- Home

- Copper Alloys

- Lead Bronze

Lead Bronze

Lead Bronze : Specifications | Grades & Standards | Product Types | Equivalent Grades | Chemical Composition | Mechanical Properties | Forged Fittings | Flanges | FAQ

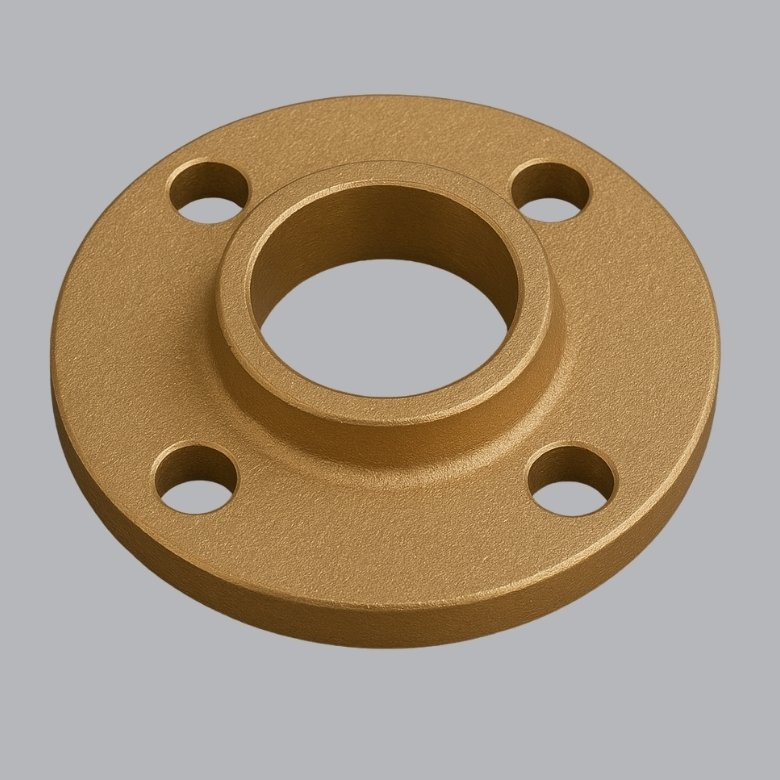

High-Quality Lead Bronze Fittings & Flanges – Including Elbows, Tees, Reducers, Caps, and Custom Headers. Engineered to ASTM B584 and ASME B16/B16.18 standards for wear and corrosion resistance. Exporting worldwide: USA, UK, Germany, Italy, UAE, Saudi Arabia, Qatar, Australia, Malaysia & Singapore.

Best Export Prices: sales@midlandforgefittings.com

Midland Forge and Fittings Pvt. Ltd is a premier manufacturer and exporter of high-quality Lead Bronze industrial pipe fittings and flanges. Our product range includes elbows, tees, reducers, caps, and custom-fabricated headers, all engineered to meet international standards such as ASTM B584, B16, and B16.18. With precision manufacturing and strict quality control, we ensure exceptional corrosion resistance, durability, and reliable performance in demanding industrial applications.

We serve clients worldwide and export Lead Bronze fittings and flanges to the USA, UK, Germany, Italy, UAE, Saudi Arabia, Qatar, Singapore, Australia, and Malaysia. Committed to quality and innovation, we combine extensive industry expertise with advanced production techniques to deliver premium, long-lasting solutions tailored for diverse industrial needs.

Lead Bronze pipe fittings and flanges are engineered from high-quality leaded bronze alloys, offering excellent corrosion resistance, wear resistance, and durability in a wide range of industrial applications. These fittings—including elbows, tees, reducers, caps, and flanges—are manufactured to strict standards such as ASTM B584, B16, and B16.18 to ensure dimensional accuracy, mechanical strength, and reliable performance under varying pressure and temperature conditions. Lead Bronze exhibits superior resistance to dezincification, erosion, and cavitation, making it ideal for use in water, oil, and chemical piping systems.

Precision forging, machining, and finishing processes, combined with rigorous quality testing including hydrostatic pressure checks and material certification, ensure that these fittings and flanges provide long-term reliability, leak-proof connections, and consistent performance. These features make Lead Bronze pipe fittings and flanges suitable for both domestic and international industrial installations, where durability, safety, and efficiency are critical.

