pressure and high-temperature systems. SW crosses require precise machining of socket depth and bore to ensure full insertion of the pipe.

- Threaded (THD): Involves internal/external threads for pipe assembly without welding. Easier to install and dismantle but generally limited to moderate pressure applications. Thread tolerances must adhere to ASME B1.20.1 standards for a secure fit.

How do forged crosses differ from cast or welded crosses?

- Forged Crosses: Superior mechanical strength, better grain structure, suitable for high-pressure and critical applications.

- Cast Crosses: More economical but weaker, prone to porosity and not recommended for high-pressure systems.

- Welded Crosses: Made by joining pipes or plates, useful for very large sizes but require more fabrication time and inspection.