Leaded Bronze Industrial Fittings - Specifications

Size Range – (Forged, Flange)

Cast Fittings / Flanges: ½” – 48” (15NB – 1200NB)

Threaded & Socket Weld: ½” – 4”

Flanges: ½” – 48”

Pressure Rating/ Wall Thickness

Flanges: Class 150, 300, 600, 900, 1500, 2500

Special Ratings: PN6 to PN400, API 3000–15000 PSI

Surface & Finish

ASTM / ASME - Grades - Material

BRONZE ALLOYS – LEAD BRONZE

C84400: Leaded Tin Bronze

C85700: Leaded Bronze / CW511L

C87850: Leaded Tin Bronze

Manufacturing Process

Testing & Inspection

Dimensional Standards

Forms

Applications

Key Features

Leaded Bronze Forged Fittings – Grades & Standards

| Product Type | Material / Alloy | ASTM / ASME Standard |

Availability | Typical Applications |

|---|---|---|---|---|

| Forged Fittings | Lead Bronze (C83600, C84400) |

ASTM B584 | Available | Corrosion-resistant piping for water, oil, and chemicals |

| Threaded Fittings | Lead Bronze (C83600, C84400) |

ASTM B584 | Available | Low-pressure piping systems, domestic and industrial |

| Socket Weld Fittings | Lead Bronze (C83600, C84400) |

ASTM B584 | Available | Low-pressure industrial applications |

| Buttweld Fittings | Lead Bronze | N/A | Not Available | Not used due to low melting point and lead content |

| Cast Flanges | Lead Bronze (C83600, C84400) |

ASTM B62 | Available | Water, oil, and chemical piping systems |

| Forged Flanges | Lead Bronze (C83600, C84400) |

ASTM B584 | Available | Corrosion-resistant industrial piping |

| Custom Fabricated Headers |

Lead Bronze | ASTM B584 / Client Spec |

Available | Specialized piping systems for industrial applications |

Explore Copper Alloys

Request for an Immediate Offer?

We will reply you in 2 hours during support time!

Conctact Now!Explore All Materials

Explore All Products

Lead Bronze Products

ASTM B584 Lead Bronze Pipe Fittings - Equivalent Grades

| Material / Alloy |

UNS / Alloy Number |

ASTM / ASME Standard |

DIN / EN Equivalent |

JIS Equivalent |

BS Equivalent |

|---|---|---|---|---|---|

| Lead Bronze | C83600 | ASTM B584 / B62 | CuZn39Pb3 / CW511L | BC6 | LG2 |

| Lead Bronze | C84400 | ASTM B584 / B62 | CuSn6Pb / CW451K | BC6 | LG2 |

| Lead Bronze (Leaded Tin Bronze) | C87850 | ASTM B584 / B62 | CuSn7Pb / CW451K | BC6 | LG2 |

| Lead Bronze (Casting & Forging) | C85700 | ASTM B584 / B62 | CuZn40Pb2 / CW511L | BC6 | LG2 |

Lead Bronze Threaded Fittings - Chemical Composition

| Alloy / UNS | Cu (%) | Pb (%) | Sn (%) | Zn (%) | Fe (%) | P (%) | Other Elements |

|---|---|---|---|---|---|---|---|

| C83600 (Leaded Bronze) | 81–85 | 2–3 | 2–4 | 11–14 | ≤1 | 0.02 max | Ni ≤0.1, others trace |

| C84400 (Leaded Tin Bronze) | 78–82 | 2–3 | 7–9 | 8–10 | ≤1 | 0.02 max | Ni ≤0.1, others trace |

| C85700 (Leaded Bronze / CW511L) | 80–85 | 2–3 | 1–2 | 12–14 | ≤1 | 0.02 max | Ni ≤0.1, others trace |

| C87850 (Leaded Tin Bronze) | 78–82 | 2–3 | 7–9 | 9–11 | ≤1 | 0.02 max | Ni ≤0.1, others trace |

Lead Bronze Cast Flanges - Mechanical Properties

| Alloy / UNS | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (BHN) |

|---|---|---|---|---|

| C83600 (Leaded Bronze) | 380–450 | 140–210 | 20–30 | 80–120 |

| C84400 (Leaded Tin Bronze) | 400–460 | 150–220 | 18–25 | 85–130 |

| C85700 (Leaded Bronze / CW511L) | 370–430 | 140–200 | 20–30 | 75–120 |

| C87850 (Leaded Tin Bronze) | 400–450 | 150–220 | 18–25 | 85–130 |

Corrosion-Resistant Lead Bronze Pipe Flanges

ASTM B584 Lead Bronze Forged Fittings

Why is Lead Bronze preferred for certain industrial pipe fittings?

Lead Bronze combines copper, tin, zinc, and small amounts of lead to offer excellent corrosion and wear resistance.

The lead addition improves machinability, allowing precise threads, flanges, and forged components.

Ideal for low-to-medium pressure piping systems, including water, oil, and mild chemical applications.

How is quality ensured in Lead Bronze fittings?

Material Testing: PMI or spectrochemical analysis to verify composition.

Dimensional Checks: Tolerance verification for threaded or flanged connections.

Hydrostatic and Pressure Testing: Ensures leak-free performance.

Mechanical Testing: Hardness, tensile, and yield strength checks.

Visual Inspection: Detects casting or forging defects before dispatch.

why Lead Bronze is used in pipe fittings and flanges?

Lead Bronze is a copper-based alloy with a small percentage of lead added to improve machinability. Common alloys include C83600, C84400, C85700, and C87850.

It offers excellent corrosion resistance, particularly against water, mild acids, and chemical solutions, making it ideal for industrial piping, valves, and flanges.

Lead Bronze also provides high wear resistance and dimensional stability, ensuring a long service life in low to medium pressure piping systems.